Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3112 of 3745

BULB SPECIFICATIONSLT-117

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

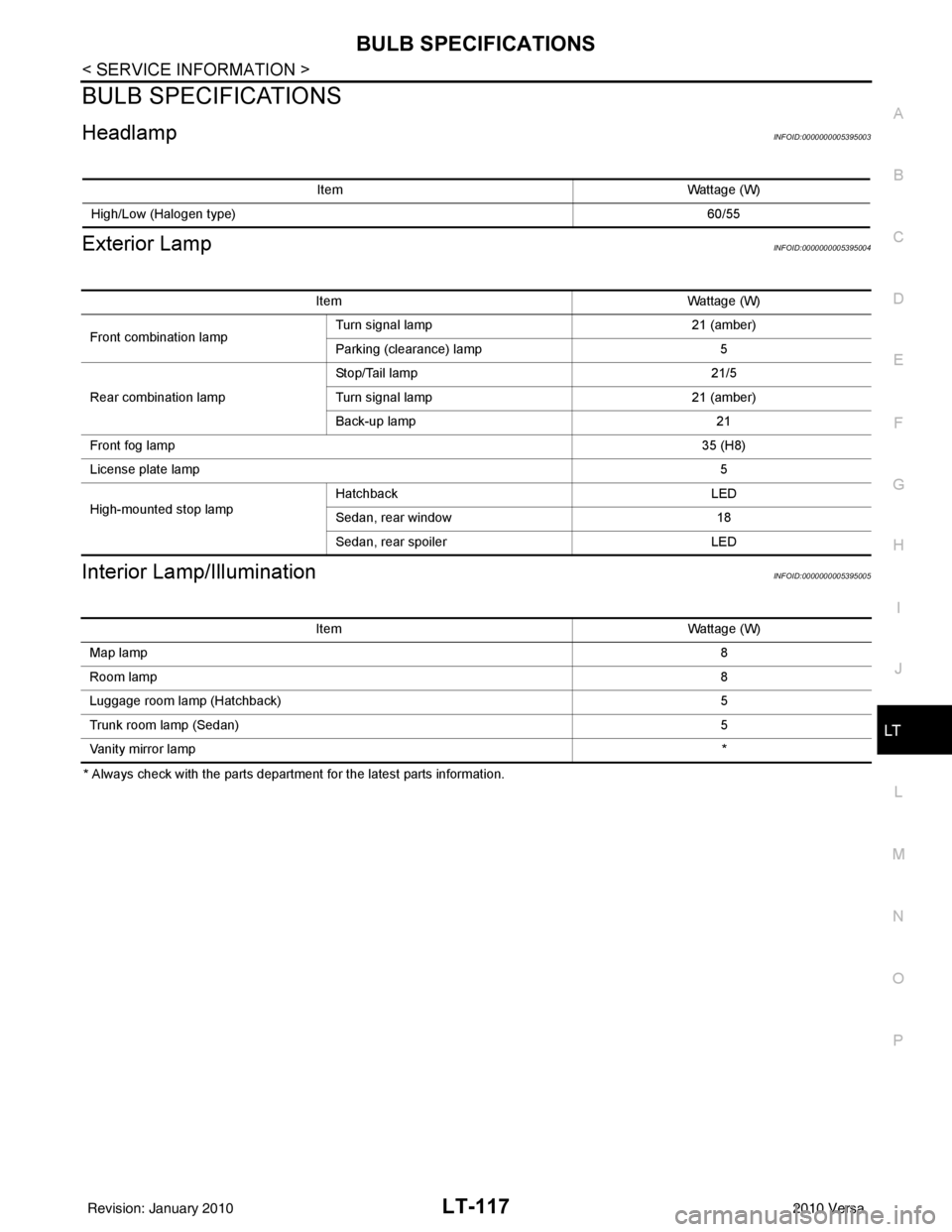

BULB SPECIFICATIONS

HeadlampINFOID:0000000005395003

Exterior LampINFOID:0000000005395004

Interior Lamp/IlluminationINFOID:0000000005395005

* Always check with the parts department for the latest parts information. Item Wattage (W)

