automatic NISSAN TIIDA 2010 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2686 of 3745

GI-20

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

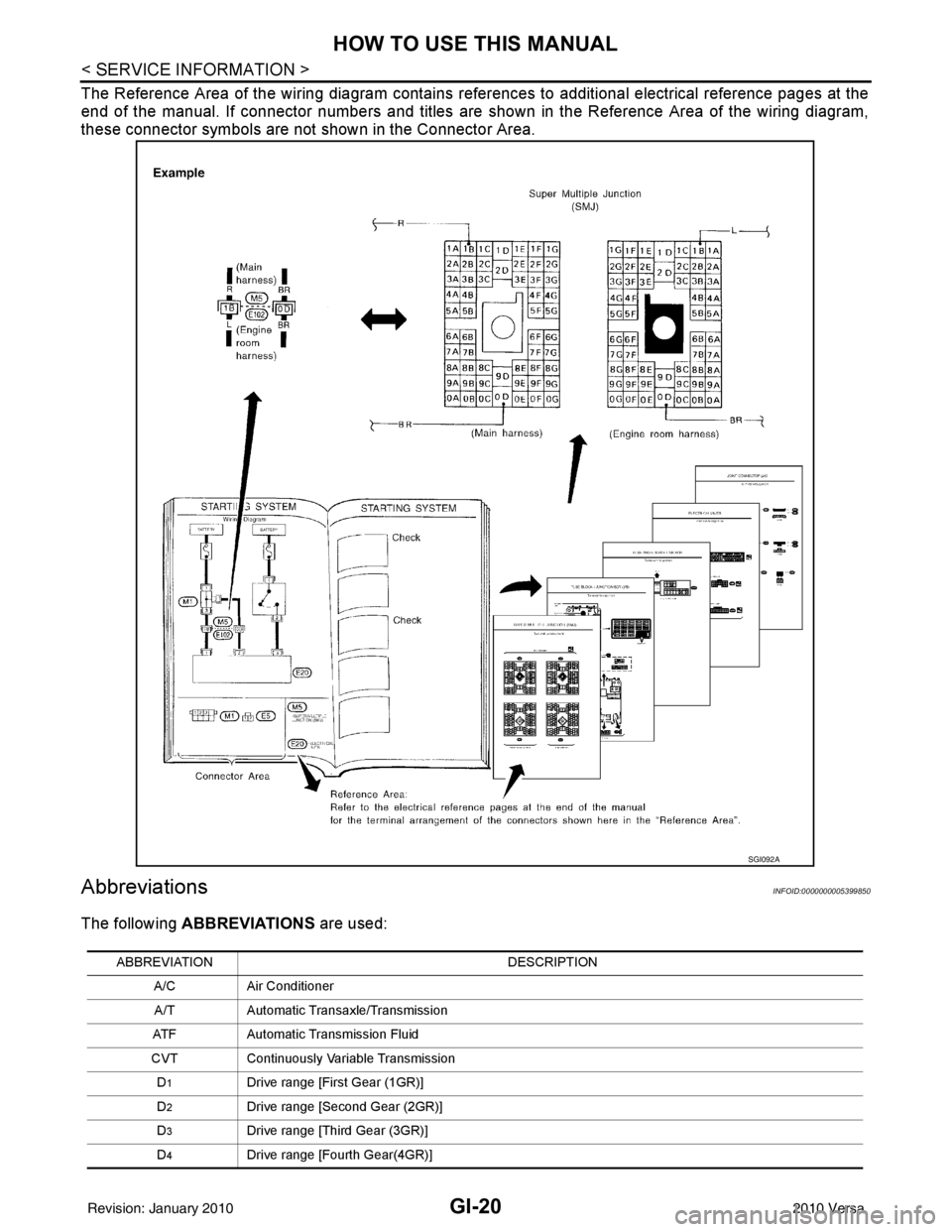

The Reference Area of the wiring diagram contains references to additional electrical reference pages at the

end of the manual. If connector numbers and titles are shown in the Reference Area of the wiring diagram,

these connector symbols are not shown in the Connector Area.

AbbreviationsINFOID:0000000005399850

The following ABBREVIATIONS are used:

SGI092A

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

CVT Continuously Variable Transmission

D

1Drive range [First Gear (1GR)]

D

2Drive range [Second Gear (2GR)]

D

3Drive range [Third Gear (3GR)]

D

4Drive range [Fourth Gear(4GR)]

Revision: January 20102010 Versa

Page 2701 of 3745

CONSULT-III CHECKING SYSTEMGI-35

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PCONSULT-III CHECKING SYSTEM

