Schedule NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 38 of 4331

AT

N

O P

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE • A/T fluid viscosity and frictional characteristics of t he clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

• The line pressure is reduced below 60 °C (140 °F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

• Line pressure is increased to a maximum irrespective of the throt- tle opening when A/T fluid temperature drops to −10 °C (14 °F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift Control INFOID:0000000004305304

The shift is regulated entirely by electronic cont rol to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals trans mitted by the revolution sensor and the ECM (accelerator

pedal position sensor). This results in improved acceleration performance and fuel economy.

CONTROL OF SHIFT SOLENOID VALVES A AND B The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and revolution sen-

sor to select the optimum gear pos ition on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS SAT008J

Page 84 of 4331

AT

N

O P

*1

: These terminals are connected to the data link connector.

*2 : These terminals are connected to the ECM.

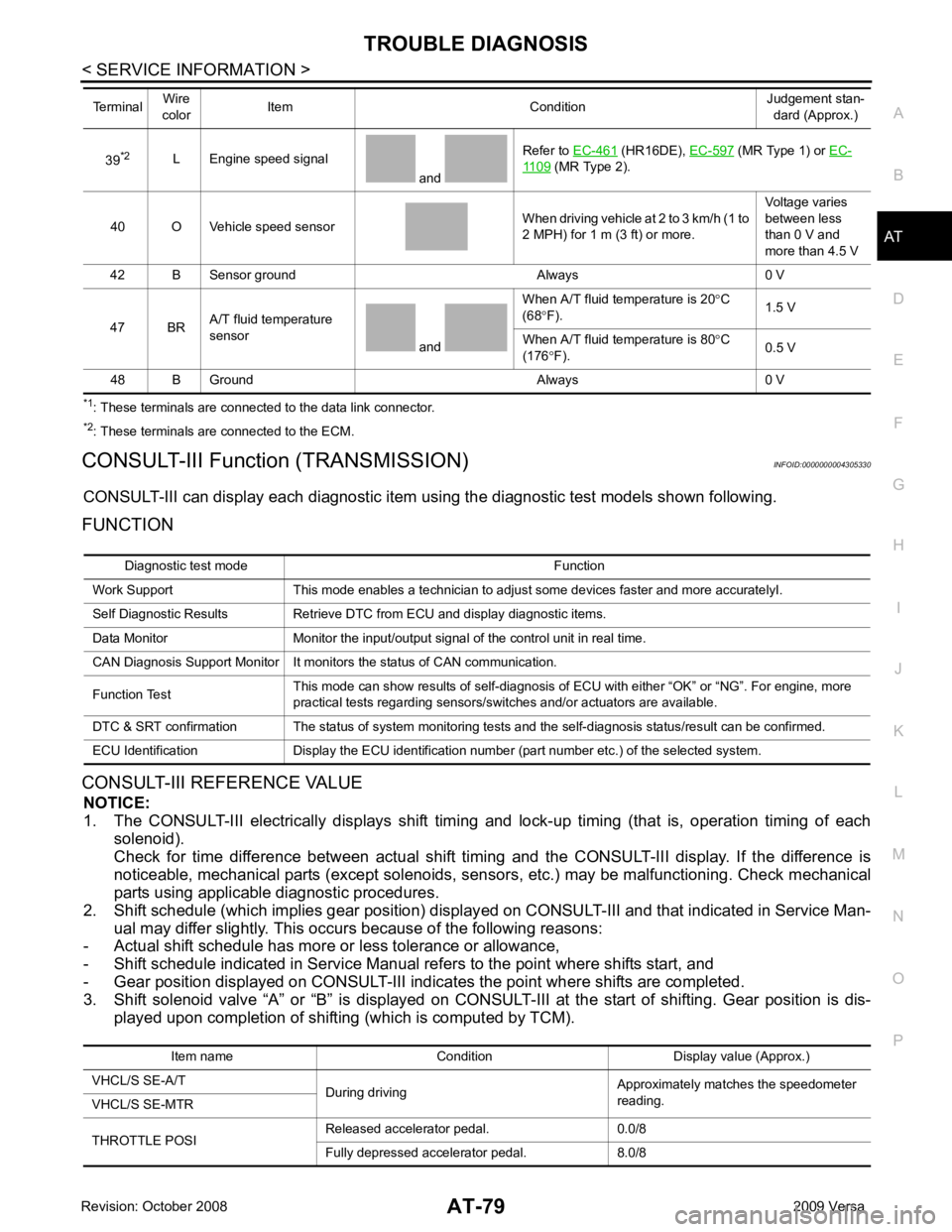

CONSULT-III Function (TRANSMISSION) INFOID:0000000004305330

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timi ng and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sens ors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) display ed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual re fers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSUL T-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

39

*2

L Engine speed signal

and Refer to

EC-461 (HR16DE),

EC-597 (MR Type 1) or

EC- 1109 (MR Type 2).

