Output speed sensor NISSAN TIIDA 2010 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 129 of 3745

AT-112

< SERVICE INFORMATION >

P0732 2GR INCORRECT RATIO

P0732 2GR INCORRECT RATIO

DescriptionINFOID:0000000005397294

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosismalfunction.

• This malfunction is detected when the A/T does not shif t into second gear position as instructed by the TCM.

This is not caused by electrical malfunction (circuit s open or shorted) but by mechanical malfunction such as

control valve sticking, improper solenoid valve operation, etc.

On Board Diagn osis LogicINFOID:0000000005397295

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0732 2GR INCORRECT RATIO” with CONSULT-III is detected when A/T cannot

be shifted to the 2GR position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (2nd) supposed by TCM, the slip ratio will be more than

normal. In case the ratio exceeds the specif ied value, TCM judges this diagnosis malfunction.

This malfunction will be caused when shift solenoid valve B is stuck open.

• Gear positions supposed by TCM are as follows: In case of gear position with no malfunctions: 1, 2 , 3 and 4 positions

In case of gear position with shift solenoid valve B stuck open: 4, 3*, 3 and 4 positions to each gear position

above

*: “P0732 2GR INCORRECT RATIO” is detected.

Possible CauseINFOID:0000000005397296

• Shift solenoid valve B

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005397297

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the vo ltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “2ND GR FNCTN P0732” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

5. Accelerate vehicle to 45 to 50 km/h (28 to 31 MPH) under the following conditions and release the accel- erator pedal completely.