DescriptionINFOID:0000000005399854

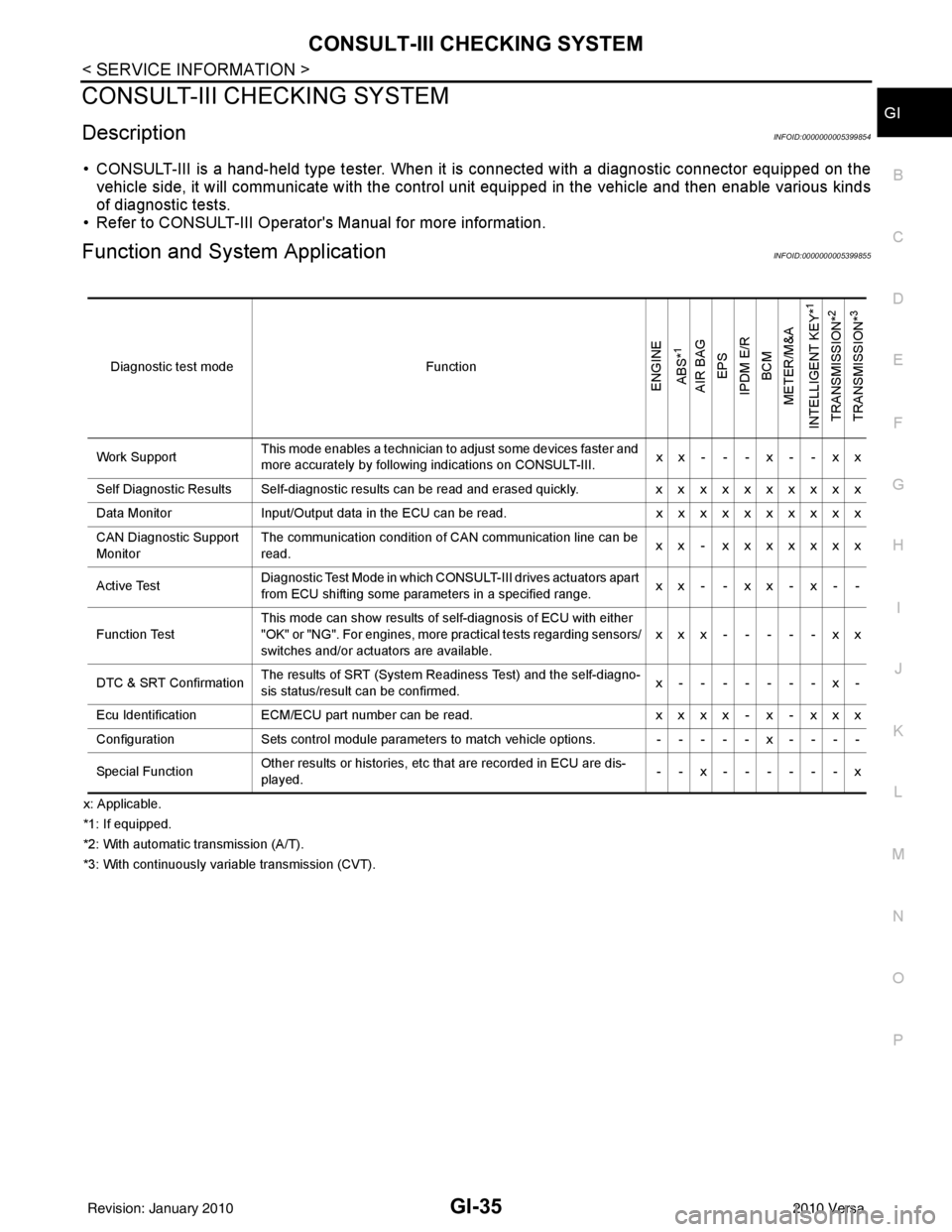

• CONSULT-III is a hand-held type tester. When it is connected with a diagnostic connector equipped on the vehicle side, it will communicate with the contro l unit equipped in the vehicle and then enable various kinds

of diagnostic tests.

• Refer to CONSULT-III Operator's Manual for more information.

Function and System ApplicationINFOID:0000000005399855

x: Applicable.

*1: If equipped.

*2: With automatic transmission (A/T).

*3: With continuously variable transmission (CVT). Diagnostic test mode

Function

ENGINE

ABS*

1

AIR BAG EPS

IPDM E/R BCM

METER/M&A

INTELLIGENT KEY*

1

TRANSMISSION*

2

TRANSMISSION*

3

Work Support This mode enables a technician to adjust some devices faster and

more accurately by following indications on CONSULT-III. xx - - - x - - xx

Self Diagnostic Results Self-diagnostic results can be read and erased quickly. x x x x x x x x x x

Data Monitor Input/Output data in the ECU can be read. x x x x x x x x x x

CAN Diagnostic Support

Monitor The communication condition of CAN communication line can be

read.

xx - xxxxxxx

Active Test Diagnostic Test Mode in which CONSULT-III drives actuators apart

from ECU shifting some parameters in a specified range. xx - - xx - x - -

Function Test This mode can show results of self-diagnosis of ECU with either

"OK" or "NG". For engines, more practical tests regarding sensors/

switches and/or actuators are available. xxx - - - - - xx

DTC & SRT Confirmation The results of SRT (System Readiness Test) and the self-diagno-

sis status/result can be confirmed. x- - - - - - -x-

Ecu Identification ECM/ECU part number can be read. x x x x - x - x x x

Configuration Sets control module parameters to match vehicle options. - - - - - x - - - -

Special Function Other results or histories, etc that are recorded in ECU are dis-

played. --x------x

Revision: January 20102010 Versa

Page 2706 of 3745

GI-40

< SERVICE INFORMATION >

TOW TRUCK TOWING

TOW TRUCK TOWING

Tow Truck TowingINFOID:0000000005399860

CAUTION:

