Output speed sensor NISSAN TIIDA 2010 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1113 of 3745

![NISSAN TIIDA 2010 Service Manual PDF CVT-80

< SERVICE INFORMATION >[RE0F08B]

P0720 OUTPUT SPEED SENSOR

3. Check continuity between TCM connector terminals and sec-

ondary speed sensor harness connector terminal. Refer to CVT-

37, "Circu NISSAN TIIDA 2010 Service Manual PDF CVT-80

< SERVICE INFORMATION >[RE0F08B]

P0720 OUTPUT SPEED SENSOR

3. Check continuity between TCM connector terminals and sec-

ondary speed sensor harness connector terminal. Refer to CVT-

37, "Circu](/img/5/57397/w960_57397-1112.png)

CVT-80

< SERVICE INFORMATION >[RE0F08B]

P0720 OUTPUT SPEED SENSOR

3. Check continuity between TCM connector terminals and sec-

ondary speed sensor harness connector terminal. Refer to CVT-

37, "Circuit Diagram" .

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> 10 A fuse (No. 49, located in the IPDM E/R) or ignition switch are malfunctioning.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK HARNESS BETWEEN TCM AND SECO NDARY SPEED SENSOR (SENSOR GROUND)

1. Turn ignition switch OFF.

2. Disconnect TCM connector and secondary speed sensor harness connector.

3. Check continuity between TCM connector terminal and second- ary speed sensor harness connector terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK DTC

Perform CVT-76, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 9.

9.CHECK TCM

1. Check TCM input/output signals. Refer to CVT-46, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Item Connector Terminal Continuity

TCM E3110

Ye s

Secondary speed sensor F483

TCM E3119

Ye s

Secondary speed sensor F483

SCIA2369E

Item Connector Terminal Continuity

TCM E3242

Ye s

Secondary speed sensor F481

SCIA2347E

Revision: January 20102010 Versa

Page 1116 of 3745

![NISSAN TIIDA 2010 Service Manual PDF P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005397852

TCM selects the gear ratio using the NISSAN TIIDA 2010 Service Manual PDF P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005397852

TCM selects the gear ratio using the](/img/5/57397/w960_57397-1115.png)

P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005397852

TCM selects the gear ratio using the engine load (throttle position), the primary pulley revolution speed, and

the secondary pulley revolution speed as input signal. T hen it changes the operating pressure of the primary

pulley and the secondary pulley and changes the groove width of the pulley.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397853

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397854

• This is not an OBD-II self-diagnostic item.

• TCM calculates the actual gear ratio with primary speed sensor and secondary speed sensor.

• Diagnostic trouble code “P0730” with CONSULT-III is detected, when TCM receives an unexpected gear

ratio signal.

Possible CauseINFOID:0000000005397855

Transaxle assembly

DTC Confirmation ProcedureINFOID:0000000005397856

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds. TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-83, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005397857

1.CHECK DTC

Perform CVT-83, "

DTC Confirmation Procedure".

Are any DTC displayed?

YES - 1>> DTC except for “P0730” is displayed: Go to Check the DTC detected item. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

YES - 2>> DTC for “P0730” is displayed: Replace the transaxle assembly. Refer to CVT-173, "

Removal and

Installation".

NO >> INSPECTION END

Item name Condition Display value (Approx.)

GEAR RATIO During driving 2.56 - 0.43

Revision: January 20102010 Versa

Page 1123 of 3745

![NISSAN TIIDA 2010 Service Manual PDF CVT-90

< SERVICE INFORMATION >[RE0F08B]

P0744 TORQUE CONVERTER

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to CVT-37, "

Inspections before Trouble D NISSAN TIIDA 2010 Service Manual PDF CVT-90

< SERVICE INFORMATION >[RE0F08B]

P0744 TORQUE CONVERTER

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to CVT-37, "

Inspections before Trouble D](/img/5/57397/w960_57397-1122.png)

CVT-90

< SERVICE INFORMATION >[RE0F08B]

P0744 TORQUE CONVERTER

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to CVT-37, "

Inspections before Trouble Diagnosis".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts. Refer to CVT-37, "

Inspections before Trouble Diagnosis".

3.DETECT MALFUNCTIONING ITEM

Check the following:

• Torque converter clutch solenoid valve. Refer to CVT-87, "

Component Inspection".

• Lock-up select solenoid valve. Refer to CVT-127, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SECONDARY SPEED SENSOR SYSTEM AND PRIMARY SPEED SENSOR SYSTEM

Check secondary speed sensor system and primary speed sensor system. Refer to CVT-76

, CVT-72.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK DTC

Perform CVT-89, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to CVT-46, "

TCM Terminal and Reference Value".

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> 1. Repair or replace damaged parts. 2. Replace the transaxle assembly. Refer to CVT-173, "

Removal and Installation".

Item nameCondition Display value

ENG SPEED SIG Eng ine runningClosely matches the ta-

chometer reading.

PRI SPEED SEN During driving (lock-up ON) Approximately matches

the engine speed.

Revision: January 20102010 Versa

Page 1144 of 3745

![NISSAN TIIDA 2010 Service Manual PDF P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005397913

• The secondary pres NISSAN TIIDA 2010 Service Manual PDF P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005397913

• The secondary pres](/img/5/57397/w960_57397-1143.png)

P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005397913

• The secondary pressure solenoid valve is included in the control valve assembly.

• The secondary pressure solenoid valve regulates the secondary pressure to suit the driving condition in

response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397914

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397915

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0868” with CONSULT-III is det ected when secondary fluid pressure is too low

compared with the commanded value while driving.

Possible CauseINFOID:0000000005397916

• Harness or connectors (Solenoid circuit is open or shorted.)

• Secondary pressure solenoid valve system

• Secondary pressure sensor

• Line pressure control system

DTC Confirmation ProcedureINFOID:0000000005397917

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Start engine and maintain the following conditions for at least 10 consecutive seconds. VEHICLE SPEED (accelerate slowly): 0 → 50 km/h (31 MPH)

ACC PEDAL OPEN: 0.5/8 - 1.0/8

RANGE: “D” position

4. If DTC is detected, go to CVT-111, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005397918

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start vehicle and read out the value of “SEC PRESS”.

OK or NG

Item name Condition Display value (Approx.)

SEC PRESS “N” position idle 0.8 MPa

Item nameConditionDisplay value (Approx.)

SEC PRESS “N” position idle0.8 MPa

Revision: January 20102010 Versa

Page 1166 of 3745

![NISSAN TIIDA 2010 Service Manual PDF P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005397968

• The step motor is included in the control valve asse NISSAN TIIDA 2010 Service Manual PDF P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005397968

• The step motor is included in the control valve asse](/img/5/57397/w960_57397-1165.png)

P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005397968

• The step motor is included in the control valve assembly.

• The step motor's 4 aspects of ON/OFF change according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when electrical system is OK, but mechanical system is NG.

• This diagnosis item is detected when the state of the changing the speed mechanism in unit does not oper- ate normally.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397969

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397970

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1778” with CONSULT-III is detected under the following conditions.

- When not changing the pulley ratio according to the instruction of TCM.

Possible CauseINFOID:0000000005397971

Step motor

DTC Confirmation ProcedureINFOID:0000000005397972

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC Confirmation Procedure”, confirm “Hi” or “Mid” or “Low” fixation by “PRI

SPEED” and “VEHICLE SPEED” on “DATA MONITOR MODE”.

• If hi-geared fixation occurred, go to CVT-134, "

Diagnosis Procedure".

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds. TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-134, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

STM STEP During driving(−

20) - (+180) step

GEAR RATIO 2.56 - 0.43

Revision: January 20102010 Versa

Page 1220 of 3745

DI-10

< SERVICE INFORMATION >

COMBINATION METERS

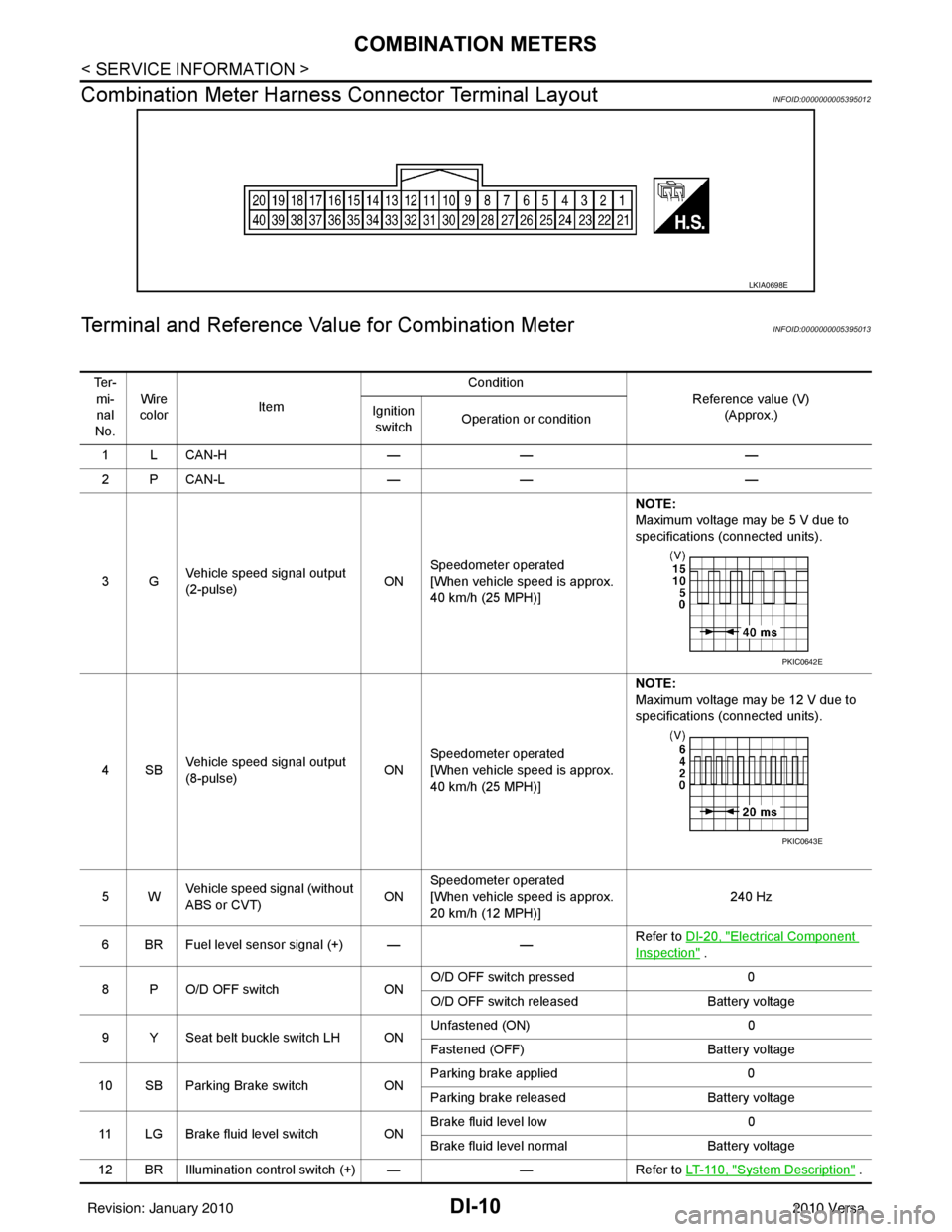

Combination Meter Harness Connector Terminal Layout

INFOID:0000000005395012

Terminal and Reference Va lue for Combination MeterINFOID:0000000005395013

LKIA0698E

Te r -

mi-nal

No. Wire

color Item Condition

Reference value (V)(Approx.)

Ignition

switch Operation or condition

1LCAN-H —— —

2PCAN-L —— —

3G Vehicle speed signal output

(2-pulse) ONSpeedometer operated

[When vehicle speed is approx.

40 km/h (25 MPH)] NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

4SB Vehicle speed signal output

(8-pulse) ONSpeedometer operated

[When vehicle speed is approx.

40 km/h (25 MPH)] NOTE:

Maximum voltage may be 12 V due to

specifications (connected units).

5W Vehicle speed signal (without

ABS or CVT) ONSpeedometer operated

[When vehicle speed is approx.

20 km/h (12 MPH)] 240 Hz

6 BR Fuel level sensor signal (+) — —Refer to DI-20, "

Electrical Component

Inspection" .

8 P O/D OFF switch ONO/D OFF switch pressed

0

O/D OFF switch released Battery voltage

9 Y Seat belt buckle switch LH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

10 SB Parking Brake switch ONParking brake applied

0

Parking brake released Battery voltage

11 LG Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

12 BR Illumination control switch (+) — —Refer to LT- 11 0 , "

System Description" .

PKIC0642E

PKIC0643E

Revision: January 20102010 Versa

Page 1221 of 3745

COMBINATION METERSDI-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

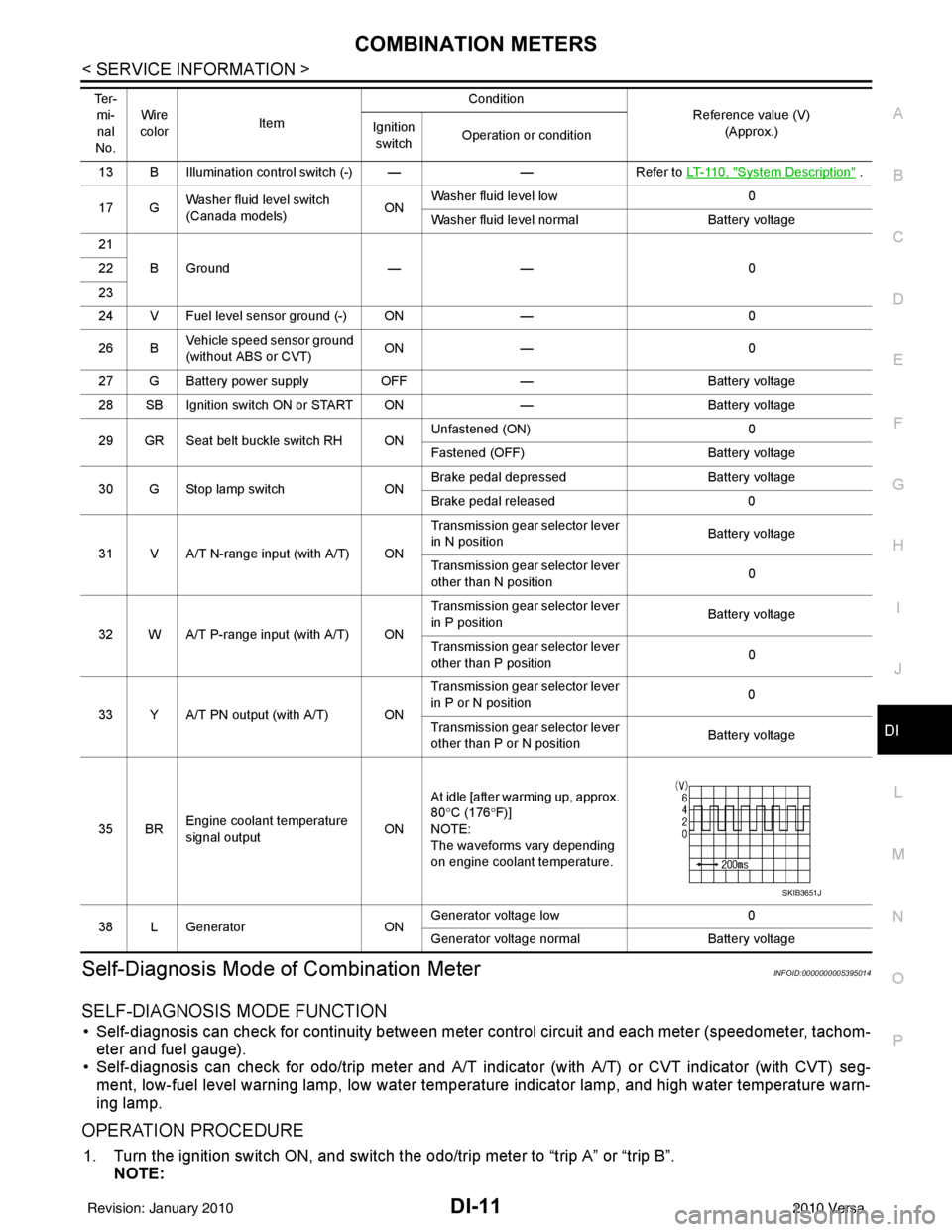

Self-Diagnosis Mode of Combination MeterINFOID:0000000005395014

SELF-DIAGNOSIS MODE FUNCTION

• Self-diagnosis can check for continuity between meter control circuit and each meter (speedometer, tachom- eter and fuel gauge).

• Self-diagnosis can check for odo/trip meter and A/T indi cator (with A/T) or CVT indicator (with CVT) seg-

ment, low-fuel level warning lamp, low water temperature indicator lamp, and high water temperature warn-

ing lamp.

OPERATION PROCEDURE

1. Turn the ignition switch ON, and switch the odo/trip meter to “trip A” or “trip B”. NOTE:

13 B Illumination control switch (-) — —Refer to LT-110, "System Description" .

17 G Washer fluid level switch

(Canada models)

ONWasher fluid level low

0

Washer fluid level normal Battery voltage

21 BGround —— 0

22

23

24 V Fuel level sensor ground (-) ON —0

26 B Vehicle speed sensor ground

(without ABS or CVT) ON

— 0

27 G Battery power supply OFF— Battery voltage

28 SB Ignition switch ON or START ON —Battery voltage

29 GR Seat belt buckle switch RH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

30 G Stop lamp switch ONBrake pedal depressed

Battery voltage

Brake pedal released 0

31 V A/T N-range input (with A/T) ON Transmission gear selector lever

in N position

Battery voltage

Transmission gear selector lever

other than N position 0

32 W A/T P-range input (with A/T) ON Transmission gear selector lever

in P position

Battery voltage

Transmission gear selector lever

other than P position 0

33 Y A/T PN output (with A/T) ON Transmission gear selector lever

in P or N position

0

Transmission gear selector lever

other than P or N position Battery voltage

35 BR Engine coolant temperature

signal output

ONAt idle [after warming up, approx.

80

°C (176 °F)]

NOTE:

The waveforms vary depending

on engine coolant temperature.

38 L Generator ONGenerator voltage low

0

Generator voltage no rmal Battery voltage

Te r -

mi-

nal

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

SKIB3651J

Revision: January 20102010 Versa

Page 1272 of 3745

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

FUEL PRESSURE .......................................... ..496

Inspection ............................................................ ..496

EVAP LEAK CHECK ........................................498

Inspection ............................................................ ..498

ON-VEHICLE REPAIR ...............................500

EVAP CANISTER .............................................500

Exploded View .................................................... ..500

Removal and Installation .......................................500

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

502

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

502

Idle Speed ........................................................... ..502

Ignition Timing .......................................................502

Calculated Load Value ..........................................502

Mass Air Flow Sensor ...........................................502

MR18DE

SERVICE INFORMATION .. .......................

503

INDEX FOR DTC ............................................ ..503

U0101-U1001 ...................................................... ..503

P0011-P0075 ........................................................503

P0101-P0128 ........................................................503

P0130-P0183 ........................................................504

P0222-P0420 ........................................................504

P0441-P0463 ........................................................505

P0500-P0643 ........................................................505

P0705-P0734 ........................................................506

P0740-P0840 ........................................................506

P0850-P1574 ........................................................507

P1610-P1615 ........................................................507

P1715-P1805 ........................................................507

P2100-P2A00 ........................................................508

PRECAUTIONS ................................................509

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

509

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

509

Precaution for Procedure without Cowl Top Cover ..510

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ...............................................................

510

Precaution .............................................................510

PREPARATION ................................................514

Special Service Tool ........................................... ..514

Commercial Service Tool ......................................514

ENGINE CONTROL SYSTEM ..........................516

Schematic ........................................................... ..516

Multiport Fuel Injection (MFI) System ...................516

Electronic Ignition (EI) System ..............................519

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

519

AIR CONDITIONING CUT CONTROL ............521

Input/Output Signal Chart ......................................521

System Description ................................................521

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

522

System Description ................................................522

Component Description .........................................523

CAN COMMUNICATION .................................524

System Description ................................................524

EVAPORATIVE EMISSION SYSTEM .............525

Description .............................................................525

Component Inspection ...........................................527

Exploded View .......................................................529

Removal and Installation .......................................529

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Idle Air Volume Learning .......................................580

Fuel Pressure Check .............................................582

TROUBLE DIAGNOSIS ..................................585

Trouble Diagnosis Introduction ..............................585

DTC Inspection Priority Chart ................................590

Fail-Safe Chart ......................................................590

Symptom Matrix Chart ...........................................592

Engine Control Component Parts Location ...........596

Vacuum Hose Drawing ..........................................602

Circuit Diagram ......................................................603

Revision: January 20102010 Versa

Page 1290 of 3745

![NISSAN TIIDA 2010 Service Manual PDF INSPECTION AND ADJUSTMENTEC-25

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION : Special Repair RequirementINFOID:0000000005398239

1.CHECK VIN

Check the VIN of the vehic NISSAN TIIDA 2010 Service Manual PDF INSPECTION AND ADJUSTMENTEC-25

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION : Special Repair RequirementINFOID:0000000005398239

1.CHECK VIN

Check the VIN of the vehic](/img/5/57397/w960_57397-1289.png)

INSPECTION AND ADJUSTMENTEC-25

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION : Special Repair RequirementINFOID:0000000005398239

1.CHECK VIN

Check the VIN of the vehicle and note it. Refer to GI-43, "

Model Variation".

>> GO TO 2.

2.PERFORM VIN REGISTRATION

With CONSULT-III

1. Turn ignition switch ON and engine stopped.

2. Select “VIN REGISTRATION” in “WORK SUPPORT” mode.

3. Follow the instruction of CONSULT-III display.

>> END

ACCELERATOR PEDAL RELEAS ED POSITION LEARNING

ACCELERATOR PEDAL RELEASED PO SITION LEARNING : DescriptionINFOID:0000000005398240

Accelerator Pedal Released Position Learning is a function of ECM to learn the fully released position of the

accelerator pedal by monitoring the accelerator pedal pos ition sensor output signal. It must be performed each

time harness connector of accelerator pedal position sensor or ECM is disconnected.

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Re-

quirement

INFOID:0000000005398241

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

>> END

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000005398242

Throttle Valve Closed Position Learning is a function of ECM to learn the fully closed position of the throttle

valve by monitoring the throttle position sensor out put signal. It must be performed each time harness connec-

tor of electric throttle contro l actuator or ECM is disconnected.

THROTTLE VALVE CLOSED POSITION LEA RNING : Special Repair Requirement

INFOID:0000000005398243

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

>> END

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING : DescriptionINFOID:0000000005398244

Idle Air Volume Learning is a function of ECM to lear n the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

Revision: January 20102010 Versa

Page 1301 of 3745

![NISSAN TIIDA 2010 Service Manual PDF EC-36

< FUNCTION DIAGNOSIS >[HR16DE]

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM

System DiagramINFOID:0000000005398252

System DescriptionINFOID:0000000005398253

INPUT/OUTPUT SIGNAL NISSAN TIIDA 2010 Service Manual PDF EC-36

< FUNCTION DIAGNOSIS >[HR16DE]

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM

System DiagramINFOID:0000000005398252

System DescriptionINFOID:0000000005398253

INPUT/OUTPUT SIGNAL](/img/5/57397/w960_57397-1300.png)

EC-36

< FUNCTION DIAGNOSIS >[HR16DE]

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM

System DiagramINFOID:0000000005398252

System DescriptionINFOID:0000000005398253

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to control the engine system under normal conditions.

JMBIA2193GB

Sensor

Input signal to ECMECM functionActuator

Crankshaft position sensor (POS) Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector

Camshaft position sensor (PHASE)

Mass air flow sensor

Amount of intake air

Intake air temperature sensor Intake air temperature

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch (M/T)

Transmission range switch (A/T) Gear position

Battery Battery voltage*

3

Knock sensorEngine knocking condition

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

EPS control unit Power steering operation*

2

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter

BCMAir conditioner ON signal*

2

Revision: January 20102010 Versa