40 O Vehicle speed sensor When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more. Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always 0 V

47 BR A/T fluid temperature

sensor and When A/T fluid temperature is 20

°C

(68 °F). 1.5 V

When A/T fluid temperature is 80 °C

(176 °F). 0.5 V

48 B Ground Always 0 V

Terminal

Wire

color Item Condition Judgement stan-

dard (Approx.) Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system. Item name Condition Display value (Approx.)

VHCL/S SE-A/T During driving Approximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSI Released accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

Page 135 of 4331

AT-130< SERVICE INFORMATION >

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

5. Accelerate vehicle to more than 80 km/h (50 MPH) and maintain the following conditions continuously until “TESTING” has turned to “COMPLETE”. (It wi ll take approximately 30 seconds after “TESTING”

shows.)

THROTTLE POSI: 1.0/8 - 2.0/8 (at all times during step 4)

SLCT LVR POSI: “D” position

TCC S/V DUTY: More than 94%

VEHICLE SPEED: Constant speed of more than 80 km/h (50 MPH)

- Make sure that “GEAR” shows “4”.

- For shift schedule, refer to AT-64, " Vehicle Speed at Which Gear Shifting Occurs " .

- If “TESTING” does not ap pear on CONSULT-III for a long ti me, select “SELF-DIAG RESULTS”. In

case a DTC other than “P0744 A/T TCC S/ V FNCTN” is shown, refer to AT-79, " CONSULT-III Func-

tion (TRANSMISSION) " .

6. Make sure that “OK” is displayed. (If “NG” is displayed, refer to “DIAGNOSTIC PROCEDURE”.)

Refer to AT-130, " Diagnosis Procedure " .

Refer to AT-64, " Vehicle Speed at Which Lock-up Occurs/Releases " .

WITH GST

Follow the procedure “WITH CONSULT-III”.