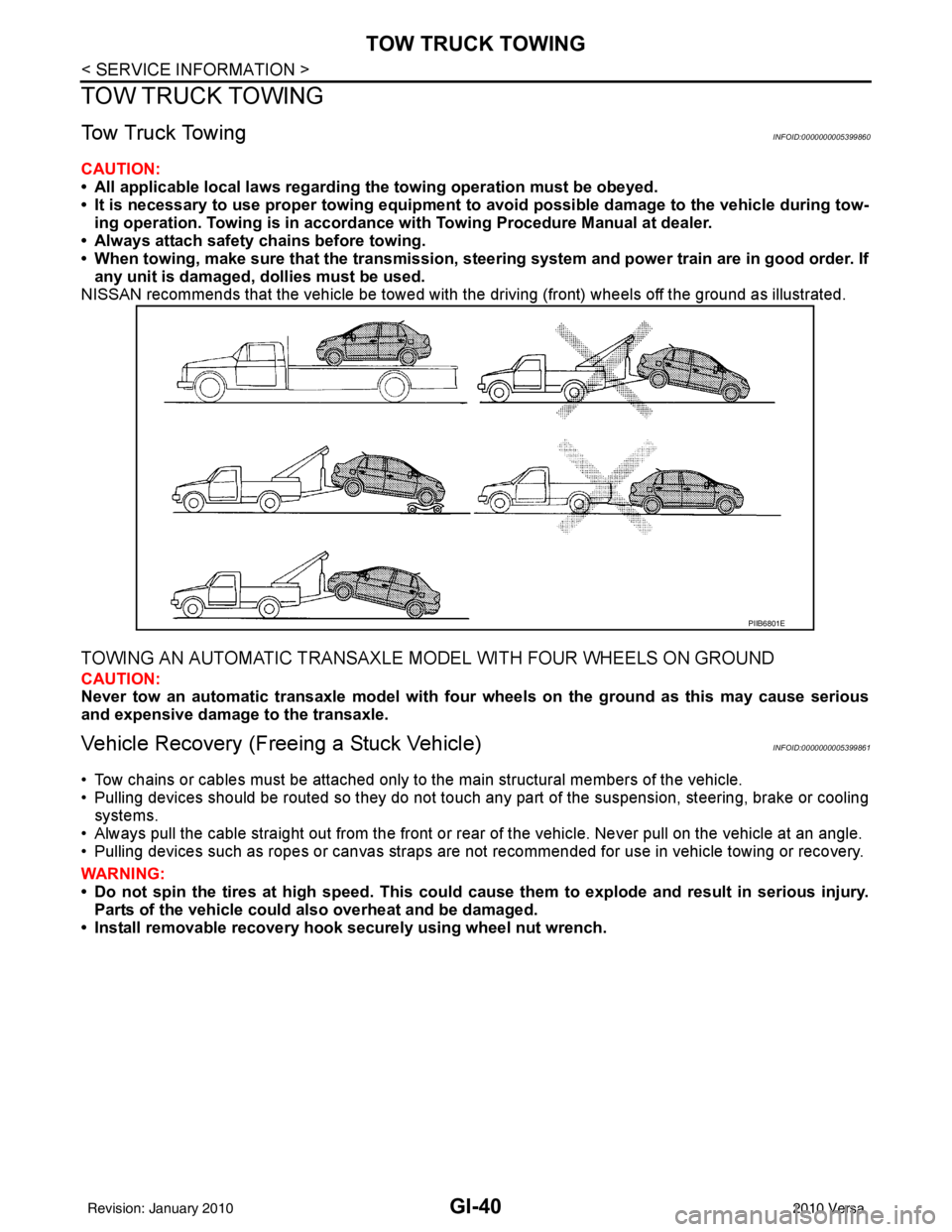

• All applicable local laws regarding the towing operation must be obeyed.

• It is necessary to use proper towi ng equipment to avoid possible damage to the vehicle during tow-

ing operation. To wing is in accordance with Towing Procedure Manual at dealer.

• Always attach safety chains before towing.

• When towing, make sure that the transmission, steering system and power train are in good order. If

any unit is damaged, dollies must be used.

NISSAN recommends that the vehicle be towed with the driving (front) wheels off the ground as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH FOUR WHEELS ON GROUND

CAUTION:

Never tow an automatic transaxle model with four wheels on the ground as this may cause serious

and expensive damage to the transaxle.

Vehicle Recovery (Freeing a Stuck Vehicle)INFOID:0000000005399861

• Tow chains or cables must be attached only to the main structural members of the vehicle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or cooling

systems.

• Always pull the cable straight out from the front or r ear of the vehicle. Never pull on the vehicle at an angle.

• Pulling devices such as ropes or canvas straps are not recommended for use in vehicle towing or recovery.

WARNING:

• Do not spin the tires at high sp eed. This could cause them to explode and result in serious injury.

Parts of the vehicle could also overheat and be damaged.

• Install removable recovery hook securely using wheel nut wrench.

