engine control system NISSAN TIIDA 2009 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1843 of 4331

EC

NP

O

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom Table INFOID:0000000004780390

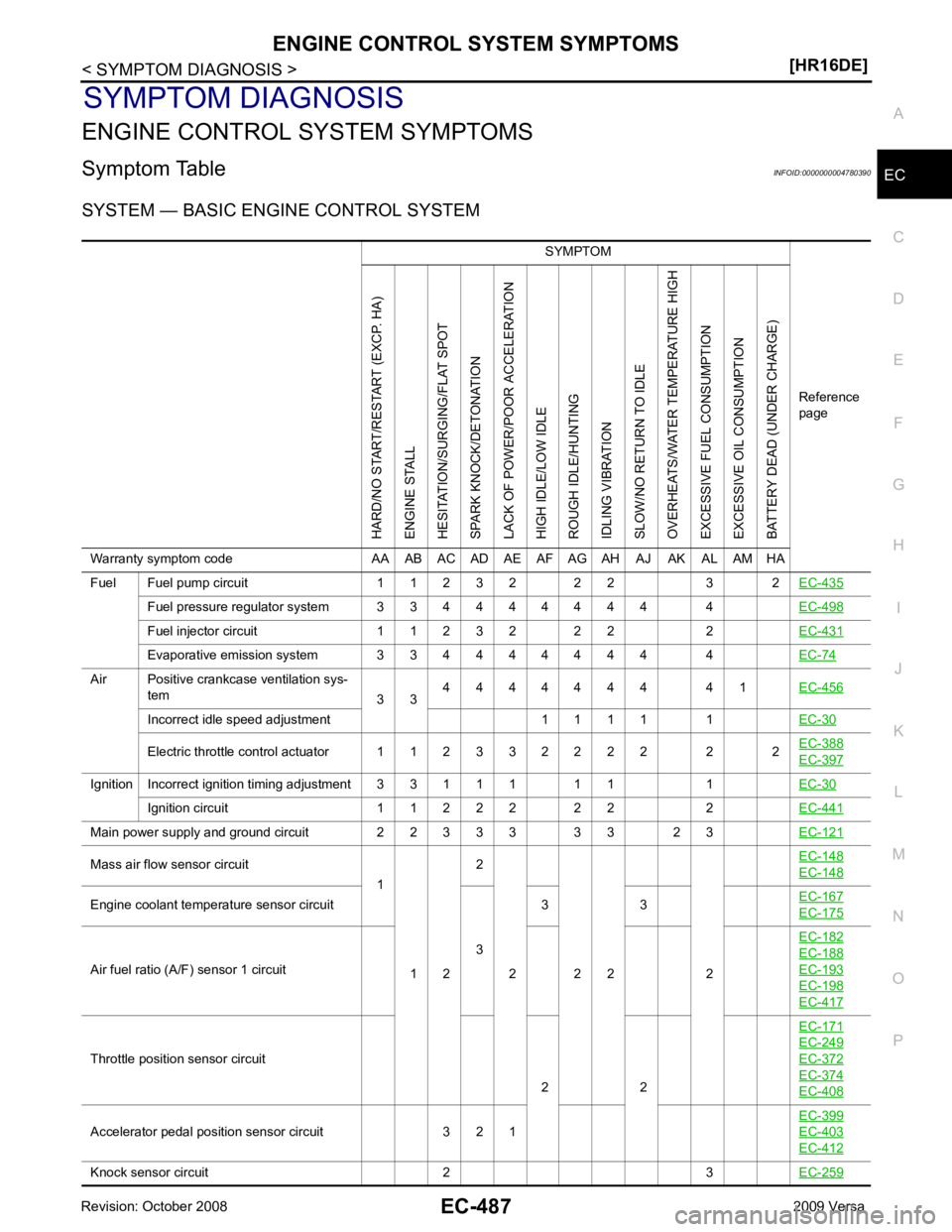

SYSTEM — BASIC ENGINE CONTROL SYSTEM SYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit 1 1 2 3 2 2 2 3 2 EC-435Fuel pressure regulator system 3 3 4 4 4 4 4 4 4 4

