Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2997 of 3745

LT-2

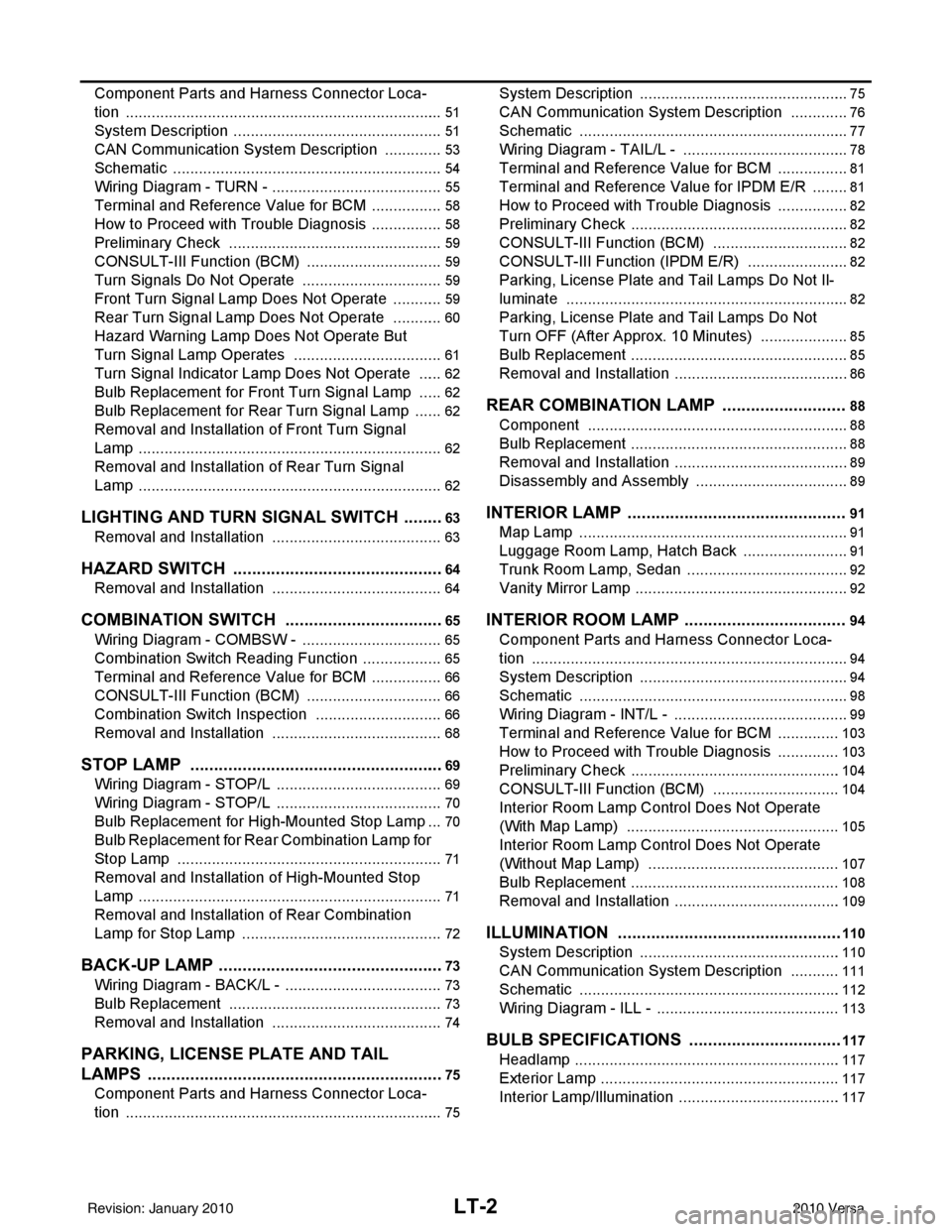

Component Parts and Harness Connector Loca-

tion ..........................................................................

51

System Description .................................................51

CAN Communication System Description ..............53

Schematic ............................................................ ...54

Wiring Diagram - TURN - ........................................55

Terminal and Reference Value for BCM .................58

How to Proceed with Trouble Diagnosis .................58

Preliminary Check ..................................................59

CONSULT-III Function (BCM) ................................59

Turn Signals Do Not Operate .................................59

Front Turn Signal Lamp Does Not Operate ............59

Rear Turn Signal Lamp Does Not Operate ............60

Hazard Warning Lamp Does Not Operate But

Turn Signal Lamp Operates ...................................

61

Turn Signal Indicator Lamp Does Not Operate ......62

Bulb Replacement for Front Turn Signal Lamp ......62

Bulb Replacement for Rear Turn Signal Lamp .......62

Removal and Installation of Front Turn Signal

Lamp .......................................................................

62

Removal and Installation of Rear Turn Signal

Lamp .......................................................................