PIIB6801E

Revision: January 20102010 Versa

Page 2708 of 3745

GI-42

< SERVICE INFORMATION >

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

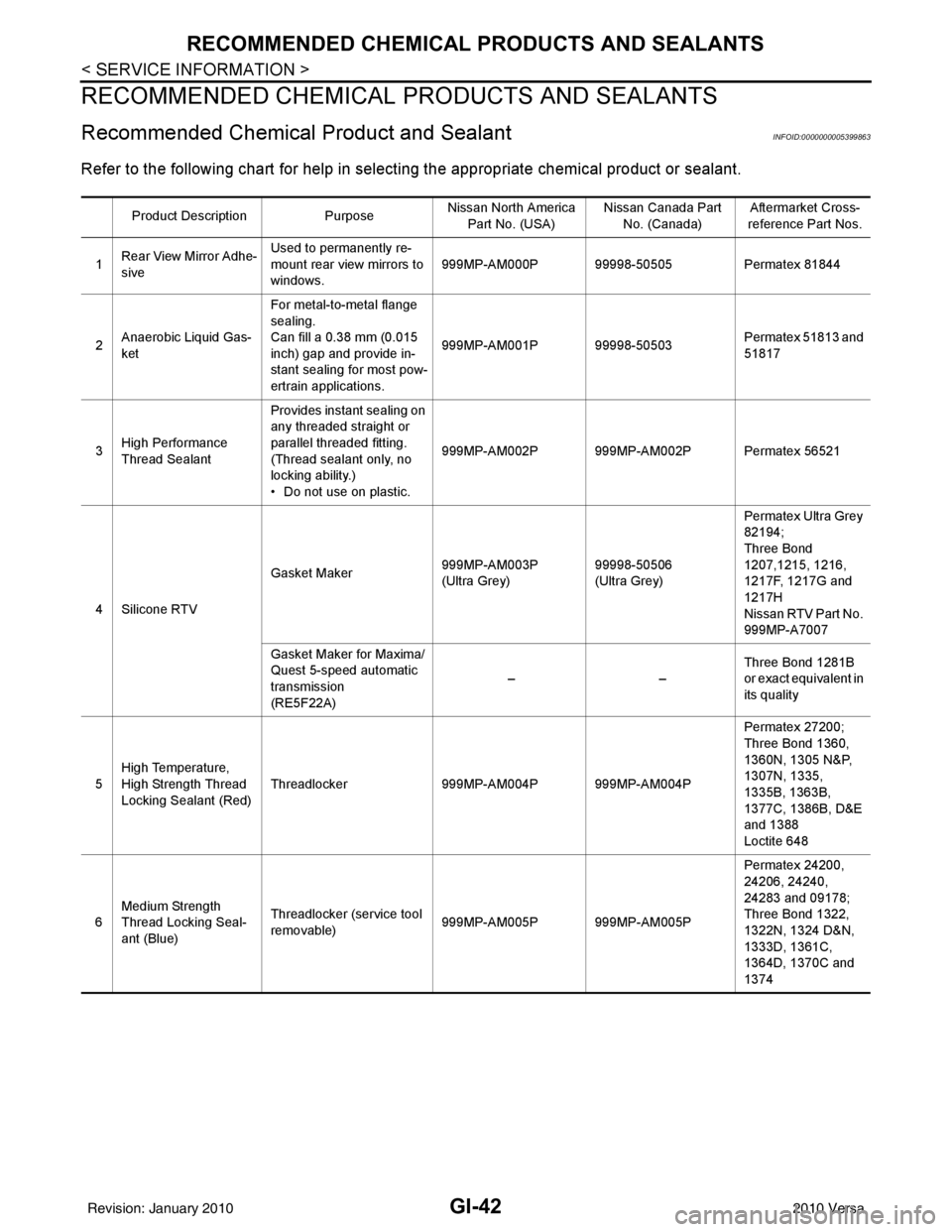

Recommended Chemical Product and SealantINFOID:0000000005399863

Refer to the following chart for help in selecting the appropriate chemical product or sealant.

Product Description PurposeNissan North America

Part No. (USA) Nissan Canada Part

No. (Canada) Aftermarket Cross-

reference Part Nos.

1 Rear View Mirror Adhe-

sive Used to permanently re-

mount rear view mirrors to

windows.

999MP-AM000P 99998-50505

Permatex 81844

2 Anaerobic Liquid Gas-

ket For metal-to-metal flange

sealing.

Can fill a 0.38 mm (0.015

inch) gap and provide in-

stant sealing for most pow-

ertrain applications.

999MP-AM001P 99998-50503

Permatex 51813 and

51817

3 High Performance

Thread Sealant Provides instant sealing on

any threaded straight or

parallel threaded fitting.

(Thread sealant only, no

locking ability.)

• Do not use on plastic.

999MP-AM002P 999MP-AM002P Permatex 56521

4 Silicone RTV Gasket Maker

999MP-AM003P

(Ultra Grey)99998-50506

(Ultra Grey)Permatex Ultra Grey

82194;

Three Bond

1207,1215, 1216,

1217F, 1217G and

1217H

Nissan RTV Part No.

999MP-A7007

Gasket Maker for Maxima/

Quest 5-speed automatic

transmission

(RE5F22A) ––

Three Bond 1281B

or exact equivalent in

its quality

5 High Temperature,

High Strength Thread

Locking Sealant (Red)

Threadlocker

999MP-AM004P 999MP-AM004P Permatex 27200;

Three Bond 1360,

1360N, 1305 N&P,

1307N, 1335,

1335B, 1363B,

1377C, 1386B, D&E

and 1388

Loctite 648

6 Medium Strength

Thread Locking Seal-

ant (Blue) Threadlocker (service tool

removable)

999MP-AM005P 999MP-AM005P Permatex 24200,

24206, 24240,

24283 and 09178;

