Accelerator NISSAN TIIDA 2010 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 222 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-205

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

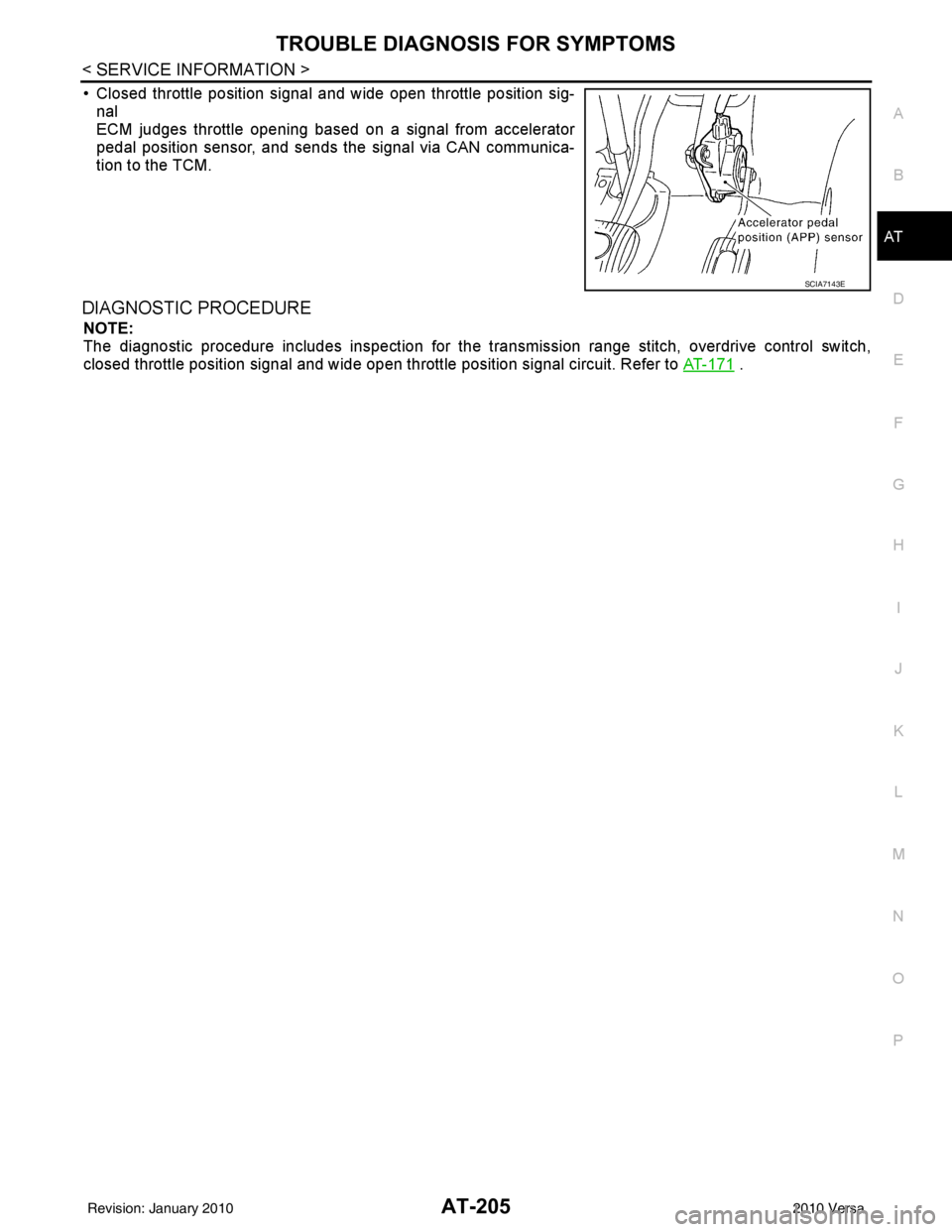

• Closed throttle position signal and wide open throttle position sig- nal

ECM judges throttle opening based on a signal from accelerator

pedal position sensor, and sends the signal via CAN communica-

tion to the TCM.

