NISSAN TIIDA 2011 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1231 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-176

< SERVICE INFORMATION >[RE0F08B]

CVT OIL WARMER SYSTEM

When installing water hoses, install them according to the following:

• Insert CVT water hose according to dimension “A” described

NISSAN TIIDA 2011 Service Repair Manual CVT-176

< SERVICE INFORMATION >[RE0F08B]

CVT OIL WARMER SYSTEM

When installing water hoses, install them according to the following:

• Insert CVT water hose according to dimension “A” described](/img/5/57396/w960_57396-1230.png)

CVT-176

< SERVICE INFORMATION >[RE0F08B]

CVT OIL WARMER SYSTEM

When installing water hoses, install them according to the following:

• Insert CVT water hose according to dimension “A” described

below.

• Set hose clamps (1) at the both ends of fluid cooler hose (2) with dimension (A) from the hose edge.

• Hose clamp should not interfere with the bulge.

*: Refer to the illustrations for the specific position of each hose clamp tab.

• The illustrations indicate the view from the hose ends.

• When installing hose clamps the center line of each clamp tab should be positioned as shown.

WATER HOSE : InspectionINFOID:0000000006068648

INSPECTION AFTER INSTALLATION

Start and warm up the engine. Visually check that there is no leakage of engine coolant and CVT fluid.

CVT FLUID COOLER HOSE

CVT water hose (1) Insert side tube (2) Dimension “A”

CVT water hose A Water inlet-outlet

End reaches the spool portion (B)

CVT oil warmer

CVT water hose B CVT oil warmer

CVT water tube

CVT water hose C CVT water tube

Water pump

JSDIA1291ZZ

Dimension (A) : 5 – 7 mm (0.20 – 0.28 in)

SCIA8123E

CVT water hose

Hose end Paint mark

Position of hose clamp*

CVT water hose A Water inlet-outlet side Facing forward A

CVT oil warmer side

Facing forward A

CVT water hose B CVT oil warmer side

Facing to the right of the vehicle B

CVT water tube side Facing forward A

CVT water hose C CVT water tube side

Facing forward A

Water pump side Facing upward C

D: Vehicle front

E : Vehicle upper

JSDIA1292ZZ

Revision: May 2010

2011 Versa

Page 1232 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT OIL WARMER SYSTEMCVT-177

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HO SE : Exploded ViewINFOID:0000000006068649

COMPONENT PARTS LOCATION

CVT FLUID COOLER NISSAN TIIDA 2011 Service Repair Manual CVT OIL WARMER SYSTEMCVT-177

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HO SE : Exploded ViewINFOID:0000000006068649

COMPONENT PARTS LOCATION

CVT FLUID COOLER](/img/5/57396/w960_57396-1231.png)

CVT OIL WARMER SYSTEMCVT-177

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HO SE : Exploded ViewINFOID:0000000006068649

COMPONENT PARTS LOCATION

CVT FLUID COOLER HOSE : Removal and InstallationINFOID:0000000006068650

REMOVAL

1. Remove air duct (inlet). Refer to EM-135, "Component".

2. Remove hose clamps, and remove CVT fluid cooler hose A.

3. Remove hose clamps, and remove CVT fluid cooler hose B.

4. Remove CVT fluid cooler tube A and CVT fluid cooler tube B.

INSTALLATION

Installation is in the reverse order of removal.

1. CVT fluid cooler hose A 2. Hose clamp3. CVT fluid cooler tube A

4. Gasket 5. Transaxle assembly6. CVT fluid cooler tube B

7. CVT fluid cooler hose B 8. CVT oil warmer

Refer to GI-8, "

Component" for symbols in the figure.