Three Bond 1322,

1322N, 1324 D&N,

1333D, 1361C,

1364D, 1370C and

1374

Revision: January 20102010 Versa

Page 2711 of 3745

IDENTIFICATION INFORMATIONGI-45

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

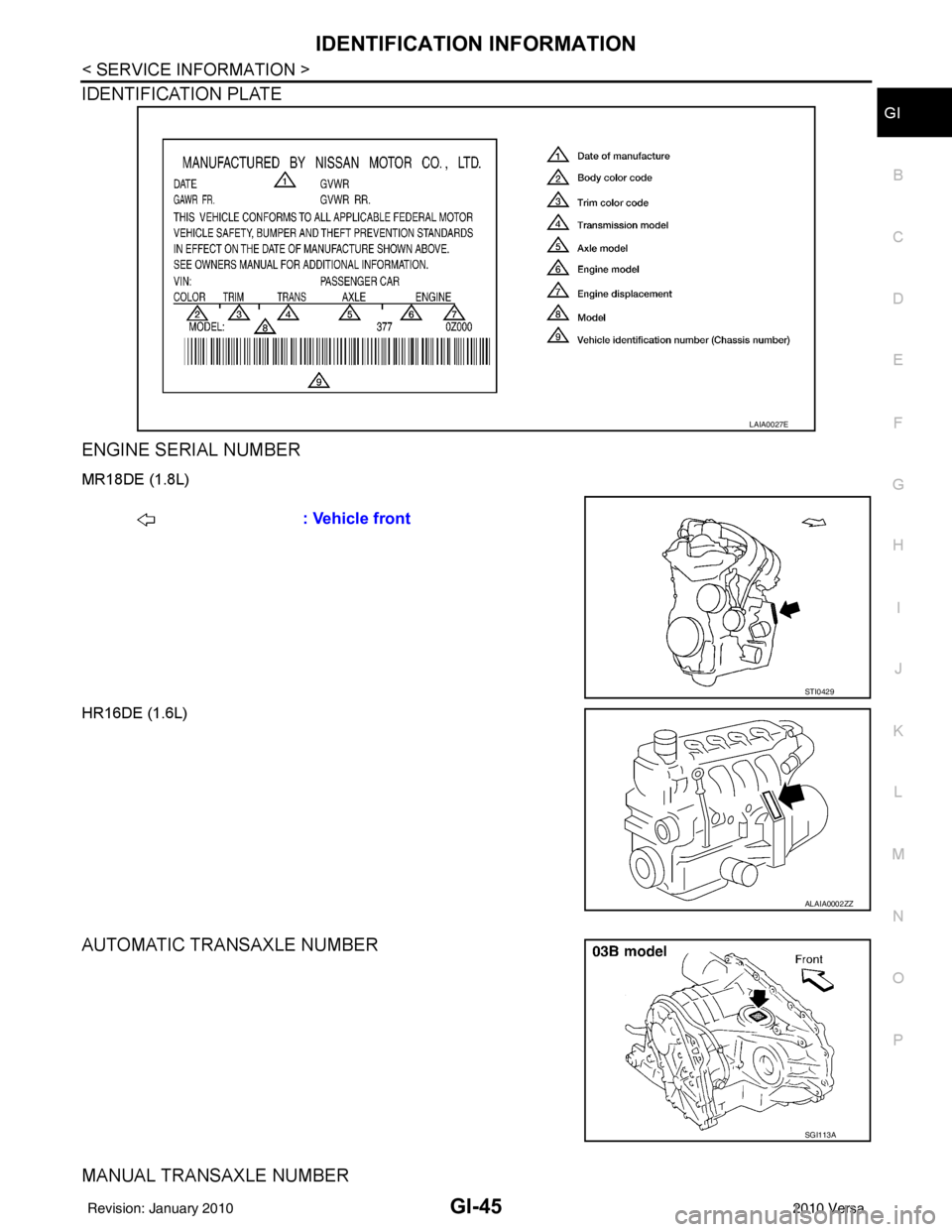

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

MR18DE (1.8L)

HR16DE (1.6L)

AUTOMATIC TRANSAXLE NUMBER

MANUAL TRANSAXLE NUMBER

LAIA0027E

: Vehicle front

STI0429

ALAIA0002ZZ

SGI113A

Revision: January 20102010 Versa

Page 2739 of 3745

GW-22

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the main power window and door lock/unlock switch (rear LH) is pressed in the down position, power is

supplied

• through main power window and door lock/unlock switch terminal 3

• to rear power window switch LH terminal 3

• through rear power window switch LH terminal 4

• to rear power window motor LH terminal 1.

Ground is supplied

• through main power window and door lock/unlock switch terminal 1

• to rear power window switch LH terminal 2

• through rear power window switch LH terminal 5

• to rear power window motor LH terminal 2.

Then, the motor lowers the window until the switch is released.

When the main power window and door lock/unlock switch (rear RH) is pressed in the down position, power is

supplied

• through main power window and door lock/unlock switch terminal 5

• to rear power window switch RH terminal 3

• through rear power window switch RH terminal 4

• to rear power window motor RH terminal 1.

Ground is supplied

• through main power window and door lock/unlock switch terminal 7

• to rear power window switch RH terminal 2

• through rear power window switch RH terminal 5

• to rear power window motor RH terminal 2.

Then, the motor lowers the window until the switch is released.

AUTO OPERATION

The power window AUTO feature enables the driver to open the window without holding the window switch in

the down position.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for front door window LH.