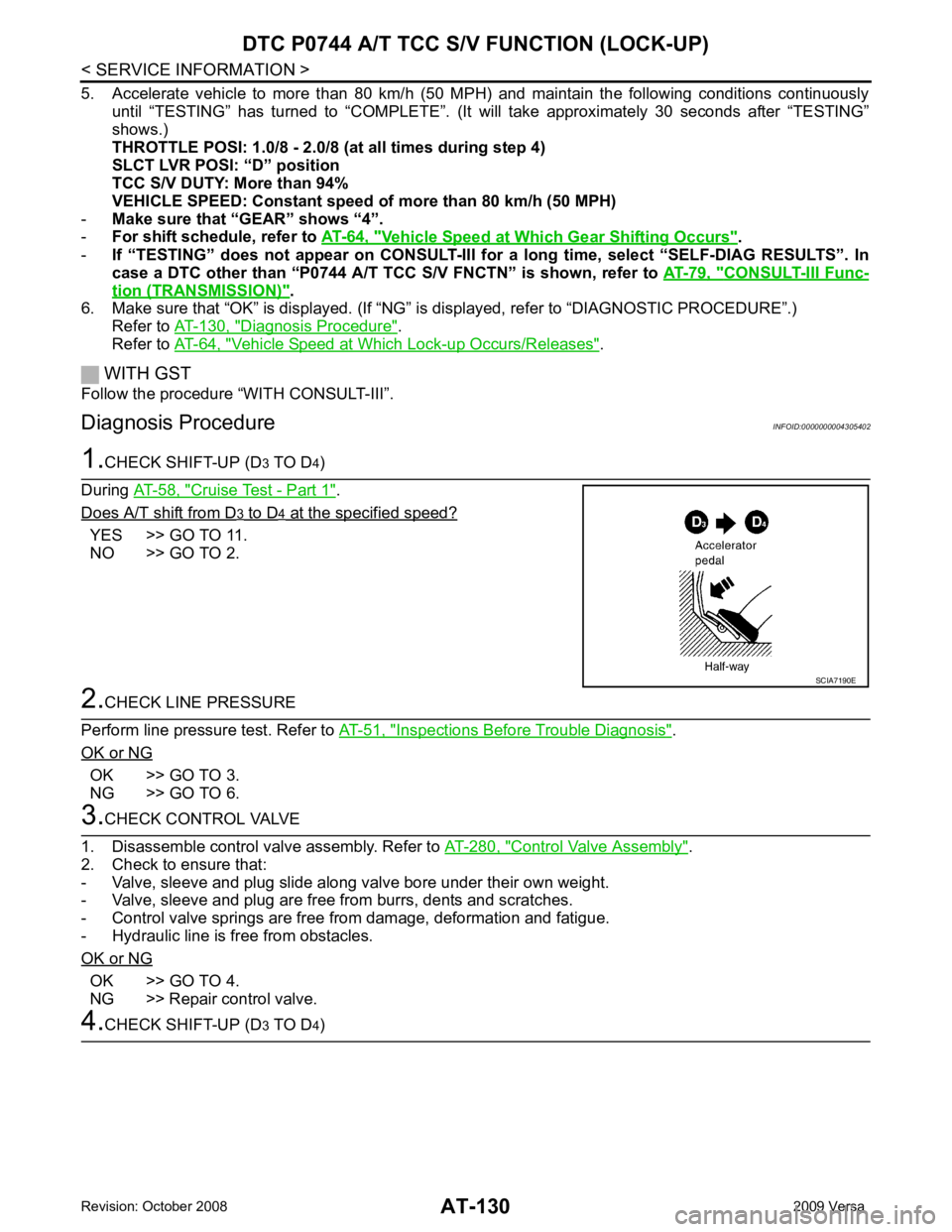

Diagnosis Procedure INFOID:00000000043054021.

CHECK SHIFT-UP (D 3 TO D 4)

During AT-58, " Cruise Test - Part 1 " .

Does A/T shift from D 3 to D 4 at the specified speed?

YES >> GO TO 11.

NO >> GO TO 2. 2.

CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 3.

NG >> GO TO 6. 3.

CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-280, " Control Valve Assembly " .

2. Check to ensure that:

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG OK >> GO TO 4.

NG >> Repair control valve. 4.

CHECK SHIFT-UP (D 3 TO D 4) SCIA7190E

Page 989 of 4331

![NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perfor NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perfor](/img/5/57398/w960_57398-988.png)

TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perform tests on all items until specified symptom is found. Trou-

bleshoot items which check out No Good after road test.

CONSULT-III START PROCEDURE • Using CONSULT-III, perform a cruise test and record the result.

• Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to CVT-47, " Cruise Test " .

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out.

Check before Engi ne Is Started INFOID:00000000046668871.

CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does O/D OFF indicator lamp come on for about 2 seconds? YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.Refer to CVT-51, " CONSULT-III Function (TRANSMISSION) " .

3. Go to CVT-45, " Check at Idle " .

NO >> Stop “Road Test”. Go to CVT-155, " O/D OFF Indicator Lamp Does Not Come On " .

Check at Idle INFOID:00000000046668881.

CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch START.

Is engine started? SAT496G

Page 1168 of 4331

![NISSAN TIIDA 2009 Service Repair Manual CVT-224< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until s NISSAN TIIDA 2009 Service Repair Manual CVT-224< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until s](/img/5/57398/w960_57398-1167.png)

CVT-224< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until s pecified symptom is found. Trou-

bleshoot items which check out No Good after road test.

CONSULT-III START PROCEDURE

• Using CONSULT-III, perform a cruise test and record the result.

• Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to CVT-226, " Cruise Test " .

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out. Check before Engine Is Started INFOID:00000000043055951.

CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does O/D OFF indicator lamp come on for about 2 seconds? YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.Refer to CVT-230, " CONSULT-III Function (TRANSMISSION) " .

3. Go to CVT-224, " Check at Idle " .

NO >> Stop “Road Test”. Go to CVT-325, " O/D OFF Indicator Lamp Does Not Come On " .

Check at Idle INFOID:00000000043055961.

CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch START.

Is engine started? SAT496G

Page 1447 of 4331

EC

NP

O

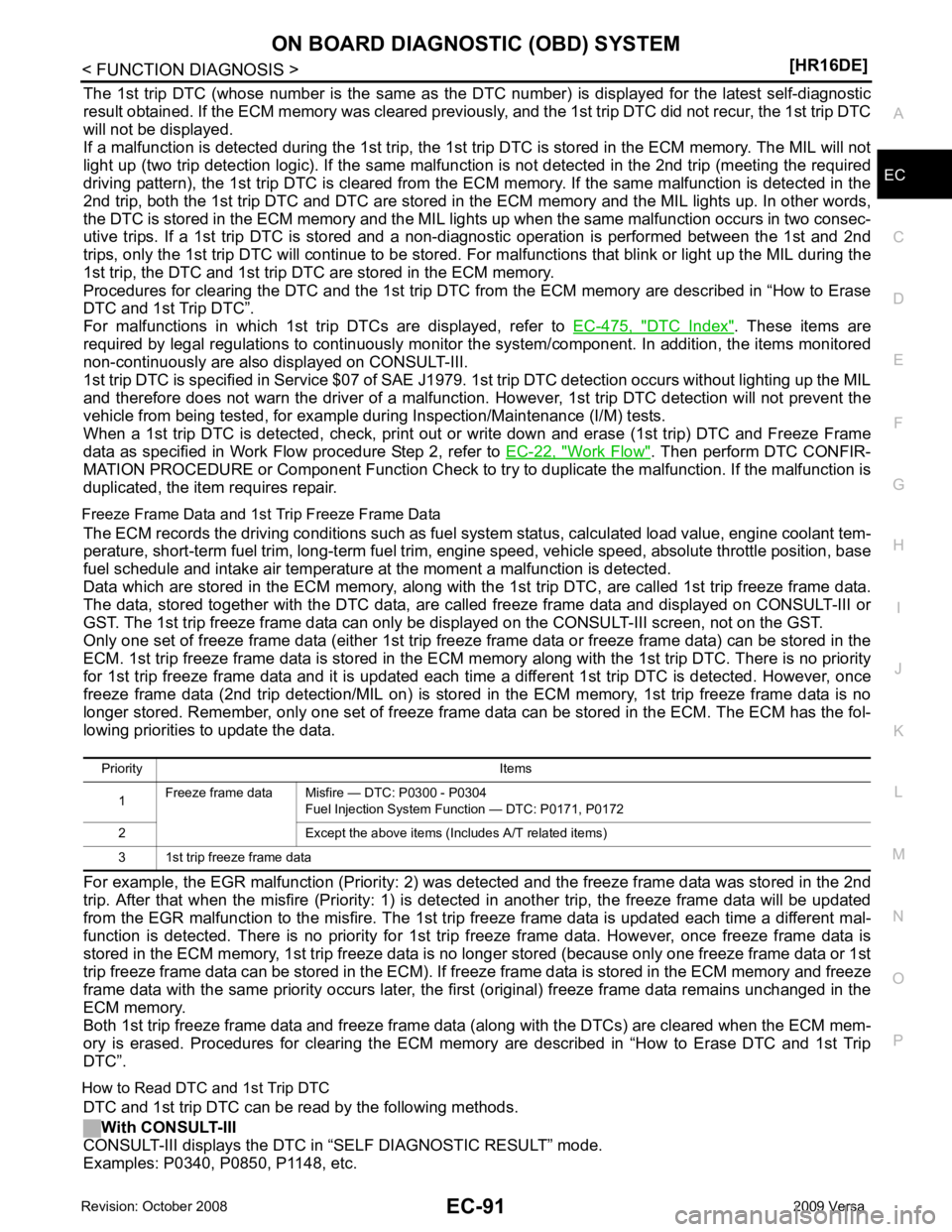

The 1st trip DTC (whose number is the same as the DT

C number) is displayed for the latest self-diagnostic

result obtained. If the ECM memory was cleared previously , and the 1st trip DTC did not recur, the 1st trip DTC

will not be displayed.

If a malfunction is detected during the 1st trip, the 1st trip DTC is stored in the ECM memory. The MIL will not

light up (two trip detection logic). If the same malfunc tion is not detected in the 2nd trip (meeting the required

driving pattern), the 1st trip DTC is cleared from the ECM memory. If the same malfunction is detected in the

2nd trip, both the 1st trip DTC and DTC are stored in t he ECM memory and the MIL lights up. In other words,

the DTC is stored in the ECM memory and the MIL light s up when the same malfunction occurs in two consec-

utive trips. If a 1st trip DTC is stored and a non-diagnostic operation is performed between the 1st and 2nd

trips, only the 1st trip DTC will continue to be stored. Fo r malfunctions that blink or light up the MIL during the

1st trip, the DTC and 1st trip DTC are stored in the ECM memory.

Procedures for clearing the DTC and the 1st trip DTC fr om the ECM memory are described in “How to Erase

DTC and 1st Trip DTC”.

For malfunctions in which 1st trip DTCs are displayed, refer to EC-475, " DTC Index " . These items are

required by legal regulations to c ontinuously monitor the system/component . In addition, the items monitored

non-continuously are also displayed on CONSULT-III.

1st trip DTC is specified in Service $07 of SAE J1979. 1st trip DTC detection occurs without lighting up the MIL

and therefore does not warn the driver of a malfunction. However, 1st trip DTC detection will not prevent the

vehicle from being tested, for example during Inspection/Maintenance (I/M) tests.

When a 1st trip DTC is detected, check, print out or write down and erase (1st trip) DTC and Freeze Frame

data as specified in Work Flow procedure Step 2, refer to EC-22, " Work Flow " . Then perform DTC CONFIR-

MATION PROCEDURE or Component Function Check to tr y to duplicate the malfunction. If the malfunction is

duplicated, the item requires repair.

Freeze Frame Data and 1st Trip Freeze Frame Data The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant tem-

perature, short-term fuel trim, long-term fuel trim, engi ne speed, vehicle speed, absolute throttle position, base

fuel schedule and intake air temperature at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are ca lled freeze frame data and displayed on CONSULT-III or

GST. The 1st trip freeze frame data can only be di splayed on the CONSULT-III screen, not on the GST.

Only one set of freeze frame data (either 1st trip freez e frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM me mory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (P riority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st tr ip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If fr eeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame dat a (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described in “How to Erase DTC and 1st Trip

DTC”.

How to Read DTC and 1st Trip DTC DTC and 1st trip DTC can be read by the following methods.

With CONSULT-III

CONSULT-III displays the DTC in “SELF DIAGNOSTIC RESULT” mode.

Examples: P0340, P0850, P1148, etc. Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0304

