automatic NISSAN TIIDA 2010 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1787 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-522

< SERVICE INFORMATION >[MR18DE]

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DescriptionINFOID:0000000005532386

INPUT/OUTPUT SIGNAL CHART

*: This signal is NISSAN TIIDA 2010 Service Service Manual EC-522

< SERVICE INFORMATION >[MR18DE]

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DescriptionINFOID:0000000005532386

INPUT/OUTPUT SIGNAL CHART

*: This signal is](/img/5/57397/w960_57397-1786.png)

EC-522

< SERVICE INFORMATION >[MR18DE]

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DescriptionINFOID:0000000005532386

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set

vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric thro ttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE indi cator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION

Press MAIN switch. (The CRUISE indicator in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indi cator in combination meter illuminates.)

ACCELERATE OPERATION

If the RESUME/ACCELERATE switch is depressed during cruise control driving, increase the vehicle speed

until the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

• CANCEL switch is pressed

• More than two switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Clutch pedal is depressed or gear position is changed to the neutral position (M/T models)

• Selector lever is changed to N, P, R position (A/T and CVT models)

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to the normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION

Sensor Input signal to ECM ECM functionActuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator

Stop lamp switch

Brake pedal operation

ASCD clutch switch (M/T models) Clutch pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) signal Gear position

ABS actuator and electric unit (con-

trol unit) Vehicle speed*

Combination meter

TCM Powertrain revolution*

Revision: January 20102010 Versa

Page 1788 of 3745

![NISSAN TIIDA 2010 Service Service Manual AUTOMATIC SPEED CONTROL DEVICE (ASCD)EC-523

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When the SET/COAST switch is depressed during cruise

control driving, decrease vehicle set NISSAN TIIDA 2010 Service Service Manual AUTOMATIC SPEED CONTROL DEVICE (ASCD)EC-523

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When the SET/COAST switch is depressed during cruise

control driving, decrease vehicle set](/img/5/57397/w960_57397-1787.png)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)EC-523

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When the SET/COAST switch is depressed during cruise

control driving, decrease vehicle set speed until the

switch is released. And then ASCD will keep the new set speed.

RESUME OPERATION

When the RESUME/ACCELERATE swit ch is depressed after cancel operation other than depressing MAIN

switch is performed, vehicle speed will return to last set speed. To resume vehicle set speed, vehicle condition

must meet following conditions.

• Brake pedal is released.

• Clutch pedal is released (M/T models)

• Selector lever is in other than P and N positions (A/T and CVT models)

• Vehicle speed is greater than 40 km/h (25 MPH) and less than 144 km/h (89 MPH)

Component DescriptionINFOID:0000000005532387

ASCD STEERING SWITCH

Refer to EC-925.

ASCD BRAKE SWITCH

Refer to EC-931 and EC-996.

ASCD CLUTCH SWITCH

Refer to EC-931 and EC-996.

STOP LAMP SWITCH

Refer to EC-931, EC-944and EC-996.

ELECTRIC THROTTLE CONTROL ACTUATOR

Refer to EC-948, EC-952, EC-958and EC-963.

ASCD INDICATOR

Refer to EC-1004.

Revision: January 20102010 Versa

Page 1797 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-532

< SERVICE INFORMATION >[MR18DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000005532393

From the beginning of refueling, the NISSAN TIIDA 2010 Service Service Manual EC-532

< SERVICE INFORMATION >[MR18DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000005532393

From the beginning of refueling, the](/img/5/57397/w960_57397-1796.png)

EC-532

< SERVICE INFORMATION >[MR18DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000005532393

From the beginning of refueling, the air and vapor insi

de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspections below, be sure to observe the following:

• Put a “CAUTION: FLAMMABLE” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-pr oof container and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-582, "

Fuel Pressure Check".

- Disconnect negative battery cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine and check for fuel leaks at connection.

• Do not attempt to top off the fuel tank afte r the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, r esulting in fuel spray and possibly a fire.

Diagnosis ProcedureINFOID:0000000005532394

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG.

