Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1207 of 3745

![NISSAN TIIDA 2010 Service Repair Manual CVT-174

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit connector (C). Refer

to CVT-9, "

Remova NISSAN TIIDA 2010 Service Repair Manual CVT-174

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit connector (C). Refer

to CVT-9, "

Remova](/img/5/57397/w960_57397-1206.png)

CVT-174

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit connector (C). Refer

to CVT-9, "

Removal and Installation Procedure for CVT Unit

Connector".

3. Remove the harness from the transaxle.

4. Remove the four drive plate to torque converter nuts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter nuts.

5. Put matching marks on the drive plate and torque converter alignment stud. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

6. Remove the transaxle to engine and engine to transaxle bolts.

7. Separate the transaxle from the engine.

8. If necessary, remove the following from the transaxle: • CVT fluid charging pipe

• Engine mounting bracket (LH)

• Fluid cooler tubes

• Air breather hose

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure any dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels m ay cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers.

• When turning crankshaft, turn it clockwi se as viewed from the front of the engine.

• When tightening the nuts for the torque converte r while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-156

.

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

AWDIA0661GB

WCIA0616E

Revision: January 20102010 Versa

Page 1211 of 3745

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ........ ....11

CONSULT-III Function (METER/M&A) ............... ....13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit ......... ....19

Electrical Component Inspection .............................20

Removal and Installation .........................................20

WARNING LAMPS ......................................... ....21

Schematic ........................................................... ....21

Wiring Diagram - WARN - ................................... ....22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Schematic ................................................................38

Wiring Diagram - CVTIND - .....................................39

CVT Indicator Does Not Illuminate ..........................41

WARNING CHIME .............................................43

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

43

System Description ..................................................43

Wiring Diagram - CHIME - .......................................46

Terminal and Reference Value for BCM ..................47

CONSULT-III Function (B CM) .................................47

Trouble Diagnosis ................................................ ....48

Combination Meter Buzzer Circuit Inspection .........49

Front Door Switch LH Signal Inspection .............. ....50

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ....