EC-498Fuel injector circuit 1 1 2 3 2 2 2 2

EC-431Evaporative emission system 3 3 4 4 4 4 4 4 4 4

EC-74Air Positive crankcase ventilation sys-

tem 3 34 4 4 4 4 4 4 4 1

EC-456Incorrect idle speed adjustment 1 1 1 1 1

EC-30Electric throttle control actuator 1 1 2 3 3 2 2 2 2 2 2

EC-388 EC-397

Ignition Incorrect ignition timing adjustment 3 3 1 1 1 1 1 1

EC-30Ignition circuit 1 1 2 2 2 2 2 2

EC-441Main power supply and ground circuit 2 2 3 3 3 3 3 2 3

EC-121Mass air flow sensor circuit

1

1 2 2

2 2 2 2 EC-148 EC-148

Engine coolant temperature sensor circuit

33 3

EC-167 EC-175

Air fuel ratio (A/F) sensor 1 circuit

EC-182 EC-188

EC-193

EC-198

EC-417

Throttle position sensor circuit

2 2EC-171 EC-249

EC-372

EC-374

EC-408

Accelerator pedal position sensor circuit 3 2 1

EC-399 EC-403

EC-412

Knock sensor circuit 2 3

EC-259

Page 1847 of 4331

EC

NP

O

NORMAL OPERATING CONDITION

Description INFOID:0000000004780391

FUEL CUT CONTROL (AT NO LOAD AND HIGH ENGINE SPEED) If the engine speed is above 2,500 rpm under no load (for ex ample, the selector lever position is neutral and

engine speed is over 2,500 rpm) fuel will be cut off after some time. The exact time when the fuel is cut off var-

ies based on engine speed.

Fuel cut will be operated until the engine speed reaches 2,000 rpm, then fuel cut will be cancelled.

NOTE:

This function is different from deceleration contro l listed under Multiport Fuel Injection (MFI) System, EC-42," System Description " .

Page 1849 of 4331

![NISSAN TIIDA 2009 Service Owners Manual PRECAUTIONS

EC-493

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to route and secure the harnesses properly

after work. The interference of the harness with

a bracket, etc. may NISSAN TIIDA 2009 Service Owners Manual PRECAUTIONS

EC-493

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to route and secure the harnesses properly

after work. The interference of the harness with

a bracket, etc. may](/img/5/57398/w960_57398-1848.png)

PRECAUTIONS

EC-493

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to route and secure the harnesses properly

after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfuncti on of the EVAP system or fuel injection system,

etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

General Precautions INFOID:0000000004780395

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect negative battery cable.

• Do not disassemble ECM.

• If a battery cable is disconnect ed, the memory will return to

the ECM value.

The ECM will now start to self-control at its initial value. Thus,

engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be cleared within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness c onnector (1), fasten (B) it

securely with a lever as far as it will go as shown in the figure.

• When connecting or disconnect ing pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and cond enser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal- SEF289H