THROTTLE POSI: Less than 1.0/8

SLCT LVR POSI: “D” position

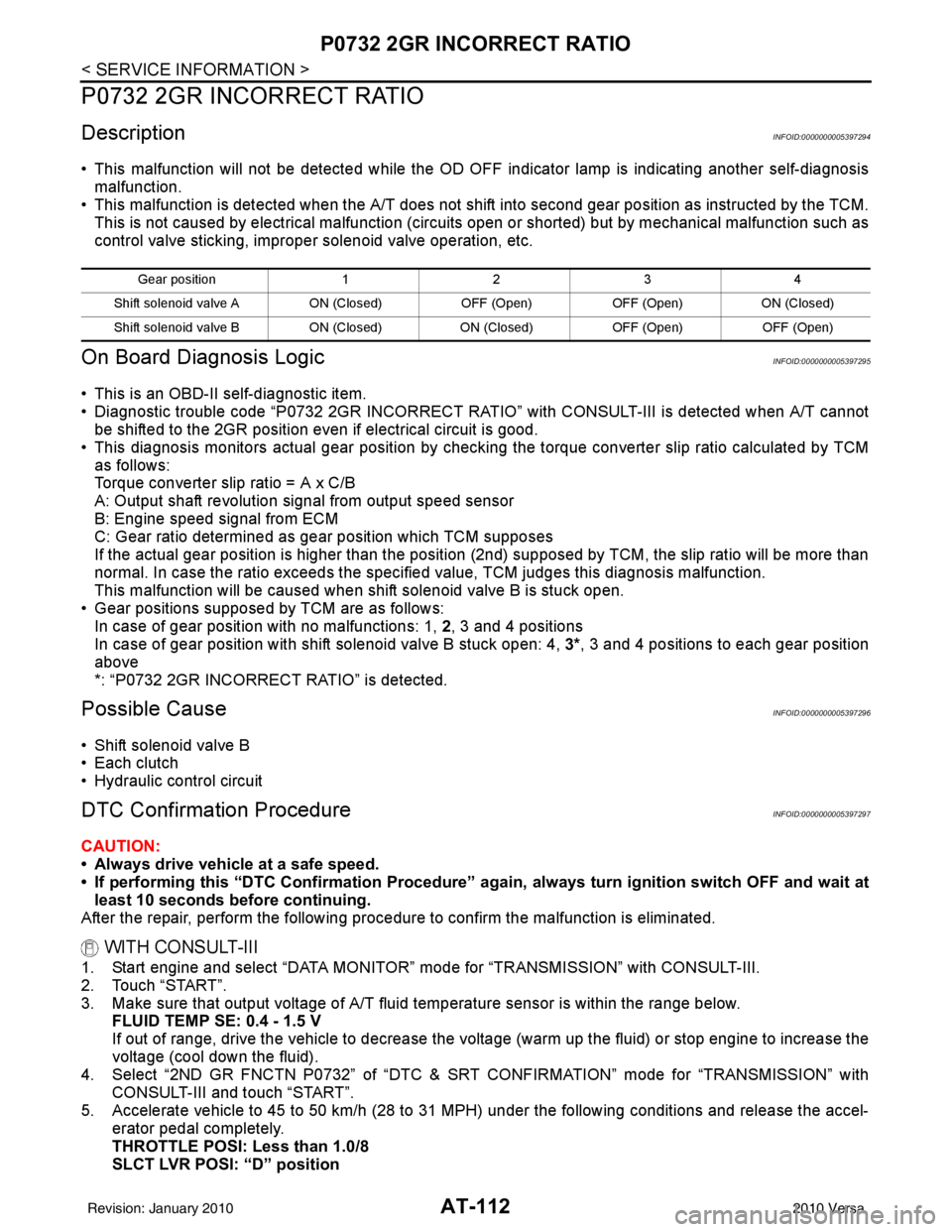

Gear position 12 34

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Revision: January 20102010 Versa

Page 132 of 3745

P0733 3GR INCORRECT RATIOAT-115

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0733 3GR INCORRECT RATIO

DescriptionINFOID:0000000005397299

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis malfunction.

• This malfunction is detected when the A/T does not shif t into third gear position as instructed by the TCM.

This is not caused by electrical malfunction (circuit s open or shorted) but by mechanical malfunction such as

control valve sticking, improper solenoid valve operat ion, malfunctioning servo piston or brake band, etc.

On Board Diagnosis LogicINFOID:0000000005397300

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0733 3GR INCORRECT RATIO” with CONSULT-III is detected when A/T cannot

be shifted to the 3GR position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (3rd) supposed by TCM, the slip ratio will be more than

normal. In case the ratio exceeds the specif ied value, TCM judges this diagnosis malfunction.

This malfunction will be caused when shift solenoid valve A is stuck closed.

• Gear positions supposed by TCM are as follows. In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve A stuck closed: 1, 1, 4* and 4 positions to each gear position

above

*: “P0733 3GR INCORRECT RATIO” is detected.

Possible CauseINFOID:0000000005397301

• Shift solenoid valve A

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005397302

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the vo ltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “3RD GR FNCTN P0733” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

5. Accelerate vehicle to 60 to 75 km/h (37 to 47 MPH) under the following conditions and release the accel- erator pedal completely.

THROTTLE POSI: Less th an 1.0/8 (at all times during step 4)