1.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK IF EVAP CANISTER SATURATED WITH WATER

PBIB1387E

Revision: January 20102010 Versa

Page 1812 of 3745

![NISSAN TIIDA 2010 Service Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-547

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of NISSAN TIIDA 2010 Service Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-547

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of](/img/5/57397/w960_57397-1811.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-547

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of SAE J1979/ISO 15031-5.

As part of an enhanced emissions test for Inspection & Ma

intenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has comple ted self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indicates “CMPLT” for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT i ndicates “INCMP” for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If permanent DTC is stored or MIL illuminates during the state emissions inspection, the vehicle is also

returned to the customer untested even though the SRT indicates “CMPLT” for all test items. Therefore, it is

important to check SRT (“CMPLT ”), DTC (No DTCs) and permanent DT C (No permanent DTCs) before the

inspection.

SRT Item

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

*: If completion of several SRTs is required, perform driving patterns (DTC confirmation procedure), one by one based on the pr iority for

models with CONSULT-III.

SRT Set Timing

SRT is set as “CMPLT” after self-diagnosis has been performed one or more times. Completion of SRT is

done regardless of whether the result is OK or NG. T he set timing is different between OK and NG results and

is shown in the table below.

SRT item

(CONSULT-III indica- tion) Perfor-

mance

Priority* Required self-diagnostic items to set the SRT to “CMPLT” Corresponding DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 —

Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139

EGR/VVT SYSTEM 3 Intake value timing control function P0011

Self-diagnosis resultExample

Diagnosis Ignition cycle

← ON → OFF ← ON → OFF ← ON → OFF ← ON →

Revision: January 20102010 Versa

Page 1882 of 3745

![NISSAN TIIDA 2010 Service Service Manual TROUBLE DIAGNOSISEC-617

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatica NISSAN TIIDA 2010 Service Service Manual TROUBLE DIAGNOSISEC-617

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatica](/img/5/57397/w960_57397-1881.png)

TROUBLE DIAGNOSISEC-617

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item

HO2 S2 DIAG2 (B1)

[INCMP/CMPLT]

• Indicates DTC P0139 self-diagnosis (slow response) condi-

tion.

INCMP: Self-diagnosis is incomplete.

CMPLT: Self-diagnosis is complete.

A/F SEN1

DIAG1(B1)

[INCMP/CMPLT] • Indicates DTC P015A or P015B self-diagnosis condition.

INCMP: Self-diagnosis is incomplete.

CMPLT: Self-diagnosis is complete.

A/F SEN1

DIAG2(B1)

[INCMP/CMPLT] • Indicates DTC P014C or P014D self-diagnosis condition.

INCMP: Self-diagnosis is incomplete.

CMPLT: Self-diagnosis is complete.

A/F SEN1

DIAG3(B1)

[ABSNT/PRSNT] • Indicates DTC P014C, P014D, P015A or P015B self-diagno-

sis condition.

ABSNT: The vehicle condition is not within the diagnosis

range.

PRSNT: The vehicle condition is within the diagnosis range.

Monitored item [Unit]

Description Remarks

Test itemCondition JudgmentCheck item (Remedy)

FUEL INJEC-

TION • Engine: Return to the original

trouble condition

• Change the amount of fuel injec- tion using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

• Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

IGNITION TIM-

ING • Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

• Perform Idle Air Volume Learning.

POWER BAL-

ANCE • Engine: After warming up, idle the

engine.

• A/C switch OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• Cut off each fuel injector signal one at a time using CONSULT-III. Engine runs rough or dies.

• Harness and connectors

• Compression

• Fuel injector

• Power transistor

•Spark plug

• Ignition coil

COOLING FAN* • Ignition switch: ON

• Turn the cooling fan “LOW”, “HI”

and “OFF” with CONSULT-III. Cooling fan moves and stops.