High/Low (Halogen type) 60/55

ItemWattage (W)

Front combination lamp Turn signal lamp

21 (amber)

Parking (clearance) lamp 5

Rear combination lamp Stop/Tail lamp

21/5

Turn signal lamp 21 (amber)

Back-up lamp 21

Front fog lamp 35 (H8)

License plate lamp 5

High-mounted stop lamp Hatchback

LED

Sedan, rear window 18

Sedan, rear spoiler LED

ItemWattage (W)

Map lamp 8

Room lamp 8

Luggage room lamp (Hatchback) 5

Trunk room lamp (Sedan) 5

Vanity mirror lamp *

Revision: January 20102010 Versa

Page 3114 of 3745

![NISSAN TIIDA 2010 Service Repair Manual LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713914

The Supplemental Res NISSAN TIIDA 2010 Service Repair Manual LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713914

The Supplemental Res](/img/5/57397/w960_57397-3113.png)

LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713914

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005398151

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3119 of 3745

![NISSAN TIIDA 2010 Service Repair Manual ENGINE OILLU-7

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000005398157

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level su NISSAN TIIDA 2010 Service Repair Manual ENGINE OILLU-7

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000005398157

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level su](/img/5/57397/w960_57397-3118.png)

ENGINE OILLU-7

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000005398157

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level surface, wait 10 minutes and check the engine oil level.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white milky appearance or excessive contamination.

• If engine oil becomes white, it is highly probable t hat it is contaminated with engine coolant. Repair or

replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder head and camshaft bracket

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• For engine oil pressure check the transaxle should be in “Park position” (A/T models) or “Neutral

position” (M/T models), and apply the parking brake securely.

1. Check engine oil level.

2. Remove engine under cover. Refer to EI-15, "

Removal and Installation".

3. Disconnect harness connector at oil pressure switch (2), and remove oil pressure switch (2) from the cylinder block (1) using

suitable tool.

CAUTION:

Never drop or shock oil pressure switch.

JPBIA0554ZZ

PBIC3817E

Revision: January 20102010 Versa

Page 3121 of 3745

![NISSAN TIIDA 2010 Service Repair Manual OIL FILTERLU-9

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

OIL FILTER

Removal and InstallationINFOID:0000000005398160

REMOVAL

1. Remove engine under cover. Refer to

EI-15, "Re NISSAN TIIDA 2010 Service Repair Manual OIL FILTERLU-9

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

OIL FILTER

Removal and InstallationINFOID:0000000005398160

REMOVAL

1. Remove engine under cover. Refer to

EI-15, "Re](/img/5/57397/w960_57397-3120.png)

OIL FILTERLU-9

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

OIL FILTER

Removal and InstallationINFOID:0000000005398160

REMOVAL

1. Remove engine under cover. Refer to

EI-15, "Removal and Installation".

2. Drain engine oil. Refer to LU-8, "

Draining".

3. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

4. Refill engine with new engine oil. Refer to LU-8, "

Refilling".

5. Install engine undercover. Refer to EI-15, "

Removal and Installation".

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-7, "Inspection".

2. Start engine, and make sure there are no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust as necessary. Refer to LU-7, "

Inspection".

Tool number : KV10115801 (J-38956)

PBIC3818E

SMA010

Oil filter: : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Revision: January 20102010 Versa

Page 3124 of 3745

![NISSAN TIIDA 2010 Service Repair Manual LU-12

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713915

T NISSAN TIIDA 2010 Service Repair Manual LU-12

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713915

T](/img/5/57397/w960_57397-3123.png)

LU-12

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713915

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005398164

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3129 of 3745

![NISSAN TIIDA 2010 Service Repair Manual ENGINE OILLU-17

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000005398169

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level surface, wait 10 minutes an NISSAN TIIDA 2010 Service Repair Manual ENGINE OILLU-17

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000005398169

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level surface, wait 10 minutes an](/img/5/57397/w960_57397-3128.png)

ENGINE OILLU-17

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000005398169

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level surface, wait 10 minutes and check the engine oil level.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white milky appearance or excessive contamination.