51

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

52

Lighting Switch Signal Inspection ............................54

Parking Brake Switch Signal Inspection ..................54

Electrical Component Inspection .............................55

Revision: January 20102010 Versa

Page 1212 of 3745

DI-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005612480

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005977485

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 1214 of 3745

DI-4

< SERVICE INFORMATION >

COMBINATION METERS

COMBINATION METERS

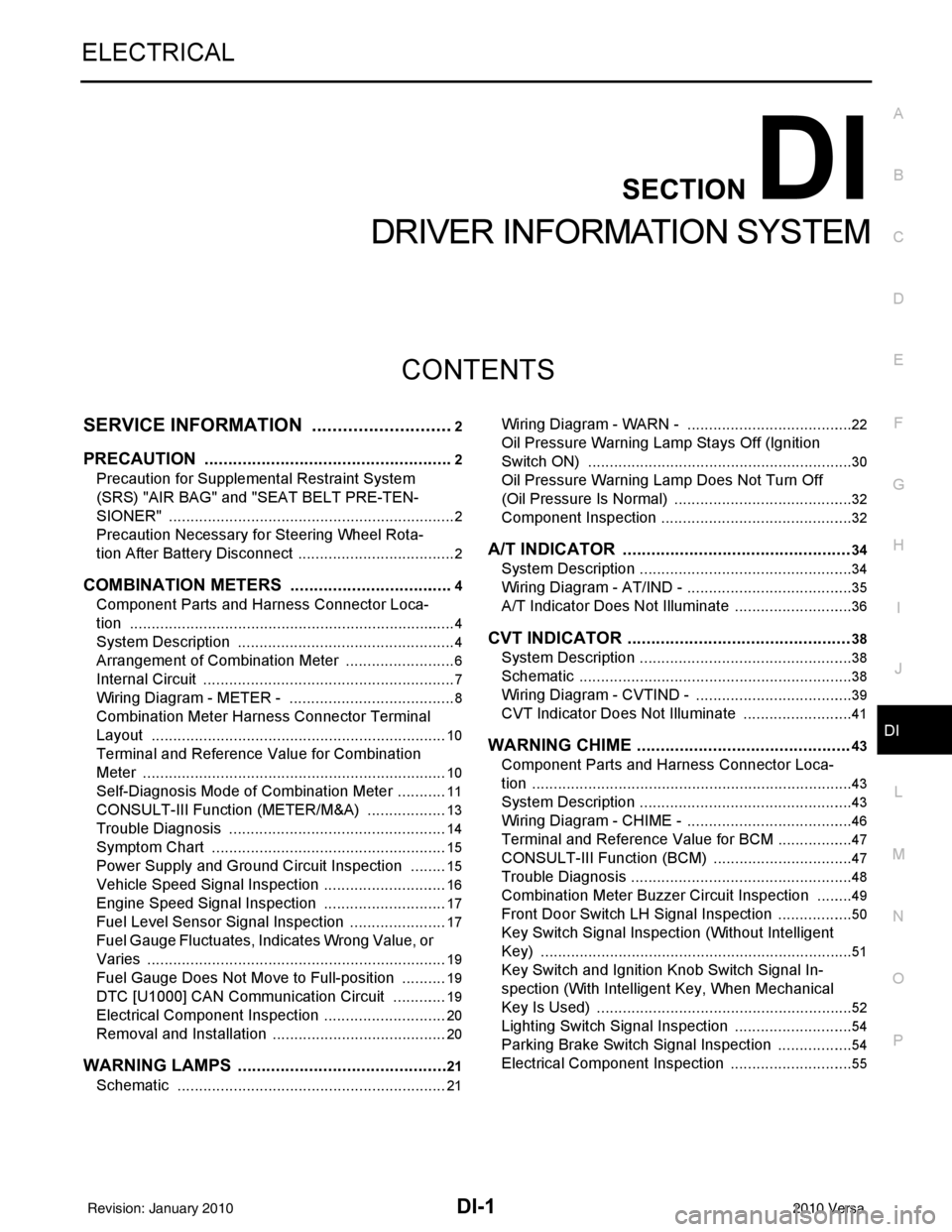

Component Parts and Harness Connector LocationINFOID:0000000005395007

System DescriptionINFOID:0000000005395008

UNIFIED METER CONTROL UNIT

• Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signals drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT i ndicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump (fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

(⇐: Front) 5. Vehicle speed sensor F41 (A/T

shown, M/T similar) 6. TCM E31 (view with

instrument low-

er finisher removed)