62

LIGHTING AND TURN SIGNAL SWITCH .........63

Removal and Installation ..................................... ...63

HAZARD SWITCH .............................................64

Removal and Installation ..................................... ...64

COMBINATION SWITCH ..................................65

Wiring Diagram - COMBSW - .............................. ...65

Combination Switch Reading Function ...................65

Terminal and Reference Value for BCM .................66

CONSULT-III Function (BCM) ................................66

Combination Switch Inspection ..............................66

Removal and Installation ..................................... ...68

STOP LAMP ......................................................69

Wiring Diagram - STOP/L .................................... ...69

Wiring Diagram - STOP/L .......................................70

Bulb Replacement for High-Mounted Stop Lamp ...70

Bulb Replacement for Rear Combination Lamp for

Stop Lamp ..............................................................

71

Removal and Installation of High-Mounted Stop

Lamp .......................................................................

71

Removal and Installation of Rear Combination

Lamp for Stop Lamp ...............................................

72

BACK-UP LAMP ................................................73

Wiring Diagram - BACK/L - .................................. ...73

Bulb Replacement ..................................................73

Removal and Installation ........................................74

PARKING, LICENSE PLATE AND TAIL

LAMPS ...............................................................

75

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

75

System Description .............................................. ...75

CAN Communication System Description ..............76

Schematic ...............................................................77

Wiring Diagram - TAIL/L - .......................................78

Terminal and Reference Value for BCM .............. ...81

Terminal and Reference Value for IPDM E/R .........81

How to Proceed with Trouble Diagnosis .................82

Preliminary Check ...................................................82

CONSULT-III Function (BCM) ............................. ...82

CONSULT-III Function (IPDM E/R) ........................82

Parking, License Plate and Tail Lamps Do Not Il-

luminate ..................................................................

82

Parking, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) .....................

85

Bulb Replacement ................................................ ...85

Removal and Installation .........................................86

REAR COMBINATION LAMP ........................ ...88

Component .......................................................... ...88

Bulb Replacement ...................................................88

Removal and Installation .........................................89

Disassembly and Assembly ................................. ...89

INTERIOR LAMP ...............................................91

Map Lamp ............................................................ ...91

Luggage Room Lamp, Hatch Back .........................91

Trunk Room Lamp, Sedan ......................................92

Vanity Mirror Lamp ..................................................92

INTERIOR ROOM LAMP ...................................94

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

94

System Description .................................................94

Schematic ...............................................................98

Wiring Diagram - INT/L - .........................................99

Terminal and Reference Value for BCM ...............103

How to Proceed with Trouble Diagnosis ...............103

Preliminary Check .................................................104

CONSULT-III Function (BCM) ............................. .104

Interior Room Lamp Control Does Not Operate

(With Map Lamp) ..................................................

105

Interior Room Lamp Control Does Not Operate

(Without Map Lamp) .............................................