SLCT LVR POSI: “D” position

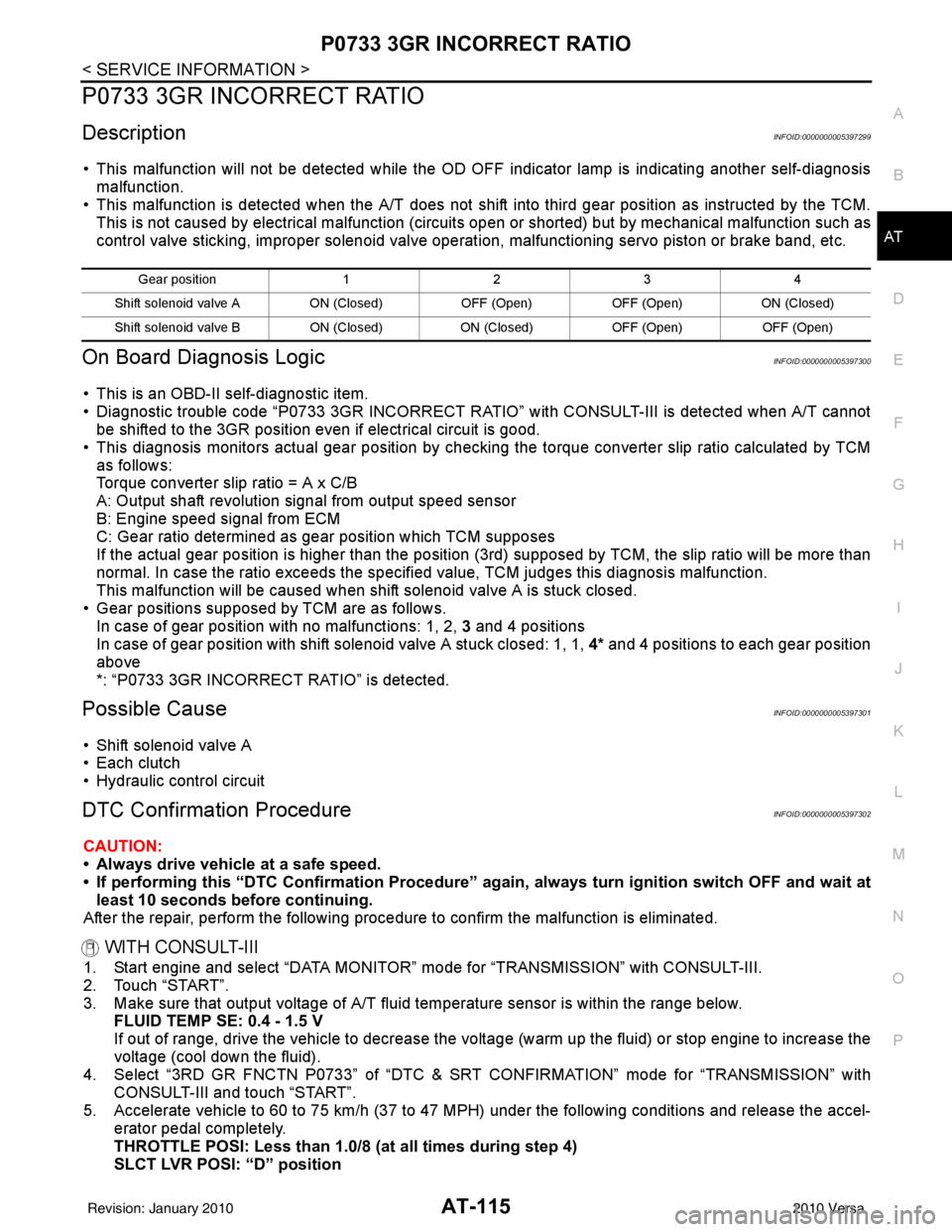

Gear position 123 4

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Revision: January 20102010 Versa

Page 135 of 3745

AT-118

< SERVICE INFORMATION >

P0734 4GR INCORRECT RATIO

P0734 4GR INCORRECT RATIO

DescriptionINFOID:0000000005397304

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosismalfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397305

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005397306

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0734 4GR INCORRECT RATIO” with CONSULT-III is detected when A/T cannot

be shifted to the 4GR position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve A is stuck open or shift solenoid valve B is stuck

closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift so lenoid valve A stuck open: 2, 2, 3 and 3* positions

In case of gear position with shift sol enoid valve B stuck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0734 4GR INCORRECT RATIO” is detected.

Possible CauseINFOID:0000000005397307

• Shift solenoid valve A

• Shift solenoid valve B

• Line pressure solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005397308