WKIA5450E

Revision: January 20102010 Versa

Page 1253 of 3745

WARNING CHIMEDI-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

WARNING CHIME

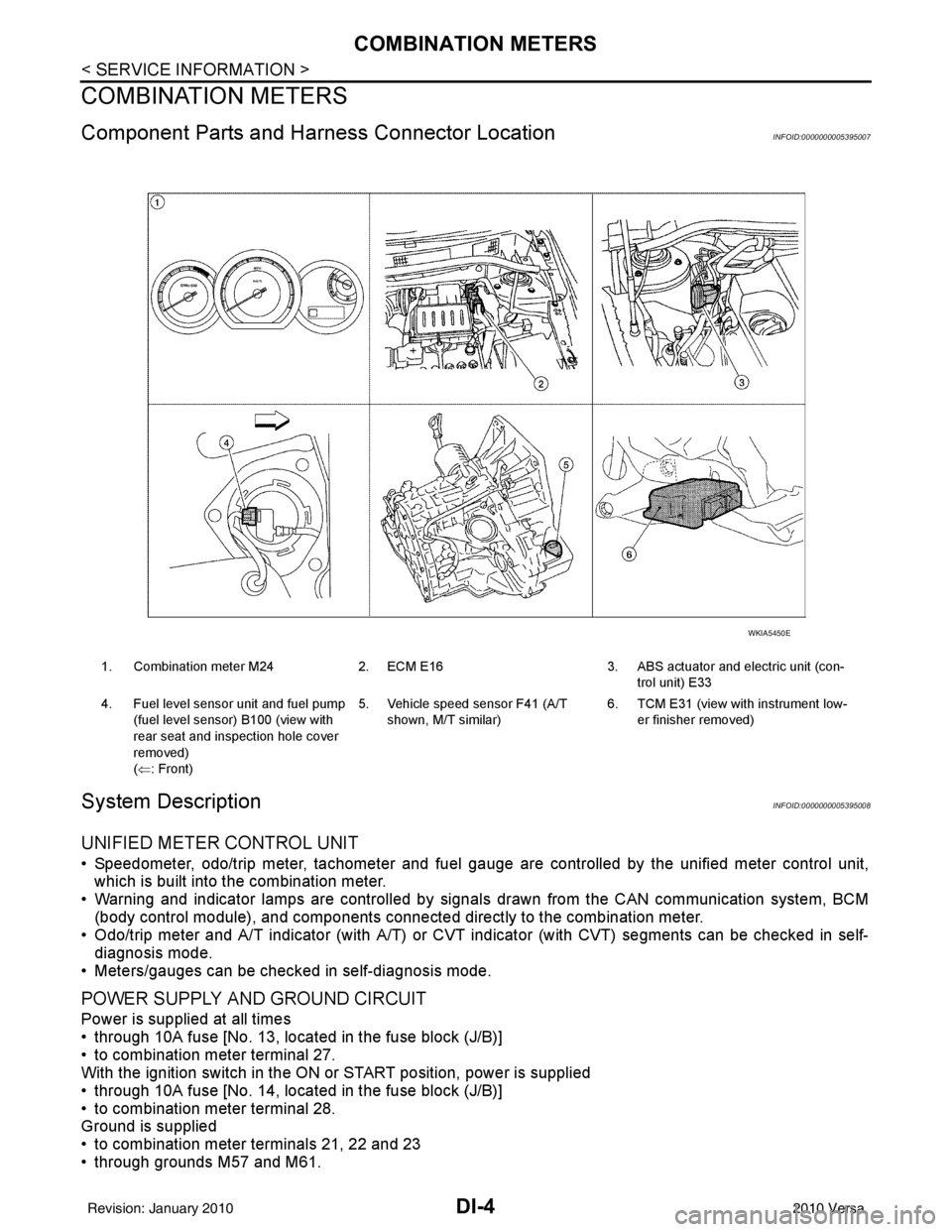

Component Parts and Har ness Connector LocationINFOID:0000000005395039

System DescriptionINFOID:0000000005395040

• Buzzer for warning chime system is installed in the combination meter.

• The buzzer sounds when combination meter receives buzzer output signal with CAN communication line.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 40A fusible link (letter g, located in the fuse and fusible link box)

• to BCM terminal 70,

1. Combination meter M24 2. BCM M18, M19, M20 (view with

glove box removed) 3. Intelligent Key unit M52 (with Intelli-

gent Key)

4. Key switch and key lock solenoid M27 (without Intelligent Key) 5. Key switch and ignition knob switch

M73 (with Intelligent Key) 6. Combination switch (lighting switch)

M28

7. Front door switch LH B8 8. Parking brake switch M17

AWMIA0117ZZ

Revision: January 20102010 Versa

Page 1258 of 3745

![NISSAN TIIDA 2010 Service Repair Manual DI-48

< SERVICE INFORMATION >

WARNING CHIME

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, afte NISSAN TIIDA 2010 Service Repair Manual DI-48

< SERVICE INFORMATION >

WARNING CHIME

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, afte](/img/5/57397/w960_57397-1257.png)

DI-48

< SERVICE INFORMATION >

WARNING CHIME

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, after printing the monitor item, go to “LAN system”. Refer to

LAN-17, "

Trouble Diagnosis Flow Chart".

Trouble DiagnosisINFOID:0000000005395044

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom and customer complaint.

2. Understand the outline of system. Refer to DI-43, "

System Description".

3. Perform the preliminary inspection. Refer to "PRELIMINARY INSPECTION".

4. According to symptom chart, repair or replac e the cause of the malfunction. Refer to "SYMPTOM

CHART".

5. Does warning chime system operate normally? If it operates normally, GO TO 6. If not, GO TO 4.

6. Inspection End.

PRELIMINARY INSPECTION

BCM diagnostic test item Diagnostic mode

Description

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU PART NUMBER BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Monitored item ALL SIGNALS SELECTION

FROM MENU Contents

IGN ON SW XX Indicates [ON/OFF] condition of ignition switch.

KEY ON SW XX Indicates [ON/OFF] condition of key switch.

DOOR SW-DR XX Indicates [ON/OFF] condition of front door switch LH.

LIGHT SW 1ST XX Indicates [ON/OFF] condition of lighting switch.

BUCKLE SW XX Indicates [ON/OFF] condition of seat belt buckle switch LH.

Test item Malfunction is detected when···

IGN KEY WARN ALM This test is able to check key warning chime operation.

LIGHT WARN ALM This test is able to check light warning chime operation.