107

Bulb Replacement .................................................108

Removal and Installation .......................................109

ILLUMINATION .............................................. ..110

System Description .............................................. .110

CAN Communication System Description ............111

Schematic .............................................................112

Wiring Diagram - ILL - ...........................................113

BULB SPECIFICATIONS ............................... ..117

Headlamp ............................................................. .117

Exterior Lamp ........................................................117

Interior Lamp/Illumination ......................................117

Revision: January 20102010 Versa

Page 2998 of 3745

PRECAUTIONSLT-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005716032

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005394874

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3010 of 3745

HEADLAMP (FOR USA)LT-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

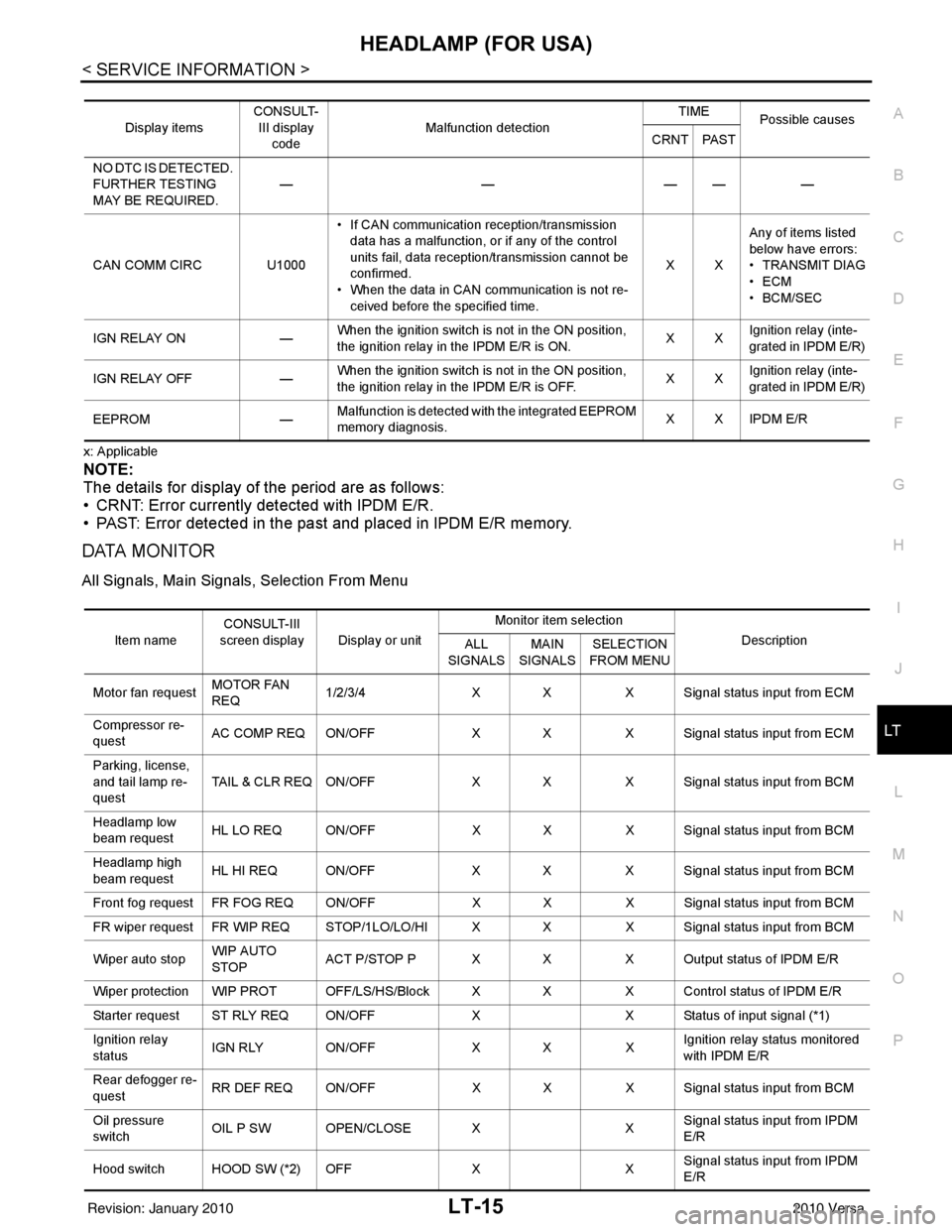

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display items CONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. ———

——

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have

errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is detected with the integrated EEPROM

memory diagnosis.