2. ECM

A. Loosen PBIA9222J

PBIB2947E

PBIB0090E

Page 1851 of 4331

EC

NP

O

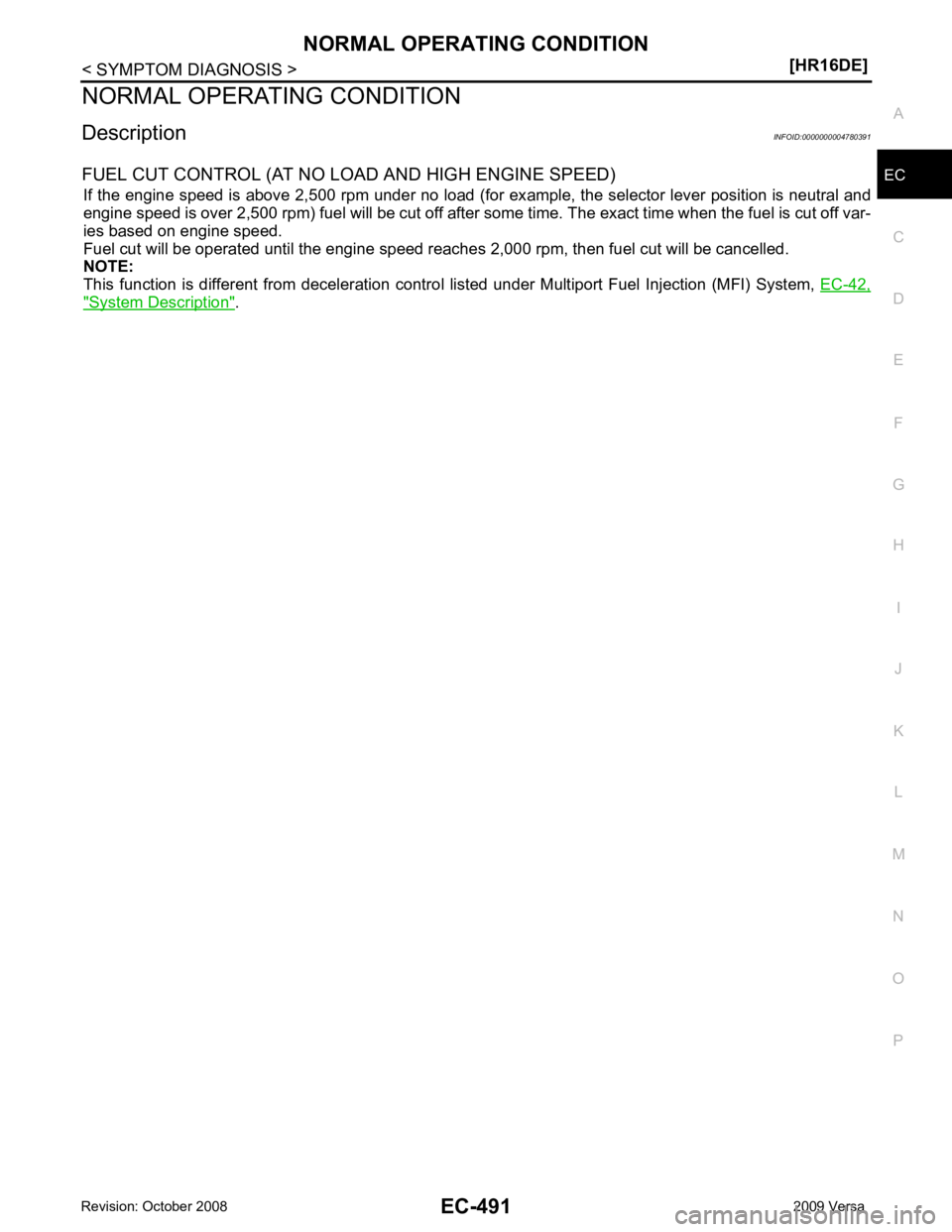

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine ju st prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run para llel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

ratio can be kept smaller.

- Be sure to ground the radio to vehicle body.

Page 1869 of 4331

![NISSAN TIIDA 2009 Service Owners Manual PRECAUTIONS

EC-513

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to connect rubber tubes properly afte

r work. A misconnected or disconnected rubber tube NISSAN TIIDA 2009 Service Owners Manual PRECAUTIONS

EC-513

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to connect rubber tubes properly afte

r work. A misconnected or disconnected rubber tube](/img/5/57398/w960_57398-1868.png)

PRECAUTIONS

EC-513

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to connect rubber tubes properly afte

r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Precaution INFOID:0000000004537016

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect negative battery cable.

• Do not disassemble ECM.

• If battery cable is disconnected, the memory will return to the

initial ECM values.

The ECM will now start to self-c ontrol at its initial values.

Engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness connector, fasten (B) it

securely with a lever (1) as far as it will go as shown in the fig-

ure.