SEAT BELT WARN TEST This test is able to check seat belt warning chime operation.

Display item [Code] Malfunction is detected when...

CAN communication [U1000] Malfunction is detected in CAN communication.

Revision: January 20102010 Versa

Page 1259 of 3745

WARNING CHIMEDI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

1.CHECK BCM

Perform self-diagnosis of BCM. Refer to DI-47, "

CONSULT-III Function (BCM)".

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK COMBINATION METER

Perform self-diagnosis of combination meter. Refer to DI-13, "

CONSULT-III Function (METER/M&A)".

Self

-diagnostic results content

No malfunction detected>> Inspection End.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

SYMPTOM CHART

Combination Meter Buzzer Circuit InspectionINFOID:0000000005395045

1.CHECK CHIME OPERATION

1. Select “BUZZER” of “BCM” on CONSULT-III.

2. Perform “LIGHT WARN ALM” or “IGN KEY WARN ALM” of “ACTIVE TEST”.

Does chime sound?

YES >> Combination meter buzzer circuit is OK. Return to DI-48, "Trouble Diagnosis".

NO >> GO TO 2.

2.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Turn on hazard switch or lighting switch while monitoring “BUZZER” of “DATA MONITOR” and check

operation status.

OK or NG

Symptom Diagnoses/Service procedure

All warning chime systems do not activate. Perform the following inspections.

•

DI-49, "

Combination Meter Buzzer Circuit Inspection"

•DI-50, "Front Door Switch LH Signal Inspection"

If above check is OK, replace BCM. Refer to BCS-19, "Removal

and Installation of BCM".

Key warning chime

does not activate. Without Intelligent Key.

Perform

DI-51, "

Key Switch Signal Inspection (Without Intelligent

Key)".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

With Intelligent Key, when mechanical key

is used. Perform

DI-52, "

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical Key Is Used)".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

With Intelligent Key, when Intelligent Key

is carried with the driver. Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

Light warning chime does not activate. Perform

DI-54, "

Lighting Switch Signal Inspection".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

Parking brake warning chime does not activate Perform the following inspections

•

DI-54, "

Parking Brake Switch Signal Inspection"

•DI-16, "Vehicle Speed Signal Inspection"

“BUZZER”

While hazard switch or

lighting switch is ON : ON and OFF repeatedly

Except above : OFF

Revision: January 20102010 Versa

Page 1260 of 3745

DI-50

< SERVICE INFORMATION >

WARNING CHIME

OK >> Check battery power supply circuit of combination meter. If OK, replace combination meter. Referto IP-12, "

Removal and Installation".

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM".