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

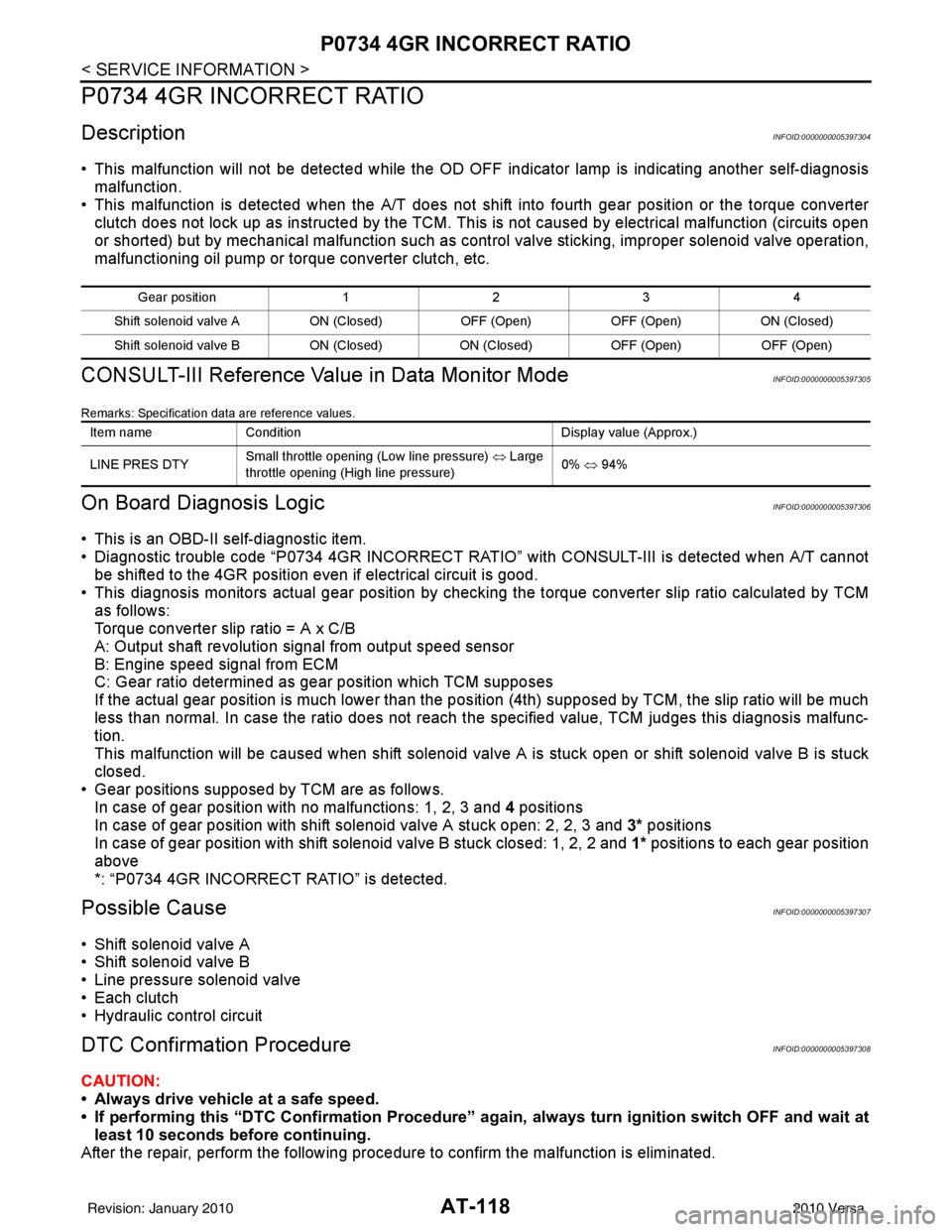

Gear position123 4

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Item name Condition Display value (Approx.)

LINE PRES DTY Small throttle opening (Low line pressure) ⇔

Large

throttle opening (High line pressure) 0%

⇔ 94%

Revision: January 20102010 Versa

Page 136 of 3745

P0734 4GR INCORRECT RATIOAT-119

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the vo ltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “4TH GR FNCTN P0734” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

5. Accelerate vehicle to 55 to 65 km/h (34 to 40 MPH) under the following conditions and release the accel-

erator pedal completely.

THROTTLE POSI: Less th an 5.5/8 (at all times during step 4)

SLCT LVR POSI: “D” position

- Make sure that “GEAR” shows “3” after releasing pedal.

6. Depress accelerator pedal steadily with 1.0/8 - 2.0/ 8 of “THROTTLE POSI” from a speed of 55 to 65 km/h

(34 to 40 MPH) until “TESTING” has turned to “STO P VEHICLE” or “COMPLETED”. (It will take approxi-

mately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-119, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT-III screen, go to following step.

- Make sure that “GEAR” shows “4” when depressing accelerator pedal with 1.0/8 - 2.0/8 of

“THROTTLE POSI”.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0734 4GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Function (TRANSMISSION)".

7. Stop vehicle.

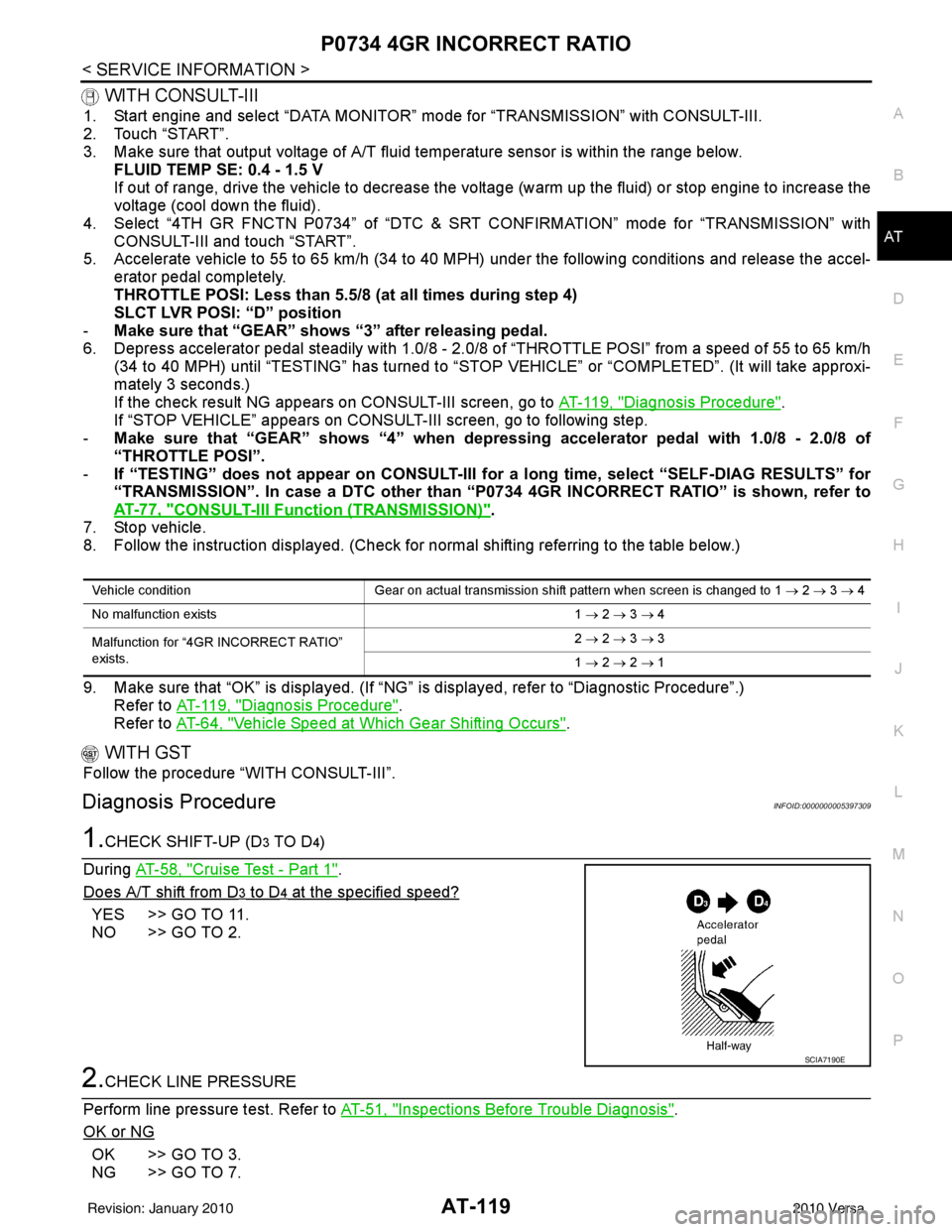

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-119, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397309

1.CHECK SHIFT-UP (D3 TO D4)

During AT-58, "

Cruise Test - Part 1".

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 11.

NO >> GO TO 2.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-51, "

Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 3.

NG >> GO TO 7.

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists 1 → 2 → 3 → 4

Malfunction for “4GR INCORRECT RATIO”

exists. 2

→ 2 → 3 → 3

1 → 2 → 2 → 1

SCIA7190E

Revision: January 20102010 Versa

Page 140 of 3745

P0740 TORQUE CONVERTERAT-123

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0740 TORQUE CONVERTER

DescriptionINFOID:0000000005397310

• The torque converter clutch solenoid valve is activated, with the gear in D4 and D3, by the TCM in response

to signals sent from the output speed sensor and t he ECM (throttle opening). Lock-up piston operation will

then be controlled.

• Lock-up operation, however, is prohibited when A/T fluid temperature is too low.

• When the accelerator pedal is depressed (less than 2/8) on lock-up condition, the engine speed should not

change abruptly. If there is an abrupt change in engine speed, there is no lock-up.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397311

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397312

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0740 T/C CLUTCH SOL” with CO NSULT-III or 7th judgement flicker without CON-

SULT-III is detected when TCM detects an improper vo ltage drop while it tries to operate solenoid valve.

Possible CauseINFOID:0000000005397313

• Torque converter clutch solenoid valve

• Harness or connector

(The solenoid circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005397314

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III and wait at least 1 second.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 80 km/h (50 MPH) or more

THROTTLE POSI: 0.5/8 - 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

5. If the check result is NG, go to AT-125, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle in D

1→ D2→ D3→ D4→ D4 lock-up position.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-125, "

Diagnosis Procedure" .

Item nameCondition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Revision: January 20102010 Versa

Page 145 of 3745

AT-128

< SERVICE INFORMATION >

P0744 TORQUE CONVERTER

P0744 TORQUE CONVERTER

DescriptionINFOID:0000000005397318

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosismalfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397319

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005397320

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 T/C CLUTCH FNCTN” wit h CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stuc k closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 T/C CLUTCH FNCTN” is detected.

Possible CauseINFOID:0000000005397321

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005397322

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Revision: January 20102010 Versa

Page 170 of 3745

VEHICLE SPEED SIGNALAT-153

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

VEHICLE SPEED SIGNAL

DescriptionINFOID:0000000005397356

The vehicle speed signal is built into the speedometer assembly. The sensor functions as an auxiliary device

to the output speed sensor when it is malfunctioning. The TCM will then use a signal sent from the vehicle

speed signal.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397357

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397358

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “VEHECLE SPEED SIGNAL” with CONSULT-III or 2nd judgement flicker without

CONSULT-III is detected when TCM does not rece ive the proper voltage signal from the sensor.

Possible CauseINFOID:0000000005397359

• Harness or connector

(The sensor circuit is open or shorted.)

• Vehicle speed signal

DTC Confirmation ProcedureINFOID:0000000005397360

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine and accelerate vehicle from 0 to 25 km/h (0 to 16 MPH).

4. If the check result is NG, go to AT-155, "

Diagnosis Procedure" .

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle under the following conditions:

Selector lever posi tion: “D” position

Vehicle speed: Higher than 25 km/h (16 MPH)

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-155, "

Diagnosis Procedure" .

Item name ConditionDisplay value

VHCL/S SE-MTR During driving Approximately matches the speedometer reading.

Revision: January 20102010 Versa

Page 179 of 3745

AT-162

< SERVICE INFORMATION >

INPUT SPEED SENSOR A

INPUT SPEED SENSOR A

DescriptionINFOID:0000000005397371

The input speed sensor detects forward clutch drum rpm (revolutions per minute). It is located on the input

side of the automatic transaxle. The output speed sensor is located on the output side of the automatic tran-

saxle. With the two sensors, input and output rpms are accurately detected. As a result, optimal shift timing

during deceleration and shift quality can be improved.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397372

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005397373

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “INPUT SPEED SENSOR A” wi th CONSULT-III or 10th judgement flicker without

CONSULT-III is detected when TCM does not rece ive the proper voltage signal from the sensor.

Possible CauseINFOID:0000000005397374

• Harness or connector

(The sensor circuit is open or shorted.)

• Input speed sensor

DTC Confirmation ProcedureINFOID:0000000005397375

CAUTION:

• Always drive vehicle at a safe speed.

• Be careful not to rev engine into the red zone on the tachometer.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine.

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Drive vehicle under the following conditions for more than 5 seconds.

SLCT LVR POSI: “D” position

VEHICLE SPEED: Higher than 40 km/h (25 MPH)

ENGINE SPEED: High er than 1,500 rpm

THROTTLE POSI: Greater than 1.0/ 8 of the full throttle position

5. If the check result is NG, go to AT-164, "

Diagnosis Procedure" .

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle under the following conditions for more than 5 seconds.

Selector lever position: “D” position

Vehicle speed: Higher than 40 km/h (25 MPH)

Engine speed: Higher than 1,500 rpm

Throttle position: 1.0/8 of the full throttle position

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-164, "

Diagnosis Procedure" .

Item nameCondition Display value

INPUT SPEED During driving (lock-up ON) Approximately matches the en gine speed.

Revision: January 20102010 Versa

Page 182 of 3745

INPUT SPEED SENSOR AAT-165

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

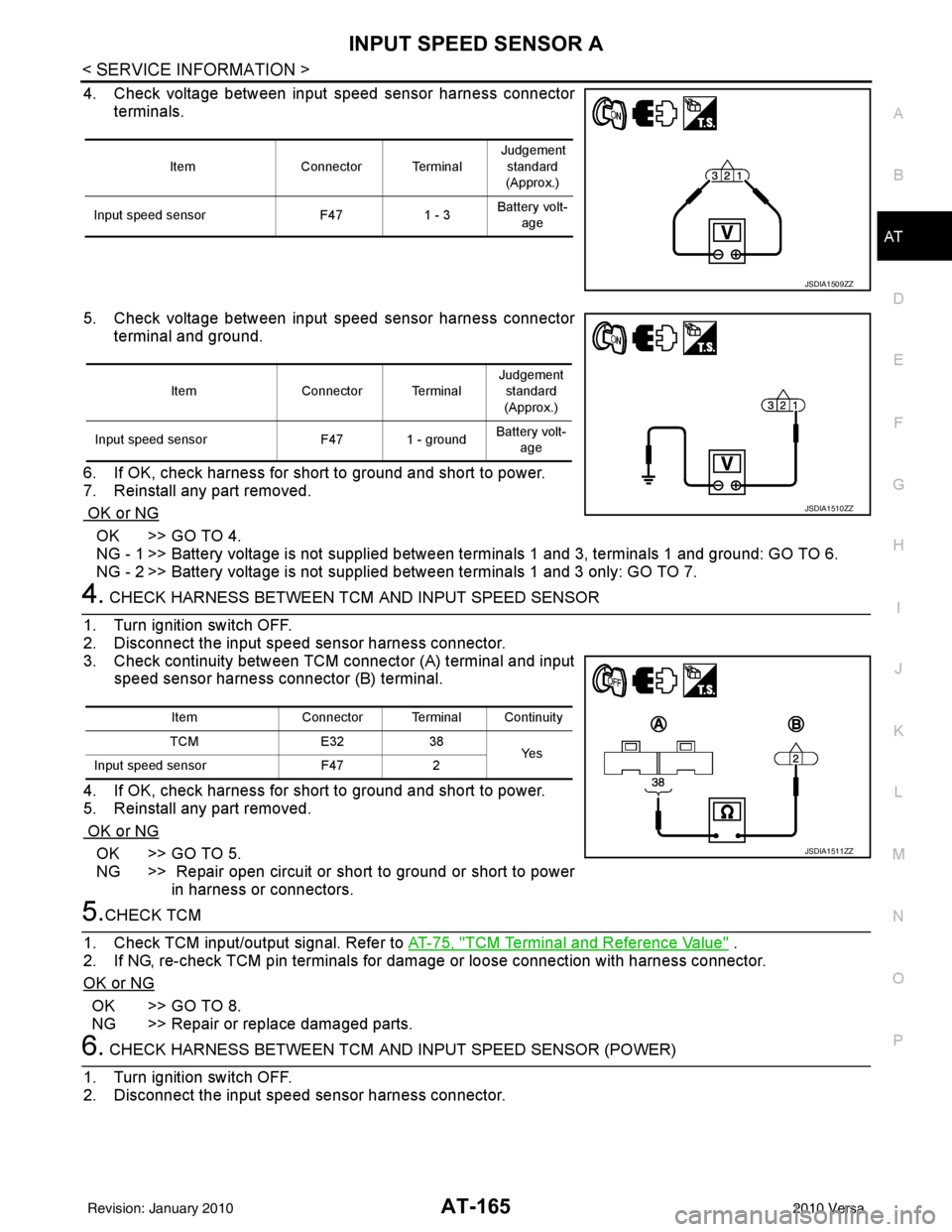

4. Check voltage between input speed sensor harness connector terminals.

5. Check voltage between input speed sensor harness connector terminal and ground.

6. If OK, check harness for short to ground and short to power.

7. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG - 1 >> Battery voltage is not supplied between terminals 1 and 3, terminals 1 and ground: GO TO 6.

NG - 2 >> Battery voltage is not supplied between terminals 1 and 3 only: GO TO 7.