- ECM (2)

- Loosen (A)

• When connecting or disconnect ing pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and cond enser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving externa l noise, degraded operation

of ICs, etc. SEF289H

PBIA9222J

PBIB2947E

PBIB0090E

Page 1870 of 4331

![NISSAN TIIDA 2009 Service Owners Manual EC-514< SERVICE INFOMATION >

[MR TYPE 1]

PRECAUTIONS

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspecti NISSAN TIIDA 2009 Service Owners Manual EC-514< SERVICE INFOMATION >

[MR TYPE 1]

PRECAUTIONS

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspecti](/img/5/57398/w960_57398-1869.png)

EC-514< SERVICE INFOMATION >

[MR TYPE 1]

PRECAUTIONS

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspection and m ake sure ECM functions prop-

erly. Refer to EC-597, " ECM Terminal and Reference Value " .

• Handle mass air flow sensor carefully to avoid damage.

• Do not disassemble m ass air flow sensor.

• Do not clean mass air flow senso r with any type of detergent.

• Do not disassemble electric throttle control actuator.

• Even a slight leak in the ai r intake system can cause serious

incidents.

• Do not shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

• After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displ ayed in the DTC Confirmation

Procedure if the repair is co mpleted. The Overall Function

Check should be a good result if the repair is completed.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Do not use ECM ground termina ls when measuring input/out-

put voltage. Doing so may result in damage to the ECM's tran-

sistor. Use a ground other than ECM terminals, such as the

ground. MEF040D

SEF217U

SEF348N

Page 1871 of 4331

![NISSAN TIIDA 2009 Service Owners Manual PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torqu NISSAN TIIDA 2009 Service Owners Manual PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torqu](/img/5/57398/w960_57398-1870.png)

PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine ju st prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run para llel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body. BBIA0704E