Fuel Injection System Function — DTC: P0171, P0172

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 1462 of 4331

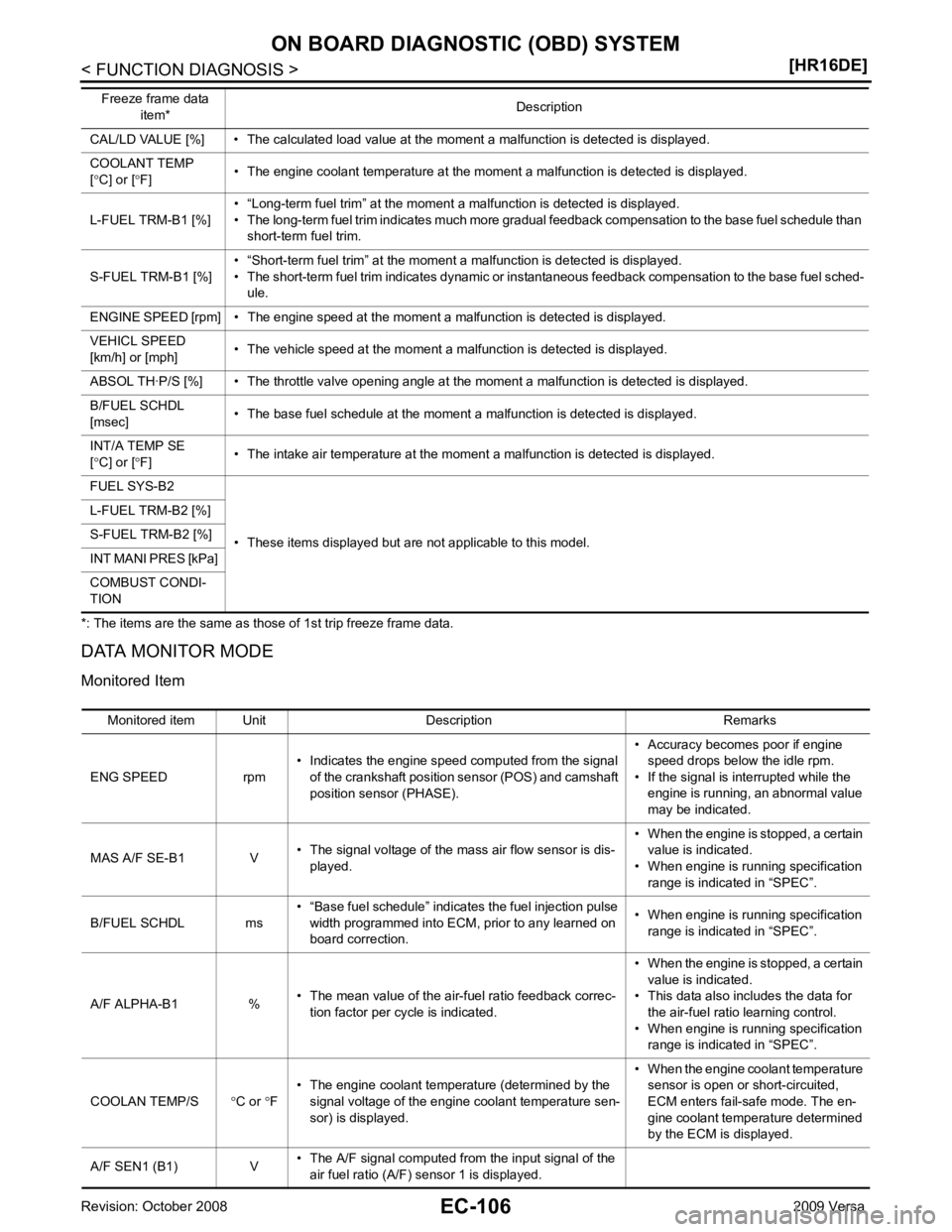

Monitored item Unit Description Remarks

ENG SPEED rpm • Indicates the engine speed computed from the signal

of the crankshaft position sensor (POS) and camshaft

position sensor (PHASE). • Accuracy becomes poor if engine

speed drops below the idle rpm.

• If the signal is interrupted while the engine is running, an abnormal value

may be indicated.

MAS A/F SE-B1 V • The signal voltage of the mass air flow sensor is dis-

played. • When the engine is stopped, a certain

value is indicated.

• When engine is running specification range is indicated in “SPEC”.

B/FUEL SCHDL ms • “Base fuel schedule” indicates the fuel injection pulse

width programmed into ECM, prior to any learned on

board correction. • When engine is running specification

range is indicated in “SPEC”.

A/F ALPHA-B1 % • The mean value of the air-fuel ratio feedback correc-

tion factor per cycle is indicated. • When the engine is stopped, a certain

value is indicated.

• This data also includes the data for

the air-fuel ratio learning control.

• When engine is running specification range is indicated in “SPEC”.

COOLAN TEMP/S °C or °F • The engine coolant temperature (determined by the

signal voltage of the engine coolant temperature sen-

sor) is displayed. • When the engine coolant temperature

sensor is open or short-circuited,

ECM enters fail-safe mode. The en-

gine coolant temperature determined

by the ECM is displayed.

A/F SEN1 (B1) V • The A/F signal computed from the input signal of the

air fuel ratio (A/F) se nsor 1 is displayed.

Page 1922 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs tha NISSAN TIIDA 2009 Service Repair Manual EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs tha](/img/5/57398/w960_57398-1921.png)

EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs that ma y indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT-III or GST.

OK or NG OK >> GO TO 3.

NG >> GO TO 2. 2.

REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3. 3.

