Output speed sensor NISSAN TIIDA 2010 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 275 of 3745

AT-258

< SERVICE INFORMATION >

DISASSEMBLY

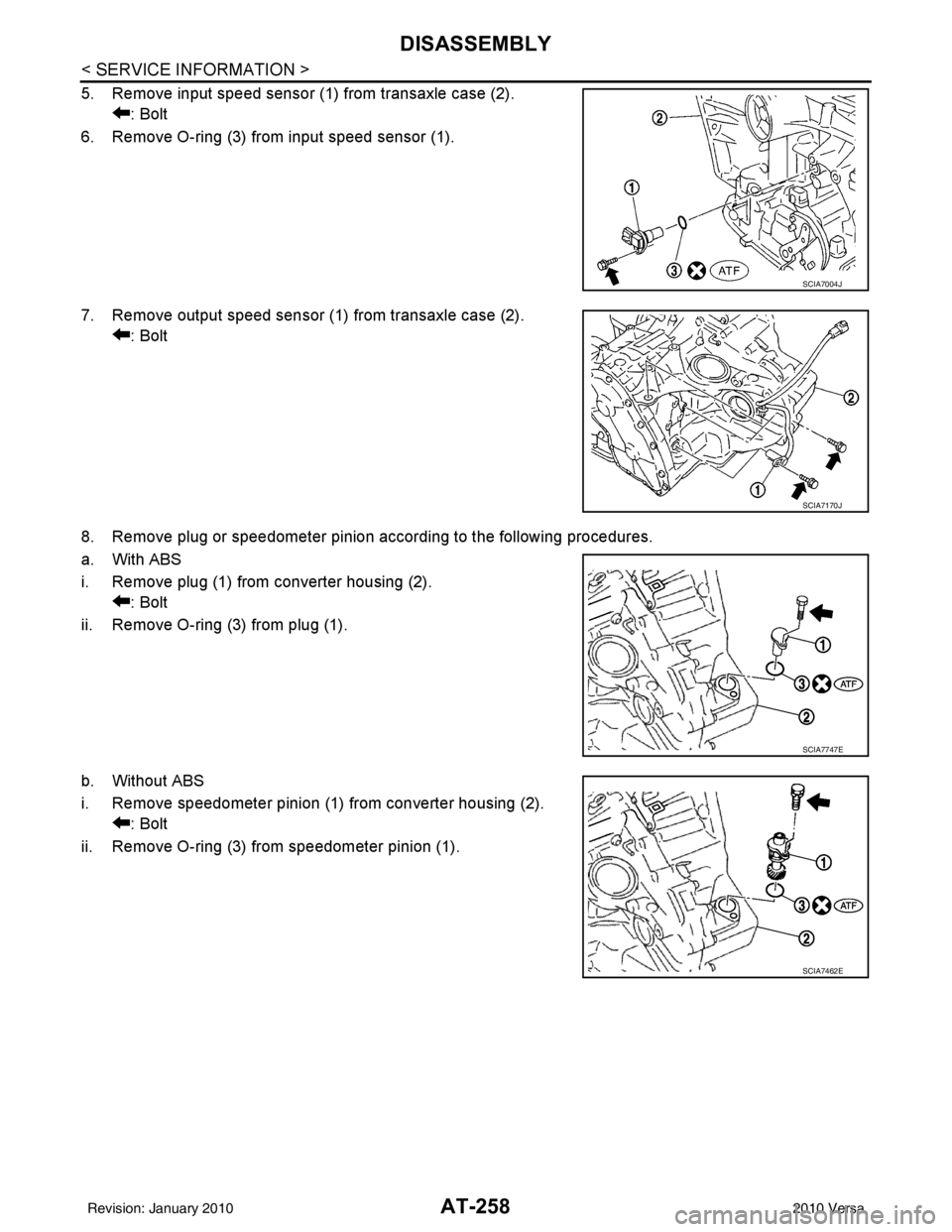

5. Remove input speed sensor (1) from transaxle case (2).: Bolt

6. Remove O-ring (3) from input speed sensor (1).

7. Remove output speed sensor (1) from transaxle case (2). : Bolt

8. Remove plug or speedometer pinion according to the following procedures.

a. With ABS

i. Remove plug (1) from converter housing (2). : Bolt

ii. Remove O-ring (3) from plug (1).

b. Without ABS

i. Remove speedometer pinion (1) from converter housing (2). : Bolt

ii. Remove O-ring (3) from speedometer pinion (1).

SCIA7004J

SCIA7170J

SCIA7747E

SCIA7462E

Revision: January 20102010 Versa

Page 388 of 3745

ASSEMBLYAT-371

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

31. Install transmission range switch (2) on transaxle case. : Bolt

a. Set manual shaft (1) in “P” position.

b. Temporarily install transmission range switch (2) on manual shaft (1).

c. Set manual shaft (1) in “N” position.

d. Use a 4 mm (0.16 in) dia. pin for this adjustment.

i. Insert the pin straight into the manual shaft (1) adjustment hole.

ii. Rotate transmission range switch (2) until the pin can also be inserted straight into hole in transmission range switch (2).

e. Tighten transmission range switch bolts to the specified torque. Refer to AT-237, "

Component".

f. Remove pin from adjustment hole after adjusting transmission range switch (2).

32. Install O-ring (3) to input speed sensor (1).

33. Install input speed sensor (1) to transaxle case (2). : Bolt

34. Tighten input speed sensor bolt to the specified torque. Refer to AT-237, "

Component".

35. Install output speed sensor (1) to transaxle case (2).

36. Tighten output speed sensor bolts to the specified torque. Refer to AT-237, "

Component".

: Bolt

CAUTION:

Ensure output speed sensor harness is firmly secured with

bolt.

(1): Output speed sensor

: Bolt

SCIA5904J

SCIA7004J

SCIA7170J

SCIA6518J

Revision: January 20102010 Versa

Page 397 of 3745

AT-380

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005397476

A/T Fluid Temperature SensorINFOID:0000000005397477

Remarks: Specification data are reference values.

Output Speed SensorINFOID:0000000005397478

Dropping ResistorINFOID:0000000005397479

Input Speed SensorINFOID:0000000005397480

Solenoid valve designation Resistance (Approx.)Terminal

Shift solenoid valve A 20 - 30 Ω 2

Shift solenoid valve B 5 - 20 Ω1

Overrun clutch solenoid valve 20 - 30 Ω 3

Line pressure solenoid valve 2.5 - 5.0 Ω 4

Torque converter clutch solenoid valve 5 - 20 Ω 5

Condition Specification (Approx.)

Cold [20 °C (68 °F)]

↓

Hot [80 °C (176 °F)] 1.5V

↓

0.5V 2.5 k

Ω

↓

0.3 k Ω

Condition Judgment standard

When driving at 20 km/h (12 MPH) 150 Hz (Approx.)

Resistance 12Ω (Approx.)

Condition Judgment standard

When driving at 20 km/h (12 MPH) 360 Hz (Approx.)

Revision: January 20102010 Versa

Page 910 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual BRC-20

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: For approximately 2 seconds after ignition switch is turned NISSAN TIIDA 2010 Service Workshop Manual BRC-20

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: For approximately 2 seconds after ignition switch is turned](/img/5/57397/w960_57397-909.png)

BRC-20

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: For approximately 2 seconds after ignition switch is turned ON, or when a malfunction is detected.

OFF: Approximately 2 seconds after ignition switch is turned ON (when system is in normal operation).

CONSULT-III Function (ABS)INFOID:0000000005397039

CONSULT-III can display each diagnostic item us

ing the diagnostic test modes shown following.

Monitor itemDisplay content Data monitor

Note: Error inspection

checklist

Condition Reference value in

normal operation

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSOR Wheel speedVehicle stopped

0 [km/h (MPH)]

BRC-26, "

Wheel Sensor

System"Vehicle running (Note 1) Almost in accor-

dance with speed-

ometer display

(within

±10%)

BATTERY VOLT Battery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit)Ignition switch ON

10 to 16VBRC-29, "

ABS Control

Unit Power and Ground

Systems Inspection"

STOP LAMP SW

Stop lamp switch oper-

ationBrake pedal depressed ON

—

Brake pedal not depressed OFF

ABS WARN LAMP ABS warning lamp ON

condition (Note 2)ABS warning lamp ON ON

BRC-18, "

Basic Inspec-

tion"ABS warning lamp OFF OFF

MOTOR RELAY Operation status of mo-

tor and motor relayIgnition switch ON or running

(ABS not activated)

OFF

BRC-28, "

Actuator Motor,

Motor Relay, and Circuit

Inspection"Ignition switch ON or engine

running (ABS activated) ON

ACTUATOR RLY Actuator relay opera-

tion statusVehicle stopped (Ignition

switch ON)

OFF

BRC-28, "

Actuator Motor,

Motor Relay, and Circuit

Inspection"Vehicle stopped (Engine run-

ning) ON

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL Solenoid valve opera-

tionActuator (solenoid) is active

(“ACTIVE TEST” with CON-

SULT-III) or actuator relay is in-

active (in fail-safe mode).

ON

BRC-27, "

Solenoid Valve

System Inspection"When actuator (solenoid) is not

active and actuator relay is ac-

tive (ignition switch ON). OFF

ABS SIGNAL

EBD SIGNAL Signal statusABS active

EBD active

ON

ABS system

EBD system

ABS not active

EBD not active OFF

ABS FAIL SIG

EBD FAIL SIG Fail signal statusABS fail

EBD fail

ON

ABS system

EBD system

ABS normal

EBD normal OFF

Diagnostic mode

Description

SELF DIAGNOSTIC RESULT Displays ABS ac tuator and electric unit (control unit) self-diagnosis results.

DATA MONITOR Displays ABS actuator and electric unit (control unit) input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Revision: January 20102010 Versa

Page 1035 of 3745

CVT-2

P0703 BRAKE SWITCH B ............................. ...60

Description ........................................................... ...60

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

60

On Board Diagnosis Logic ......................................60

Possible Cause .......................................................60

DTC Confirmation Procedure .................................60

Diagnosis Procedure ..............................................60

P0705 TRANSMISSION RANGE SWITCH A ....62

Description ..............................................................62

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

62

On Board Diagnosis Logic ......................................62

Possible Cause .......................................................62

DTC Confirmation Procedure .................................62

Wiring Diagram - CVT - TR/SW ..............................63

Diagnosis Procedure ..............................................64

Component Inspection ............................................65

P0710 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A ..............................................

67

Description ........................................................... ...67

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

67

On Board Diagnosis Logic ......................................67

Possible Cause .......................................................67

DTC Confirmation Procedure .................................67

Wiring Diagram - CVT - FTS ...................................68

Diagnosis Procedure ..............................................69

Component Inspection ............................................70

P0715 INPUT SPEED SENSOR A ....................72

Description ........................................................... ...72

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

72

On Board Diagnosis Logic ......................................72

Possible Cause .......................................................72

DTC Confirmation Procedure .................................72

Wiring Diagram - CVT - PRSCVT ...........................73

Diagnosis Procedure ..............................................74

P0720 OUTPUT SPEED SENSOR ....................76

Description ........................................................... ...76

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

76

On Board Diagnosis Logic ......................................76

Possible Cause .......................................................76

DTC Confirmation Procedure .................................76

Wiring Diagram - CVT - SESCVT ...........................77

Diagnosis Procedure ........................................... ...78

P0725 ENGINE SPEED .....................................81

Description ........................................................... ...81

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

81

On Board Diagnosis Logic ......................................81

Possible Cause .......................................................81

DTC Confirmation Procedure .................................81

Diagnosis Procedure ..............................................81

P0730 INCORRECT GEAR RATIO ...................83

Description ........................................................... ...83

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

83

On Board Diagnosis Logic ......................................83

Possible Cause .......................................................83

DTC Confirmation Procedure ..................................83

Diagnosis Procedure ...............................................83

P0740 TORQUE CONVERTER .........................84

Description ........................................................... ...84

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

84

On Board Diagnosis Logic ......................................84

Possible Cause .......................................................84

DTC Confirmation Procedure ..................................84

Wiring Diagram - CVT - TCV ..................................85

Diagnosis Procedure ...............................................86

Component Inspection ............................................87

P0744 TORQUE CONVERTER .........................89

Description ........................................................... ...89

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

89

On Board Diagnosis Logic ......................................89

Possible Cause .......................................................89

DTC Confirmation Procedure ..................................89

Diagnosis Procedure ...............................................89

P0745 PRESSURE CONTROL SOLENOID A ...91

Description ........................................................... ...91

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

91

On Board Diagnosis Logic ......................................91

Possible Cause .......................................................91

DTC Confirmation Procedure ..................................91

Wiring Diagram - CVT - LPSV ................................92

Diagnosis Procedure ............................................ ...93

Component Inspection ............................................94

P0746 PRESSURE CONTROL SOLENOID A ...96

Description ........................................................... ...96

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

96

On Board Diagnosis Logic ......................................96

Possible Cause .......................................................96

DTC Confirmation Procedure ..................................96

Diagnosis Procedure ...............................................96

P0776 PRESSURE CONTROL SOLENOID B ...98

Description ........................................................... ...98

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

98

On Board Diagnosis Logic ......................................98

Possible Cause .......................................................98

DTC Confirmation Procedure ..................................98

Diagnosis Procedure ...............................................98

P0778 PRESSURE CONTROL SOLENOID B ..100

Description ........................................................... .100

Revision: January 20102010 Versa

Page 1038 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual INDEX FOR DTCCVT-5

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000005397756

NOTE:

If DTC “U1000” is displayed NISSAN TIIDA 2010 Service Workshop Manual INDEX FOR DTCCVT-5

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000005397756

NOTE:

If DTC “U1000” is displayed](/img/5/57397/w960_57397-1037.png)

INDEX FOR DTCCVT-5

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000005397756

NOTE:

If DTC “U1000” is displayed with other DTCs, fi rst perform the trouble diagnosis for DTC “U1000”.

Refer to CVT-56

.

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. IndexINFOID:0000000005397757

NOTE:

If DTC “U1000” is displayed with other DTCs, fi rst perform the trouble diagnosis for DTC “U1000”.

Refer to CVT-56

.

Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II

Except OBD-II

CONSULT-III GST*

1 CONSULT-III only

“TRANSMISSION”

BRAKE SWITCH B —P0703 CVT-60

CAN COMM CIRCUIT U1000 U1000 CVT-56

CONTROL UNIT (CAN)—U1010 CVT-59

ENGINE SPEED —P0725 CVT-81

FLUID PRESS LOW —P0868C V T- 111

FLUID PRESS SEN/SW A P0840P0840CVT-105

FLUID PRESS SEN/SW A —P0841CVT-109

FLUID TEMP SENSOR A P0710P0710CVT-67

INCORRECT GR RATIO —P0730 CVT-83

INPUT SPEED SENSOR A P0715P0715CVT-72

LINE PRESS CONTROL —P1745CVT-128

OUTPUT SPEED SENSOR P0720P0720CVT-76

PC SOLENOID A P0745P0745CVT-91

PC SOLENOID A P0746P0746CVT-96

PC SOLENOID B P0776P0776CVT-98

PC SOLENOID B P0778P0778CVT-100

SLCT SOLENOID P1740P1740CVT-124

SPEED SENSOR —P1723CVT-121

STEP MOTOR P1777P1777CVT-129

STEP MOTOR P1778P1778CVT-133

TCM —P1701CVT-113

THROTTLE CONTROL SIG —P1726CVT-123

T/M RANGE SENSOR A P0705P0705CVT-62

TORQUE CONVERTER P0740P0740CVT-84

TORQUE CONVERTER P0744 P0744 CVT-89

TP SENSOR —P1705CVT-117

VEHICLE SPEED*2— P1722CVT-119

Revision: January 20102010 Versa

Page 1039 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT-6

< SERVICE INFORMATION >[RE0F08B]

INDEX FOR DTC

*1: These numbers are pr

escribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms) Reference page

OBD-I NISSAN TIIDA 2010 Service Workshop Manual CVT-6

< SERVICE INFORMATION >[RE0F08B]

INDEX FOR DTC

*1: These numbers are pr

escribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms) Reference page

OBD-I](/img/5/57397/w960_57397-1038.png)

CVT-6

< SERVICE INFORMATION >[RE0F08B]

INDEX FOR DTC

*1: These numbers are pr

escribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms) Reference page

OBD-II

Except OBD-II

CONSULT-III GST*

1CONSULT-III only

“TRANSMISSION”

— P0703 BRAKE SWITCH B CVT-60

P0705P0705 T/M RANGE SENSOR A CVT-62

P0710P0710 FLUID TEMP SENSOR A CVT-67

P0715P0715 INPUT SPEED SENSOR A CVT-72

P0720P0720 OUTPUT SPEED SENSOR CVT-76

—P0725 ENGINE SPEED CVT-81

—P0730 INCORRECT GR RATIO CVT-83

P0740P0740 TORQUE CONVERTER CVT-84

P0744 P0744 TORQUE CONVERTER CVT-89

P0745P0745 PC SOLENOID A CVT-91

P0746P0746 PC SOLENOID A CVT-96

P0776P0776 PC SOLENOID B CVT-98

P0778P0778 PC SOLENOID B CVT-100

P0840P0840 FLUID PRESS SEN/SW A CVT-105

—P0841 FLUID PRESS SEN/SW A CVT-109

—P0868 FLUID PRESS LOW C V T- 111

—P1701 TCM CVT-113

—P1705 TP SENSOR CVT-117

—P1722

VEHICLE SPEED*2CVT-119

— P1723 SPEED SENSOR CVT-121

—P1726 THROTTLE CONTROL SIG CVT-123

P1740P1740 SLCT SOLENOID CVT-124

—P1745 LINE PRESS CONTROL CVT-128

P1777P1777 STEP MOTOR CVT-129

P1778P1778 STEP MOTOR CVT-133

U1000U1000 CAN COMM CIRCUIT CVT-56

—U1010 CONTROL UNIT(CAN) CVT-59

Revision: January 20102010 Versa

Page 1054 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:

NISSAN TIIDA 2010 Service Workshop Manual CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:](/img/5/57397/w960_57397-1053.png)

CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting point, and lock-up operation.

• Send required output signals to the step motor and the respective solenoids.

CONTROL SYSTEM OUTLINE

The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

AWDIA0768GB

SENSORS (or SIGNAL)

⇒TCM

⇒ACTUATORS

Transmission range switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Overdrive control signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Secondary pressure sensor Shift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system

On board diagnosis Step motor

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid

valve

Shift position indicator

O/D OFF indicator lamp

Starter relay

Revision: January 20102010 Versa

Page 1055 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for NISSAN TIIDA 2010 Service Workshop Manual CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for](/img/5/57397/w960_57397-1054.png)

CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s

peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-7,

"System Description".

Input/Output Signal of TCMINFOID:0000000005397775

AWDIA0769GB

Control itemFluid

pressure control Select con-

trol Shift control Lock-up

control CAN com-

munication control Fail-safe

function (*3)

Input T

ra n sm is sio n r ang e s wit c h XXXXXX

Accelerator pedal position signal

(*1)XXXXXX

Closed throttle position signal

(*1)X XXX

Engine speed signal

(*1)XX XXX

CVT fluid temperature sensor XX XX X

Stop lamp switch signal

(*1)X XXX

Overdrive control signal

(*1)XX

Primary speed sensor X XXXX

Secondary speed sensor XXXXXX

Secondary pressure sensor XX X

T C M pow er s upp ly v olt a ge s ig n al XXXXXX

Revision: January 20102010 Versa

Page 1056 of 3745

![NISSAN TIIDA 2010 Service Workshop Manual CVT SYSTEMCVT-23

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

*1: Input by CAN communications.

*2: Output by CAN communications.

*3: If these input and output signals are differ NISSAN TIIDA 2010 Service Workshop Manual CVT SYSTEMCVT-23

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

*1: Input by CAN communications.

*2: Output by CAN communications.

*3: If these input and output signals are differ](/img/5/57397/w960_57397-1055.png)

CVT SYSTEMCVT-23

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

*1: Input by CAN communications.

*2: Output by CAN communications.

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

Line Pressure and Secondary Pressure ControlINFOID:0000000005397776

• When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the TCM

controls the line pressure solenoid valve and secondary pressure solenoid valve.

• This line pressure solenoid controls the pressure regulat or valve as the signal pressure and adjusts the pres-

sure of the operating oil discharged from the oil pump to the line pressure most appropriate to the driving

state. Secondary pressure is cont rolled by decreasing line pressure.

NORMAL CONTROL

Optimize the line pressure and secondary pressure, dependi ng on driving conditions, on the basis of the throt-

tle position, the engine speed, the primary pulley (input ) revolution speed, the secondary pulley (output) revo-

lution speed, the brake signal, the transmission range switch signal, the lock-up signal, the voltage, the target

gear ratio, the fluid temperat ure, and the fluid pressure.

FEEDBACK CONTROL

When controlling the normal fluid pressure or the sele cted fluid pressure, the secondary pressure can be set

more accurately by using the fluid pressure sensor to detect the secondary pressure and controlling the feed-

back.

Shift ControlINFOID:0000000005397777

In order to select the gear ratio which can obtain the dr iving force in accordance with driver's intention and the

vehicle condition, TCM monitors the driving conditions, such as the vehicle speed and the throttle position and

selects the optimum gear ratio, and determines the gear change steps to the gear ratio. Then send the com-

Out-

putSte p mo tor

XX

TCC solenoid valve XXX

Lock-up select solenoid valve XXX

Line pressure solenoid valve XXX X

Secondary pressure solenoid valve XX X

O/D OFF indicator signal

(*2)XX

Control item

Fluid

pressure

control Select con-

trol Shift control

Lock-up

control CAN com-

munication

control Fail-safe

function

(*3)

SCIA1846E

Revision: January 20102010 Versa