SEF709Y

SEF708Y

Page 1875 of 4331

EC

NP

O

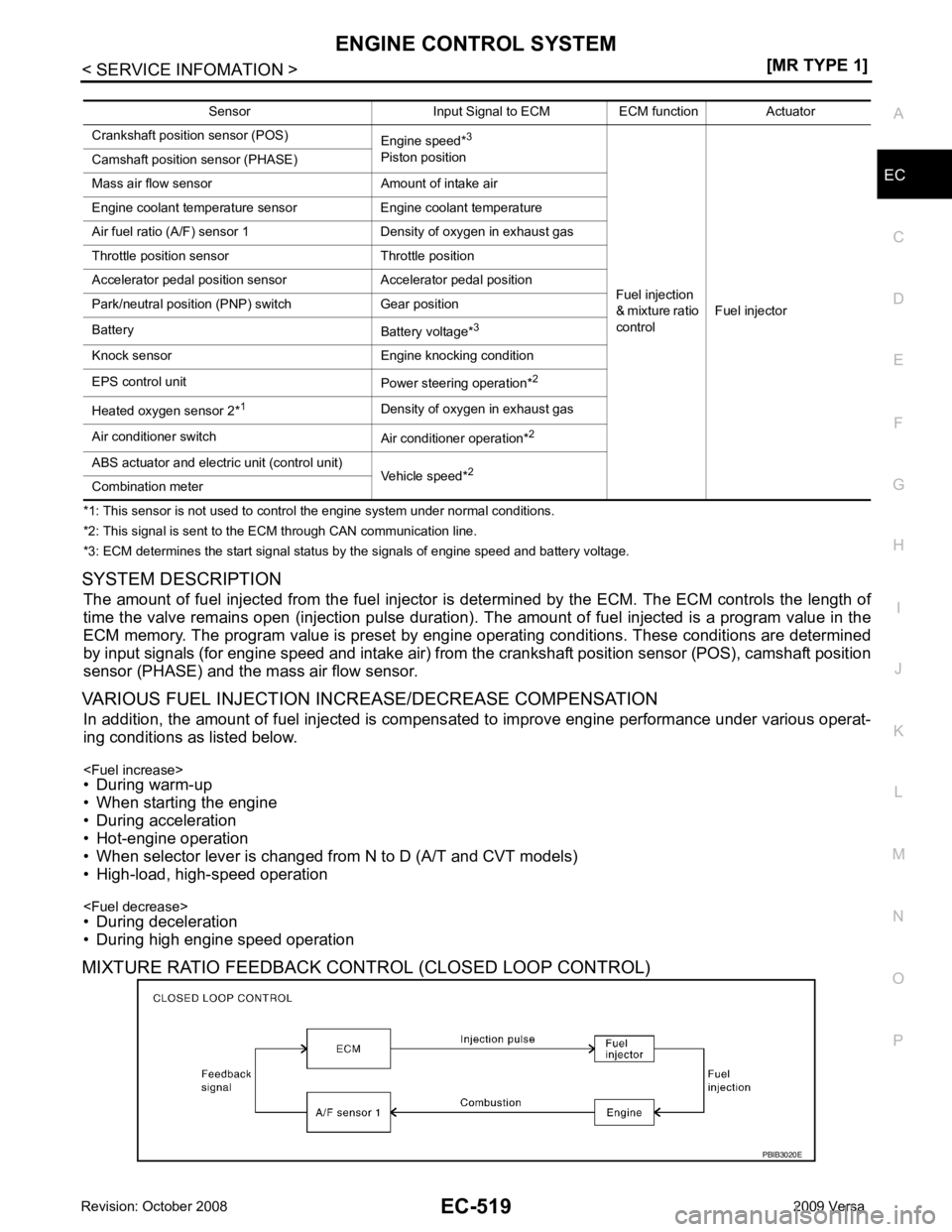

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). T he amount of fuel injected is a program value in the

ECM memory. The program value is preset by engi ne operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from t he crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the mass air flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION In addition, the amount of fuel injected is compens ated to improve engine performance under various operat-

ing conditions as listed below.

• During warm-up

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D (A/T and CVT models)

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL) Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*3

Piston position

Fuel injection

& mixture ratio

control Fuel injector

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Battery Battery voltage*3

Knock sensor Engine knocking condition

EPS control unit Power steering operation*2

Heated oxygen sensor 2* 1

Density of oxygen in exhaust gas

Air conditioner switch Air conditioner operation*2

ABS actuator and electric unit (control unit) Vehicle speed*2

Combination meter

Page 1876 of 4331

![NISSAN TIIDA 2009 Service Owners Manual EC-520< SERVICE INFOMATION >

[MR TYPE 1]

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air/ fuel mixture ratio for driveability and emission control.

The three way catal NISSAN TIIDA 2009 Service Owners Manual EC-520< SERVICE INFOMATION >

[MR TYPE 1]

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air/ fuel mixture ratio for driveability and emission control.

The three way catal](/img/5/57398/w960_57398-1875.png)

EC-520< SERVICE INFOMATION >

[MR TYPE 1]

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air/ fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better r educe CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to t he sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-698 . This maintains the mixture ratio within the range of stoichiometric

(ideal air/fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, the air/fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the EC M detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

• Deceleration and acceleration

• High-load, high-speed operation

• Malfunction of air fuel ratio (A/F) sensor 1 or its circuit

• Insufficient activation of air fuel ratio (A /F) sensor 1 at low engine coolant temperature

• High engine coolant temperature

• During warm-up

• After shifting from N to D (A/T and CVT models)

• When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixt ure ratio signal transmitted from air fuel ratio (A/F)

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the bas ic mixture ratio is not necessarily controlled as orig-

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic

changes during operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from air fuel ratio (A/F) sensor 1 i ndicates whether the mixture ratio is RICH or LEAN com-

pared to the theoretical value. The signal then triggers a r eduction in fuel volume if the mixture ratio is rich, and

an increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carri ed out long-term to compensate for continual deviation

of the short term fuel trim from t he central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycl e according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four fuel injectors will then receive the signals two times for each engine cycle. SEF337W

Page 1877 of 4331

EC

NP

O

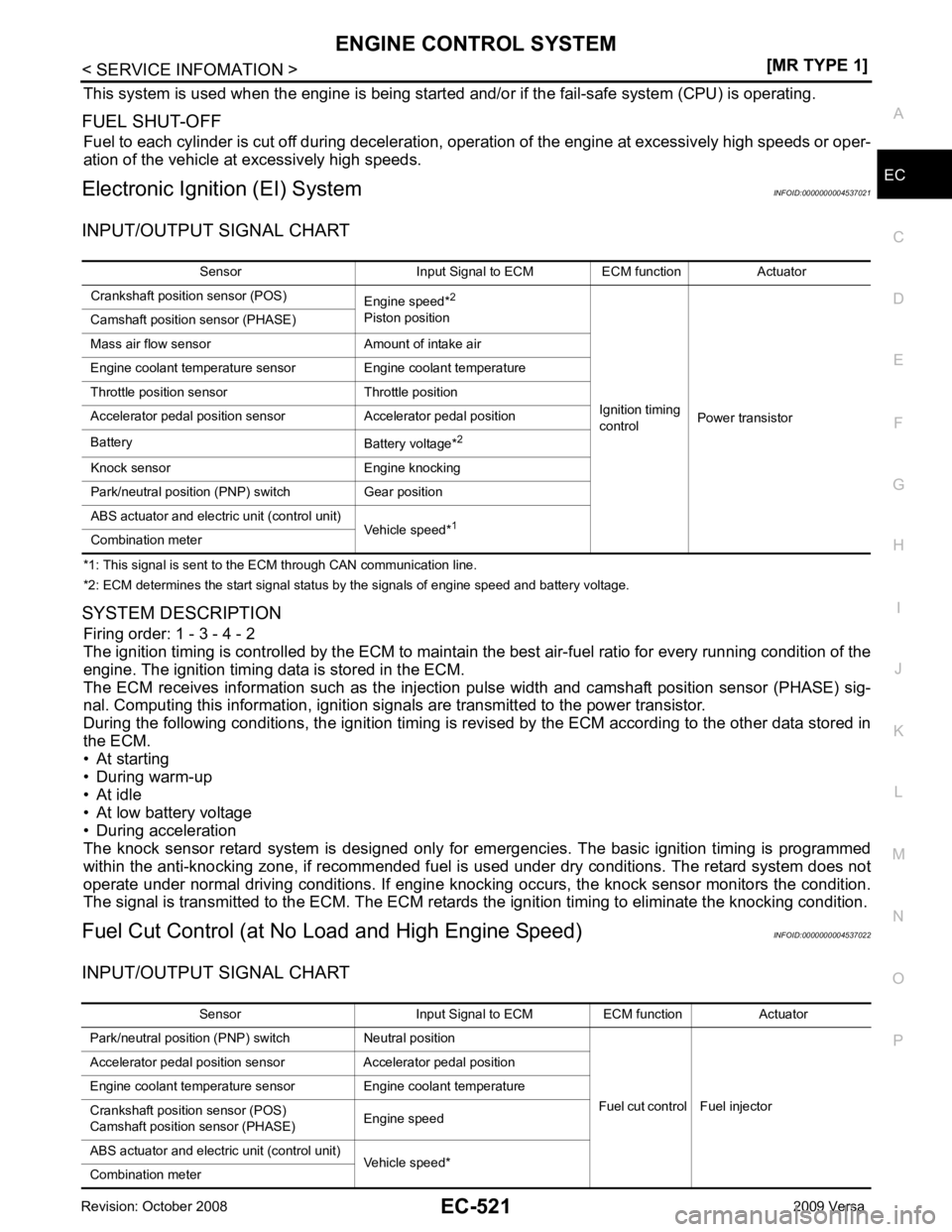

This system is used when the engine is being started

and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speeds.

Electronic Ignition (EI) System INFOID:0000000004537021

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION Firing order: 1 - 3 - 4 - 2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injecti on pulse width and camshaft position sensor (PHASE) sig-

nal. Computing this information, ignition si gnals are transmitted to the power transistor.

During the following conditions, the ignition timing is revi sed by the ECM according to the other data stored in

the ECM.

• At starting

• During warm-up

• At idle

• At low battery voltage

• During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Fuel Cut Control (at No Load and High Engine Speed) INFOID:0000000004537022

INPUT/OUTPUT SIGNAL CHART Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*2

Piston position

Ignition timing

control Power transistor

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Battery Battery voltage*2

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

ABS actuator and electric unit (control unit) Vehicle speed*1

Combination meter Sensor Input Signal to ECM ECM function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injector

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed

ABS actuator and electric unit (control unit) Vehicle speed*

Combination meter