Front Door Switch LH Signal InspectionINFOID:0000000005395046

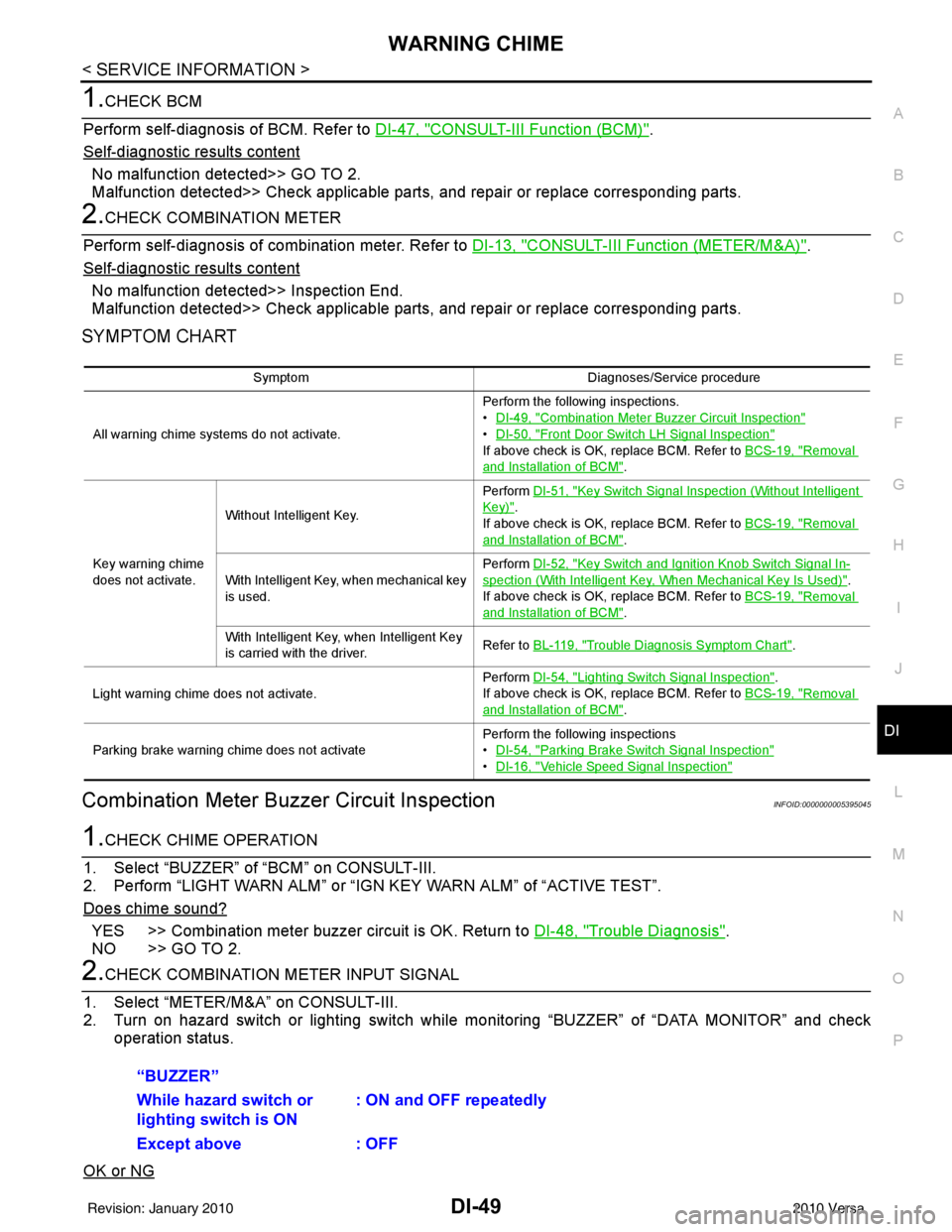

1.CHECK BCM INPUT SIGNAL

With CONSULT-III

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “DOOR SW-DR” when the driver's door is operated.

Without CONSULT-III

Check voltage between BCM harness connector and ground.

OK or NG

OK >> Front door switch LH signal is OK. Return to DI-48, "Trouble Diagnosis".

NG >> GO TO 2.

