ecu connector NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3 of 4331

ACC

NP

O

ACCELERATOR CONTROL SYSTEM

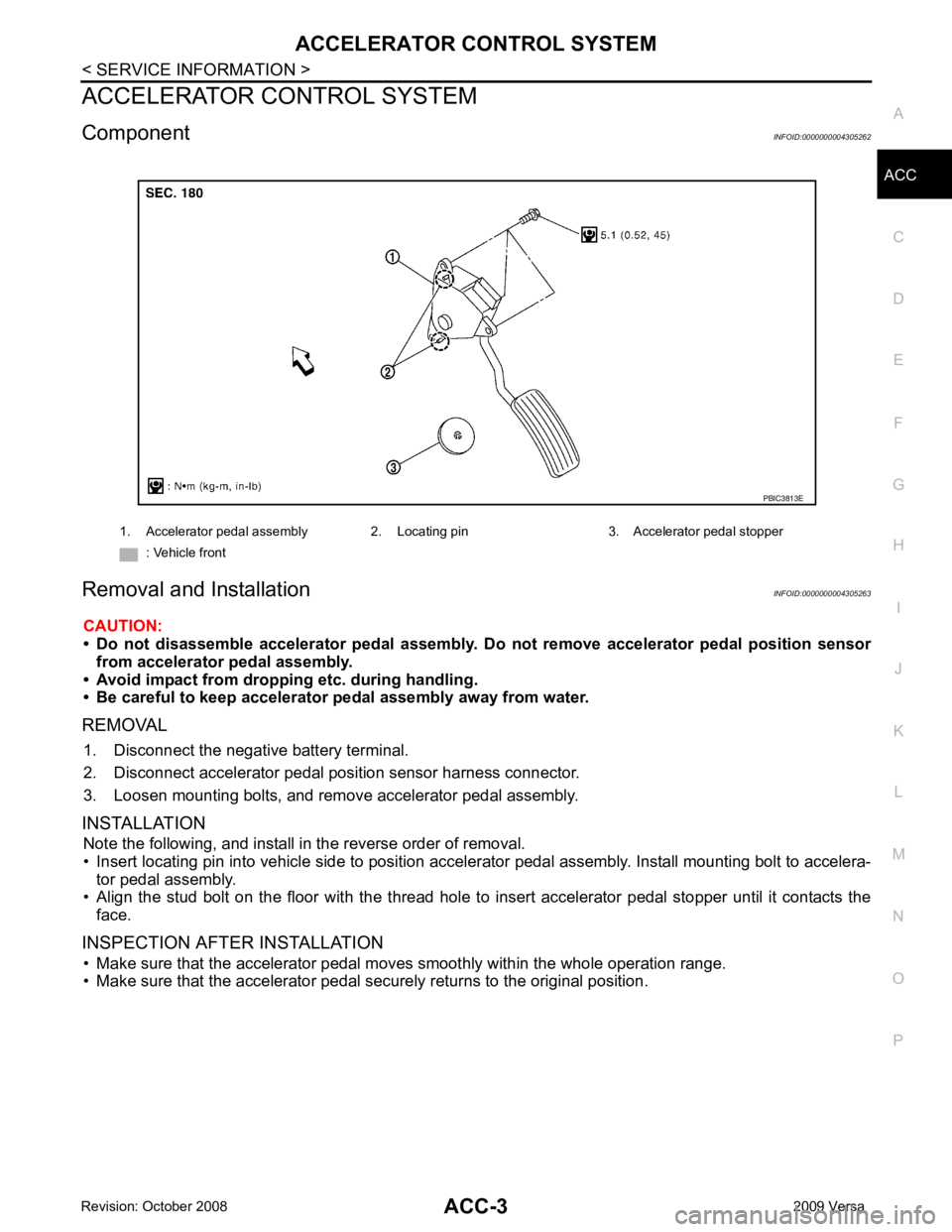

Component INFOID:0000000004305262

Removal and Installation INFOID:0000000004305263

CAUTION:

• Do not disassemble accelerator pedal assembly. Do not remove accelerator pedal position sensor

from accelerator pedal assembly.

• Avoid impact from dropping etc. during handling.

• Be careful to keep accelerator pedal assembly away from water.

REMOVAL 1. Disconnect the negative battery terminal.

2. Disconnect accelerator pedal position sensor harness connector.

3. Loosen mounting bolts, and remove accelerator pedal assembly.

INSTALLATION Note the following, and install in the reverse order of removal.

• Insert locating pin into vehicle side to position accelerator pedal assembly. Install mounting bolt to accelera- tor pedal assembly.

• Align the stud bolt on the floor with the thread hole to in sert accelerator pedal stopper until it contacts the

face.

INSPECTION AFTER INSTALLATION • Make sure that the accelerator pedal mo ves smoothly within the whole operation range.

• Make sure that the accelerator pedal securely returns to the original position. 1. Accelerator pedal assembly 2. Locating pin 3. Accelerator pedal stopper

: Vehicle front

Page 84 of 4331

AT

N

O P

*1

: These terminals are connected to the data link connector.

*2 : These terminals are connected to the ECM.

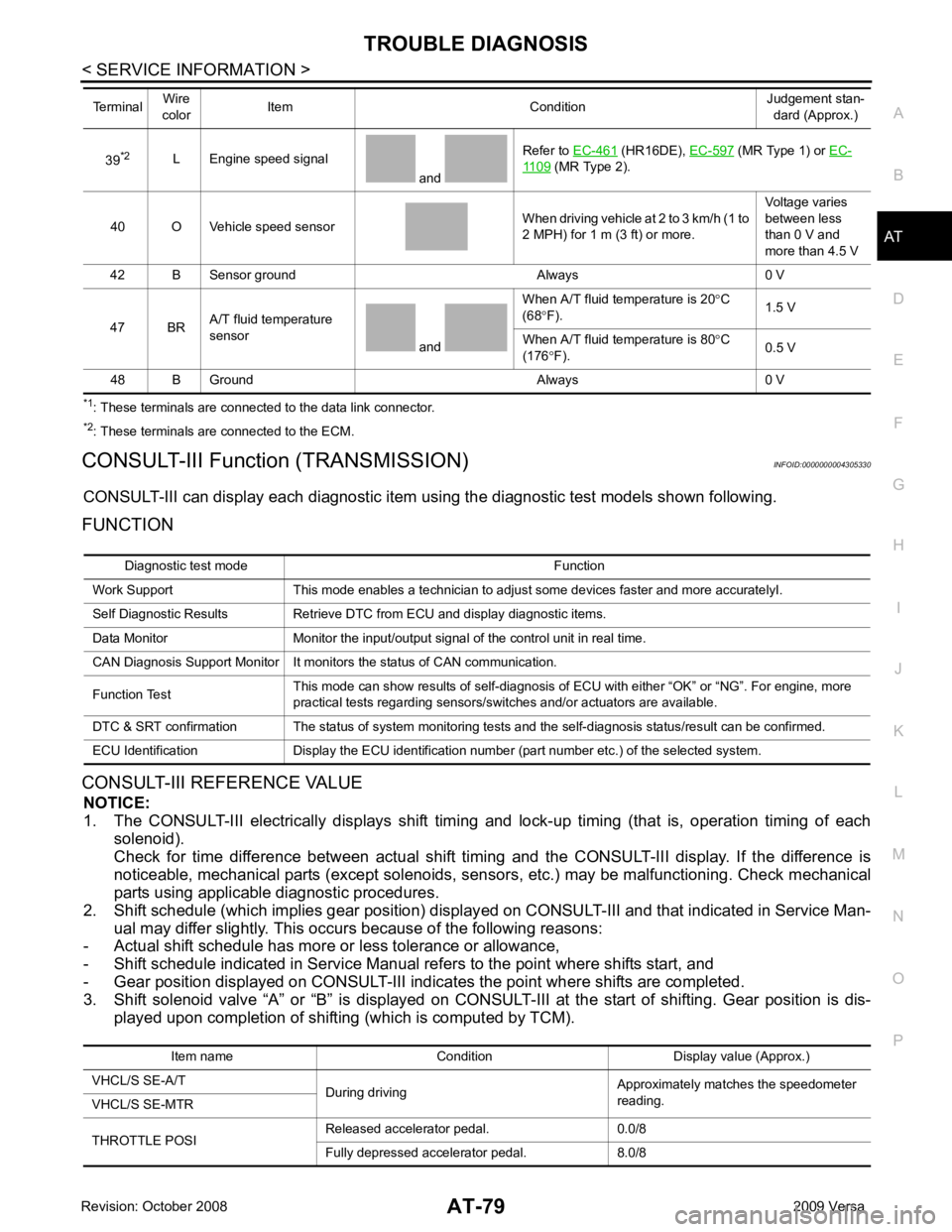

CONSULT-III Function (TRANSMISSION) INFOID:0000000004305330

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timi ng and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sens ors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) display ed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual re fers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSUL T-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

39

*2

L Engine speed signal

and Refer to

EC-461 (HR16DE),

EC-597 (MR Type 1) or

EC- 1109 (MR Type 2).

40 O Vehicle speed sensor When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more. Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always 0 V

47 BR A/T fluid temperature

sensor and When A/T fluid temperature is 20

°C

(68 °F). 1.5 V

When A/T fluid temperature is 80 °C

(176 °F). 0.5 V

48 B Ground Always 0 V

Terminal

Wire

color Item Condition Judgement stan-

dard (Approx.) Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system. Item name Condition Display value (Approx.)

VHCL/S SE-A/T During driving Approximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSI Released accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

Page 96 of 4331

AT

N

O P

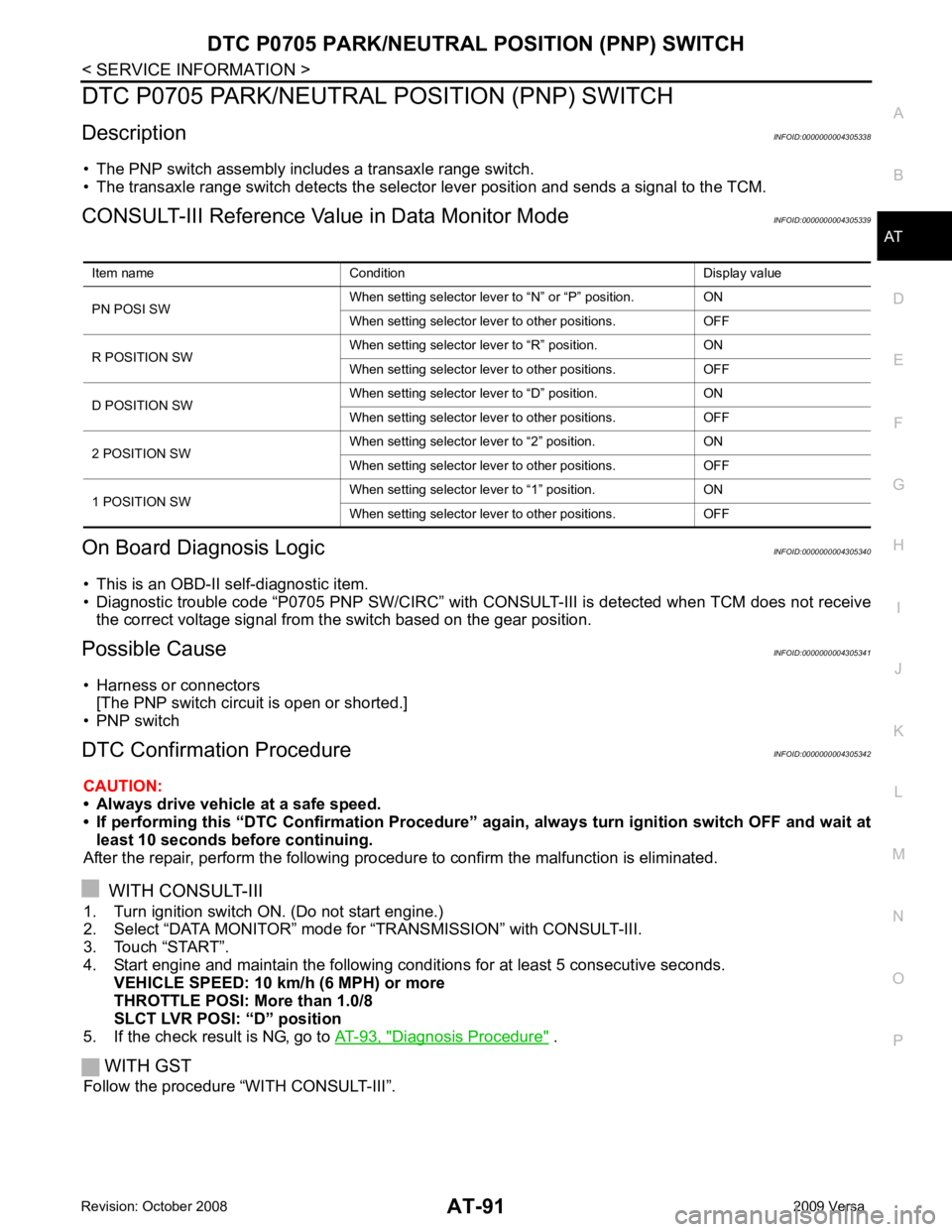

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Description INFOID:0000000004305338

• The PNP switch assembly includes a transaxle range switch.

• The transaxle range switch detects the selector lever position and sends a signal to the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305339

On Board Diagnosis Logic INFOID:0000000004305340

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 PNP SW/CIRC” with CONS ULT-III is detected when TCM does not receive

the correct voltage signal from the switch based on the gear position.

Possible Cause INFOID:0000000004305341

• Harness or connectors [The PNP switch circuit is open or shorted.]

• PNP switch

DTC Confirmation Procedure INFOID:0000000004305342

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

5. If the check result is NG, go to AT-93, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 106 of 4331

AT

N

O P

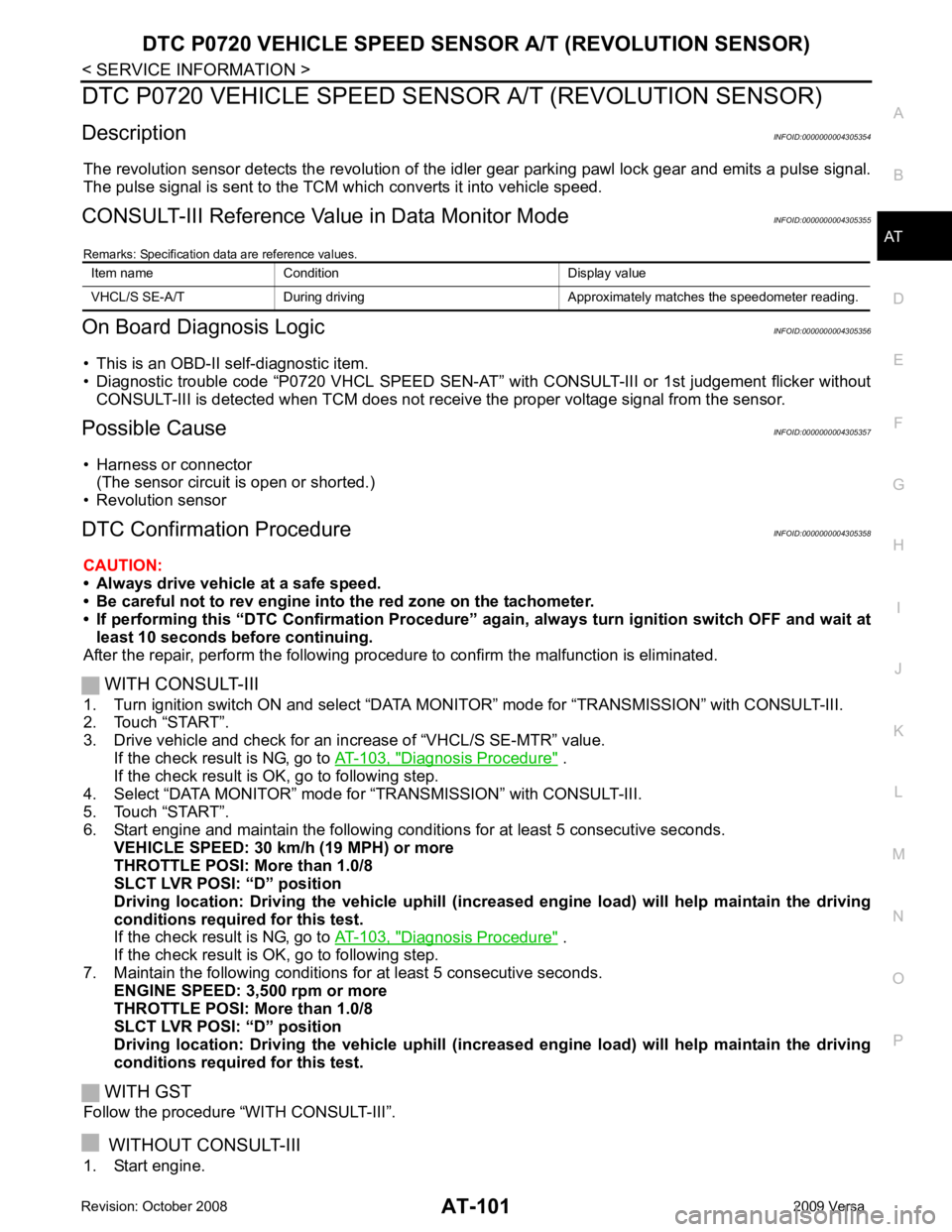

DTC P0720 VEHICLE SPEED SENS

OR A/T (REVOLUTION SENSOR)

Description INFOID:0000000004305354

The revolution sensor detects the revolution of the id ler gear parking pawl lock gear and emits a pulse signal.

The pulse signal is sent to the TCM which converts it into vehicle speed.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305355

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305356

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0720 VHCL SPEED SEN-AT” with CONSULT-III or 1st judgement flicker without

CONSULT-III is detected when TCM does not rece ive the proper voltage signal from the sensor.

Possible Cause INFOID:0000000004305357

• Harness or connector (The sensor circuit is open or shorted.)

• Revolution sensor

DTC Confirmation Procedure INFOID:0000000004305358

CAUTION:

• Always drive vehicle at a safe speed.

• Be careful not to rev engine into the red zone on the tachometer.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Drive vehicle and check for an in crease of “VHCL/S SE-MTR” value.

If the check result is NG, go to AT-103, " Diagnosis Procedure " .

If the check result is OK, go to following step.

4. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

5. Touch “START”.

6. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 30 km/h (19 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

If the check result is NG, go to AT-103, " Diagnosis Procedure " .

If the check result is OK, go to following step.

7. Maintain the following conditions for at least 5 consecutive seconds. ENGINE SPEED: 3,500 rpm or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine. Item name Condition Display value

VHCL/S SE-A/T During driving Approxima tely matches the speedometer reading.

Page 232 of 4331

AT

N

O P

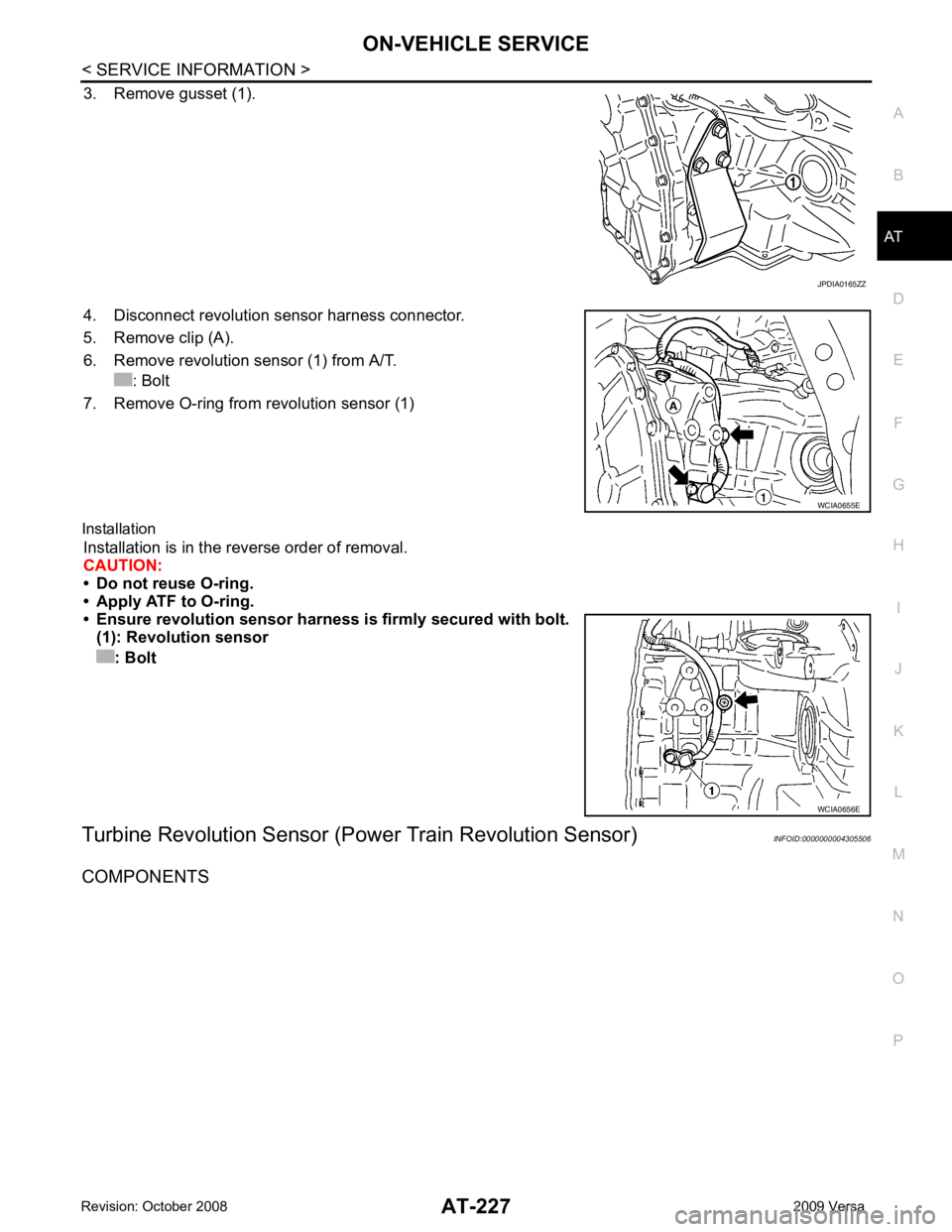

3. Remove gusset (1).

4. Disconnect revolution sensor harness connector.

5. Remove clip (A).

6. Remove revolution sensor (1) from A/T. : Bolt

7. Remove O-ring from revolution sensor (1)

Installation Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

• Ensure revolution sensor harn ess is firmly secured with bolt.

(1): Revolution sensor

: Bolt

Turbine Revolution Sensor (Power Train Revolution Sensor) INFOID:0000000004305506

COMPONENTS

Page 238 of 4331

AT

N

O P

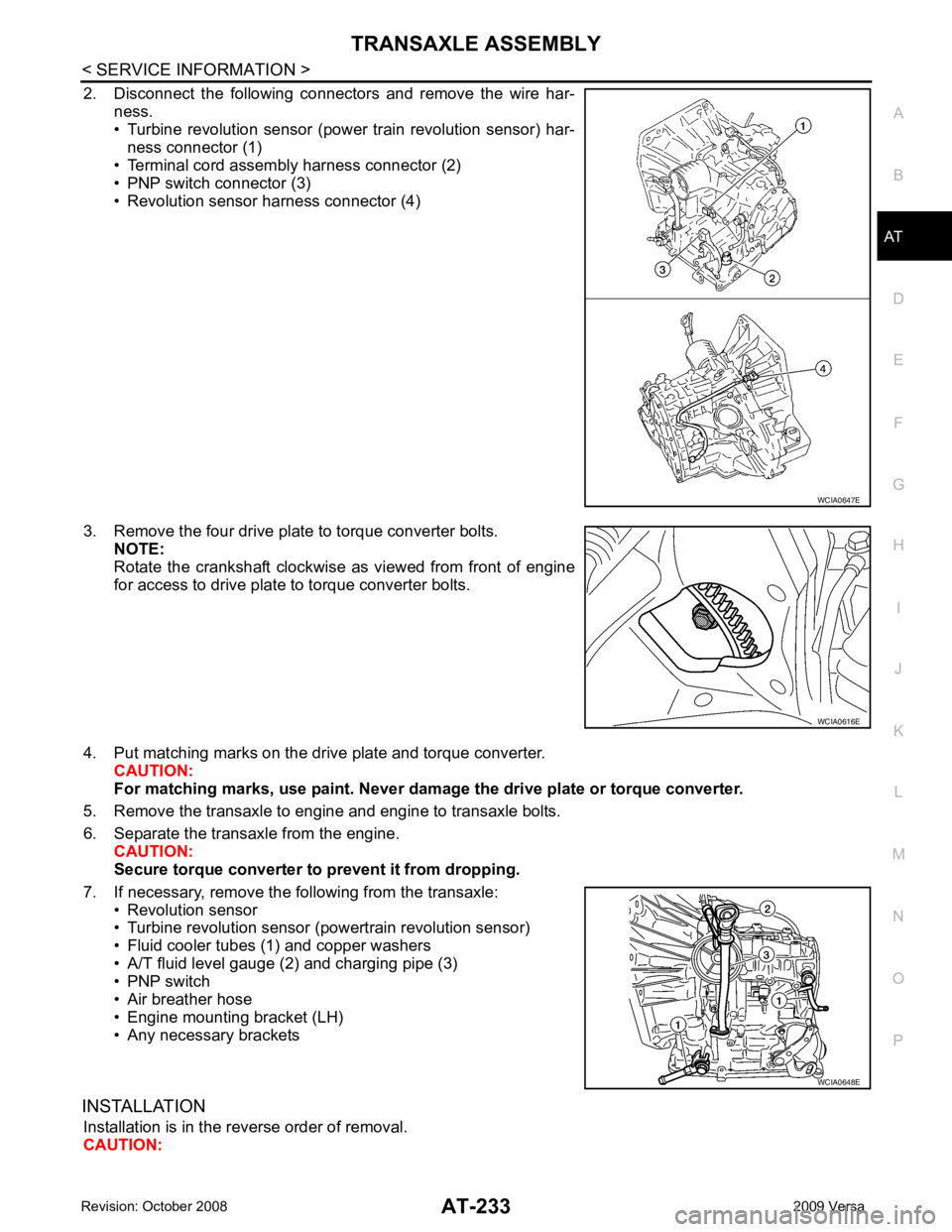

2. Disconnect the following connectors and remove the wire har-

ness.

• Turbine revolution sensor (power train revolution sensor) har-

ness connector (1)

• Terminal cord assembly harness connector (2)

• PNP switch connector (3)

• Revolution sensor harness connector (4)

3. Remove the four drive plate to torque converter bolts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter bolts.

4. Put matching marks on the drive plate and torque converter. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

5. Remove the transaxle to engine and engine to transaxle bolts.

6. Separate the transaxle from the engine. CAUTION:

Secure torque converter to prevent it from dropping.

7. If necessary, remove the following from the transaxle: • Revolution sensor

• Turbine revolution sensor (powertrain revolution sensor)

• Fluid cooler tubes (1) and copper washers

• A/T fluid level gauge (2) and charging pipe (3)

• PNP switch

• Air breather hose

• Engine mounting bracket (LH)

• Any necessary brackets

INSTALLATION Installation is in the reverse order of removal.

CAUTION: WCIA0616E

WCIA0648E

Page 458 of 4331

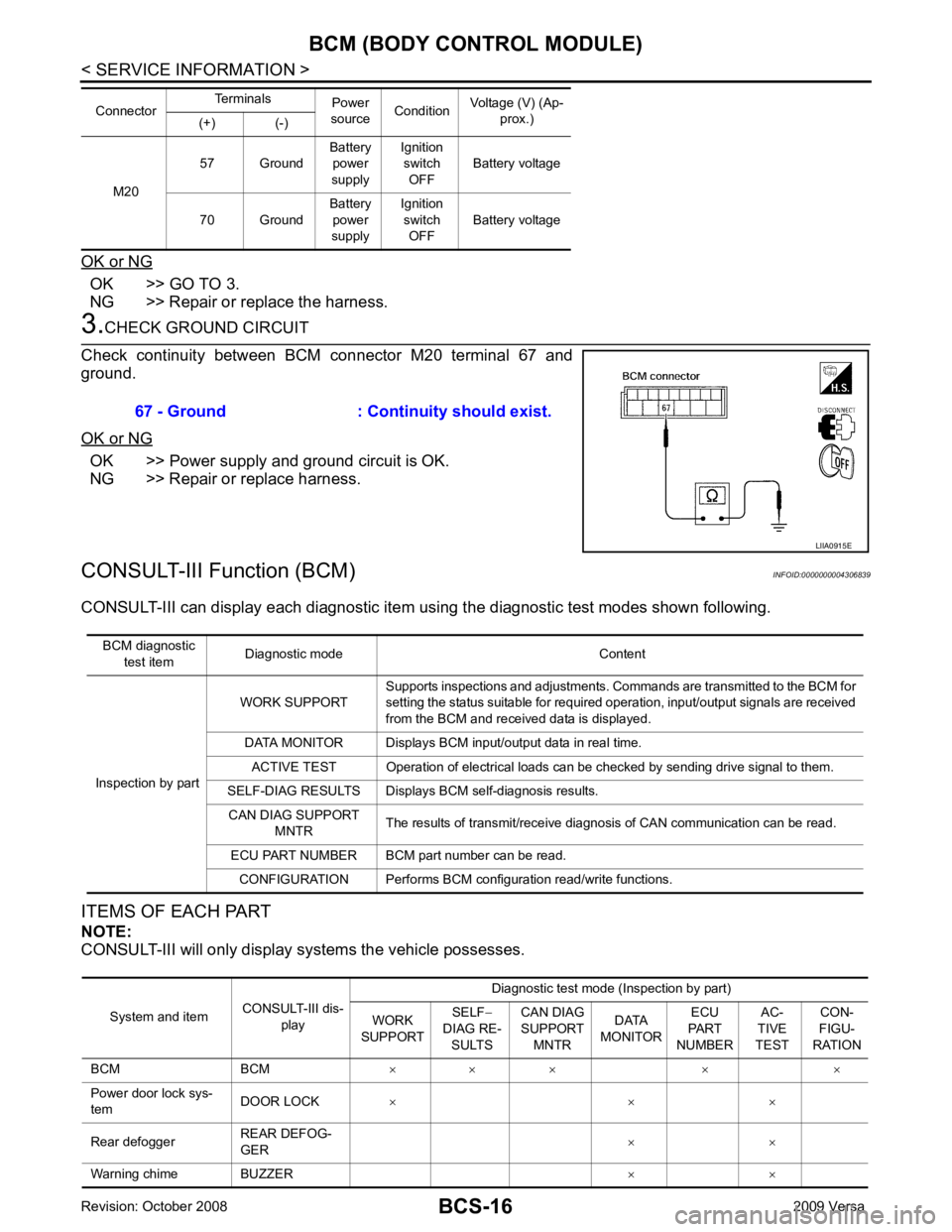

OK >> GO TO 3.