DIAGNOSTIC PROCEDURE

NOTE:

The diagnostic procedure includes inspection for the tr ansmission range stitch, overdrive control switch,

closed throttle position signal and wide open throttle position signal circuit. Refer to AT-171

.

SCIA7143E

Revision: January 20102010 Versa

Page 390 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)AT-373

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397455

*: Refer to MA-14.

Vehicle Speed at Which Gear Shifting OccursINFOID:0000000005397456

HR16DE engine models

MR18DE engine models

• At half throttle, the accelerator opening is 4/8 of the full opening.

Vehicle Speed at When Lock-up Occurs/ReleasesINFOID:0000000005397457

HR16DE engine models

MR18DE engine models

Engine HR16DEMR18DE

Automatic transaxle model RE4F03B

Automatic transaxle assembly Model code number 3CX3D, 3CX3E3CX0D

Transaxle gear ratio 1st

2.861

2nd 1.562

3rd 1.000

4th 0.697

Reverse 2.310

Final drive 4.072

Recommended fluid Genuine NISSAN Matic S ATF (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid*

Fluid capacity [ (US qt, Imp qt)] 7.7 (8-1/8, 6-3/4)

7.9 (8-3/8, 7)

Throttle position Vehicle speed km/h (MPH)

D1 → D2D2 → D3D3 → D4D4 → D3D3 → D2D2 → D1

Full throttle 49 - 57

(31 - 35) 93 - 101

(58 - 62) 148 - 156

(92 - 96) 144 - 152

(90 - 94) 82 - 90

(51 - 55) 39 - 47

(25 - 29)

Half throttle 35 - 43

(22 - 26) 59 - 67

(37 - 41) 117 - 125

(73 - 77) 59 - 67

(37 - 41) 34 - 42

(22 - 26) 15 - 23

(10 - 14)

Throttle position Vehicle speed km/h (MPH)

D

1 → D2D2 → D3D3 → D4D4 → D3D3 → D2D2 → D1

Full throttle 51 - 59

(32 - 37) 97 - 105

(60 - 65) 154 - 162

(96 - 101) 150 - 158

(93 - 98) 87 - 95

(54 - 59) 40 - 48

(25 - 30)

Half throttle 34 - 42

(21 - 26) 62 - 70

(39 - 43) 124 - 132

(77 - 82) 69 - 77

(43 - 48) 36 - 44

(22 - 27) 19 - 27

(12 - 17)

Throttle position Selector lever position Vehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

2.0/8 “D” position

73 - 81 (46 - 50) 49 - 57 (31 - 35)

“D” position (OD OFF) 86 - 94 (53 - 58) 82 - 90 (51 - 55)

Throttle position Selector lever position Vehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

2.0/8 “D” position

86 - 94 (53 - 58) 59 - 67 (37 - 42)

“D” position (OD OFF) 86 - 94 (53 - 58) 83 - 91 (52 - 57)

Revision: January 20102010 Versa

Page 856 of 3745

BR-8

< SERVICE INFORMATION >

BRAKE PEDAL

1. Disconnect accelerator pedal position sensor harness connec-tor.

2. Remove stop lamp switch and ASCD cancel switch (if equipped) from brake pedal assembly.

3. Remove snap pin and clevis pin from clevis of brake booster.

4. Remove nuts from brake pedal bracket, and remove brake pedal assembly from vehicle.

5. Remove accelerator pedal from brake pedal assembly.

INSPECTION AFTER REMOVAL

• Check brake pedal upper rivet for deformation.

• Make sure that the lapping length of sub-bracket and slide plate is at least 6.9 mm (0.272 in).

• Check brake pedal for bend, damage, and cracks on the welded parts.

• Replace brake pedal assembly if any non-standard condition is

detected.

• Check clevis pin and plastic stopper for damage and deformation. Replace clevis pin as necessary.