X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: January 20102010 Versa

Page 3011 of 3745

LT-16

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

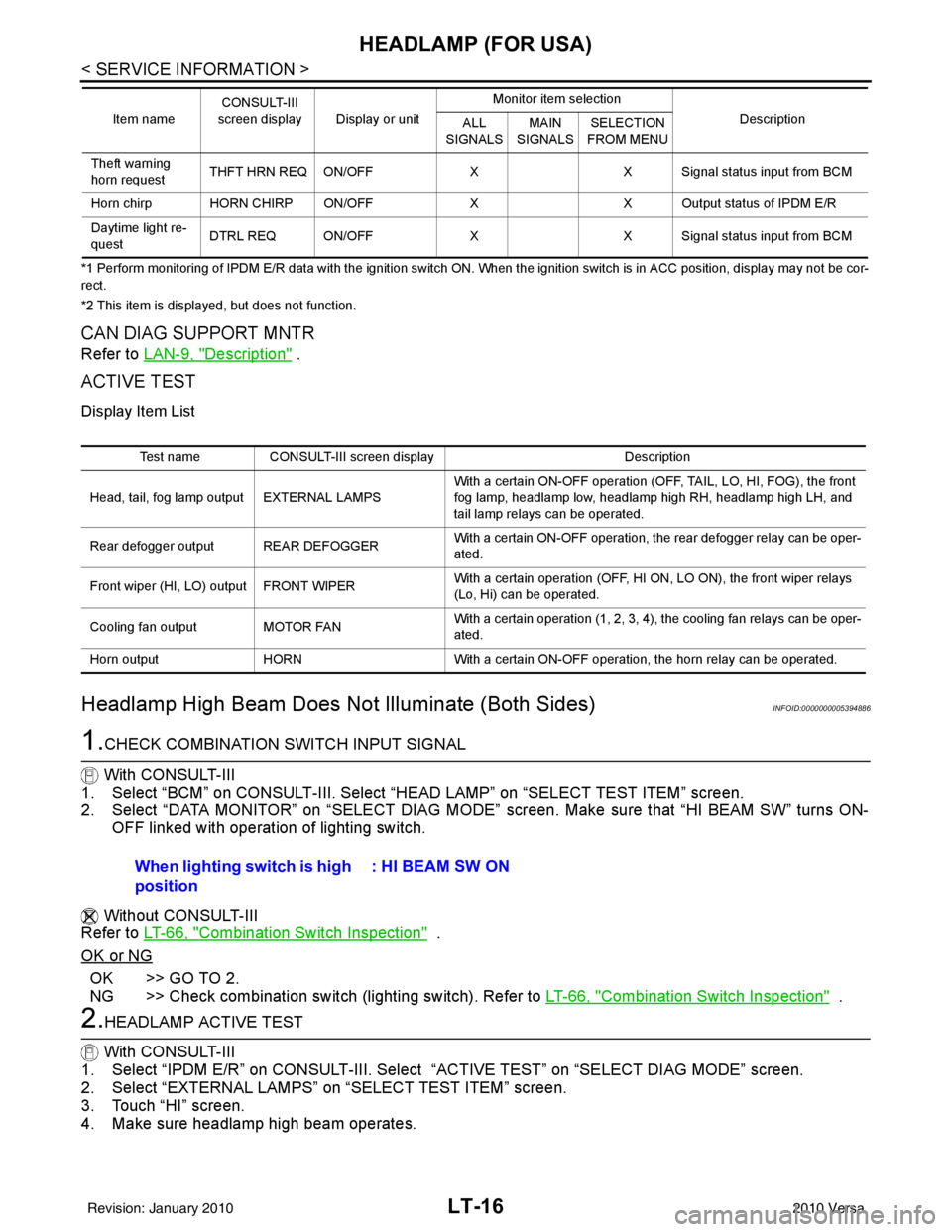

*1 Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position, display may not be cor-

rect.

*2 This item is displayed, but does not function.

CAN DIAG SUPPORT MNTR

Refer to LAN-9, "Description" .

ACTIVE TEST

Display Item List

Headlamp High Beam Does No t Illuminate (Both Sides)INFOID:0000000005394886

1.CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen. Make sure that “HI BEAM SW” turns ON-

OFF linked with operation of lighting switch.

Without CONSULT-III

Refer to LT-66, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-66, "

Combination Switch Inspection" .

2.HEADLAMP ACTIVE TEST

With CONSULT-III

1. Select “IPDM E/R” on CONSULT-III. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “HI” screen.

4. Make sure headlamp high beam operates.

Theft warning

horn request THFT HRN REQ ON/OFF

XX Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF XX Output status of IPDM E/R

Daytime light re-

quest DTRL REQ ON/OFF

XX Signal status input from BCM

Item name

CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Test name CONSULT-III screen display Description

Head, tail, fog lamp output EXTERNAL LAMPS With a certain ON-OFF operation (OFF, TAIL, LO, HI, FOG), the front

fog lamp, headlamp low, headlamp high RH, headlamp high LH, and

tail lamp relays can be operated.

Rear defogger output REAR DEFOGGER With a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPER With a certain operation (OFF, HI ON, LO ON), the front wiper relays

(Lo, Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan relays can be oper-

ated.

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

When lighting switch is high

position : HI BEAM SW ON

Revision: January 20102010 Versa

Page 3013 of 3745

LT-18

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

4. When headlamp high beam is operating, check voltage between headlamp harness connector andground.

OK or NG

OK >> GO TO 7.

NG >> GO TO 8.