JSDIA1288GB

Revision: May 2010 2011 Versa

Page 1233 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-178

< SERVICE INFORMATION >[RE0F08B]

CVT OIL WARMER SYSTEM

• When installing CVT fluid cooler tube (1) and (2) to transaxle

assembly, install them so that CVT fluid cooler tube rotation stop-

pe NISSAN TIIDA 2011 Service Repair Manual CVT-178

< SERVICE INFORMATION >[RE0F08B]

CVT OIL WARMER SYSTEM

• When installing CVT fluid cooler tube (1) and (2) to transaxle

assembly, install them so that CVT fluid cooler tube rotation stop-

pe](/img/5/57396/w960_57396-1232.png)

CVT-178

< SERVICE INFORMATION >[RE0F08B]

CVT OIL WARMER SYSTEM

• When installing CVT fluid cooler tube (1) and (2) to transaxle

assembly, install them so that CVT fluid cooler tube rotation stop-

per (A) and (B) touch to transaxle case (C) and (D).

• Insert CVT fluid cooler hose according to dimension (A) described below.

• Set hose clamps (1) at the both ends of fluid cooler hose (2) with dimension (A) from the hose edge.

• Hose clamp should not interfere with the bulge.

*: Refer to the illustrations for the specific position of each hose clamp tab.

• The illustrations indicate the view from the hose ends.

• When installing hose clamps the center line of each clamp tab should be positioned as shown.

: Vehicle front

JPDIA0698ZZ

CVT fluid cooler hose (1) Insert side tube (2) Dimension (A)

CVT fluid cooler hose A CVT fluid cooler tube

End reaches the 2-stage

bulge (B)

CVT oil warmer

CVT fluid cooler hose B CVT oil warmer

CVT fluid cooler tube

JSDIA1289ZZ

Dimension (A) : 5 – 7 mm (0.20 – 0.28 in)

SCIA8123E

CVT fluid cooler hose

Hose endPaint mark Position of hose clamp*

CVT fluid cooler hose A CVT fluid cooler tube side

Vehicle frontA

CVT oil warmer side Vehicle frontA

CVT fluid cooler hose B CVT oil warmer side

Vehicle frontA

CVT fluid cooler tube side Vehicle frontA

B : Vehicle front

JPDIA0675ZZ

Revision: May 2010

2011 Versa

Page 1234 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT OIL WARMER SYSTEMCVT-179

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HOSE : InspectionINFOID:0000000006068651

INSPECTION AFTER INSTALLATION

Check for CVT f NISSAN TIIDA 2011 Service Repair Manual CVT OIL WARMER SYSTEMCVT-179

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HOSE : InspectionINFOID:0000000006068651

INSPECTION AFTER INSTALLATION

Check for CVT f](/img/5/57396/w960_57396-1233.png)

CVT OIL WARMER SYSTEMCVT-179

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HOSE : InspectionINFOID:0000000006068651

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

CVT OIL WARMER

CVT OIL WARMER : Exploded ViewINFOID:0000000006068652

CVT OIL WARMER : Removal and InstallationINFOID:0000000006068653

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

CAUTION:

Perform this step engine is cold.

1. Remove CVT water hose from CVT oil warmer. Refer to CVT-175, "

WATER HOSE : Exploded View".

2. Remove CVT fluid cooler hose from CVT oil warmer. Refer to CVT-177, "

CVT FLUID COOLER HOSE :

Exploded View".

3. Remove CVT oil warmer.

4. Remove bracket.

INSTALLATION

Installation is in the reverse order of removal.

CVT OIL WARMER : InspectionINFOID:0000000006068654

INSPECTION AFTER INSTALLATION

• Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

• Start and warm up the engine. Visually check that there is no leakage of engine coolant and CVT fluid.

1. CVT oil warmer2. Bracket3. Transaxle assembly

Refer to GI-8, "

Component" for symbols in the figure.

JPDIA0725GB

Revision: May 2010 2011 Versa

Page 1235 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-180

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000005928976

COMPONENTS

REMOVAL

WARNING:

Never remove the radiator cap when the engine NISSAN TIIDA 2011 Service Repair Manual CVT-180

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000005928976

COMPONENTS

REMOVAL

WARNING:

Never remove the radiator cap when the engine](/img/5/57396/w960_57396-1234.png)

CVT-180

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000005928976

COMPONENTS

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns coul

d occur from high pressure

coolant escaping from the radiator.

CAUTION:

• Perform this step engine is cold.

• When replacing TCM and transaxle assembly as a set, replace transaxle assembly first and then replace TCM. Refer to CVT-8, "

Service After Replacing TCM and Transaxle Assembly".

1. Remove the engine and transaxle as an assembly. Refer to EM-197, "

Removal and Installation".

1. CVT fluid level gauge2. CVT fluid charging pipe 3. O-ring

4. Copper washer 5. Fluid cooler tube6. Transaxle assembly

7. Engine mounting bracket (LH) 8. Air breather hose A. Refer to "INSTALLATION".

WCIA0614E

Revision: May 2010 2011 Versa

Page 1236 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TRANSAXLE ASSEMBLYCVT-181

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit conn NISSAN TIIDA 2011 Service Repair Manual TRANSAXLE ASSEMBLYCVT-181

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit conn](/img/5/57396/w960_57396-1235.png)

TRANSAXLE ASSEMBLYCVT-181

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit connector (C). Refer

to CVT-9, "

Removal and Installation Procedure for CVT Unit

Connector".

3. Remove the harness from the transaxle.

4. Remove the four drive plate to torque converter nuts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter nuts.

5. Put matching marks on the drive plate and torque converter alignment stud. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

6. Remove the transaxle to engine and engine to transaxle bolts.

7. Separate the transaxle from the engine.

8. If necessary, remove the following from the transaxle: • CVT fluid charging pipe

• Engine mounting bracket (LH)

• Fluid cooler tubes

• Air breather hose

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure any dowels are installed correctlyduring re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive train components.

• Do not reuse O-rings and copper washers.

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the nuts for the torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-159

.

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

AWDIA0661GB

WCIA0616E

Revision: May 2010 2011 Versa

Page 1237 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-182

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

• When installing the torque converter to the transaxle measure dis-

tance A.

• When installing the cooler outlet tube (1) to the transa NISSAN TIIDA 2011 Service Repair Manual CVT-182

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

• When installing the torque converter to the transaxle measure dis-

tance A.

• When installing the cooler outlet tube (1) to the transa](/img/5/57396/w960_57396-1236.png)

CVT-182

< SERVICE INFORMATION >[RE0F08B]

TRANSAXLE ASSEMBLY

• When installing the torque converter to the transaxle measure dis-

tance A.

• When installing the cooler outlet tube (1) to the transaxle assembly (2), align the cooler tube bracket (A) against the transaxle as

shown.

• When installing the transaxle to the engine, align t he matching mark on the drive plate with the matching

mark on the torque converter alignment stud.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard.

• When installing the drive plate to torque converter nuts, tighten them temporarily. Then tighten the nuts to the specified torque.

• After completing installation check for fluid level, fluid leakage, and the positions of CVT. Refer to CVT-14,

"Checking CVT Fluid", CVT-164, "Adjustment of CVT Position" and CVT-164, "Checking of CVT Position".

• When replacing the CVT assembly, erase EEP ROM in TCM. Refer to CVT-8, "

Service After Replacing TCM

and Transaxle Assembly".

Distance A: 14.4 mm (0.57 in) or more

WCIA0617E

WCIA0618E

Bolt No.

1 (Transaxle to engine) 2 (Engine to transaxle)

Number of bolts 27

Bolt length

“A” mm (in) 55 (2.17)

50 (1.97)

Tightening torque

N·m (kg-m, ft-lb) 62 (6.3, 46)

WCIA0619E

Converter nuts: : 51 N·m (5.2 kg-m, 38 ft-lb)

WCIA0616E

Revision: May 2010

2011 Versa

Page 1238 of 3787

![NISSAN TIIDA 2011 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)CVT-183

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005928977

*: T NISSAN TIIDA 2011 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)CVT-183

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005928977

*: T](/img/5/57396/w960_57396-1237.png)

SERVICE DATA AND SPECIFICATIONS (SDS)CVT-183

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005928977

*: The fluid capacity is the reference value. Check the fluid level with CVT fluid level gauge.

Vehicle Speed When Shifting GearsINFOID:0000000005928978

Numerical value data are reference values.

CAUTION:

Lock-up clutch is engaged when vehi cle speed is approximately 18 km/h (11 MPH) to 90 km/h (56 MPH).

Stall SpeedINFOID:0000000005928979

Line PressureINFOID:0000000005928980

Applied model MR18DE engine

CVT model RE0F08B

CVT assembly Model code number 1XC6B

Transmission gear ratio “D” position

Variable

Reverse 2.689

Final drive 5.473

Recommended fluid NISSAN CVT Fluid NS-2

Fluid capacity 6.9 liter (7-1/4 US qt, 6-1/8 Imp qt)*

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-2. Do not mix with other fluid.

• Using CVT fluid other than Genuine NISSAN CVT Fluid NS-2 will deteriorate in driveability and CVT durability, and may dam- age the CVT, which is not covered by the warranty.

Engine type Throttle position Shift pattern Engine speed (rpm)

At 40 km/h (25 MPH) At 60 km/h (37 MPH)

MR18DE 8/8

“D” position

Overdrive-off mode

“L” position 3,600 - 4,500

4,400 - 5,300

2/8 “D” position

1,300 - 3,100 1,400 - 3,500

Overdrive-off mode 2,200 - 3,000 2,800 - 3,600

“L” position 3,100 - 4,000 3,800 - 4,700

Stall speed 2,600 - 3,150 rpm

Engine speed Line pressure kPa (kg/cm

2 , psi)

“R”, “D” and “L” positions

At idle 650 (6.63, 94.3)

At stall 4,250 (43.35, 616.3)

Revision: May 2010 2011 Versa

Page 1239 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-184

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005928981

CVT Fluid Temperature SensorINFOID:0000000005928982

Primary Speed SensorINFOID:00 NISSAN TIIDA 2011 Service Repair Manual CVT-184

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005928981

CVT Fluid Temperature SensorINFOID:0000000005928982

Primary Speed SensorINFOID:00](/img/5/57396/w960_57396-1238.png)

CVT-184

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005928981

CVT Fluid Temperature SensorINFOID:0000000005928982

Primary Speed SensorINFOID:0000000005928983

Secondary Speed SensorINFOID:0000000005928984

Removal and InstallationINFOID:0000000005928985

Name Resistance (Approx.) Terminal

secondary pressure solenoid valve 3 - 9 Ω3

Line pressure solenoid valve 2

Torque converter clutch solenoid valve 12

Lock-up select solenoid valve 6 - 19Ω 13

NameCondition CONSULT-III “DATA MONI TOR” (Approx.) Resistance (Approx.)

ATF TEMP SEN 20

°C (68 °F) 2.0 V 6.5 kΩ

80 °C (176 °F) 1.0 V 0.9 kΩ

Name ConditionData (Approx.)

Primary speed sensor When driving [“L” position, 20 km/h (12 MPH)]. 1250 Hz

NameConditionData (Approx.)

Secondary speed sensor When driving [“D” position, 20 km/h (12 MPH)]. 570 Hz

Distance between end of converter housing and torque converter 14.4 mm (0.57 in)

Revision: May 2010 2011 Versa

Page 1240 of 3787

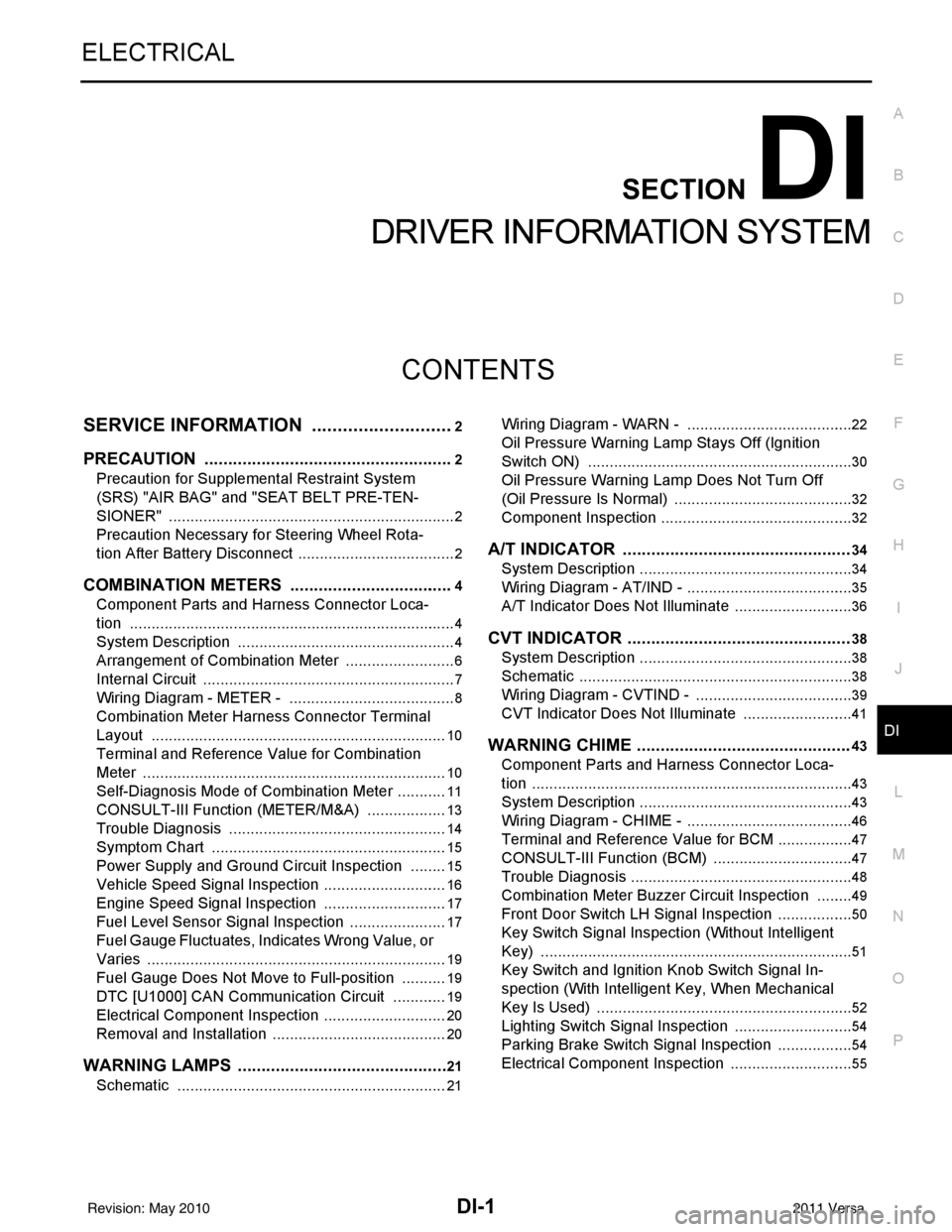

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ........ ....11

CONSULT-III Function (METER/M&A) ............... ....13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit ......... ....19

Electrical Component Inspection .............................20

Removal and Installation .........................................20

WARNING LAMPS ......................................... ....21

Schematic ........................................................... ....21

Wiring Diagram - WARN - ................................... ....22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Schematic ................................................................38

Wiring Diagram - CVTIND - .....................................39

CVT Indicator Does Not Illuminate ..........................41

WARNING CHIME .............................................43

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

43

System Description ..................................................43

Wiring Diagram - CHIME - .......................................46

Terminal and Reference Value for BCM ..................47

CONSULT-III Function (B CM) .................................47

Trouble Diagnosis ................................................ ....48

Combination Meter Buzzer Circuit Inspection .........49

Front Door Switch LH Signal Inspection .............. ....50

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ....

51

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

52

Lighting Switch Signal Inspection ............................54

Parking Brake Switch Signal Inspection ..................54

Electrical Component Inspection .............................55

Revision: May 2010 2011 Versa