• If engine oil becomes white, it is highly probable t hat it is contaminated with engine coolant. Repair or

replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• For engine oil pressure check the transaxle should be in “ Park position” (A/T models) and (CVT models) or “Neutral position” (M/T mode ls), and apply the parking brake securely.

1. Check engine oil level.

2. Remove engine under cover. Refer to EI-15, "

Removal and Installation".

3. Disconnect harness connector at oil pressure switch (1), and remove oil pressure switch (1) from the cylinder block using suit-

able tool.

• Oil pan (lower) (2)

• : Front

CAUTION:

Do not drop or shock oil pressure switch.

WBIA0776E

PBIC3310E

Revision: January 20102010 Versa

Page 3131 of 3745

![NISSAN TIIDA 2010 Service Repair Manual ENGINE OILLU-19

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil. NISSAN TIIDA 2010 Service Repair Manual ENGINE OILLU-19

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil.](/img/5/57397/w960_57397-3130.png)

ENGINE OILLU-19

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil.

5. Install drain plug (2) with new washer. Refer to EM-143, "

Com-

ponent".

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14

.

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these specifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to LU-17, "

Inspection".

PBIC3915E

Revision: January 20102010 Versa

Page 3132 of 3745

![NISSAN TIIDA 2010 Service Repair Manual LU-20

< SERVICE INFORMATION >[MR18DE]

OIL FILTER

OIL FILTER

Removal and InstallationINFOID:0000000005398171

REMOVAL

1. Remove engine under cover. Refer to

EI-15, "Removal and Installation".

2. Drain NISSAN TIIDA 2010 Service Repair Manual LU-20

< SERVICE INFORMATION >[MR18DE]

OIL FILTER

OIL FILTER

Removal and InstallationINFOID:0000000005398171

REMOVAL

1. Remove engine under cover. Refer to

EI-15, "Removal and Installation".

2. Drain](/img/5/57397/w960_57397-3131.png)

LU-20

< SERVICE INFORMATION >[MR18DE]

OIL FILTER

OIL FILTER

Removal and InstallationINFOID:0000000005398171

REMOVAL

1. Remove engine under cover. Refer to

EI-15, "Removal and Installation".

2. Drain engine oil. Refer to LU-18, "

Changing Engine Oil".

3. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oilmay be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine NISSAN Oil Filter or equivalent.

• When removing, prepare a sh op cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil th at spills on engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

4. Refill engine with new engine oil. Refer to LU-18, "

Changing Engine Oil".

5. Install engine under cover. Refer to EI-15, "

Removal and Installation".

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-17, "Inspection".

2. Start engine, and make sure there are no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust as necessary. Refer to LU-17, "

Inspection".

Tool number : KV10115801 (J-38956)

PBIC3818E

SMA010

Oil filter: : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Revision: January 20102010 Versa

Page 3134 of 3745

![NISSAN TIIDA 2010 Service Repair Manual LU-22

< SERVICE INFORMATION >[MR18DE]

OIL PUMP

2. Remove oil pump.

• Loosen bolts in reverse order as shown.

INSTALLATION

1. Install oil pump. • Tighten bolts in numerical order as shown.

2. Insta NISSAN TIIDA 2010 Service Repair Manual LU-22

< SERVICE INFORMATION >[MR18DE]

OIL PUMP

2. Remove oil pump.

• Loosen bolts in reverse order as shown.

INSTALLATION

1. Install oil pump. • Tighten bolts in numerical order as shown.

2. Insta](/img/5/57397/w960_57397-3133.png)

LU-22

< SERVICE INFORMATION >[MR18DE]

OIL PUMP

2. Remove oil pump.

• Loosen bolts in reverse order as shown.

INSTALLATION

1. Install oil pump. • Tighten bolts in numerical order as shown.

2. Install the timing chain and oil pump drive chain. Refer to EM-157, "

Removal and Installation".