When in the lock position, the power window lock di sables power window and door lock/unlock switch RH and

rear power window switch LH and RH by disconnecting switch ground signal. This prevents the power window

motors from operating.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position, power is supplied for 45

seconds

• through BCM terminal 68

• to main power window and door lock/unlock switch terminal 10

• to power window and door lock/unlock switch RH terminal 8 and

• to rear power window switches LH and RH terminal 1.

When power and ground are supplied, the BCM conti nues to be energized, and the power window can be

operated.

The retained power operation is canceled when the front LH or front RH door is opened.

Retained power operation period can be changed by CONSULT-III. Refer to GW-30, "

CONSULT-III Function

(BCM)" .

ANTI-PINCH SYSTEM

Main power window and door lock/unlock switch monitors the power window motor operation and the power

window position (full closed or other) for front LH power window by the signal from encoder in front power win-

dow motor LH.

When main power window and door lock/unlock switch detects interruption during the following close opera-

tions

• automatic close operation when igniti on switch is in the ON position

• automatic close operation during retained power operation

Main power window and door lock/unlock switch controls front power window motor LH for open and the

power window will be lowered.

Revision: January 20102010 Versa

Page 2749 of 3745

GW-32

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

BCM Power Supply and Ground Circuit Inspection

INFOID:0000000005396751

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

Main Power Window and Door Lock/Unlock Switch Po wer Supply and Ground Circuit

Inspection

INFOID:0000000005396752

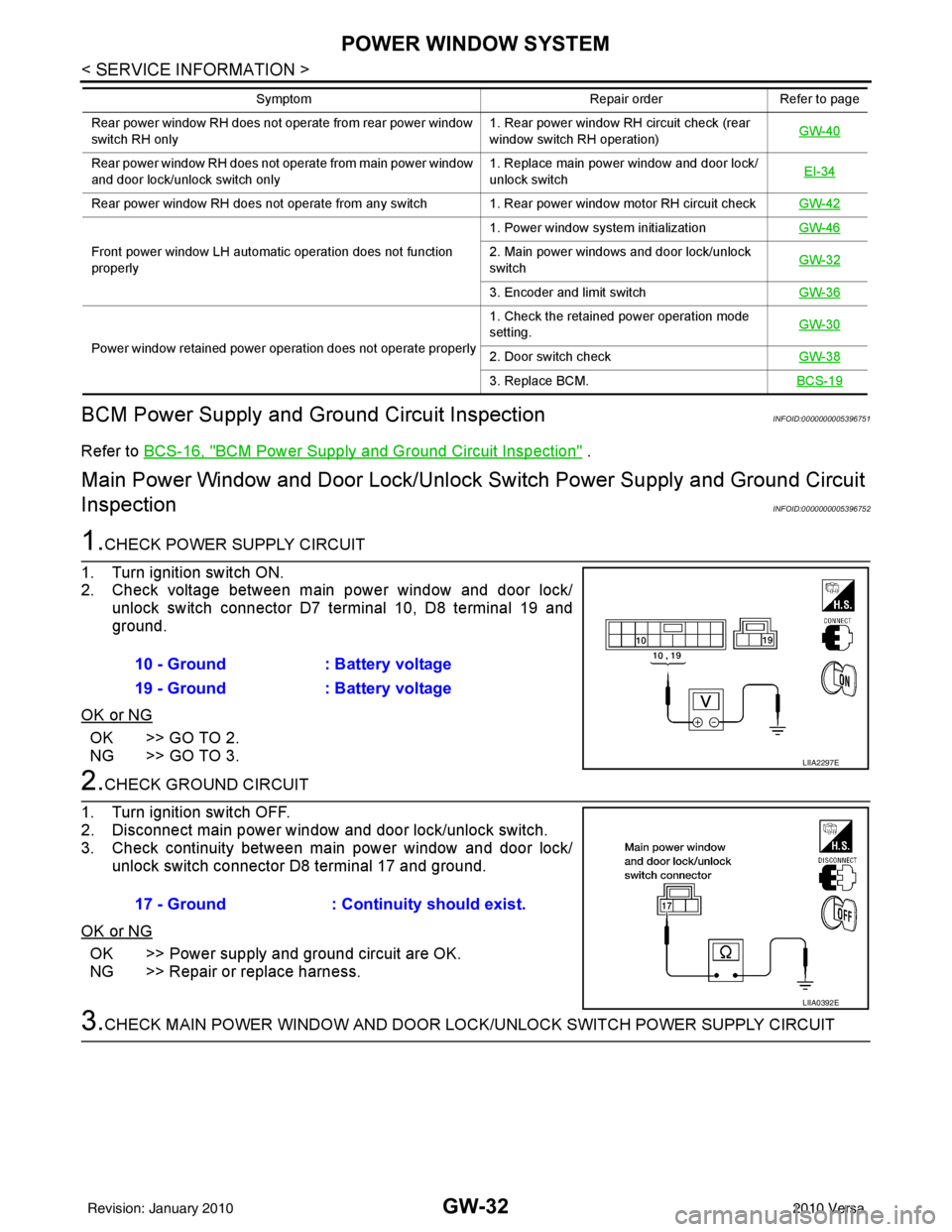

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between main power window and door lock/ unlock switch connector D7 terminal 10, D8 terminal 19 and

ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch.

3. Check continuity between main power window and door lock/ unlock switch connector D8 terminal 17 and ground.

OK or NG

OK >> Power supply and ground circuit are OK.

NG >> Repair or replace harness.

3.CHECK MAIN POWER WINDOW AND DOOR LO CK/UNLOCK SWITCH POWER SUPPLY CIRCUIT

Rear power window RH does not operate from rear power window

switch RH only 1. Rear power window RH circuit check (rear

window switch RH operation)

GW-40

Rear power window RH does not operate from main power window

and door lock/unlock switch only 1. Replace main power window and door lock/

unlock switch

EI-34

Rear power window RH does not operate from any switch 1. Rear power window motor RH circuit check

GW-42

Front power window LH automatic operation does not function

properly1. Power window system initialization

GW-462. Main power windows and door lock/unlock

switchGW-32

3. Encoder and limit switch

GW-36

Power window retained power operation does not operate properly 1. Check the retained power operation mode

setting.

GW-302. Door switch check

GW-38

3. Replace BCM.BCS-19

Symptom Repair orderRefer to page

10 - Ground: Battery voltage

19 - Ground : Battery voltage

LIIA2297E

17 - Ground : Continuity should exist.

LIIA0392E

Revision: January 20102010 Versa

Page 2827 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual LAN-18

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

DIAGNOSIS AND REPAIR WORKFLOW

• Indication of the combination meter is important to det

ect the root cause because it is the most obvious to

the custo NISSAN TIIDA 2010 Service Workshop Manual LAN-18

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

DIAGNOSIS AND REPAIR WORKFLOW

• Indication of the combination meter is important to det

ect the root cause because it is the most obvious to

the custo](/img/5/57397/w960_57397-2826.png)

LAN-18

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

DIAGNOSIS AND REPAIR WORKFLOW

• Indication of the combination meter is important to det

ect the root cause because it is the most obvious to

the customer, and it performs CAN communication with many units.

INSPECTION OF VEHICLE CONDITION

Check whether the symptom is reproduced or not.

NOTE:

Do not turn the ignition switch OFF or disconnect the bat tery cable while reproducing the error. The error may

temporarily correct itself, making it difficult to determine the root cause.

CHECK OF CAN SYSTEM TYPE (HOW TO U SE CAN SYSTEM TYPE SPECIFICATION CHART)

Determine CAN system type based on vehicle equipment.

NOTE:

• This chart is used if CONSULT-III does not automatically recognize CAN system type.

• There are two styles for CAN system type specific ation charts. Depending on the number of available sys-

tem types, either style A or style B may be used.

CAN System Type Specification Chart (Style A)

NOTE:

SKIB8717E

Revision: January 20102010 Versa

Page 3092 of 3745

INTERIOR ROOM LAMPLT-97

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

• through front door key cylinder switch LH terminal 2

• through grounds M57 and M61.

At the time the front door LH is opened, the BCM detects the front door LH is unlocked. It determines that the

interior room lamp timer operation conditions are met, and interior room lamp ON for 30 seconds.

When the key is in ignition key cylinder (key switch ON), or ignition knob switch is pushed, power is supplied

• through key switch and ignition knob switch terminal 1

• to BCM terminal 37, or

• through key switch and ignition knob switch terminal 3

• to Intelligent Key unit terminal 27.

When the key is removed from key switch (key switch OFF), power supply to BCM terminal 37 is terminated.

When the ignition knob switch is released, power supply to intelligent key unit is terminated. The BCM detects

that the key has been removed, determines that interior room lamp timer conditions are met, and turns room

lamp ON for 30 seconds.

When the front door LH opens → closes, and key is not inserted in key switch (or ignition knob switch is

released), BCM terminal 47 changes between 0V (door open) → 12V (door closed). BCM determines that

conditions for room lamp operation are met, and turns room lamp ON for 30 seconds.

Interior room lamp timer control is canceled under the following conditions:

• Front door LH is locked (with keyfob, front door ke y cylinder switch LH or door lock/unlock switch).

• Front door LH is opened (front door switch LH).

• Ignition switch ON.

INTERIOR LAMP BATTERY SAVER CONTROL

If an interior room lamp is left ON, it will not be turned OFF even when door is closed.

BCM turns off interior lamp automatically to save battery 30 minutes after ignition switch is turned off.

After lamps are turned OFF by the battery saver system, the lamps illuminate again when

• front door key cylinder switch LH is locked or unlocked

• door is opened or closed

• key is removed from ignition key cylinder or inserted in ignition key cylinder, or the ignition knob switch is pushed or released.

Interior lamp battery saver control time period can be changed by the function setting of CONSULT-III.

