Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 879 of 3745

FRONT DISC BRAKEBR-31

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

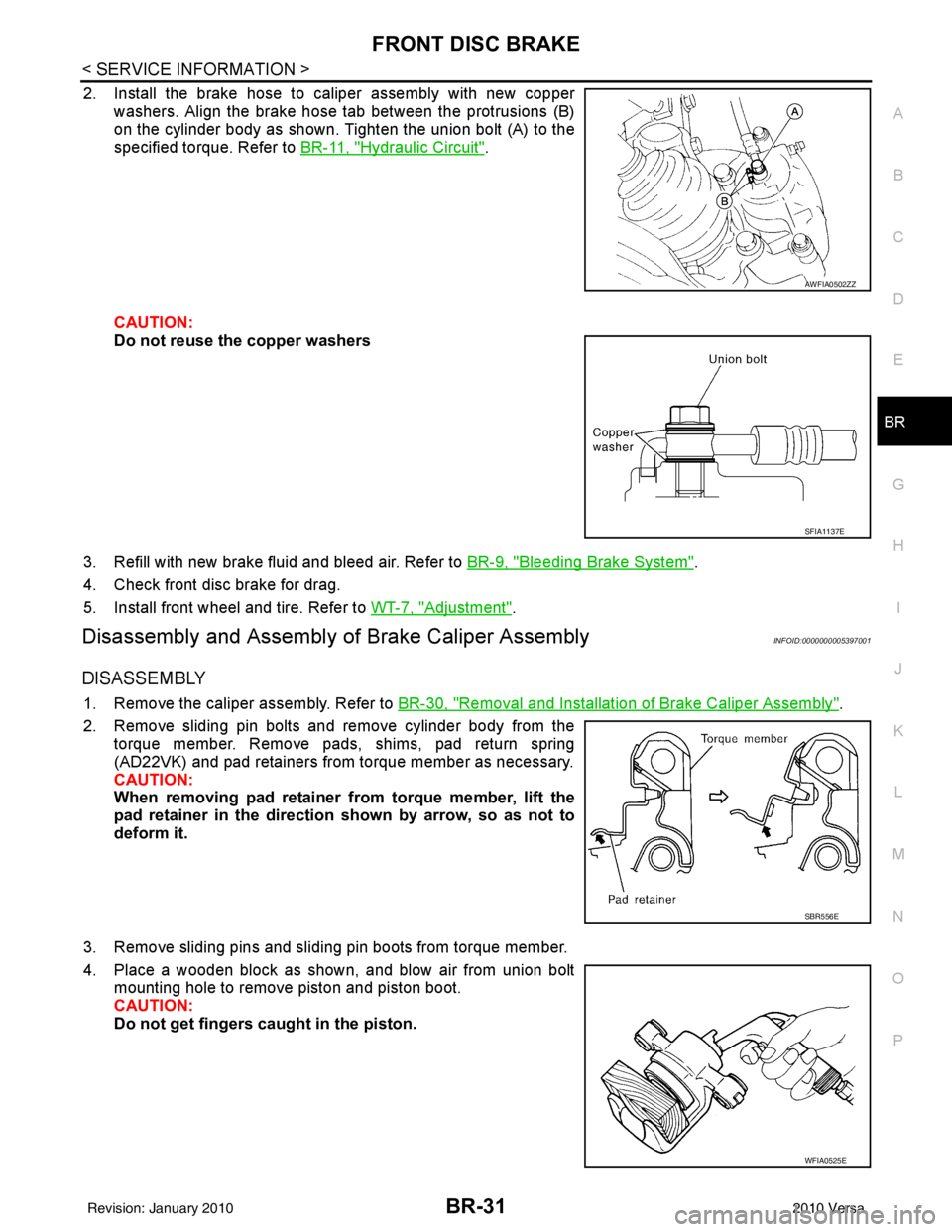

2. Install the brake hose to caliper assembly with new copper washers. Align the brake hose tab between the protrusions (B)

on the cylinder body as shown. Tighten the union bolt (A) to the

specified torque. Refer to BR-11, "

Hydraulic Circuit".

CAUTION:

Do not reuse the copper washers

3. Refill with new brake fluid and bleed air. Refer to BR-9, "

Bleeding Brake System".

4. Check front disc brake for drag.

5. Install front wheel and tire. Refer to WT-7, "

Adjustment".

Disassembly and Assembly of Brake Caliper AssemblyINFOID:0000000005397001

DISASSEMBLY

1. Remove the caliper assembly. Refer to BR-30, "Removal and Installation of Brake Caliper Assembly".

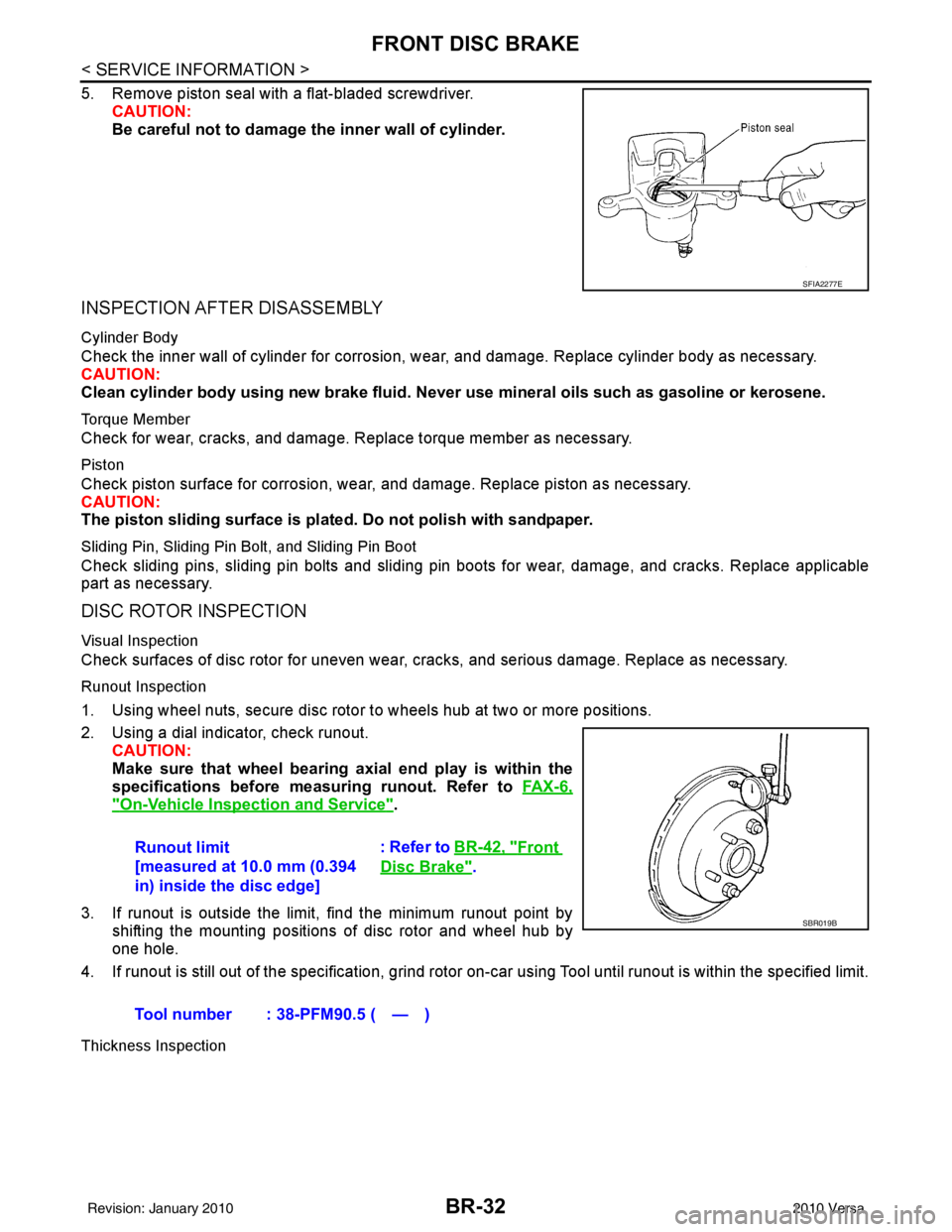

2. Remove sliding pin bolts and remove cylinder body from the torque member. Remove pads, shims, pad return spring

(AD22VK) and pad retainers from torque member as necessary.

CAUTION:

When removing pad retainer from torque member, lift the

pad retainer in the direction shown by arrow, so as not to

deform it.

3. Remove sliding pins and sliding pin boots from torque member.

4. Place a wooden block as shown, and blow air from union bolt mounting hole to remove piston and piston boot.

CAUTION:

Do not get fingers caught in the piston.

AWFIA0502ZZ

SFIA1137E

SBR556E

WFIA0525E

Revision: January 20102010 Versa

Page 880 of 3745

BR-32

< SERVICE INFORMATION >

FRONT DISC BRAKE

5. Remove piston seal with a flat-bladed screwdriver.CAUTION:

Be careful not to damage the inner wall of cylinder.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, w ear, and damage. Replace cylinder body as necessary.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. R eplace torque member as necessary.

Piston

Check piston surface for corrosion, wear, and damage. Replace piston as necessary.

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

Check sliding pins, sliding pin bolts and sliding pin boots for wear, damage, and cracks. Replace applicable

part as necessary.

DISC ROTOR INSPECTION

Visual Inspection

Check surfaces of disc rotor for uneven wear, cr acks, and serious damage. Replace as necessary.

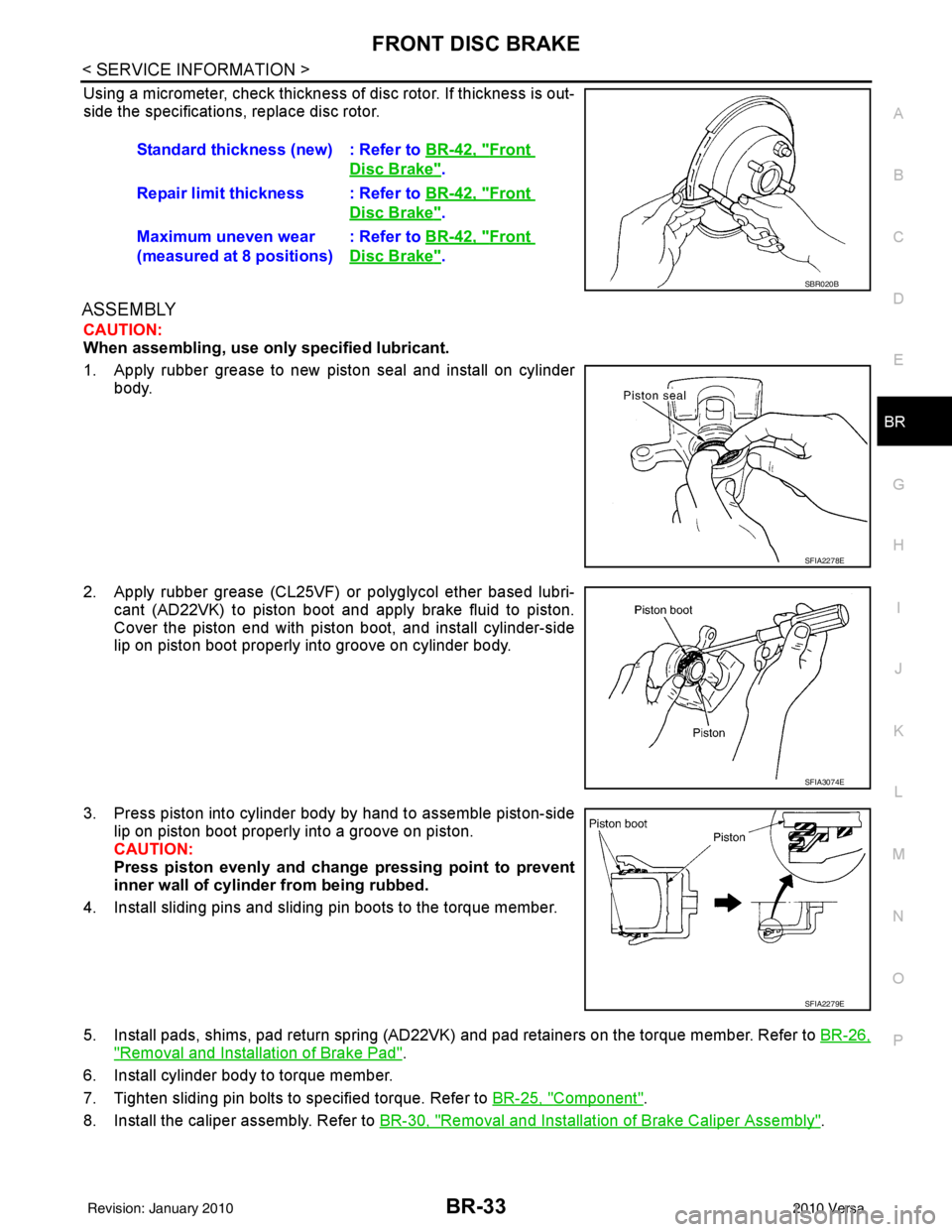

Runout Inspection

1. Using wheel nuts, secure disc rotor to wheels hub at two or more positions.

2. Using a dial indicator, check runout.

CAUTION:

Make sure that wheel bearing axial end play is within the

specifications before measuring runout. Refer to FA X - 6 ,

"On-Vehicle Inspection and Service".

3. If runout is outside the limit, find the minimum runout point by shifting the mounting positions of disc rotor and wheel hub by

one hole.

4. If runout is still out of the specification, grind rotor on-car using Tool until runout is within the specified limit.

Thickness Inspection

SFIA2277E

Runout limit

[measured at 10.0 mm (0.394

in) inside the disc edge] : Refer to BR-42, "Front

Disc Brake".

Tool number : 38-PFM90.5 ( — )

SBR019B

Revision: January 20102010 Versa

Page 881 of 3745

FRONT DISC BRAKEBR-33

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Using a micrometer, check thickness of disc rotor. If thickness is out-

side the specifications, replace disc rotor.

ASSEMBLY

CAUTION:

When assembling, use only specified lubricant.

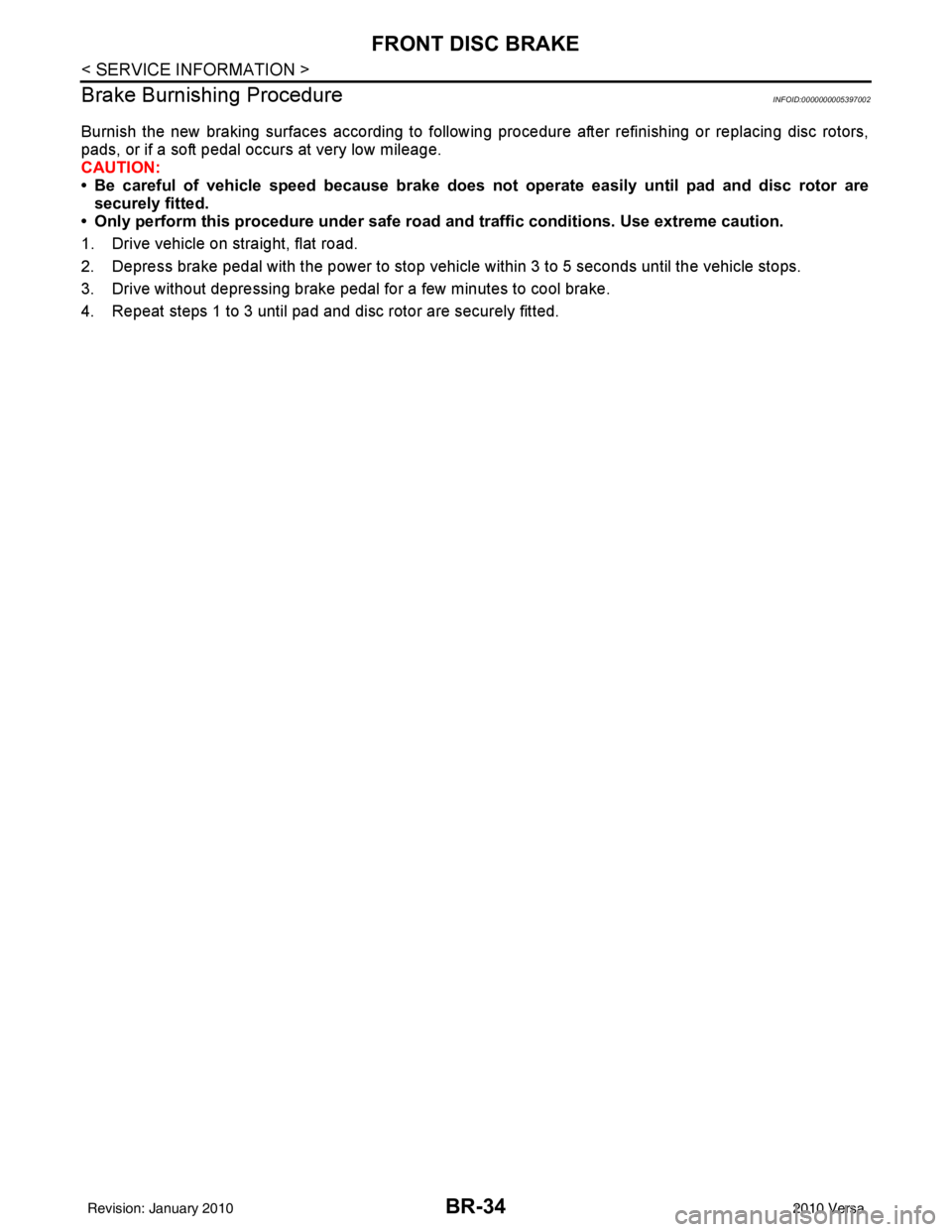

1. Apply rubber grease to new piston seal and install on cylinder body.

2. Apply rubber grease (CL25VF) or polyglycol ether based lubri- cant (AD22VK) to piston boot and apply brake fluid to piston.

Cover the piston end with piston boot, and install cylinder-side

lip on piston boot properly into groove on cylinder body.

3. Press piston into cylinder body by hand to assemble piston-side lip on piston boot properly into a groove on piston.

CAUTION:

Press piston evenly and change pressing point to prevent

inner wall of cylinder from being rubbed.

4. Install sliding pins and sliding pin boots to the torque member.

5. Install pads, shims, pad return spring (AD22VK) and pad retainers on the torque member. Refer to BR-26,

"Removal and Installation of Brake Pad".

6. Install cylinder body to torque member.

7. Tighten sliding pin bolts to specified torque. Refer to BR-25, "

Component".

8. Install the caliper assembly. Refer to BR-30, "

Removal and Installation of Brake Caliper Assembly".

Standard thickness (new) : Refer to

BR-42, "

Front

Disc Brake".

Repair limit thickness : Refer to BR-42, "

Front

Disc Brake".

Maximum uneven wear

(measured at 8 positions) : Refer to

BR-42, "

Front

Disc Brake".

SBR020B

SFIA2278E

SFIA3074E

SFIA2279E

Revision: January 20102010 Versa

Page 882 of 3745

BR-34

< SERVICE INFORMATION >

FRONT DISC BRAKE

Brake Burnishing Procedure

INFOID:0000000005397002

Burnish the new braking surfaces according to following procedure after refinishing or replacing disc rotors,

pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because brake does not operate easily until pad and disc rotor are securely fitted.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake pedal for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

Revision: January 20102010 Versa

Page 888 of 3745

BR-40

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

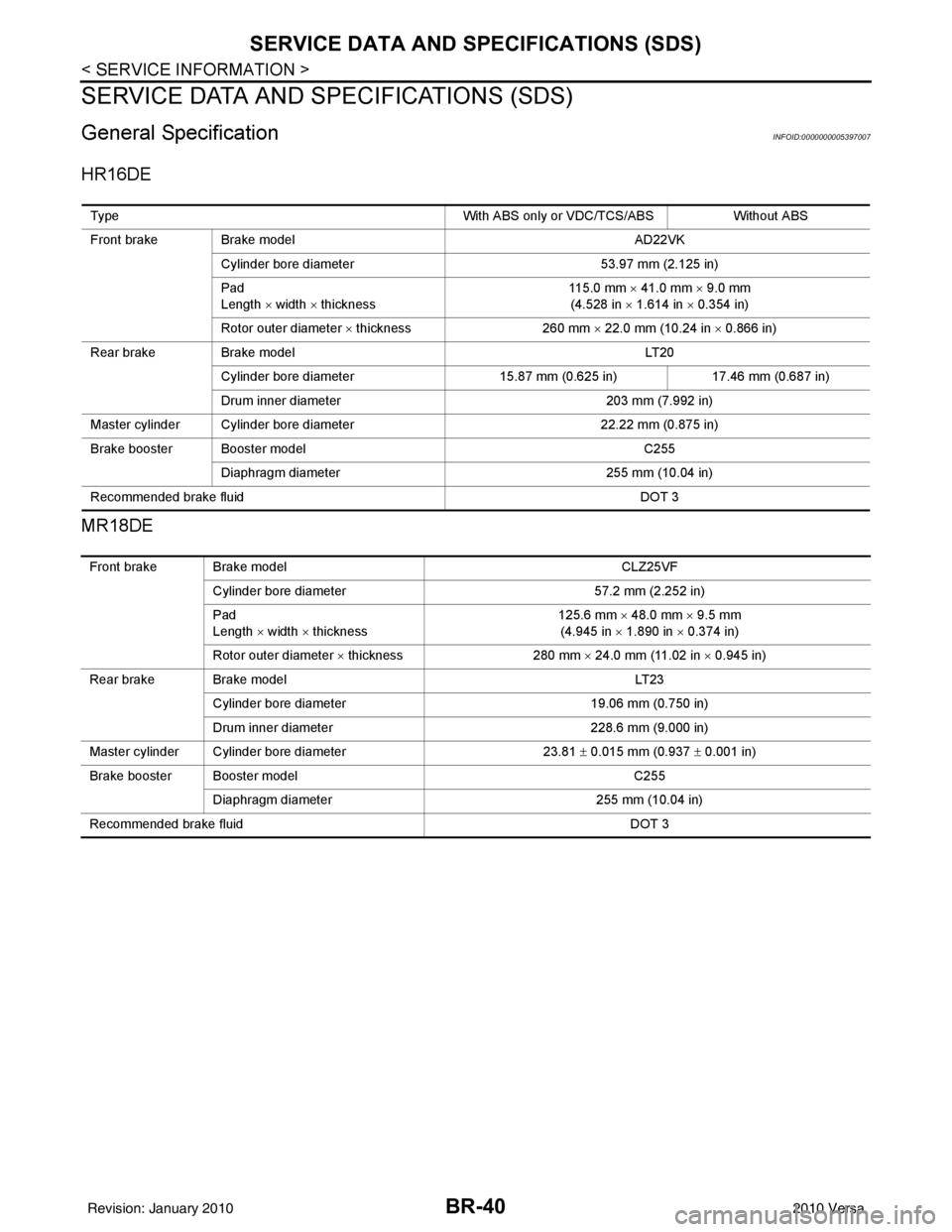

General SpecificationINFOID:0000000005397007

HR16DE

MR18DE

TypeWith ABS only or VDC/TCS/ABSWithout ABS

Front brake Brake model AD22VK

Cylinder bore diameter 53.97 mm (2.125 in)

Pad

Length × width × thickness 115.0 mm ×

41.0 mm × 9.0 mm

(4.528 in × 1.614 in × 0.354 in)

Rotor outer diameter × thickness 260 mm × 22.0 mm (10.24 in × 0.866 in)

Rear brake Brake model LT20

Cylinder bore diameter 15.87 mm (0.625 in)17.46 mm (0.687 in)

Drum inner diameter 203 mm (7.992 in)

Master cylinder Cylinder bore diameter 22.22 mm (0.875 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Front brake Brake modelCLZ25VF

Cylinder bore diameter 57.2 mm (2.252 in)

Pad

Length × width × thickness 125.6 mm

× 48.0 mm × 9.5 mm

(4.945 in × 1.890 in × 0.374 in)

Rotor outer diameter × thickness 280 mm × 24.0 mm (11.02 in × 0.945 in)

Rear brake Brake model LT23

Cylinder bore diameter 19.06 mm (0.750 in)

Drum inner diameter 228.6 mm (9.000 in)

Master cylinder Cylinder bore diameter 23.81 ± 0.015 mm (0.937 ± 0.001 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Revision: January 20102010 Versa

Page 890 of 3745

BR-42

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

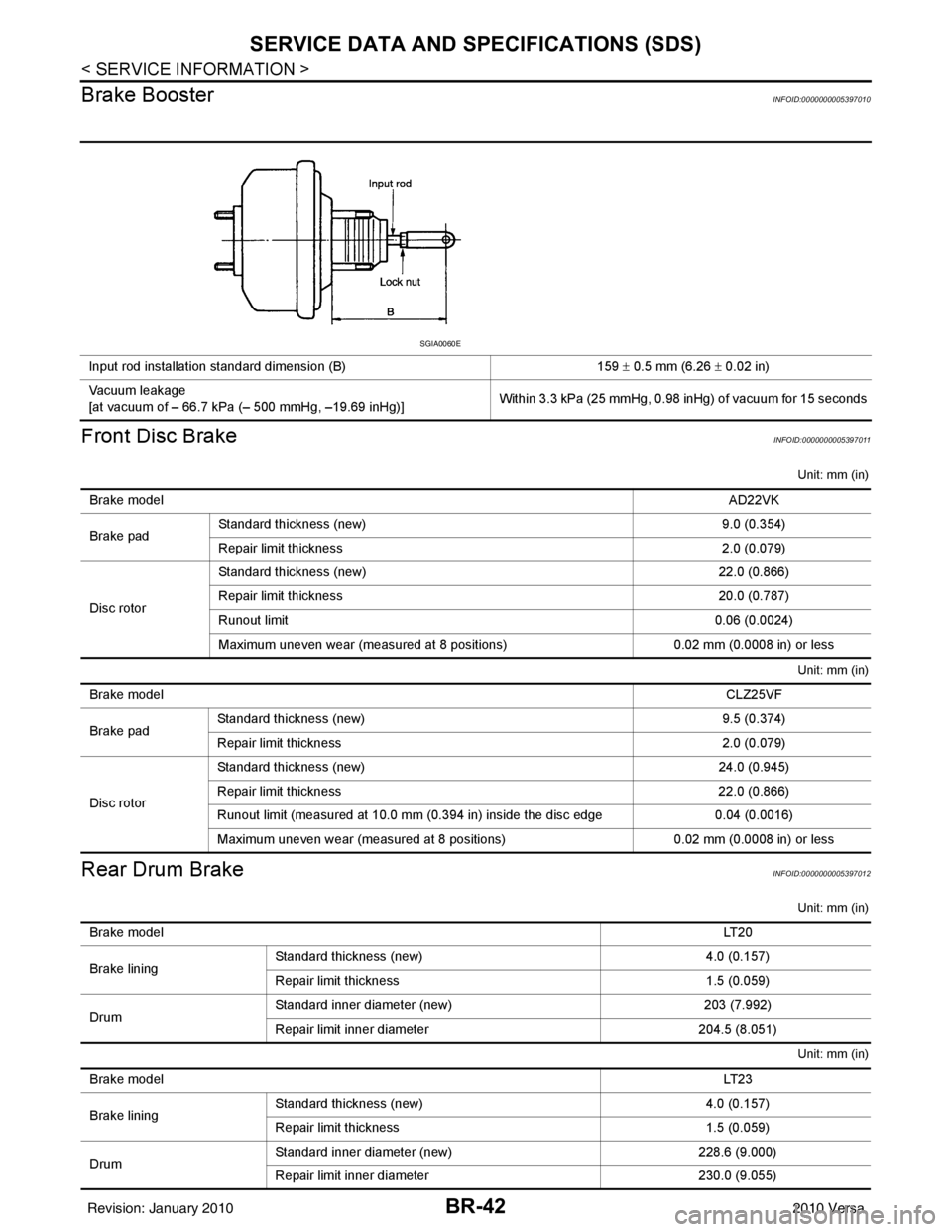

Brake Booster

INFOID:0000000005397010

Front Disc BrakeINFOID:0000000005397011

Unit: mm (in)

Unit: mm (in)

Rear Drum BrakeINFOID:0000000005397012

Unit: mm (in)

Unit: mm (in)

Input rod installation standard dimension (B) 159 ± 0.5 mm (6.26 ± 0.02 in)

Vacuum leakage

[at vacuum of – 66.7 kPa (– 500 mmHg, –19.69 inHg)] Within 3.3 kPa (25 mmHg, 0.98 inHg) of vacuum for 15 seconds

SGIA0060E

Brake model

AD22VK

Brake pad Standard thickness (new)

9.0 (0.354)

Repair limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new)

22.0 (0.866)

Repair limit thickness 20.0 (0.787)

Runout limit 0.06 (0.0024)

Maximum uneven wear (measured at 8 positions) 0.02 mm (0.0008 in) or less

Brake model CLZ25VF

Brake pad Standard thickness (new)

9.5 (0.374)

Repair limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new)

24.0 (0.945)

Repair limit thickness 22.0 (0.866)

Runout limit (measured at 10.0 mm (0.394 in) inside the disc edge 0.04 (0.0016)

Maximum uneven wear (measured at 8 positions) 0.02 mm (0.0008 in) or less

Brake model LT 2 0

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model LT 2 3

Brake lining Standard thickness (new)

4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

Revision: January 20102010 Versa

Page 893 of 3745

![NISSAN TIIDA 2010 Service Repair Manual PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSI NISSAN TIIDA 2010 Service Repair Manual PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSI](/img/5/57397/w960_57397-892.png)

PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005397020

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000006044767

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 897 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock NISSAN TIIDA 2010 Service Repair Manual SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock](/img/5/57397/w960_57397-896.png)

SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles during emergency braking.

• If the electrical system malfunctions, the Fail-Safe function is activated, t he ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD FunctionINFOID:0000000005397028

• Electronic Brake Distribution is a function that detects subtle slippages between the front and rear wheels during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera- tive, and the ABS warning lamp and brake warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

Fail-Safe FunctionINFOID:0000000005397029

CAUTION:

If the Fail-Safe function is activated, perform the Self Diagnosis for ABS system.

ABS/EBD SYSTEM

In case of an electrical malfunction with the ABS, the ABS warning lamp wi ll turn on. In case of an electrical

malfunction with the EBD system, the brake warni ng lamp and the ABS warning lamp will turn on.

The system will revert to one of the follo wing conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and t he condition of the vehicle is the same condition of

vehicles without ABS system.

WFIA0118E

Revision: January 20102010 Versa

Page 903 of 3745

![NISSAN TIIDA 2010 Service Repair Manual TROUBLE DIAGNOSISBRC-13

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component Parts and Har ness Connector LocationINFOID:0000000005397033

1. Front wheel sensor

LH E18

RH E117 2. R NISSAN TIIDA 2010 Service Repair Manual TROUBLE DIAGNOSISBRC-13

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component Parts and Har ness Connector LocationINFOID:0000000005397033

1. Front wheel sensor

LH E18

RH E117 2. R](/img/5/57397/w960_57397-902.png)

TROUBLE DIAGNOSISBRC-13

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component Parts and Har ness Connector LocationINFOID:0000000005397033

1. Front wheel sensor

LH E18

RH E117 2. Rear wheel sensor

LH B123

RH B122 3. ABS actuator and electric unit (con-

trol unit) E33

4. Combination meter M24 5. Stop lamp switch E13

AWFIA0619GB

Revision: January 20102010 Versa

Page 912 of 3745

![NISSAN TIIDA 2010 Service Repair Manual BRC-22

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Self-diagnostic item

Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101] Circuit of rear RH wheel sensor is open.

BRC-26, "

Wheel NISSAN TIIDA 2010 Service Repair Manual BRC-22

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Self-diagnostic item

Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101] Circuit of rear RH wheel sensor is open.

BRC-26, "

Wheel](/img/5/57397/w960_57397-911.png)

BRC-22

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Self-diagnostic item

Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101] Circuit of rear RH wheel sensor is open.

BRC-26, "

Wheel Sensor

System" (Note 1)

RR LH SENSOR-1

[C1102]

Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of front LH wheel sensor is open.

RR RH SENSOR-2

[C1105] When the circuit in the rear RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2

[C1106] When the circuit in the rear LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2

[C1107] When the circuit in the front RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2

[C1108] When the circuit in the front LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

ABS SENSOR

[ABNORMAL SIGNAL]

[ C 111 5 ] Wheel sensor input is abnormal.

BATTERY VOLTAGE

[ABNORMAL]

[C1109] ABS actuator and electric unit (control unit) power voltage is too

low. BRC-29, "

ABS Control

Unit Power and Ground

Systems Inspection"

CONTROLLER FAILURE

[ C 111 0 ]

Internal malfunction of ABS actuator

and electric unit (control unit)BRC-27, "ABS Control

Unit Inspection"

PUMP MOTOR

[ C 1111 ] During actuator motor operation with ON, when actuator motor

turns OFF or when control line for actuator motor relay is open.

BRC-28, "Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

FR LH IN ABS SOL

[C1120] Circuit of front LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-27, "

Solenoid Valve

System Inspection"

FR LH OUT ABS SOL

[C1121]Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122] Circuit of front RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123] Circuit of front RH OUT ABS solenoid is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124] Circuit of rear LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126] Circuit of rear RH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127] Circuit of rear RH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

Revision: January 20102010 Versa