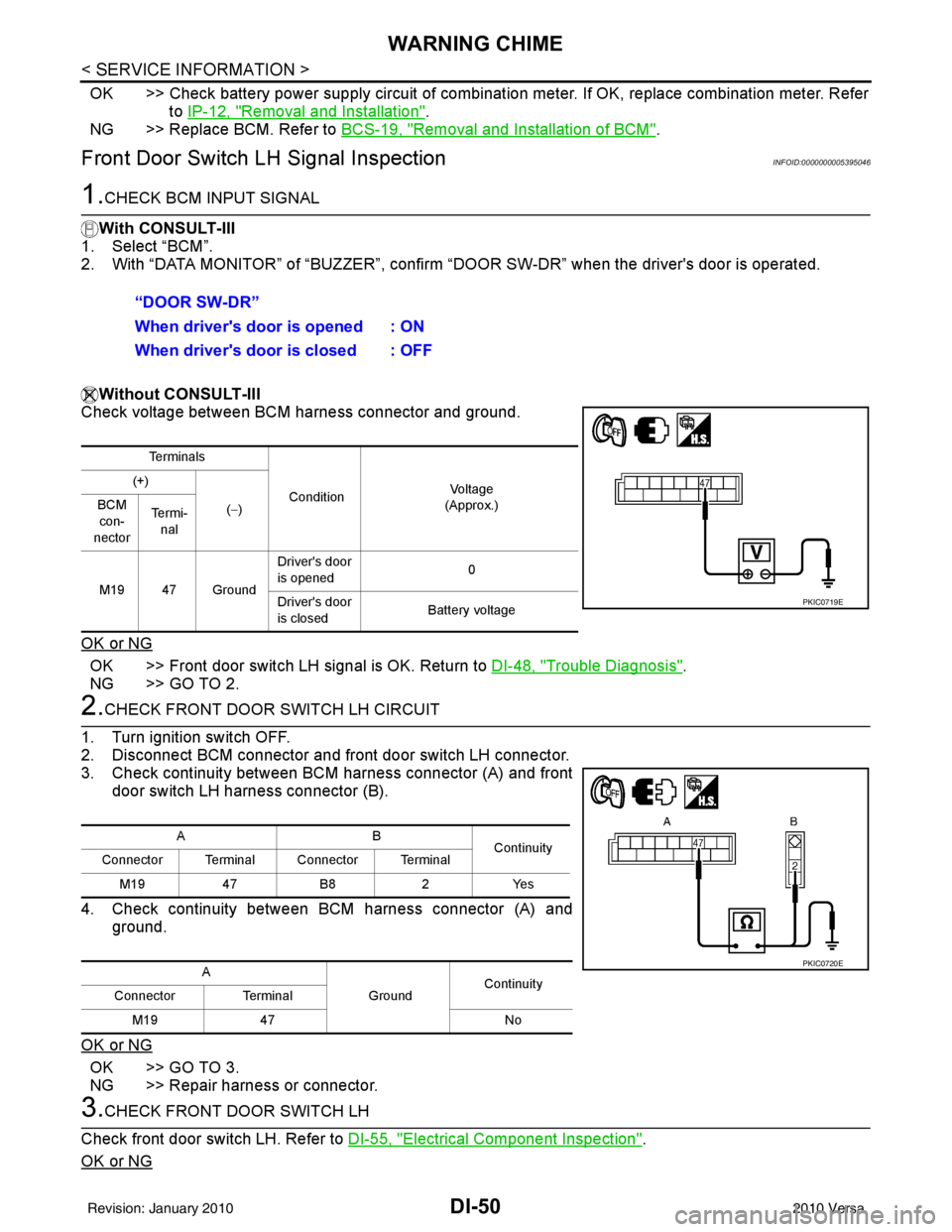

2.CHECK FRONT DOOR SWITCH LH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch LH connector.

3. Check continuity between BCM harness connector (A) and front door switch LH harness connector (B).

4. Check continuity between BCM harness connector (A) and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FRONT DOOR SWITCH LH

Check front door switch LH. Refer to DI-55, "

Electrical Component Inspection".

OK or NG

“DOOR SW-DR”

When driver's door is opened : ON

When driver's door is closed : OFF

Te r m i n a l s

Condition Vol tag e

(Approx.)

(+)

(−)

BCM

con-

nector Te r m i -

nal

M19 47 Ground Driver's door

is opened

0

Driver's door

is closed Battery voltage

PKIC0719E

AB

Continuity

Connector Terminal Connector Terminal

M19 47B8 2Yes

A GroundContinuity

Connector Terminal

M19 47 No

PKIC0720E

Revision: January 20102010 Versa

Page 1261 of 3745

WARNING CHIMEDI-51

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

OK >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NG >> Replace front door switch LH.

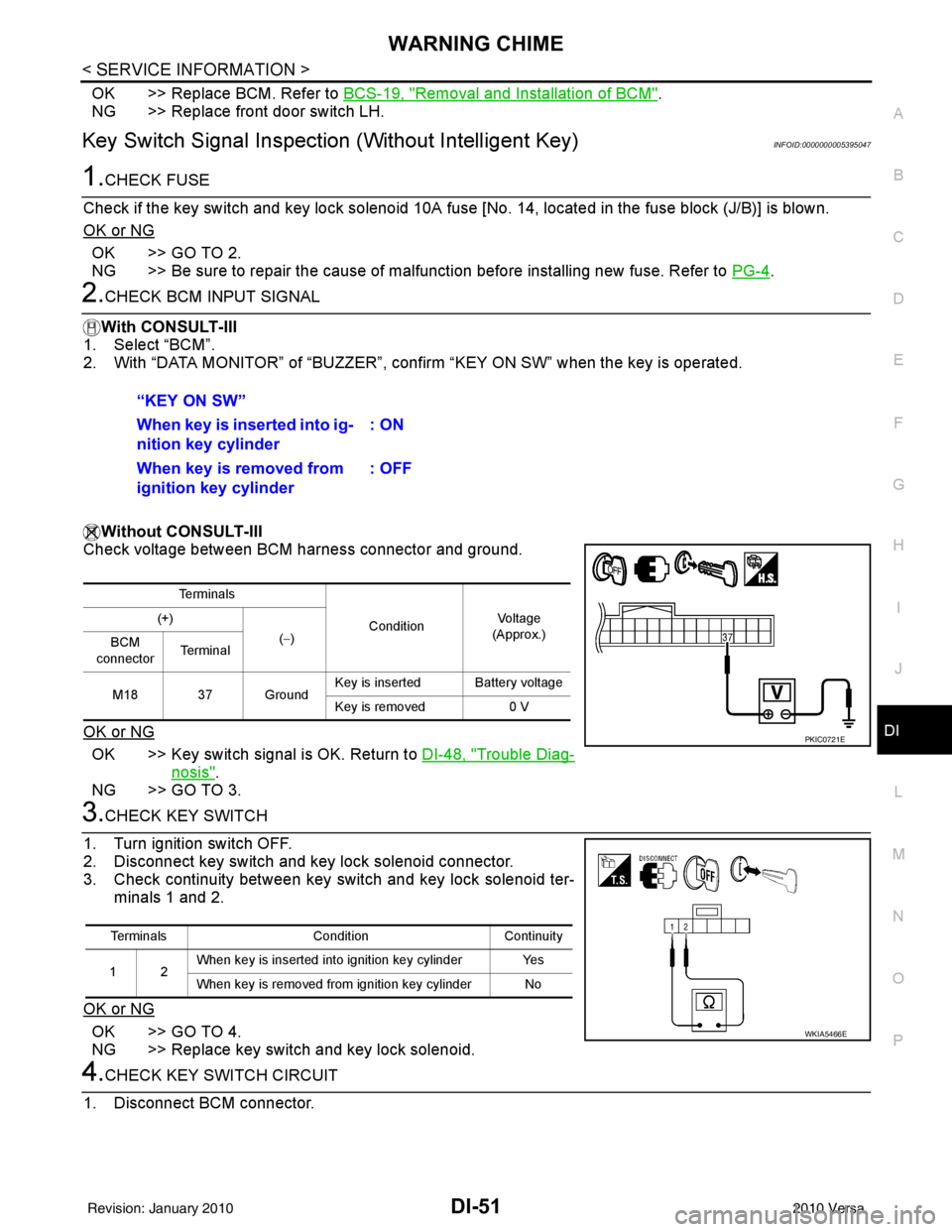

Key Switch Signal Inspection (Without Intelligent Key)INFOID:0000000005395047

1.CHECK FUSE

Check if the key switch and key lock solenoid 10A fuse [No. 14, located in the fuse block (J/B)] is blown.

OK or NG

OK >> GO TO 2.

NG >> Be sure to repair the cause of malfunction before installing new fuse. Refer to PG-4

.

2.CHECK BCM INPUT SIGNAL

With CONSULT-III

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “KEY ON SW” when the key is operated.

Without CONSULT-III

Check voltage between BCM harness connector and ground.

OK or NG

OK >> Key switch signal is OK. Return to DI-48, "Trouble Diag-

nosis".

NG >> GO TO 3.

3.CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and key lock solenoid connector.

3. Check continuity between key switch and key lock solenoid ter- minals 1 and 2.

OK or NG

OK >> GO TO 4.

NG >> Replace key switch and key lock solenoid.

4.CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector. “KEY ON SW”

When key is inserted into ig-

nition key cylinder

: ON

When key is removed from

ignition key cylinder : OFF

Te r m i n a l s

ConditionVoltag e

(Approx.)

(+)

(−)

BCM

connector Te r m i n a l

M18 37 Ground Key is inserted Battery voltage

Key is removed

0 V

PKIC0721E

Terminals ConditionContinuity

12 When key is inserted into ignition key cylinder Yes

When key is removed from ignition key cylinder No

WKIA5466E

Revision: January 20102010 Versa

Page 1265 of 3745

WARNING CHIMEDI-55

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

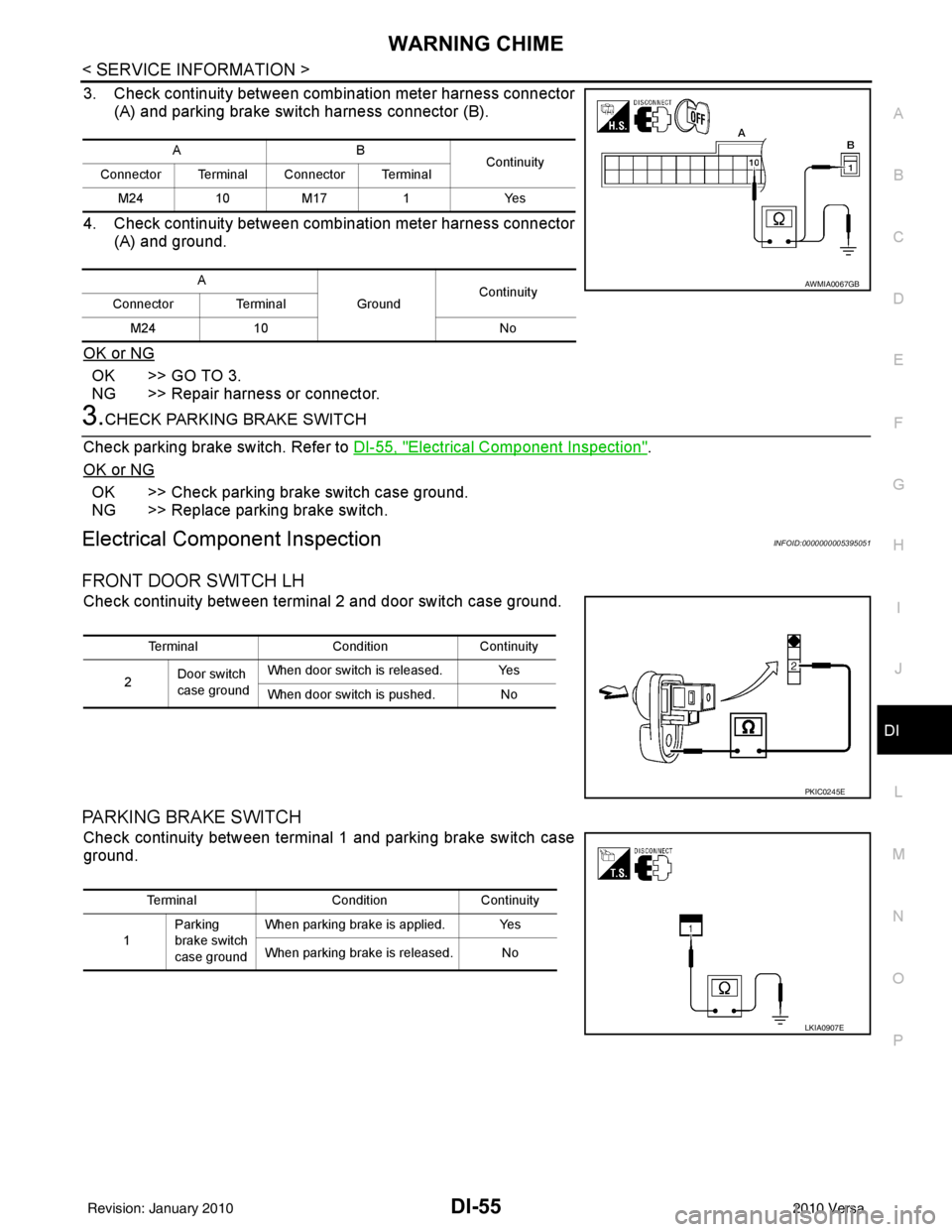

3. Check continuity between combination meter harness connector (A) and parking brake switch harness connector (B).

4. Check continuity between combination meter harness connector (A) and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK PARKING BRAKE SWITCH

Check parking brake switch. Refer to DI-55, "

Electrical Component Inspection".

OK or NG

OK >> Check parking brake switch case ground.

NG >> Replace parking brake switch.

Electrical Component InspectionINFOID:0000000005395051

FRONT DOOR SWITCH LH

Check continuity between terminal 2 and door switch case ground.

PARKING BRAKE SWITCH

Check continuity between terminal 1 and parking brake switch case

ground.

AB Continuity

Connector Terminal Connector Terminal

M241 0M 17 1 Y es

A GroundContinuity

Connector Terminal

M24 10 No

AWMIA0067GB

TerminalConditionContinuity

2 Door switch

case ground When door switch is released. Yes

When door switch is pushed. No

PKIC0245E

Terminal

ConditionContinuity

1 Parking

brake switch

case ground When parking brake is applied. Yes

When parking brake is released. No

LKIA0907E

Revision: January 20102010 Versa