Revision: January 20102010 Versa

Page 3143 of 3745

MA-8

< SERVICE INFORMATION >

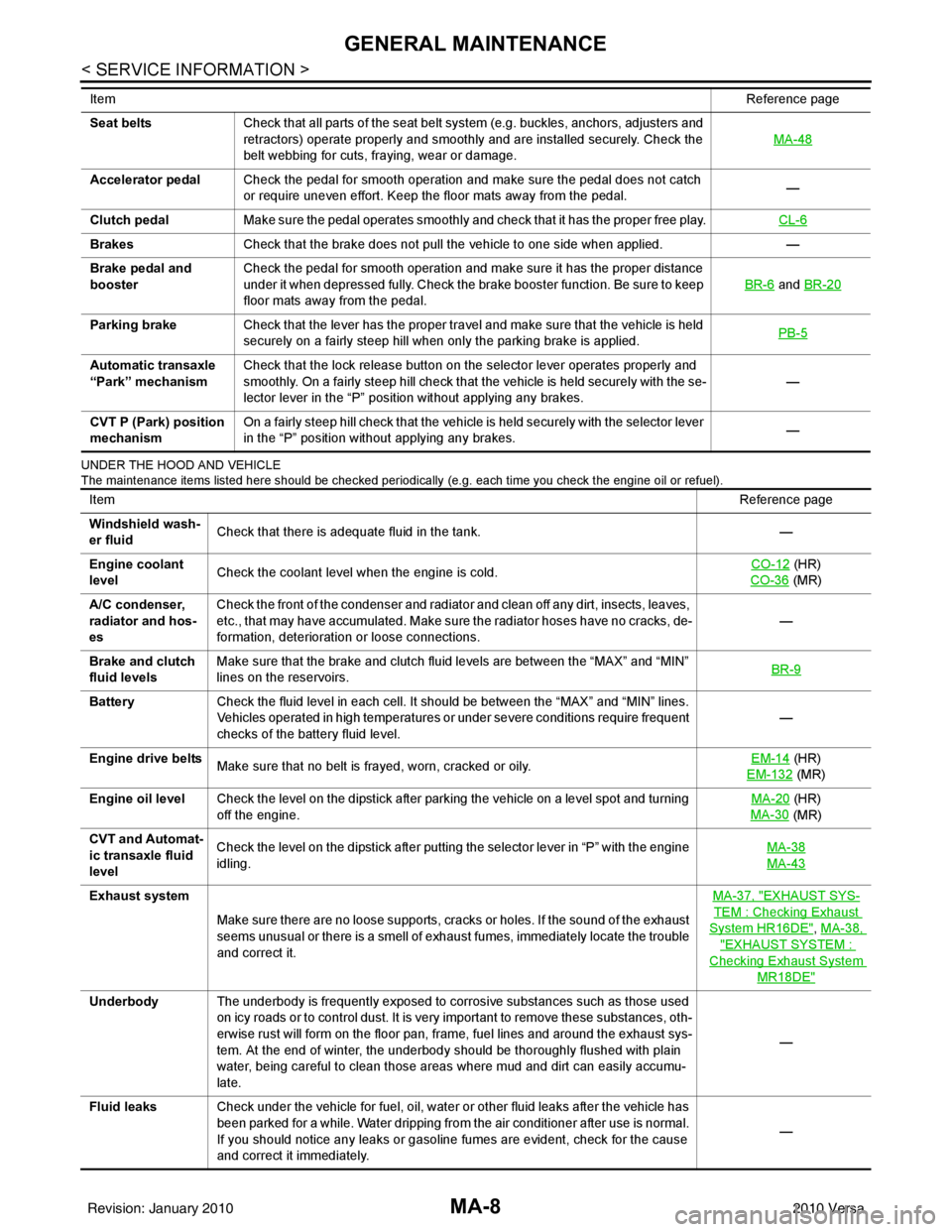

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-48

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Clutch pedal Make sure the pedal operates smoothly and check that it has the proper free play. CL-6

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-6

and

BR-20

Parking brake Check that the lever has the proper travel and make sure that the vehicle is held

securely on a fairly steep hill when only the parking brake is applied. PB-5

Automatic transaxle

“Park” mechanismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the se-

lector lever in the “P” position without applying any brakes. —

CVT P (Park) position

mechanism On a fairly steep hill check that the vehicle is held securely with the selector lever

in the “P” position without applying any brakes.

—

Item

Reference page

ItemReference page

Windshield wash-

er fluid Check that there is adequate fluid in the tank.

—

Engine coolant

level Check the coolant level when the engine is cold. CO-12

(HR)

CO-36

(MR)

A/C condenser,

radiator and hos-

es Check the front of the condenser and radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure the radiator hoses have no cracks, de-

formation, deterioration or loose connections.

—

Brake and clutch

fluid levels Make sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs.

BR-9

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require frequent

checks of the battery fluid level. —

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. EM-14

(HR)

EM-132

(MR)

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turning

off the engine. MA-20

(HR)

MA-30

(MR)

CVT and Automat-

ic transaxle fluid

level Check the level on the dipstick after putting the selector lever in “P” with the engine

idling.

MA-38

MA-43

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the exhaust

seems unusual or there is a smell of exhaust fumes, immediately locate the trouble

and correct it. MA-37, "EXHAUST SYS-

TEM : Checking Exhaust

System HR16DE", MA-38,

"EXHAUST SYSTEM :

Checking Exhaust System

MR18DE"

Underbody

The underbody is frequently exposed to corrosive substances such as those used

on icy roads or to control dust. It is very important to remove these substances, oth-

erwise rust will form on the floor pan, frame, fuel lines and around the exhaust sys-

tem. At the end of winter, the underbody should be thoroughly flushed with plain

water, being careful to clean those areas where mud and dirt can easily accumu-

late. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has

been parked for a while. Water dripping from the air conditioner after use is normal.

If you should notice any leaks or gasoline fumes are evident, check for the cause

and correct it immediately. —

Revision: January 20102010 Versa