1 : Oil pump

2 : Oil pan (upper)

: Engine front

PBIC3532J

1 : Oil pump

2 : Oil pan (upper): Engine front

PBIC3532J

Revision: January 20102010 Versa

Page 3138 of 3745

PRECAUTIONSMA-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

SERVICE INFORMATION

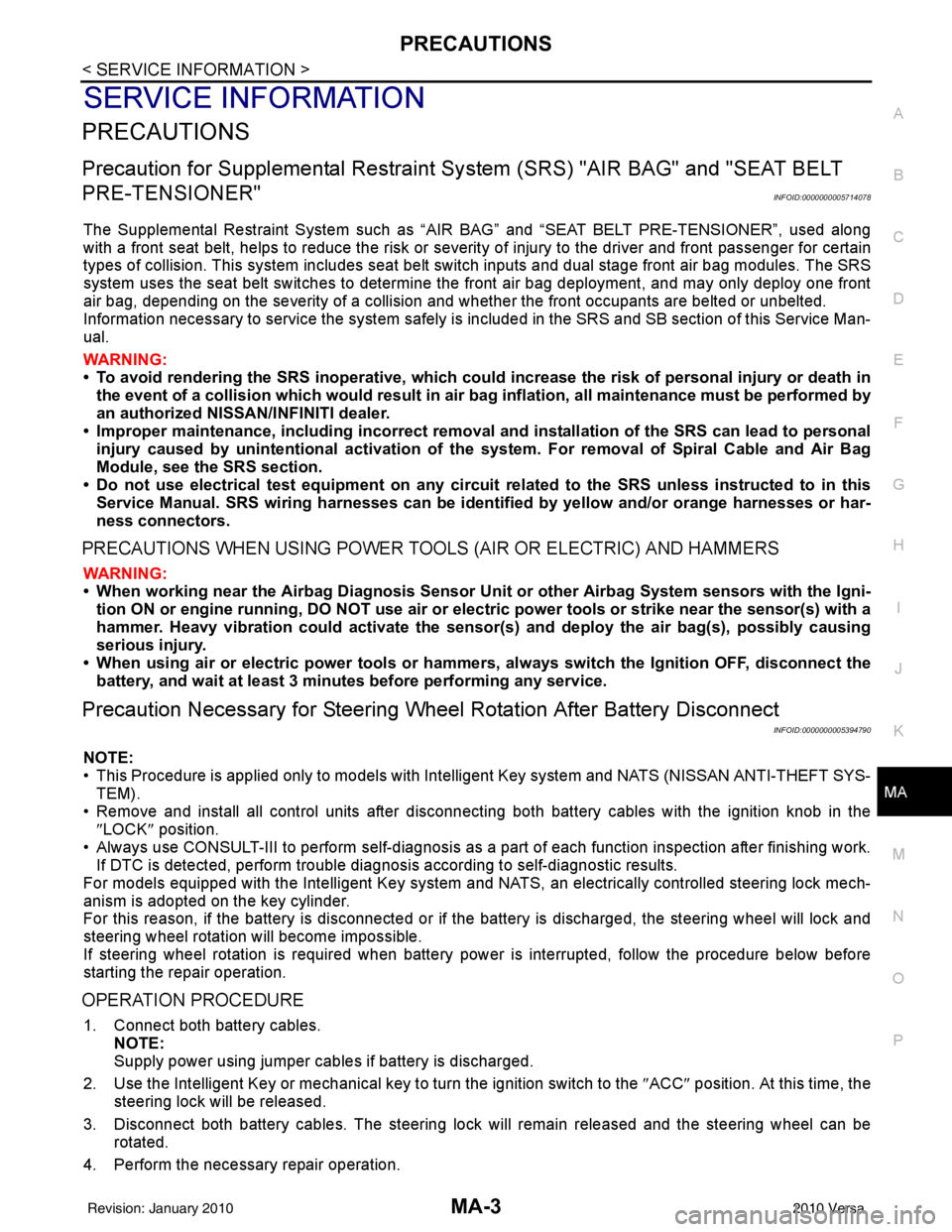

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005714078

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005394790

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa