Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 858 of 3745

BR-10

< SERVICE INFORMATION >

BRAKE FLUID

3. With brake pedal depressed, loosen bleed valve to let the air out, and then tighten it immediately.

4. Repeat steps 2, 3 until no more air comes out.

5. Tighten bleed valve to specified torque. Refer to BR-25, "

Component" (front disc brake), BR-35, "Compo-

nent" (rear drum brake).

6. Following the steps 1 to 5 above, with master cylinder reservoir tank filled at least half way, bleed air from

the rear right, front left, rear left, and front right brake, in that order.

Revision: January 20102010 Versa

Page 859 of 3745

BRAKE TUBE AND HOSEBR-11

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE TUBE AND HOSE

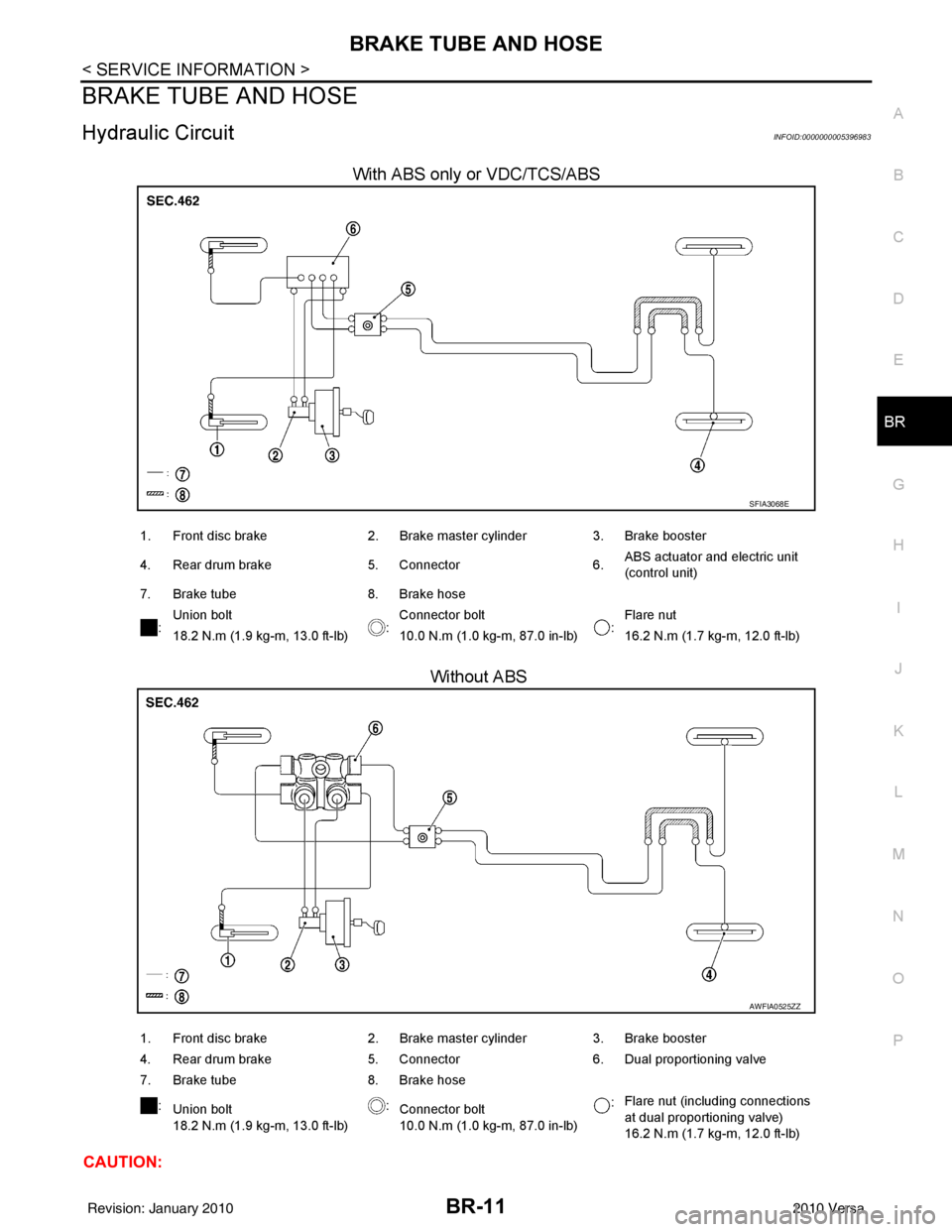

Hydraulic CircuitINFOID:0000000005396983

With ABS only or VDC/TCS/ABS

Without ABS

CAUTION:

SFIA3068E

1. Front disc brake 2. Brake master cylinder3. Brake booster

4. Rear drum brake 5. Connector6.ABS actuator and electric unit

(control unit)

7. Brake tube 8. Brake hose

: Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

AWFIA0525ZZ

1. Front disc brake 2. Brake master cylinder3. Brake booster

4. Rear drum brake 5. Connector6. Dual proportioning valve

7. Brake tube 8. Brake hose

: Union bolt

18.2 N.m (1.9 kg-m, 13.0 ft-lb) :

Connector bolt

10.0 N.m (1.0 kg-m, 87.0 in-lb) :

Flare nut (including connections

at dual proportioning valve)

16.2 N.m (1.7 kg-m, 12.0 ft-lb)

Revision: January 20102010 Versa

Page 860 of 3745

BR-12

< SERVICE INFORMATION >

BRAKE TUBE AND HOSE

• All tubes and hoses must be free from excessive bending, twisting and pulling.

• Make sure there is no interference with other part s when turning steering both clockwise and coun-

terclockwise.

• Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part

is detected.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted surfaces of body , immediately wipe them with cloth and then wash it away with

water.

• Do not bend or twist brake hose sharply, or strongly pull it.

• When removing components, cover brake line connect ions so that dirt, dust, or other foreign mat-

ters do not get in.

• Refill using recommended brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

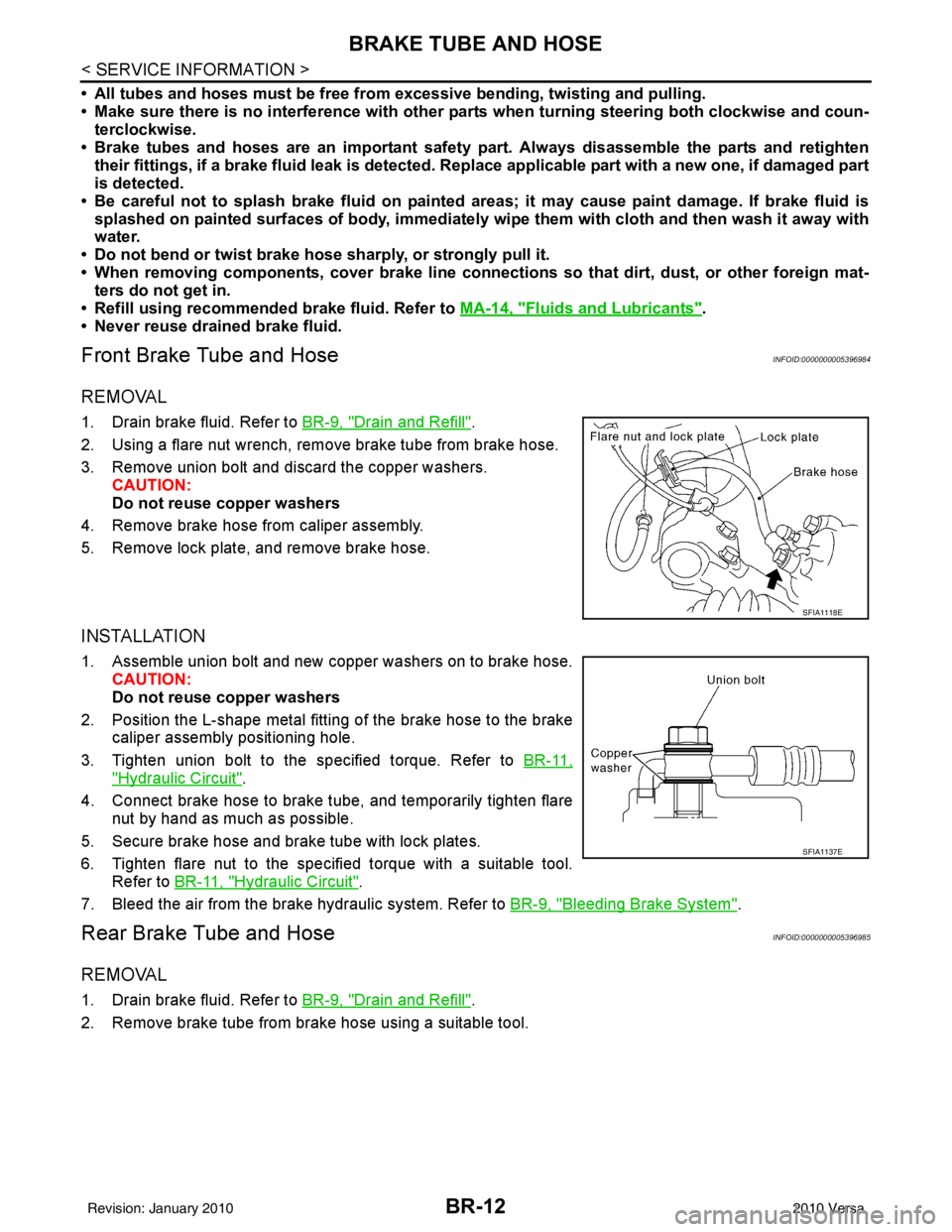

Front Brake Tube and HoseINFOID:0000000005396984

REMOVAL

1. Drain brake fluid. Refer to BR-9, "Drain and Refill".

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove union bolt and discard the copper washers. CAUTION:

Do not reuse copper washers

4. Remove brake hose from caliper assembly.

5. Remove lock plate, and remove brake hose.

INSTALLATION

1. Assemble union bolt and new copper washers on to brake hose. CAUTION:

Do not reuse copper washers

2. Position the L-shape metal fitting of the brake hose to the brake caliper assembly positioning hole.

3. Tighten union bolt to the specified torque. Refer to BR-11,

"Hydraulic Circuit".

4. Connect brake hose to brake tube, and temporarily tighten flare nut by hand as much as possible.

5. Secure brake hose and brake tube with lock plates.

6. Tighten flare nut to the specified torque with a suitable tool. Refer to BR-11, "

Hydraulic Circuit".

7. Bleed the air from the brake hydraulic system. Refer to BR-9, "

Bleeding Brake System".

Rear Brake Tube and HoseINFOID:0000000005396985

REMOVAL

1. Drain brake fluid. Refer to BR-9, "Drain and Refill".

2. Remove brake tube from brake hose using a suitable tool.

SFIA1118E

SFIA1137E

Revision: January 20102010 Versa

Page 862 of 3745

BR-14

< SERVICE INFORMATION >

DUAL PROPORTIONING VALVE

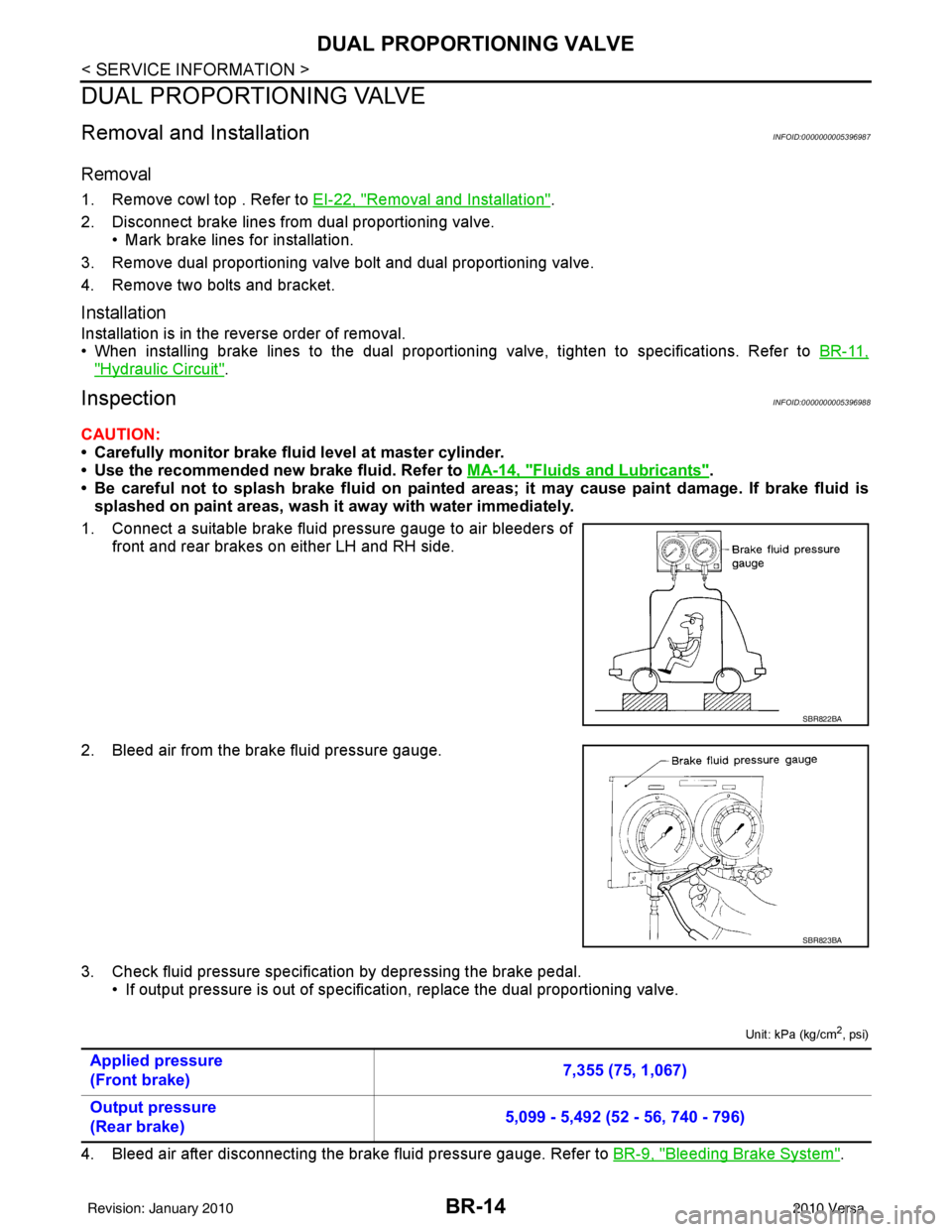

DUAL PROPORTIONING VALVE

Removal and InstallationINFOID:0000000005396987

Removal

1. Remove cowl top . Refer to EI-22, "Removal and Installation".

2. Disconnect brake lines from dual proportioning valve. • Mark brake lines for installation.

3. Remove dual proportioning valve bolt and dual proportioning valve.

4. Remove two bolts and bracket.

Installation

Installation is in the reverse order of removal.

• When installing brake lines to the dual proportioning valve, tighten to specifications. Refer to BR-11,

"Hydraulic Circuit".

InspectionINFOID:0000000005396988

CAUTION:

• Carefully monitor brake fluid level at master cylinder.

• Use the recommended new brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on paint areas, wash it away with water immediately.

1. Connect a suitable brake fluid pressure gauge to air bleeders of front and rear brakes on either LH and RH side.

2. Bleed air from the brake fluid pressure gauge.

3. Check fluid pressure specific ation by depressing the brake pedal.

• If output pressure is out of specification, replace the dual proportioning valve.

Unit: kPa (kg/cm2, psi)

4. Bleed air after disconnecting the brake fluid pressure gauge. Refer to BR-9, "Bleeding Brake System".

SBR822BA

SBR823BA

Applied pressure

(Front brake) 7,355 (75, 1,067)

Output pressure

(Rear brake) 5,099 - 5,492 (52 - 56, 740 - 796)

Revision: January 20102010 Versa

Page 873 of 3745

FRONT DISC BRAKEBR-25

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

On Board InspectionINFOID:0000000005396997

PAD WEAR INSPECTION

• Check pad thickness from check hole on cylinder body.

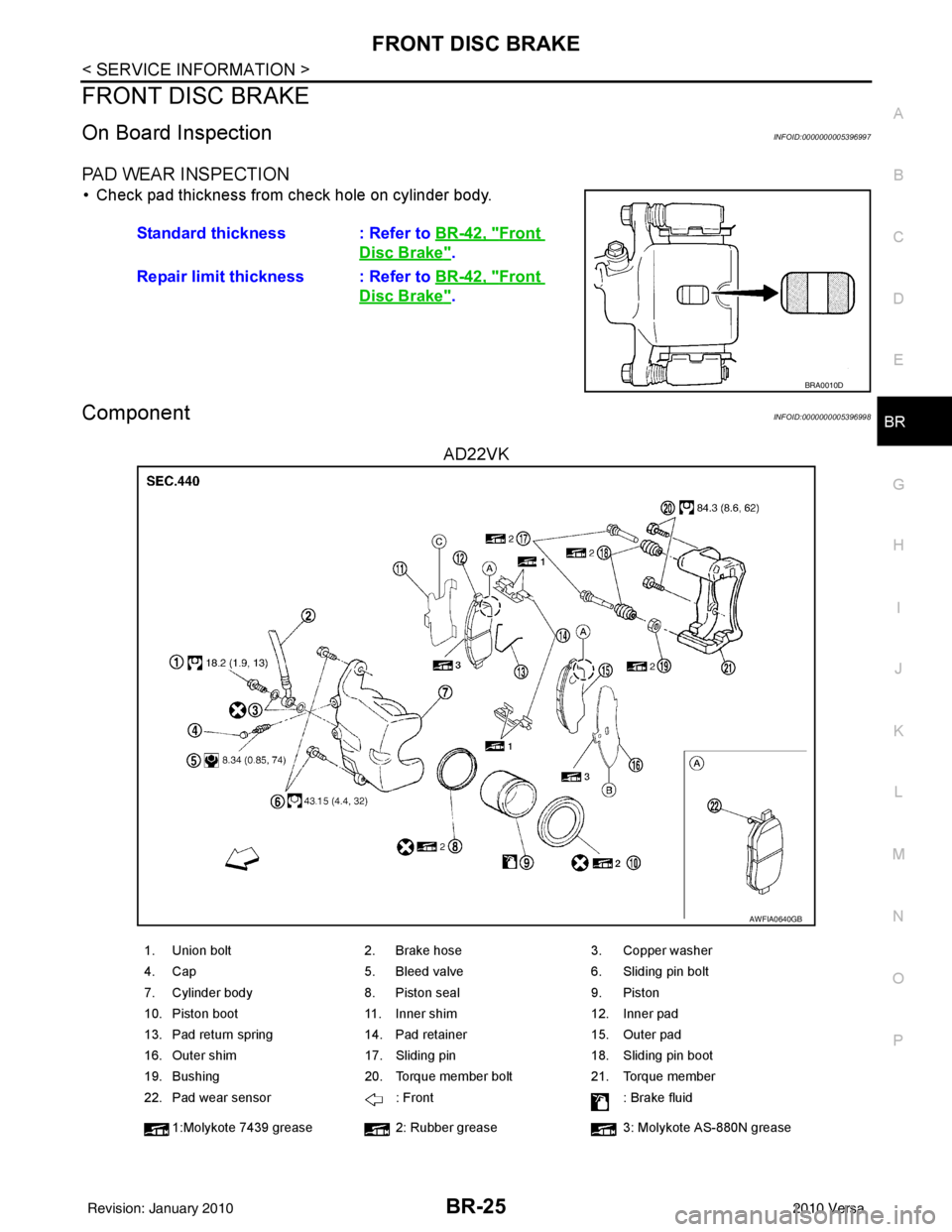

ComponentINFOID:0000000005396998

AD22VK

Standard thickness : Refer to BR-42, "Front

Disc Brake".

Repair limit thickness : Refer to BR-42, "

Front

Disc Brake".