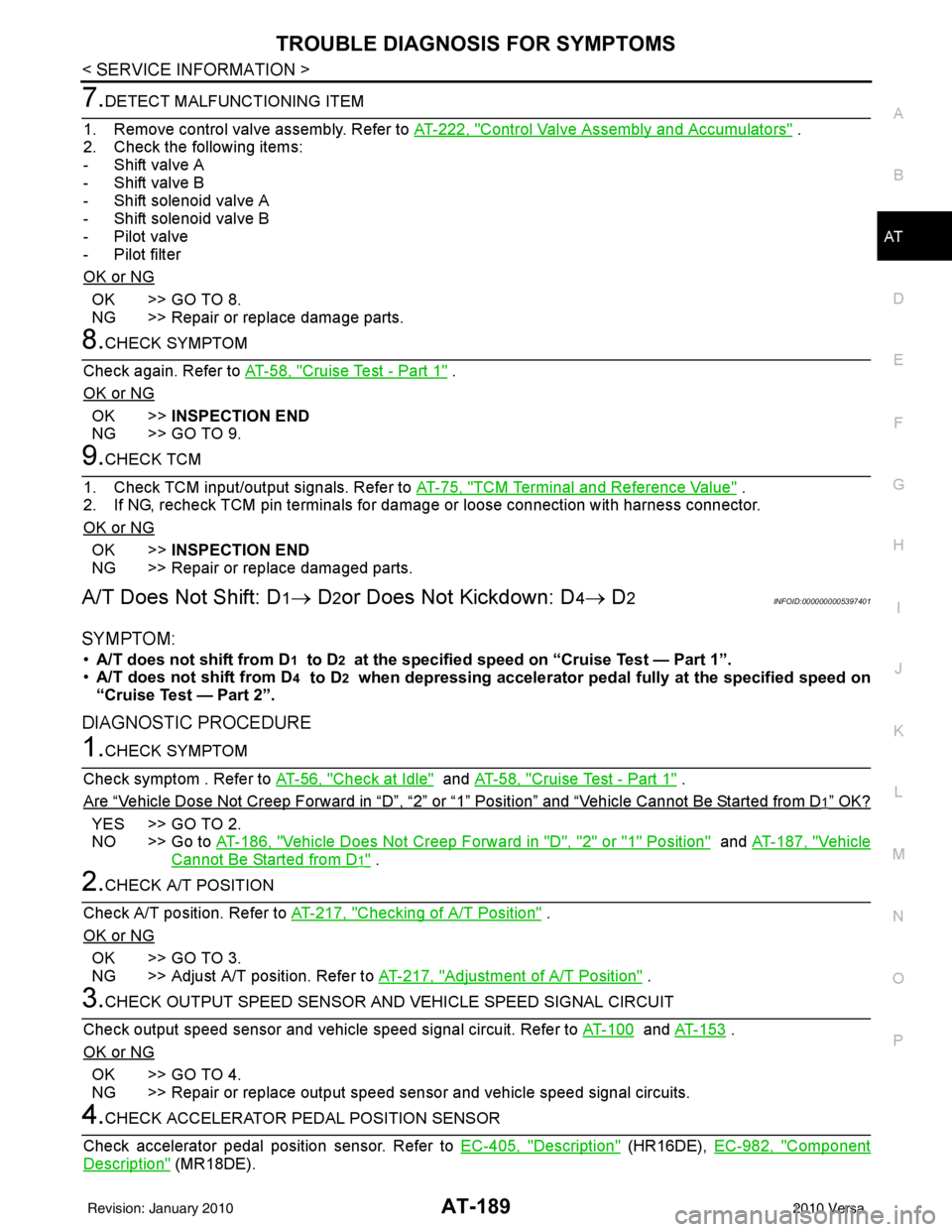

4. CHECK HARNESS BETWEEN TCM AND INPUT SPEED SENSOR

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and input

speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6. CHECK HARNESS BETWEEN TCM AND INPUT SPEED SENSOR (POWER)

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

ItemConnector Terminal Judgement

standard

(Approx.)

Input speed sensor F471 - 3Battery volt-

age

JSDIA1509ZZ

Item Connector Terminal Judgement

standard

(Approx.)

Input speed sensor F47 1 - groundBattery volt-

age

JSDIA1510ZZ

Item Connector Terminal Continuity

TCM E3238

Ye s

Input speed sensor F472

JSDIA1511ZZ

Revision: January 20102010 Versa

Page 206 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-189

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

7.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift valve B

- Shift solenoid valve A

- Shift solenoid valve B

- Pilot valve

- Pilot filter

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damage parts.

8.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 9.

9.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2INFOID:0000000005397401

SYMPTOM:

•A/T does not shift from D1 to D2 at the specified speed on “Cruise Test — Part 1”.

• A/T does not shift from D

4 to D2 when depressing accelerator pedal fully at the specified speed on

“Cruise Test — Part 2”.

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom . Refer to AT-56, "

Check at Idle" and AT-58, "Cruise Test - Part 1" .

Are

“Vehicle Dose Not Creep Forward in “D”, “2” or “1” Position” and “Vehicle Cannot Be Started from D1” OK?

YES >> GO TO 2.

NO >> Go to AT-186, "

Vehicle Does Not Creep Forward in "D", "2" or "1" Position" and AT-187, "Vehicle

Cannot Be Started from D1" .

2.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 3.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

3.CHECK OUTPUT SPEED SENSOR AND VEHICLE SPEED SIGNAL CIRCUIT

Check output speed sensor and vehicle speed signal circuit. Refer to AT-100

and AT-153 .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace output speed sensor and vehicle speed signal circuits.

4.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-405, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

Revision: January 20102010 Versa