• Harness and connectors

• Cooling fan relay

• Cooling fan motor

ENG COOLANT

TEMP • Engine: Return to the original

trouble condition

• Change the engine coolant tem-

perature using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Engine coolant temperature sen-

sor

• Fuel injector

FUEL PUMP RE-

LAY • Ignition switch: ON

(Engine stopped)

• Turn the fuel pump relay ON and

OFF using CONSULT-III and lis-

ten to operating sound. Fuel pump relay makes the operat-

ing sound.

• Harness and connectors

• Fuel pump relay

PURG VOL

CONT/V • Engine: After warming up, run en-

gine at 1,500 rpm.

• Change the EVAP canister purge volume control solenoid valve

opening percent using CON-

SULT-III. Engine speed changes according to

the opening percent.

• Harness and connectors

• EVAP canister purge volume con-

trol solenoid valve

FUEL/T TEMP

SEN • Change the fuel tank temperature using CONSULT-III.

Revision: January 20102010 Versa

Page 2491 of 3745

![NISSAN TIIDA 2010 Service Service Manual EM-132

< SERVICE INFORMATION >[MR18DE]

DRIVE BELTS

DRIVE BELTS

ComponentINFOID:0000000005398110

Checking Drive BeltsINFOID:0000000005398111

WARNING:

Be sure to perform this step

when the engine is st NISSAN TIIDA 2010 Service Service Manual EM-132

< SERVICE INFORMATION >[MR18DE]

DRIVE BELTS

DRIVE BELTS

ComponentINFOID:0000000005398110

Checking Drive BeltsINFOID:0000000005398111

WARNING:

Be sure to perform this step

when the engine is st](/img/5/57397/w960_57397-2490.png)

EM-132

< SERVICE INFORMATION >[MR18DE]

DRIVE BELTS

DRIVE BELTS

ComponentINFOID:0000000005398110

Checking Drive BeltsINFOID:0000000005398111

WARNING:

Be sure to perform this step

when the engine is stopped.

NOTE:

On vehicles not equipped with A/C, there is an idler pulley in the position for the drive belt routing.

• Make sure that the indicator (notch on fixed side) of drive belt auto-tensioner is within the possible use

range.

NOTE:

• Check the drive belt auto-tensioner indication when the engine is cold.

• When new drive belt is installed, the indicator (notch on fixed side) should be within the range.

• Visually check entire drive belt for wear, damage or cracks.

• If the indicator (notch on fixed side) is out of t he possible use range or belt is damaged, replace drive belt.

Tension AdjustmentINFOID:0000000005398112

Belt tension is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

Removal and InstallationINFOID:0000000005398113

REMOVAL

1. Remove fender protector (RH). Refer to EI-24, "Removal and Installation".

2. Hold the hexagonal part (A) of drive belt auto-tensioner (1) with a wrench securely. Then move the wrench handle in the direc-

tion of arrow (loosening direction of tensioner).

WARNING:

Never place hand in a location where pinching may occur if

the holding tool acci dentally comes off.

CAUTION:

Do not loosen the auto-tensione r pulley bolt. (Do not turn it

counterclockwise.) If turned counterclockwise, the com-

plete auto-tensioner must be replaced as a unit, including

pulley.

3. Insert a rod such as short-length screwdriver approximately 6 mm (0.24 in) in diameter into the hole (B) of t he retaining boss to fix drive belt auto-tensioner.

• Leave tensioner pulley arm locked until belt is installed again.

4. Remove drive belt.

INSTALLATION

1. Generator 2. Drive belt auto–tensioner 3. Crankshaft pulley

4. A/C compressor (models with A/C)

Idler pulley (models without A/C) 5. Water pump

6. Drive belt

A. Possible use range B. Range when new drive belt is installed C. Indicator

PBIC3137J

PBIC3936E

Revision: January 20102010 Versa

Page 2615 of 3745

FAX-10

< SERVICE INFORMATION >

FRONT DRIVE SHAFT

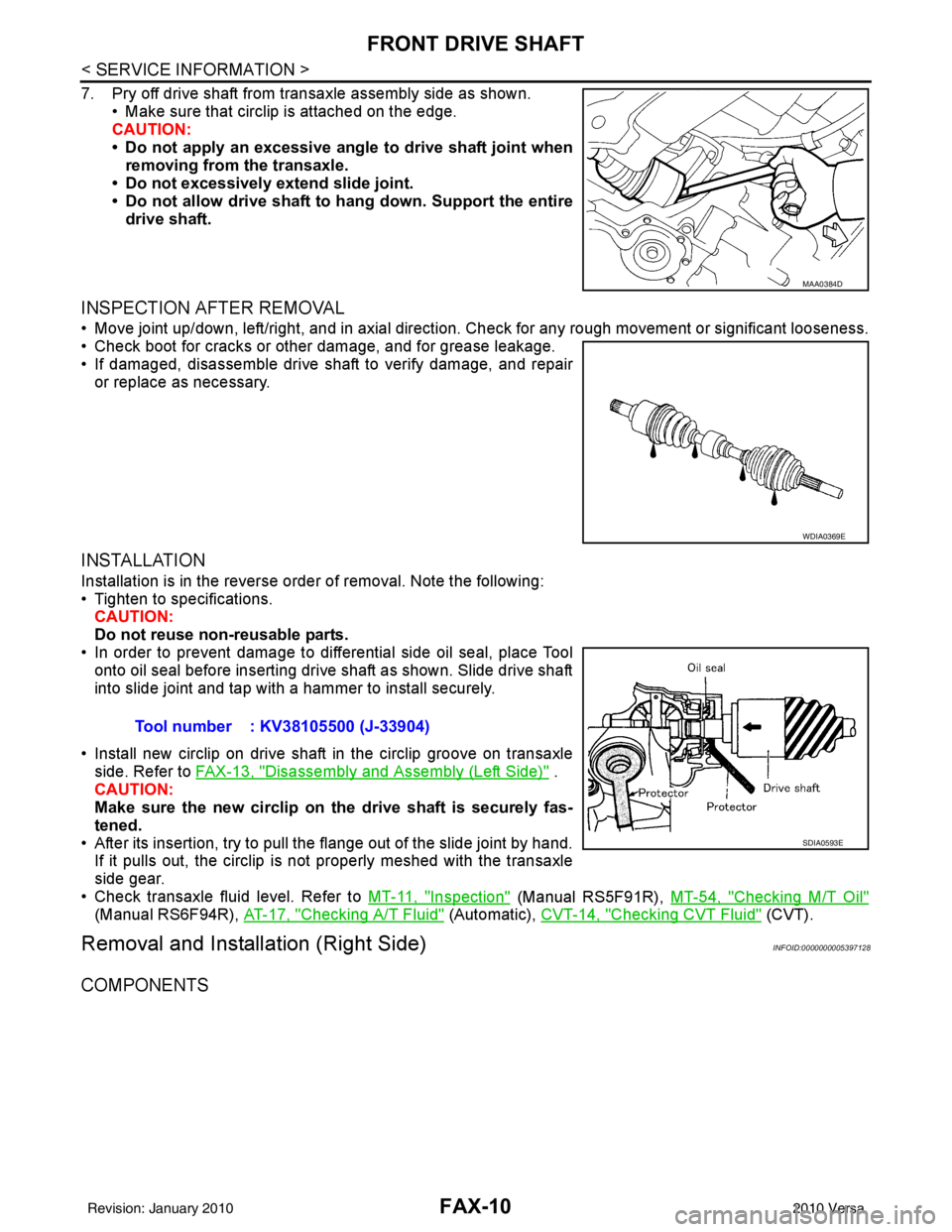

7. Pry off drive shaft from transaxle assembly side as shown.• Make sure that circlip is attached on the edge.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the transaxle.

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang down. Support the entire

drive shaft.

INSPECTION AFTER REMOVAL

• Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair or replace as necessary.

INSTALLATION

Installation is in the reverse order of removal. Note the following:

• Tighten to specifications.CAUTION:

Do not reuse non-reusable parts.

• In order to prevent damage to differential side oil seal, place Tool

onto oil seal before inserting drive shaft as shown. Slide drive shaft

into slide joint and tap with a hammer to install securely.

• Install new circlip on drive shaft in the circlip groove on transaxle side. Refer to FAX-13, "

Disassembly and Assembly (Left Side)" .

CAUTION:

Make sure the new circlip on the drive shaft is securely fas-

tened.

• After its insertion, try to pull the flange out of the slide joint by hand. If it pulls out, the circlip is not properly meshed with the transaxle

side gear.

• Check transaxle fluid level. Refer to MT-11, "

Inspection" (Manual RS5F91R), MT-54, "Checking M/T Oil"

(Manual RS6F94R), AT-17, "Checking A/T Fluid" (Automatic), CVT-14, "Checking CVT Fluid" (CVT).

Removal and Installation (Right Side)INFOID:0000000005397128

COMPONENTS

MAA0384D

WDIA0369E

Tool number : KV38105500 (J-33904)

SDIA0593E

Revision: January 20102010 Versa

Page 2617 of 3745

FAX-12

< SERVICE INFORMATION >

FRONT DRIVE SHAFT

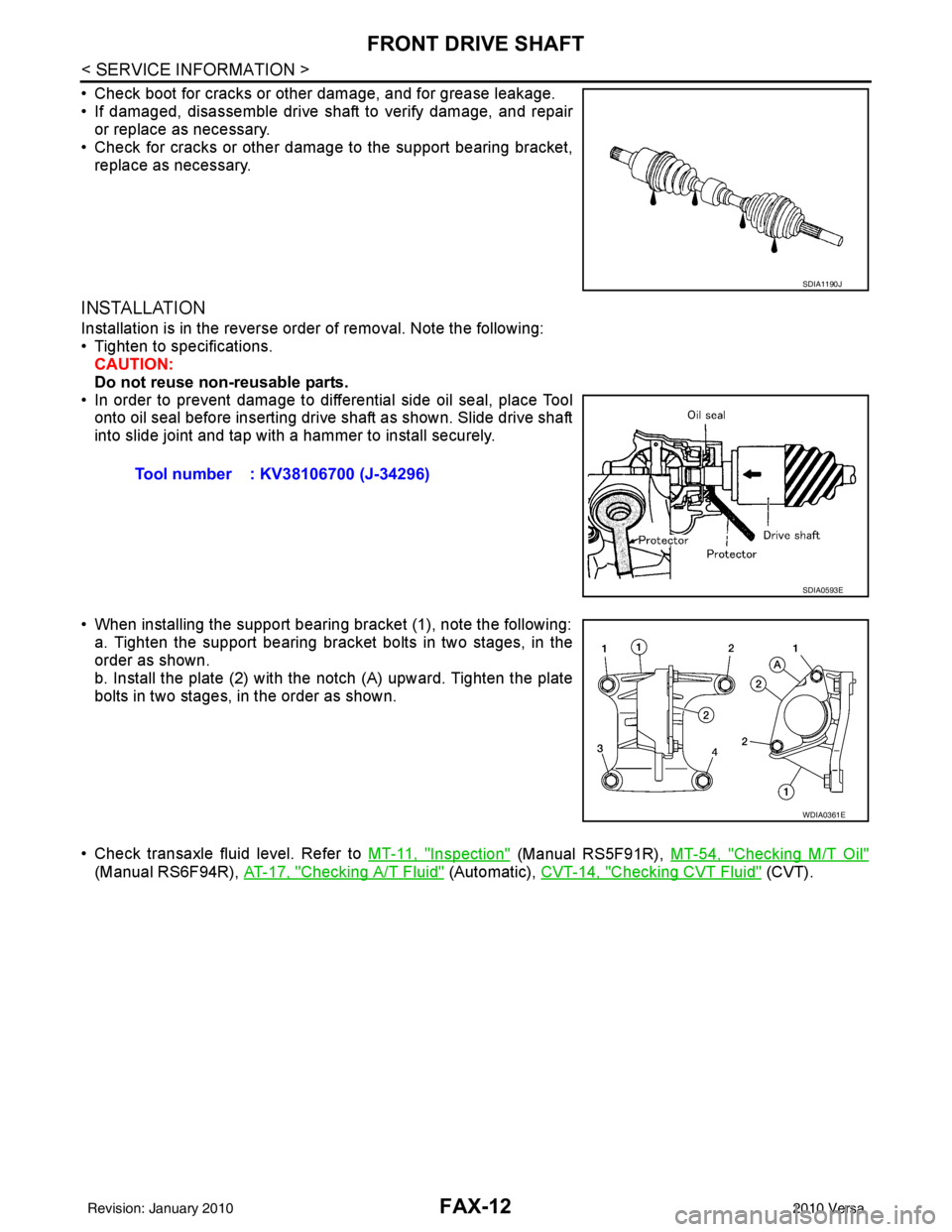

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repairor replace as necessary.

• Check for cracks or other damage to the support bearing bracket, replace as necessary.

INSTALLATION

Installation is in the reverse order of removal. Note the following:

• Tighten to specifications.CAUTION:

Do not reuse non-reusable parts.

• In order to prevent damage to differential side oil seal, place Tool onto oil seal before inserting drive shaft as shown. Slide drive shaft

into slide joint and tap with a hammer to install securely.

• When installing the support bearing bracket (1), note the following: a. Tighten the support bearing bracket bolts in two stages, in the

order as shown.

b. Install the plate (2) with the notch (A) upward. Tighten the plate

bolts in two stages, in the order as shown.

• Check transaxle fluid level. Refer to MT-11, "

Inspection" (Manual RS5F91R), MT-54, "Checking M/T Oil"

(Manual RS6F94R), AT-17, "Checking A/T Fluid" (Automatic), CVT-14, "Checking CVT Fluid" (CVT).

SDIA1190J

Tool number : KV38106700 (J-34296)

SDIA0593E

WDIA0361E

Revision: January 20102010 Versa

Page 2669 of 3745

PRECAUTIONSGI-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

General PrecautionINFOID:0000000005399835

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any flammable

materials. Special care should be taken when handling any flam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

• Before starting repairs which do not require battery power: Turn off ignition switch.

Disconnect the negative battery terminal.

• If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

• Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands after handling.

• To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

• Dispose of or recycle drained oil or the solvent used for cleaning

parts in an appropriate manner.

• Do not attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

• Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

SGI285

SGI231

SEF289H

SGI233

Revision: January 20102010 Versa

Page 2673 of 3745

HOW TO USE THIS MANUALGI-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PHOW TO USE THIS MANUAL

DescriptionINFOID:0000000005399842

This volume explains “Removal, Disassembly, Inst allation, Inspection and Adjustment” and “Trouble Diag-

noses”.

Te r m sINFOID:0000000005399843

• The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNING indicates the possibility of personal injury if instructions are not followed.

CAUTION indicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpful information.

Standard value:Tolerance at inspection and adjustment.

Limit value:The maximum or minimum limit value t hat should not be exceeded at inspection and adjustment.

UnitsINFOID:0000000005399844

• The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit), and

alternatively expressed in the metric system and in the yard/pound system.

Also with regard to tightening torque of bolts and nuts, there are descriptions both about range and about the

standard tightening torque.

“Example”

Range

Standard

ContentsINFOID:0000000005399845

• A QUICK REFERENCE INDEX , a black tab (e.g. ) is provided on the first page. You can quickly find the

first page of each section by matching it to the section's black tab.

• THE CONTENTS are listed on the first page of each section.

• THE TITLE is indicated on the upper portion of each page and shows the part or system.

• THE PAGE NUMBER of each section consists of two or three letters which designate the particular section

and a number (e.g. “BR-5”).

• THE SMALL ILLUSTRATIONS show the important steps such as ins pection, use of special tools, knacks of

work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary. Outer Socket Lock Nut : 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb)

Revision: January 20102010 Versa