BRA0010D

AWFIA0640GB

1. Union bolt2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Inner shim 12. Inner pad

13. Pad return spring 14. Pad retainer 15. Outer pad

16. Outer shim 17. Sliding pin 18. Sliding pin boot

19. Bushing 20. Torque member bolt 21. Torque member

22. Pad wear sensor : Front: Brake fluid

1:Molykote 7439 grease 2: Rubber grease 3: Molykote AS-880N grease

Revision: January 20102010 Versa

Page 874 of 3745

BR-26

< SERVICE INFORMATION >

FRONT DISC BRAKE

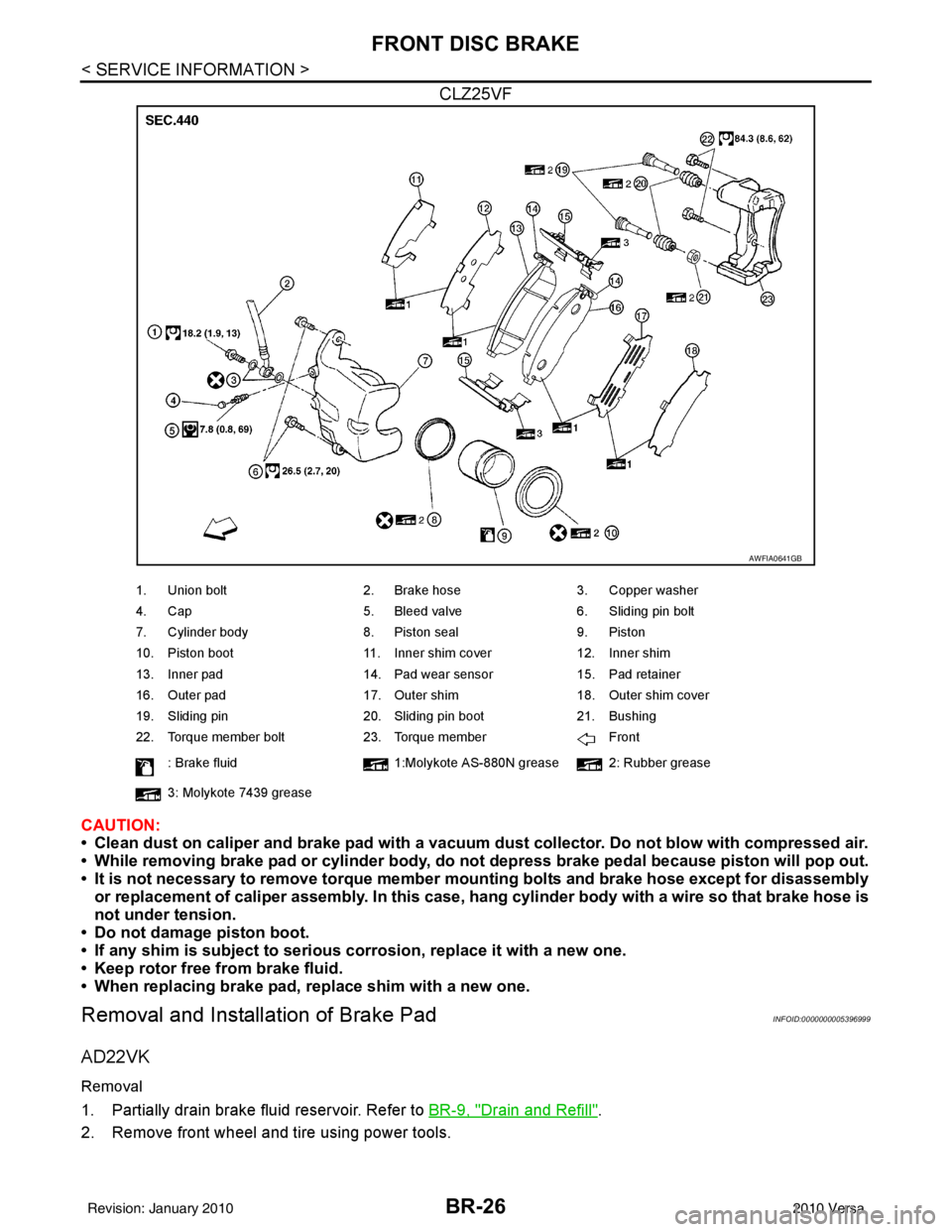

CLZ25VF

CAUTION:

• Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

• While removing brake pad or cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to remove torque member mounting bolts and brake hose except for disassembly

or replacement of caliper assembly. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Keep rotor free from brake fluid.

• When replacing brake pad, replace shim with a new one.

Removal and Installation of Brake PadINFOID:0000000005396999

AD22VK

Removal

1. Partially drain brake fluid reservoir. Refer to BR-9, "Drain and Refill".

2. Remove front wheel and tire using power tools.

AWFIA0641GB

1. Union bolt 2. Brake hose3. Copper washer

4. Cap 5. Bleed valve6. Sliding pin bolt

7. Cylinder body 8. Piston seal9. Piston

10. Piston boot 11. Inner shim cover12. Inner shim

13. Inner pad 14. Pad wear sensor15. Pad retainer

16. Outer pad 17. Outer shim18. Outer shim cover

19. Sliding pin 20. Sliding pin boot21. Bushing

22. Torque member bolt 23. Torque member Front

: Brake fluid 1:Molykote AS-880N grease 2: Rubber grease

3: Molykote 7439 grease

Revision: January 20102010 Versa

Page 875 of 3745

FRONT DISC BRAKEBR-27

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

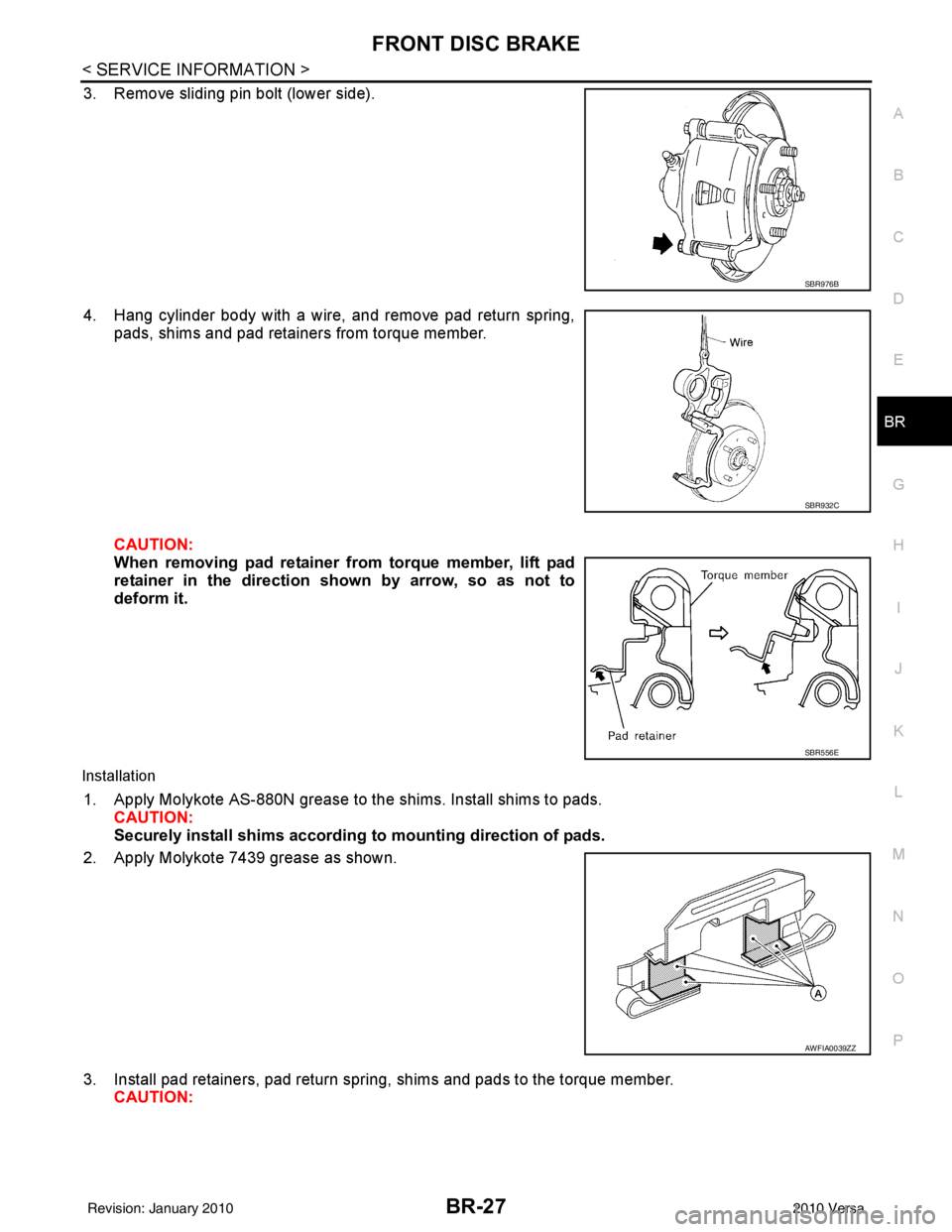

3. Remove sliding pin bolt (lower side).

4. Hang cylinder body with a wire, and remove pad return spring, pads, shims and pad retainers from torque member.

CAUTION:

When removing pad retainer from torque member, lift pad

retainer in the direction shown by arrow, so as not to

deform it.

Installation

1. Apply Molykote AS-880N grease to the shims. Install shims to pads.CAUTION:

Securely install shims according to mounting direction of pads.

2. Apply Molykote 7439 grease as shown.

3. Install pad retainers, pad return spring, shims and pads to the torque member. CAUTION:

SBR976B

SBR932C

SBR556E

AWFIA0039ZZ

Revision: January 20102010 Versa

Page 876 of 3745

BR-28

< SERVICE INFORMATION >

FRONT DISC BRAKE

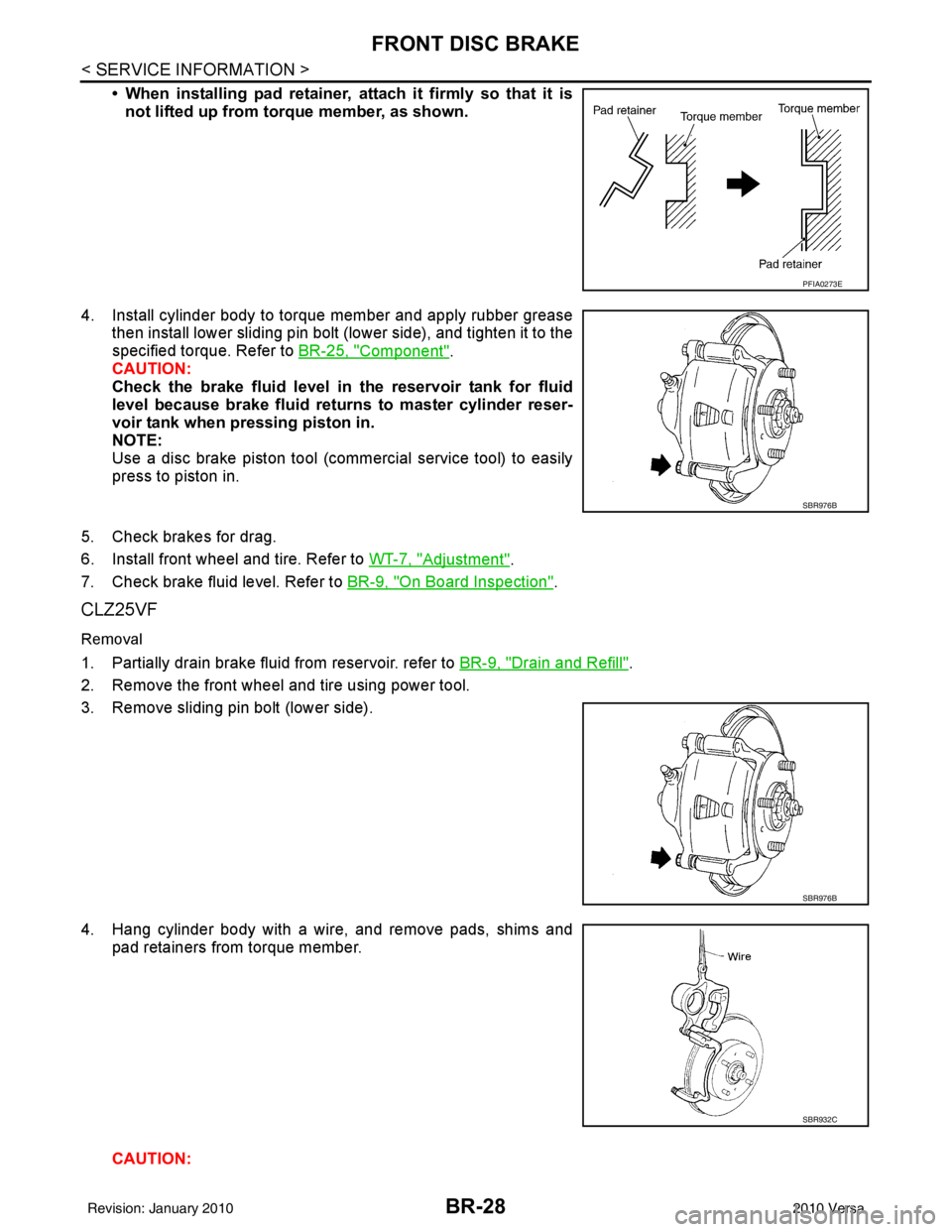

• When installing pad retainer, attach it firmly so that it isnot lifted up from torque member, as shown.

4. Install cylinder body to torque member and apply rubber grease then install lower sliding pin bolt (lower side), and tighten it to the

specified torque. Refer to BR-25, "

Component".

CAUTION:

Check the brake fluid level in the reservoir tank for fluid

level because brake fluid returns to master cylinder reser-

voir tank when pressing piston in.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily

press to piston in.

5. Check brakes for drag.

6. Install front wheel and tire. Refer to WT-7, "

Adjustment".

7. Check brake fluid level. Refer to BR-9, "

On Board Inspection".

CLZ25VF

Removal

1. Partially drain brake fluid from reservoir. refer to BR-9, "Drain and Refill".

2. Remove the front wheel and tire using power tool.

3. Remove sliding pin bolt (lower side).

4. Hang cylinder body with a wire, and remove pads, shims and pad retainers from torque member.

CAUTION:

PFIA0273E

SBR976B

SBR976B

SBR932C

Revision: January 20102010 Versa

Page 877 of 3745

FRONT DISC BRAKEBR-29

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

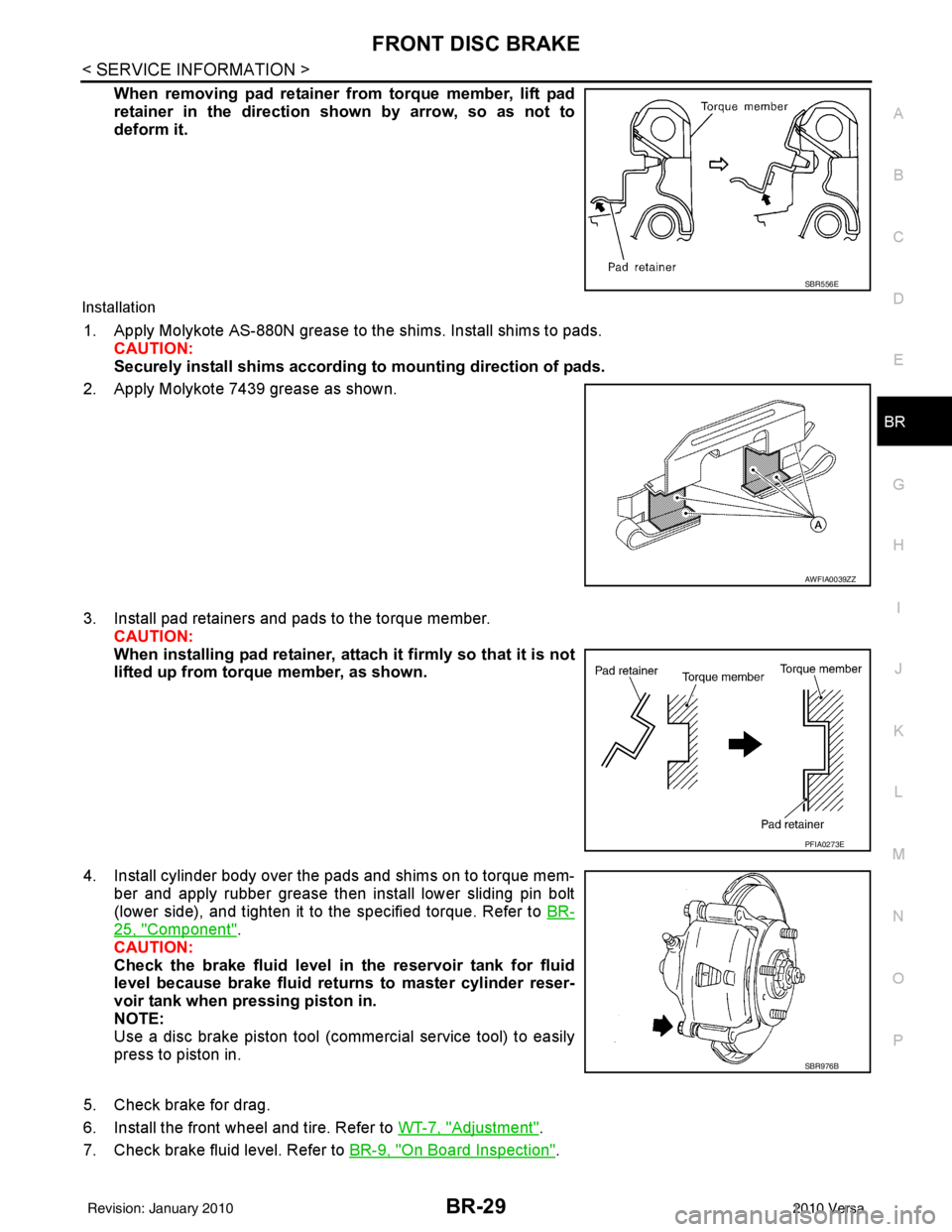

When removing pad retainer from torque member, lift pad

retainer in the direction shown by arrow, so as not to

deform it.

Installation

1. Apply Molykote AS-880N grease to the shims. Install shims to pads. CAUTION:

Securely install shims according to mounting direction of pads.

2. Apply Molykote 7439 grease as shown.

3. Install pad retainers and pads to the torque member. CAUTION:

When installing pad retainer, att ach it firmly so that it is not

lifted up from torque member, as shown.

4. Install cylinder body over the pads and shims on to torque mem- ber and apply rubber grease then install lower sliding pin bolt

(lower side), and tighten it to the specified torque. Refer to BR-

25, "Component".

CAUTION:

Check the brake fluid level in th e reservoir tank for fluid

level because brake fluid returns to master cylinder reser-

voir tank when pressing piston in.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily

press to piston in.

5. Check brake for drag.

6. Install the front wheel and tire. Refer to WT-7, "

Adjustment".

7. Check brake fluid level. Refer to BR-9, "

On Board Inspection".

SBR556E

AWFIA0039ZZ

PFIA0273E

SBR976B

Revision: January 20102010 Versa

Page 878 of 3745

BR-30

< SERVICE INFORMATION >

FRONT DISC BRAKE

Removal and Installation of Brake Caliper Assembly

INFOID:0000000005397000

REMOVAL

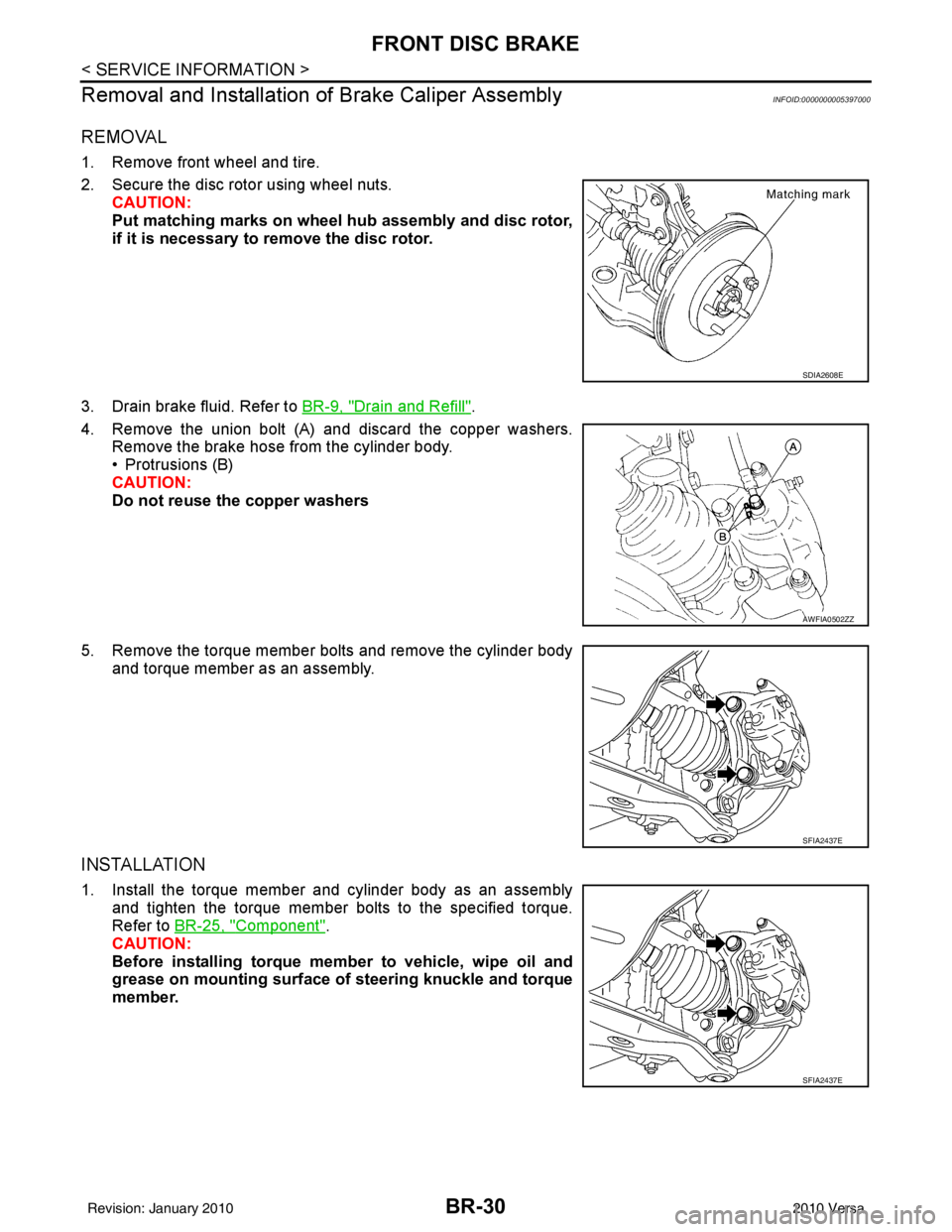

1. Remove front wheel and tire.

2. Secure the disc rotor using wheel nuts.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor,

if it is necessary to remove the disc rotor.

3. Drain brake fluid. Refer to BR-9, "

Drain and Refill".

4. Remove the union bolt (A) and discard the copper washers. Remove the brake hose from the cylinder body.

• Protrusions (B)

CAUTION:

Do not reuse the copper washers

5. Remove the torque member bolts and remove the cylinder body and torque member as an assembly.

INSTALLATION

1. Install the torque member and cylinder body as an assemblyand tighten the torque member bolts to the specified torque.

Refer to BR-25, "

Component".

CAUTION:

Before installing torque member to vehicle, wipe oil and

grease on mounting surface of steering knuckle and torque

member.

SDIA2608E

AWFIA0502ZZ

SFIA2437E

SFIA2437E

Revision: January 20102010 Versa