CHECK TARGET IDLE SPEED

With CONSULT-III

1. Run engine at about 2,000 rpm for about 2 minutes under no load. SEF983U

SEF976U

SEF977U

Page 1963 of 4331

EC

NP

O

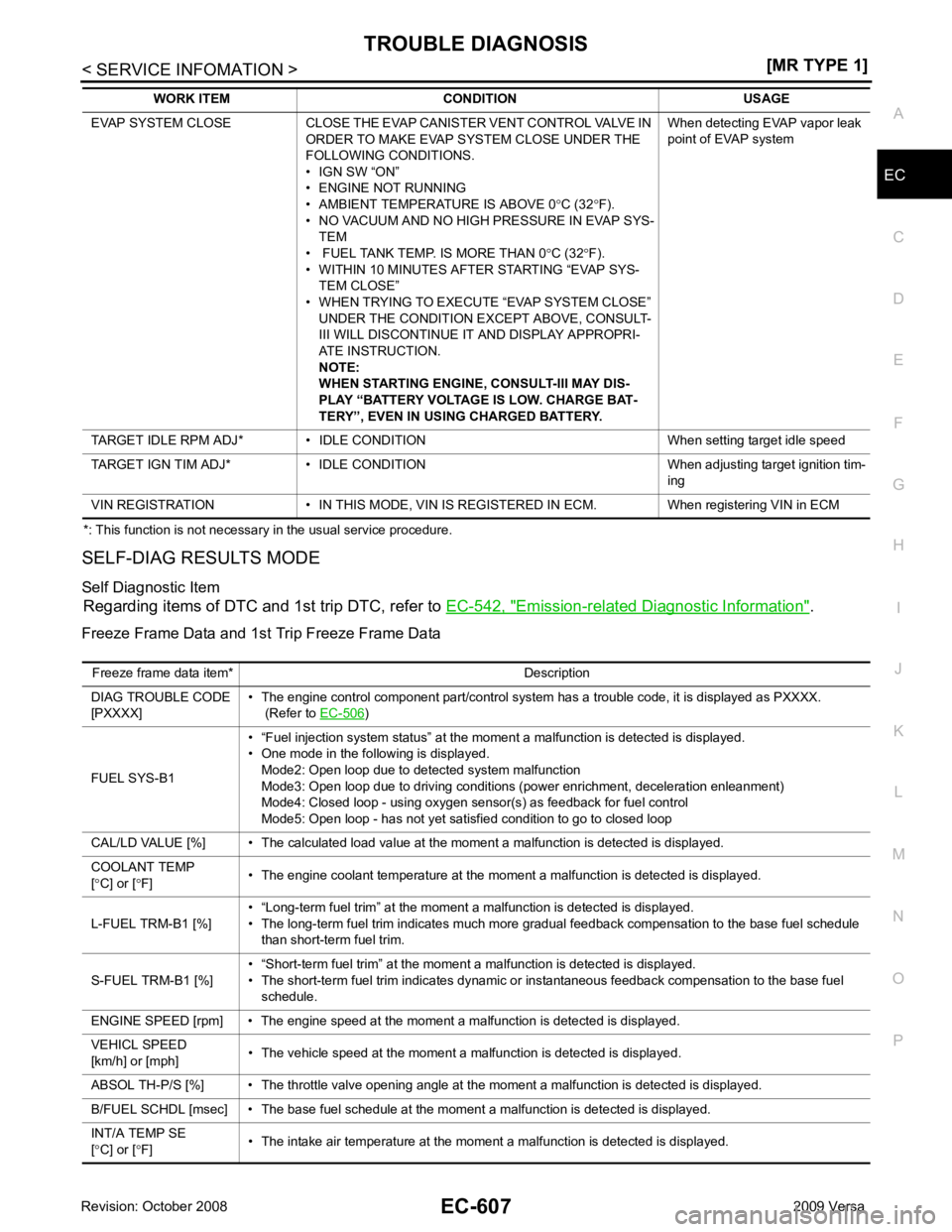

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item Regarding items of DTC and 1st trip DTC, refer to EC-542, " Emission-related Diagnostic Information " .

Freeze Frame Data and 1st Trip Freeze Frame Data EVAP SYSTEM CLOSE CLOSE THE EVAP CANISTER VENT CONTROL VALVE IN

ORDER TO MAKE EVAP SYSTEM CLOSE UNDER THE

FOLLOWING CONDITIONS.

• IGN SW “ON”

• ENGINE NOT RUNNING

• AMBIENT TEMPERATURE IS ABOVE 0 °C (32 °F).

• NO VACUUM AND NO HIGH PRESSURE IN EVAP SYS- TEM

• FUEL TANK TEMP. IS MORE THAN 0 °C (32 °F).

• WITHIN 10 MINUTES AFTER STARTING “EVAP SYS- TEM CLOSE”

• WHEN TRYING TO EXECUTE “EVAP SYSTEM CLOSE” UNDER THE CONDITION EXCEPT ABOVE, CONSULT-

III WILL DISCONTINUE IT AND DISPLAY APPROPRI-

ATE INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-III MAY DIS-

PLAY “BATTERY VOLTAGE IS LOW. CHARGE BAT-

TERY”, EVEN IN USING CHARGED BATTERY. When detecting EVAP vapor leak

point of EVAP system

TARGET IDLE RPM ADJ* • IDLE CONDITION When setting target idle speed

TARGET IGN TIM ADJ* • IDLE CONDITION Wh en adjusting target ignition tim-

ing

VIN REGISTRATION • IN THIS MODE, VIN IS REGISTERED IN ECM. When registering VIN in ECM WORK ITEM CONDITION USAGE )

FUEL SYS-B1 • “Fuel injection system status” at the moment a malfunction is detected is displayed.