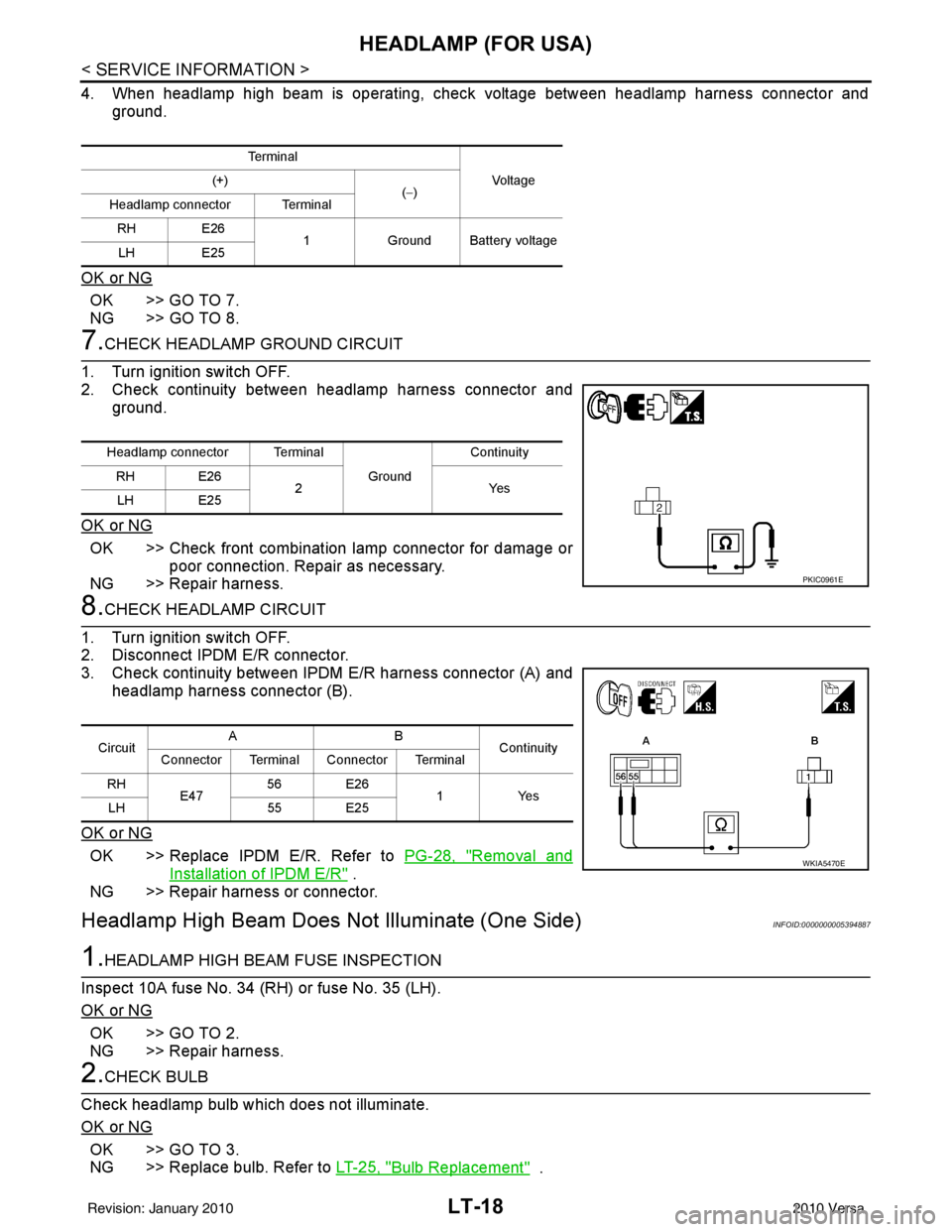

7.CHECK HEADLAMP GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between headlamp harness connector and ground.

OK or NG

OK >> Check front combination lamp connector for damage or poor connection. Repair as necessary.

NG >> Repair harness.

8.CHECK HEADLAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector (A) and

headlamp harness connector (B).

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

Headlamp High Beam Does Not Illuminate (One Side)INFOID:0000000005394887

1.HEADLAMP HIGH BEAM FUSE INSPECTION

Inspect 10A fuse No. 34 (RH) or fuse No. 35 (LH).

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

2.CHECK BULB

Check headlamp bulb which does not illuminate.

OK or NG

OK >> GO TO 3.

NG >> Replace bulb. Refer to LT-25, "

Bulb Replacement" .

Te r m i n a l

Vo l ta g e

(+)

(−)