INSTALLATION

1. Install the accelerator pedal on the brake pedal assembly. Refer to ACC-4, "Removal and Installation".

2. Install the brake pedal assembly on the lower dash panel and tighten the brake pedal assembly nuts in the order as shown to

specification.

3. Installation of the remaining components are in the reverse order of the removal. • After installing brake pedal assembly to vehicle, adjust brake pedal. Refer to BR-6, "

Inspection and

Adjustment".

• After installing accelerator pedal, check accelerator pedal. Refer to ACC-4, "

Removal and Installation".

SFIA2044E

SFIA2866E

SBR997

AWFIA0524GB

Revision: January 20102010 Versa

Page 949 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual TROUBLE DIAGNOSISBRC-59

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACCEL POS SIG Open/close condition

of throttle valve (linked

with accelerator pedal)Accelerator pedal NISSAN TIIDA 2010 Service Workshop Manual TROUBLE DIAGNOSISBRC-59

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACCEL POS SIG Open/close condition

of throttle valve (linked

with accelerator pedal)Accelerator pedal](/img/5/57397/w960_57397-948.png)

TROUBLE DIAGNOSISBRC-59

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACCEL POS SIG Open/close condition

of throttle valve (linked

with accelerator pedal)Accelerator pedal not de-

pressed (ignition switch is ON)

0%

BRC-79, "

CAN Commu-

nication System Inspec-

tion"Depress accelerator pedal (ig-

nition switch is ON) 0 to 100%

SIDE G-SENSOR Transverse G detected

by side G-sensorVehicle stopped

Approx. 0 m/s

2

BRC-70, "Yaw Rate/Side/

Decel G Sensor System

Inspection"

Vehicle turning rightnegative value (m/

s2)

Vehicle turning left positive value (m/

s

2)

STR ANGLE SIG Steering angle detect-

ed by steering angle

sensorStraight-ahead

Approx. 0°BRC-69, "

Steering Angle

Sensor System Inspec-

tion"Steering wheel turned –720 to 720 °

PRESS SENSOR Brake fluid pressure

detected by pressure

sensorWith ignition switch ON and

brake pedal released

Approx. 0 bar

BRC-77, "

Pressure Sen-

sor System Inspection"With ignition switch ON and

brake pedal depressed –40 to 300 bar

EBD SIGNAL EBD operation EBD is active

On

—

EBD is inactive Off

ABS SIGNAL ABS operationABS is active

On

—

ABS is inactive Off

TCS SIGNAL TCS operationTCS is active

On

—

TCS is inactive Off

VDC SIGNAL VDC operationVDC is active

On

—

VDC is inactive Off

EBD FAIL SIG EBD fail-safe signal In EBD fail safe mode On

—

EBD is normal Off

ABS FAIL SIG ABS fail-safe signal In ABS fail safe mode

On

—

ABS is normal Off

TCS FAIL SIG TCS fail-safe signal In TCS fail safe mode

On

—

TCS is normal Off

VDC FAIL SIG VDC fail-safe signal In VDC fail safe mode On

—

VDC is normal Off

CRANKING SIG Crank operation Crank is active

On

—

Crank is inactive Off

FLUID LEV SW Status of brake fluid

level switchWhen brake fluid level switch

ON

On

BRC-76, "

Brake Fluid

Level Switch System In-

spection"When brake fluid level switch

OFF Off

PARK BRAKE SW Status of parking brake

switchParking brake switch is active On

BRC-79, "

Component In-

spection"Parking brake switch is inactive Off

Monitor item Display content

Data monitor

Note: Error inspection

checklist

Condition Reference value in

normal operation

Revision: January 20102010 Versa

Page 1042 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual PRECAUTIONSCVT-9

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. Turn ignition switch ON. CAUTION:

Never start engine.

7. Select “Self Diagnostic Results” in “TRANSMISSION NISSAN TIIDA 2010 Service Workshop Manual PRECAUTIONSCVT-9

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. Turn ignition switch ON. CAUTION:

Never start engine.

7. Select “Self Diagnostic Results” in “TRANSMISSION](/img/5/57397/w960_57397-1041.png)

PRECAUTIONSCVT-9

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. Turn ignition switch ON. CAUTION:

Never start engine.

7. Select “Self Diagnostic Results” in “TRANSMISSION”.

8. Shift the selector lever to “R” position.

9. Depress slightly the accelerator pedal (Pedal angle: 2/8) while depressing the brake pedal.

10. Select “Erase” with step 9.

11. Release brake pedal and accelerator pedal.

12. Turn ignition switch OFF while keeping the selector lever in “R” position.

13. Wait approximately 10 seconds.

14. Turn ignition switch ON while keeping the selector lever in “R” position.

15. Select “Special function” in “TRANSMISSION”.

16. Check that the value on “CALIB DATA” in CONSULT-II I is the same as the data listed in the table below.

• Restart the procedure from step 3 if the values are not the same.

CALIB DATA

17. Shift the selector lever to “P” position.

18. Check that the shift position indicator in combinat ion meter turns ON. (It indicates approximately 1 or 2

seconds after shifting the selector lever to “P” position.)

• Check the following items if shift position indicator does not turn ON. Repair or replace accordingly as

necessary.

- The harness between TCM and ROM ASSY in transaxle assembly is open or shorted.

- Terminals disconnected, loose, or bent from connector housing.

- Power supply and ground of TCM. Refer to CVT-113, "

Description".

PATTERN C

1. Replace transaxle assembly first, and then replace TCM.

2. Perform the service of “PATTERN A”.

(Perform the service of “PATTERN B” if TCM is replaced first.)

Removal and Installation Procedure for CVT Unit ConnectorINFOID:0000000005397762

REMOVAL

Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION

Item name Display value

UNIT CLB ID 1 00

UNIT CLB ID 2 00

UNIT CLB ID 3 00

UNIT CLB ID 4 00

UNIT CLB ID 5 00

UNIT CLB ID 6 00

SCIA2096E

Revision: January 20102010 Versa

Page 1054 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:

NISSAN TIIDA 2010 Service Workshop Manual CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:](/img/5/57397/w960_57397-1053.png)

CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting point, and lock-up operation.

• Send required output signals to the step motor and the respective solenoids.

CONTROL SYSTEM OUTLINE

The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

AWDIA0768GB

SENSORS (or SIGNAL)

⇒TCM

⇒ACTUATORS

Transmission range switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Overdrive control signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Secondary pressure sensor Shift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system

On board diagnosis Step motor

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid

valve

Shift position indicator

O/D OFF indicator lamp

Starter relay

Revision: January 20102010 Versa

Page 1055 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for NISSAN TIIDA 2010 Service Workshop Manual CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for](/img/5/57397/w960_57397-1054.png)

CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s

peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-7,

"System Description".

Input/Output Signal of TCMINFOID:0000000005397775

AWDIA0769GB

Control itemFluid

pressure control Select con-

trol Shift control Lock-up

control CAN com-

munication control Fail-safe

function (*3)

Input T

ra n sm is sio n r ang e s wit c h XXXXXX

Accelerator pedal position signal

(*1)XXXXXX

Closed throttle position signal

(*1)X XXX

Engine speed signal

(*1)XX XXX

CVT fluid temperature sensor XX XX X

Stop lamp switch signal

(*1)X XXX

Overdrive control signal

(*1)XX

Primary speed sensor X XXXX

Secondary speed sensor XXXXXX

Secondary pressure sensor XX X

T C M pow er s upp ly v olt a ge s ig n al XXXXXX

Revision: January 20102010 Versa

Page 1057 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT-24

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

mand to the step motor, and control the flow-in/flow-out of line pressure from the primary pulley to determine

the position of the moving-pulley and NISSAN TIIDA 2010 Service Workshop Manual CVT-24

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

mand to the step motor, and control the flow-in/flow-out of line pressure from the primary pulley to determine

the position of the moving-pulley and](/img/5/57397/w960_57397-1056.png)

CVT-24

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

mand to the step motor, and control the flow-in/flow-out of line pressure from the primary pulley to determine

the position of the moving-pulley and control the gear ratio.

NOTE:

The gear ratio is set for every position separately.

“D” POSITION

Shifting over all the ranges of gear ratios from the lowest to the high-

est.

OVERDRIVE-OFF MODE

Use this position for the improved engine braking.

“L” POSITION

By limiting the gear range to the lowest position, the strong driving

force and the engine brake can be secured.

DOWNHILL ENGINE BRAKE CONTROL

(AUTO ENGINE BRAKE CONTROL)

When downhill is detected with the accelerator pedal released, the engine brake will be strengthened up by

downshifting so as not to accelerate the vehicle more than necessary.

ACCELERATION CONTROL

According to vehicle speed and a change of accelerator pedal angle, driver's request for acceleration and driv-

ing scene are judged. This function assists improvem ent in acceleration feeling by making the engine speed

proportionate to the vehicle speed. And a shift map which can gain a larger driving force is available for com-

patibility of mileage with driveability.

AWDIA0770GB

SCIA1953E

SCIA1955E

Revision: January 20102010 Versa

Page 1069 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT-36

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

CVT Electrical Parts Location

INFOID:0000000005397788

1. O/D OFF indicator lamp 2. Shift position indicator3. Accelerator pedal position senso NISSAN TIIDA 2010 Service Workshop Manual CVT-36

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

CVT Electrical Parts Location

INFOID:0000000005397788

1. O/D OFF indicator lamp 2. Shift position indicator3. Accelerator pedal position senso](/img/5/57397/w960_57397-1068.png)

CVT-36

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

CVT Electrical Parts Location

INFOID:0000000005397788

1. O/D OFF indicator lamp 2. Shift position indicator3. Accelerator pedal position sensor

4. CVT unit harness connector 5. Fuel door release 6. TCM

7. Overdrive control switch

BCIA0033E

Revision: January 20102010 Versa

Page 1072 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual TROUBLE DIAGNOSISCVT-39

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. While holding down the foot brake, gradually press down the accelerator pedal.

7. Quickly read off the st NISSAN TIIDA 2010 Service Workshop Manual TROUBLE DIAGNOSISCVT-39

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. While holding down the foot brake, gradually press down the accelerator pedal.

7. Quickly read off the st](/img/5/57397/w960_57397-1071.png)

TROUBLE DIAGNOSISCVT-39

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. While holding down the foot brake, gradually press down the accelerator pedal.

7. Quickly read off the stall speed, and then quickly remove your foot from the accelerator pedal.

CAUTION:

Do not hold down the accelerat or pedal for more than 5 sec-

onds during this test.

8. Move the selector lever to the “N” position.

9. Cool down the CVT fluid. CAUTION:

Run the engine at idle for at least 1 minute.

10. Repeat steps 6 through 9 with selector lever in “R” position.

Judgement Stall Test

O: Stall speed within standard value position.

H: Stall speed is higher than standard value.

L: Stall speed is lower than standard value.

LINE PRESSURE TEST

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the CVT fluid reaches in the range of 50 to 80°C

(122 to 176 °F), then inspect the amount of CVT fluid and replenish if necessary.

NOTE: Stall speed:

CVT-176, "

Stall Speed"

SAT514G

SAT771B

Selector lever position

Expected problem location

“D” “R”

Stall rotation HO•F

orw ard c lu tc h

O H • Reverse brake

L L • Engine and torque converter one-way clutch

HH • Line pressure low

• Primary pulley

• Secondary pulley

•Steel belt

SCIA6184E

Revision: January 20102010 Versa