• One mode in the following is displayed.

Mode2: Open loop due to detected system malfunction

Mode3: Open loop due to driving conditions (power enrichment, deceleration enleanment)

Mode4: Closed loop - using oxygen sensor(s) as feedback for fuel control

Mode5: Open loop - has not yet satisfied condition to go to closed loop

CAL/LD VALUE [%] • The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP

[ ° C] or [ °F] • The engine coolant temperature at the moment a malfunction is detected is displayed.

L-FUEL TRM-B1 [%] • “Long-term fuel trim” at the moment a malfunction is detected is displayed.

• The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule than short-term fuel trim.

S-FUEL TRM-B1 [%] • “Short-term fuel trim” at the moment a malfunction is detected is displayed.

• The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel schedule.

ENGINE SPEED [rpm] • The engine speed at the moment a malfunction is detected is displayed.

VEHICL SPEED

[km/h] or [mph] • The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL TH-P/S [%] • The throttle valve opening angle at th e moment a malfunction is detected is displayed.

B/FUEL SCHDL [msec] • The ba se fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake air temperature at the moment a malfunction is detected is displayed.

Page 1964 of 4331

![NISSAN TIIDA 2009 Service Repair Manual Monitored item [Unit] Description Remarks

ENG SPEED

[rpm] • Indicates the engine speed computed from the signals of the

crankshaft position sensor (POS) and camshaft position sen-

sor (PHASE). • NISSAN TIIDA 2009 Service Repair Manual Monitored item [Unit] Description Remarks

ENG SPEED

[rpm] • Indicates the engine speed computed from the signals of the

crankshaft position sensor (POS) and camshaft position sen-

sor (PHASE). •](/img/5/57398/w960_57398-1963.png)

Monitored item [Unit] Description Remarks

ENG SPEED

[rpm] • Indicates the engine speed computed from the signals of the

crankshaft position sensor (POS) and camshaft position sen-

sor (PHASE). • Accuracy becomes poor if engine speed

drops below the idle rpm.

• If the signal is interrupted while the engine is running, an abnormal value may be indicat-

ed.

MAS A/F SE-B1

[V] • The signal voltage of the mass air flow sensor is displayed. • When the engine is stopped, a certain value

is indicated.

• When engine is running, specification range is indicated in "SPEC".

B/FUEL SCHDL

[msec] • “Base fuel schedule” indicates the fuel injection pulse width

programmed into ECM, prior to any learned on board correc-

tion. • When engine is running, specification range

is indicated in "SPEC".

A/F ALPHA-B1

[%] • The mean value of the air-fuel ratio feedback correction fac-

tor per cycle is indicated. • When the engine is stopped, a certain value

is indicated.

• This data also includes the data for the air/ fuel ratio learning control.

• When engine is running, specification range

is indicated in "SPEC".

COOLAN TEMP/S

[ ° C] or [ °F] • The engine coolant temperature (determined by the signal

voltage of the engine coolant temperature sensor) is dis-

played. • When the engine coolant temperature sen-

sor is open or short-circuited, ECM enters

fail-safe mode. The engine coolant temper-

ature determined by the ECM is displayed.

A/F SEN1 (B1)

[V] • The A/F signal computed from the input signal of the A/F sen-

sor 1 is displayed.

HO2S2 (B1)

[V] • The signal voltage of the heated oxygen sensor 2 is dis-

played.

HO2S2 MNTR (B1)

[RICH/LEAN] • Display of heated oxygen sensor 2 signal:

RICH: means the amount of oxygen after three way catalyst

is relatively small.

LEAN: means the amount of oxygen after three way catalyst

is relatively large. • When the engine is stopped, a certain value

is indicated.

VHCL SPEED SE

[km/h] or [mph] • The vehicle speed computed from the vehicle speed signal is

displayed.

BATTERY VOLT

[V] • The power supply voltage of ECM is displayed.

ACCEL SEN 1

[V] • The accelerator pedal position sensor signal voltage is dis-

played. • ACCEL SEN 2 signal is converted by ECM

internally. Thus, it differs from ECM terminal

voltage signal.

ACCEL SEN 2

[V]

TP SEN 1-B1

[V] • The throttle position sensor signal voltage is displayed. • TP SEN 2-B1 signal is converted by ECM in-

ternally. Thus, it differs from ECM terminal

voltage signal.

TP SEN 2-B1

[V]