Headlamp connector Terminal

RH E26 1Ground Battery voltage

LH E25

Headlamp connector Terminal

Ground Continuity

RH E26 2Y es

LH E25

PKIC0961E

Circuit AB

Continuity

Connector Terminal Connector Terminal

RH E47 56 E26

1 Yes

LH 55 E25

WKIA5470E

Revision: January 20102010 Versa

Page 3016 of 3745

HEADLAMP (FOR USA)LT-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

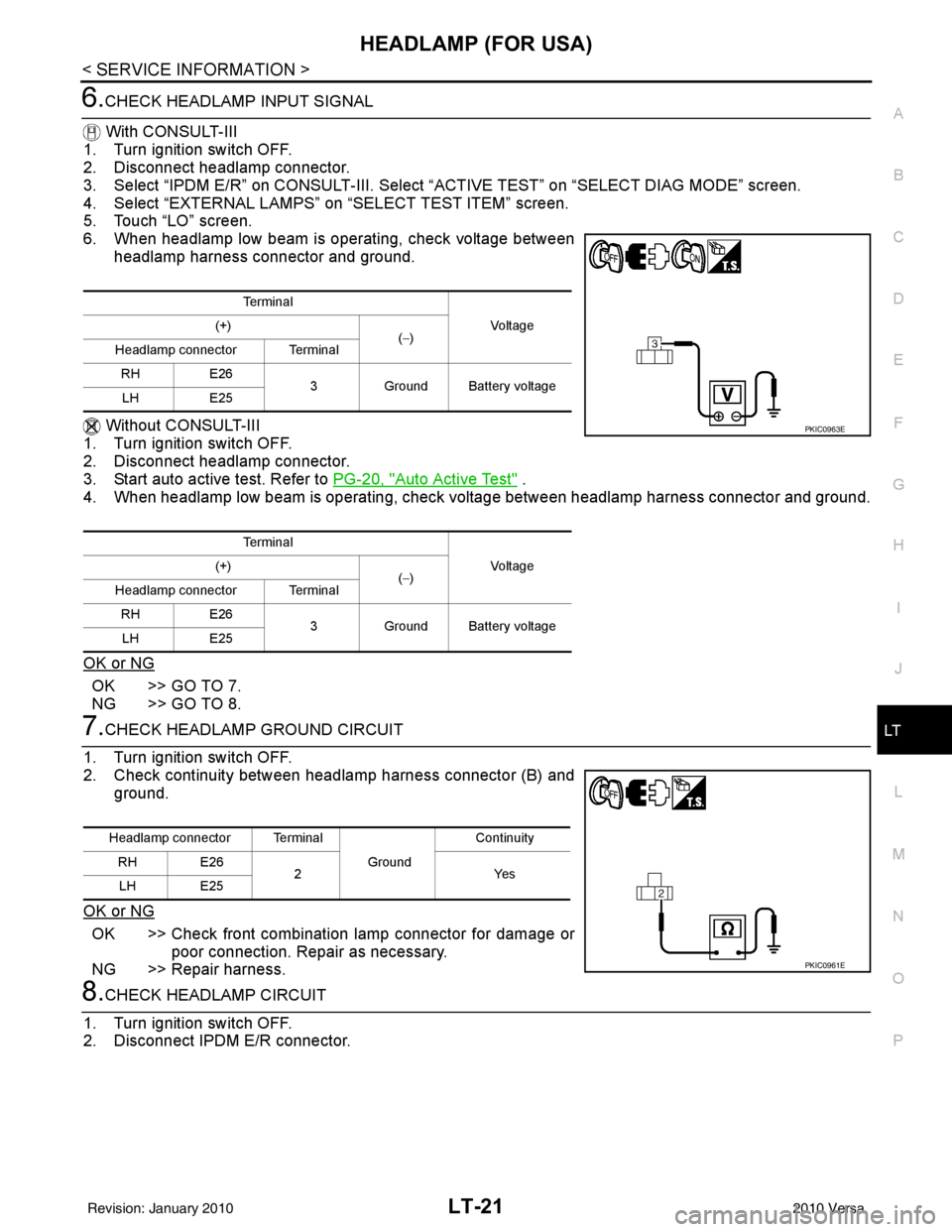

6.CHECK HEADLAMP INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect headlamp connector.

3. Select “IPDM E/R” on CONSUL T-III. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “LO” screen.

6. When headlamp low beam is operating, check voltage between

headlamp harness connector and ground.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect headlamp connector.

3. Start auto active test. Refer to PG-20, "

Auto Active Test" .

4. When headlamp low beam is operating, check voltage between headlamp harness connector and ground.

OK or NG

OK >> GO TO 7.

NG >> GO TO 8.

7.CHECK HEADLAMP GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between headlamp harness connector (B) and ground.

OK or NG

OK >> Check front combination lamp connector for damage or poor connection. Repair as necessary.

NG >> Repair harness.

8.CHECK HEADLAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

Te r m i n a l

Voltag e

(+)

(−)

Headlamp connector Terminal

RH E26

3Ground Battery voltage

LH E25

Te r m i n a l Voltag e

(+)

(−)

Headlamp connector Terminal

RH E26

3Ground Battery voltage

LH E25

PKIC0963E

Headlamp connector Terminal

Ground Continuity

RH E26 2Yes

LH E25

PKIC0961E

Revision: January 20102010 Versa

Page 3021 of 3745

LT-26

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

2. Remove the headlamp. Refer to LT-26, "Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-26, "

Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

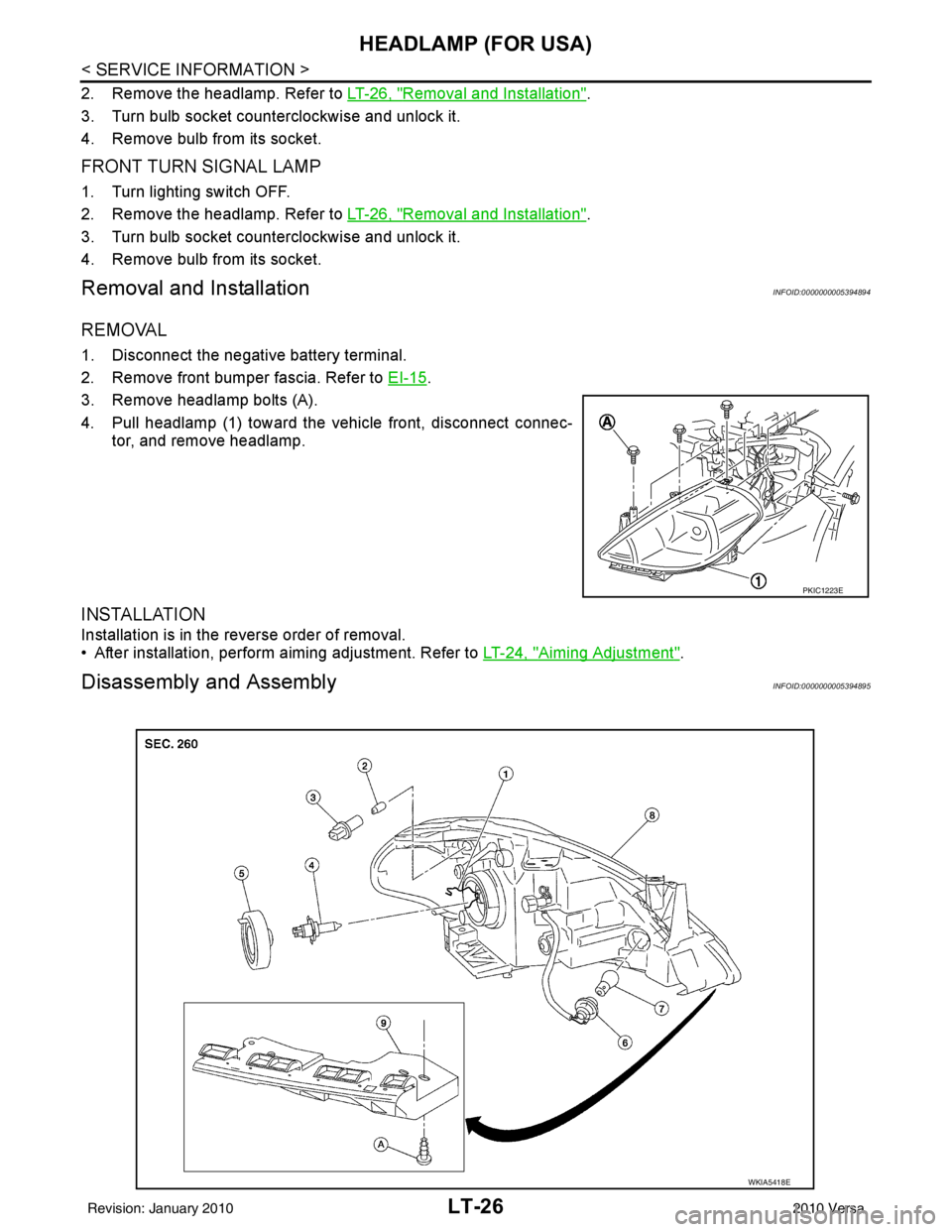

Removal and InstallationINFOID:0000000005394894

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove front bumper fascia. Refer to EI-15

.

3. Remove headlamp bolts (A).

4. Pull headlamp (1) toward the vehicle front, disconnect connec- tor, and remove headlamp.

INSTALLATION

Installation is in the reverse order of removal.

• After installation, perform aiming adjustment. Refer to LT-24, "

Aiming Adjustment".

Disassembly and AssemblyINFOID:0000000005394895

PKIC1223E

WKIA5418E

Revision: January 20102010 Versa

Page 3022 of 3745

HEADLAMP (FOR USA)LT-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

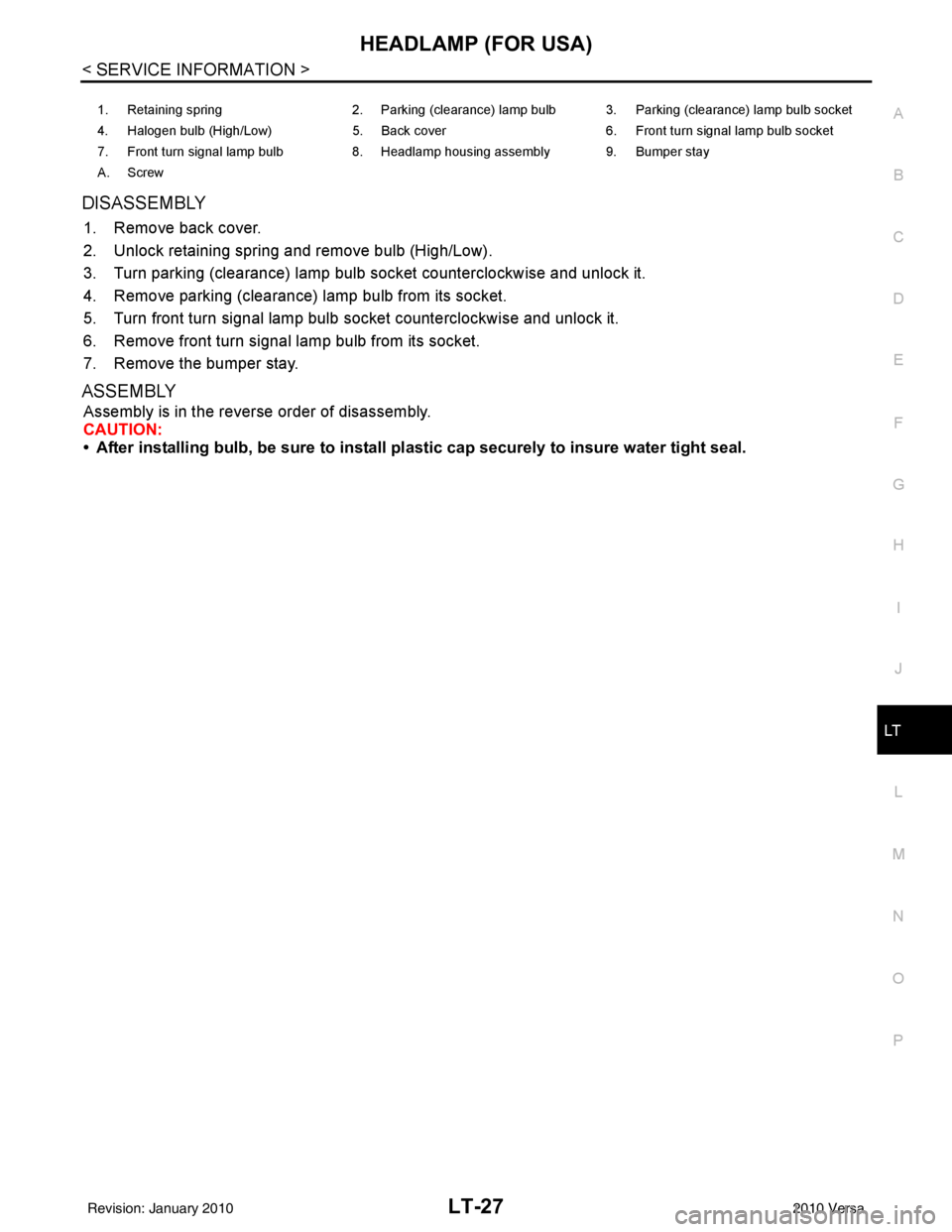

DISASSEMBLY

1. Remove back cover.

2. Unlock retaining spring and remove bulb (High/Low).

3. Turn parking (clearance) lamp bulb socket counterclockwise and unlock it.

4. Remove parking (clearance) lamp bulb from its socket.

5. Turn front turn signal lamp bulb socket counterclockwise and unlock it.

6. Remove front turn signal lamp bulb from its socket.

7. Remove the bumper stay.

ASSEMBLY

Assembly is in the reverse order of disassembly.

CAUTION:

• After installing bulb, be sure to install plastic cap securely to insure water tight seal.

1. Retaining spring 2. Parking (clearance) lamp bulb 3. Parking (clearance) lamp bulb socket

4. Halogen bulb (High/Low) 5. Back cover6. Front turn signal lamp bulb socket

7. Front turn signal lamp bulb 8. Headlamp housing assembly 9. Bumper stay

A. Screw

Revision: January 20102010 Versa

Page 3024 of 3745

![NISSAN TIIDA 2010 Service Repair Manual HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-29

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter termina NISSAN TIIDA 2010 Service Repair Manual HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-29

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter termina](/img/5/57397/w960_57397-3023.png)

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-29

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24,

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in 2ND position, the BCM re ceives an input signal requesting the headlamps to illumi-

nate. This input signal is communicated to the IPDM E/R via the CAN communication lines. The CPU located

in the IPDM E/R controls the headlamp low relay coil, which when energized, directs power

• through 15A fuse (No. 41, located in IPDM E/R)

• through IPDM E/R terminal 54

• to daytime light relay 2 terminals 1 and 5 (energizing the relay),

• through daytime light relay 2 terminal 3

• to front combination lamp RH terminal 3, and

• through 15A fuse (No. 40, located in IPDM E/R)

• through IPDM E/R terminal 52

• to front combination lamp LH terminal 3.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24,

• to headlamp RH terminal 2 via

• daytime light relay 1 terminals 3 and 4

• through grounds E15 and E24.

With power and ground supplied, low beam headlamps illuminate.

High Beam/Flash-to-Pass Operation

With the lighting switch in 2ND position and high beam s witch in the HIGH position, the BCM receives input

signal requesting the headlamp high beams to illuminate. The flash-to-pass feature can be used any time and

also sends a signal to the BCM. This input signal is communicated to the IPDM E/R and the combination

meter via the CAN communication lines. The CPU locat ed in the IPDM E/R controls the headlamp high relay

coil, which when energized, directs power

• through 10A fuse (No. 34, located in IPDM E/R)

• through IPDM E/R terminal 56

• to front combination lamp RH terminal 1, and

• through 10A fuse (No. 35, located in IPDM E/R)

• through IPDM E/R terminal 55

• to front combination lamp LH terminal 1.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24, and

• to front combination lamp RH terminal 2 via

• daytime light relay 1 terminals 3 and 4

• through grounds E15 and E24.

With power and ground supplied, the high beam headlamps illuminate.

The BCM sends a signal to the combination meter requesting the high beam indicator lamp to turn ON.

Daytime Light System Operation

With the lighting switch in the OFF or 1ST position (parking lamps ON), the BCM receives inputs requesting

the headlights off. If the parking brake is released and the engine is running, the BCM then sends a signal, via

the CAN communication lines, requesting the IPDM E/R to activate the daytime light system. The CPU located

in the IPDM E/R controls the daytime light relay 1 coil, which when energized, directs power

• from daytime light relay 1 terminal 3

• to front combination lamp RH terminal 2,

• through front combination lamp RH high beam terminal 1

Revision: January 20102010 Versa

Page 3025 of 3745

LT-30

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

• to IPDM E/R terminal 56,

• through 10A fuse (No. 34, located in IPDM E/R) and

• through both de-energized headlamp high relays

• to 10A fuse (No. 35, located in IPDM E/R),

• through IPDM E/R terminal 55

• to front combination lamp LH terminal high beam 1.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24,

• to daytime light relay 1 terminal 1

• through IPDM E/R terminal 6.

With power and ground supplied, high beam headlamps illuminate at reduced intensity.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-75, "System Description" .

CAN Communication System DescriptionINFOID:0000000005394898

Refer to LAN-7, "System Description" .

Revision: January 20102010 Versa