NG >> Repair or replace the harness. OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

CONSULT-III Function (BCM) INFOID:0000000004306839

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

ITEMS OF EACH PART

NOTE:

CONSULT-III will only display systems the vehicle possesses. M20

57 Ground

Battery

power

supply Ignition

switch

OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

Connector

Terminals

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-) System and item

CONSULT-III dis-

play Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

−

DIAG RE- SULTS CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

PART

NUMBER AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM × × × × ×

Power door lock sys-

tem DOOR LOCK

× × ×

Rear defogger REAR DEFOG-

GER × ×

Warning chime BUZZER × ×

Page 462 of 4331

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ............................................ ......5

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool .................................... ......6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ...... ......9

Diagnostic Worksheet ......................................... ....11

HOOD ............................................................. ....13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspec tion .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ............................................ ....21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description ............................................. ....23

CAN Communication System Description ........... ....25

Schematic ........................................................... ....26

Wiring Diagram - D/LOCK - ................................. ....27

Schematic ........................................................... ....31

Wiring Diagram - D/LOCK - ................................. ....32 Terminal and Reference

Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (B CM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection ....43

Door Switch Check (Hatchback) .......................... ....44

Door Switch Check (Sedan) ................................ ....47

Key Switch (Insert) Check ................................... ....48

Door Lock and Unlock Switch Check .................. ....49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder S witch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM ............. 58

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

58

System Description .............................................. ....58

CAN Communication System Description ........... ....60

Schematic ............................................................ ....61

Wiring Diagram - KEYLES - ................................ ....62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ............................................... ....69

CONSULT-III Function (B CM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ...................... ....71

Keyfob Battery and Function Check .................... ....72

ACC Switch Check .............................................. ....74

Door Switch Check (Hatchback) .......................... ....74

Door Switch Check (Sedan) ................................ ....76

Key Switch (Insert) Check ................................... ....78

Hazard Function Check ....................................... ....78

Horn Function Check ........................................... ....79

Interior Lamp and Ignition Keyhole Illumination

Function Check .................................................... ....

79

Remote Keyless Entry Rece iver Check ...................80

Keyfob Function (Lock) Check ............................ ....82

Page 464 of 4331

BL

N

O P

Check Trunk Lid Opener S

witch Circuit (With Intel-

ligent Key) ........................................................... ..

212

Check Trunk Release Solenoid Circuit ............... ..214

FUEL FILLER LID OPENER .......................... ..217

Removal and Installation of Fuel Filler Lid Opener ..217

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ......................................................... ..

218

Component Parts and Harness Connector Loca-

tion ...................................................................... ..

218

System Description ............................................. ..219

CAN Communication System Description ........... ..221

Schematic ........................................................... ..222

Wiring Diagram - VEHSEC - ............................... ..223

Terminal and Reference Value for BCM ............. ..227

Terminal and Re ference Value for Intelligent Key

Unit ...................................................................... ..

231

CONSULT-III Function (BCM) ............................. ..233

Trouble Diagnosis ............................................... ..235

Preliminary Check ............................................... ..235

Symptom Chart ................................................... ..237

Diagnosis Procedure 1 ........................................ ..238

Diagnosis Procedure 2 ........................................ ..241

Diagnosis Procedure 3 ........................................ ..242

Diagnosis Procedure 4 ........................................ ..242

Diagnosis Procedure 5 ........................................ ..242

Diagnosis Procedure 6 ........................................ ..242

Diagnosis Procedure 7 ........................................ ..242

Diagnosis Procedure 8 ........................................ ..244

Diagnosis Procedure 9 ........................................ ..245 NATS (Nissan Anti-Theft System) ................

248

Component Parts and Harness Connector Loca-

tion ....................................................................... ..

248

System Description .............................................. ..248

System Composition ............................................ ..249

ECM Re-communicating Function ....................... ..249

Wiring Diagram - NATS - ..................................... ..251

Terminal and Reference Value for BCM ................252

CONSULT-III Function ........................................ ..256

Trouble Diagnosis Procedure .............................. ..257

Trouble Diagnosis ................................................ ..259

Diagnosis Procedure 1 ........................................ ..260

Diagnosis Procedure 2 ........................................ ..262

Diagnosis Procedure 3 ........................................ ..263

Diagnosis Procedure 4 ........................................ ..264

Diagnosis Procedure 5 ........................................ ..265

Diagnosis Procedure 6 ........................................ ..266

How to Replace NATS Antenna Amp .................. ..266

BODY REPAIR ................................................ 267

Body Exterior Paint Color .................................... ..267

Body Component Parts ....................................... ..269

Corrosion Protection ............................................ ..274

Body Sealing ....................................................... ..278

Body Construction ............................................... ..284

Body Alignment ................................................... ..286

Handling Precaution for Plastics .......................... ..303

Precaution in Repairing High Strength Steel ....... ..307

Foam Repair ........................................................ ..310

Replacement Operation ....................................... ..313

Page 469 of 4331

Generic Squeak and Rattle Troubleshooting " .

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISS AN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movemen t is present. Ideal for instrument panel applications.