system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3350 of 3787

MTC-34

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

>> GO TO 5.

5.CHECK AIR MIX DOOR CONTROL LINKAGE

Check and verify air mix door mechanism for smooth operation.

OK or NG

OK >> If the symptom still exists, perform a complete operational check. Refer to MTC-31, "Operational

Check" If other symptoms exist, refer to MTC-23, "How to Perform Trouble Diagnosis for Quick

and Accurate Repair".

NG >> Repair or adjust air mix door control linkage. Refer to MTC-65, "

Air Mix Door Cable Adjustment".

Intake DoorINFOID:0000000005930851

SYMPTOM:

• Intake door does not change.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - REC ( )

1. Slide the intake door lever to the REC ( ) position.

2. Turn the blower motor to maximum speed.

3. Slide the intake door lever to the FRE position.

4. Listen for intake door position change (you should hear blower sound change slightly).

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to MTC-31, "

Operational Check" .

Can a symptom be duplicated?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK INTAKE DOOR CONTROL LINKAGE

Check intake door control linkage mechanism for smooth operation.

OK or NG

OK >> If the symptom still exists, perform a complete operational check. Refer to MTC-31, "Operational

Check" . If other symptoms exist, refer to MTC-23, "How to Perform Trouble Diagnosis for Quick

and Accurate Repair" .

NG >> Repair or adjust control linkage. Refer to MTC-64, "

Intake Door Cable Adjustment" .

Front Blower Motor CircuitINFOID:0000000005930852

SYMPTOM: Front blower motor operation is malfunctioning.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - FRONT BLOWER

1. Turn blower control dial to "1" position. Blower should operate on low speed.

2. Turn the blower control dial to "2" position, and continue checking blower speed until all speeds are

checked.

Can the symptom be duplicated?

YES >> GO TO 3.

Revision: May 2010 2011 Versa

Page 3351 of 3787

TROUBLE DIAGNOSISMTC-35

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to MTC-31, "

Operational Check".

Can a symptom be duplicated?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK FRONT BLOWER MOTOR CIRCUIT

Check front blower motor circuit. Refer to "D IAGNOSTIC PROCEDURE FOR FRONT BLOWER MOTOR" .

OK or NG

OK >> If the symptom still exists, perform a complete operational check. Refer to MTC-31, "Operational

Check". If other symptoms exist, refer to MTC-23, "How to Perform Trouble Diagnosis for Quick

and Accurate Repair".

NG >> Repair as necessary.

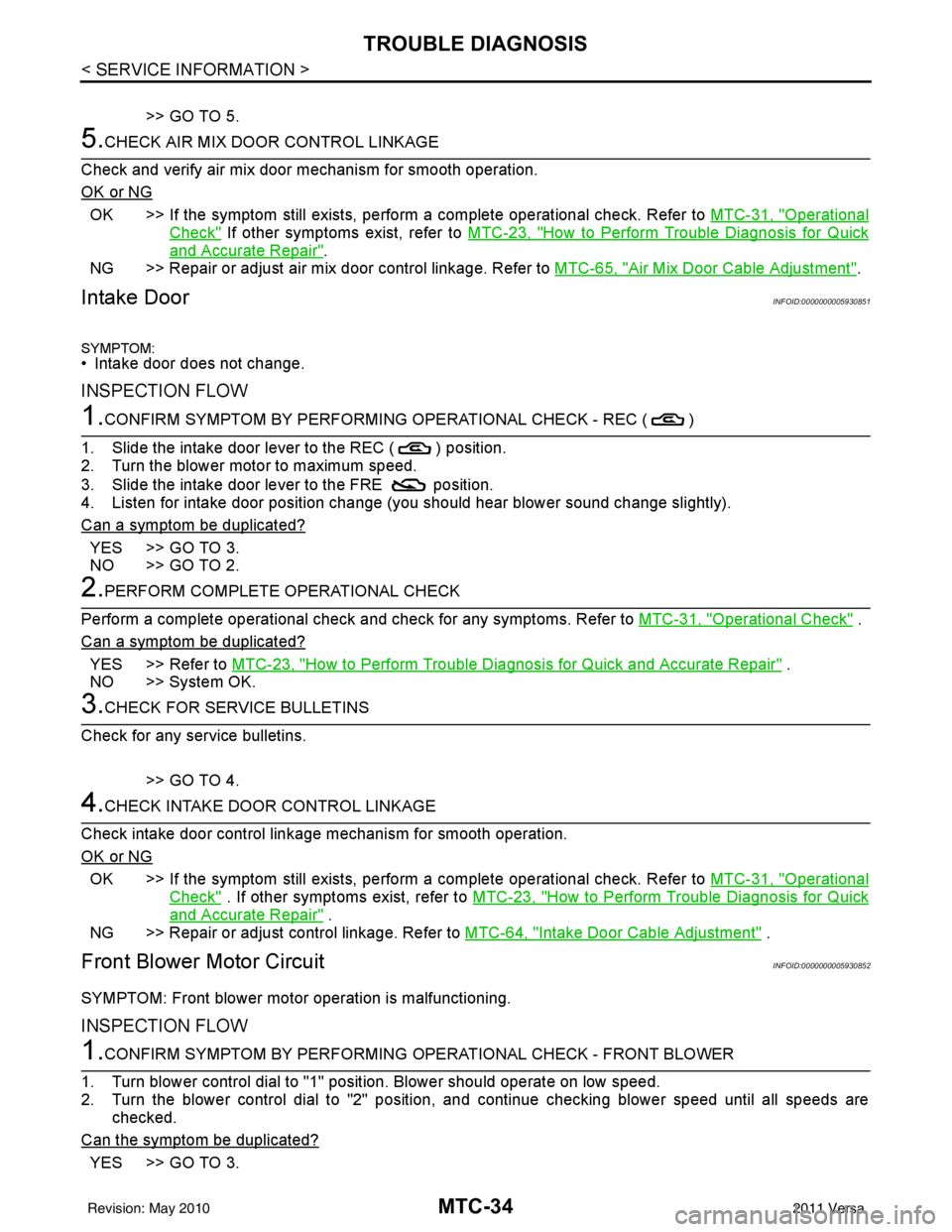

DIAGNOSTIC PROCEDURE FOR FRONT BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning.

1.CHECK FRONT BLOWER MOTOR OPERATION

1. Turn ignition switch ON.

2. Check front blower motor operation at each fan speed.

OK or NG

OK >> Inspection End.

NG >> • Front blower motor does not operate at any speed, GO TO 2. • Front blower motor does not operate at one or more of the four speeds, GO TO 10.

2.CHECK POWER SUPPLY FOR FRONT BLOWER MOTOR

1. Turn ignition switch OFF.

2. Disconnect front blower motor connector.

3. Turn ignition switch ON.

4. Check voltage between front blower motor harness connector M62 terminal 1 and ground.

OK or NG

OK >> GO TO 6.

WJIA2259E

Te r m i n a l s Vol tag e

(Approx.)

(+)

(− )

Connector Terminal Ground

Front blower

motor: M62 1

Battery voltage

WJIA2228E

Revision: May 2010 2011 Versa

Page 3354 of 3787

MTC-38

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

OK >> GO TO 11.

NG >> Repair harness or connector.

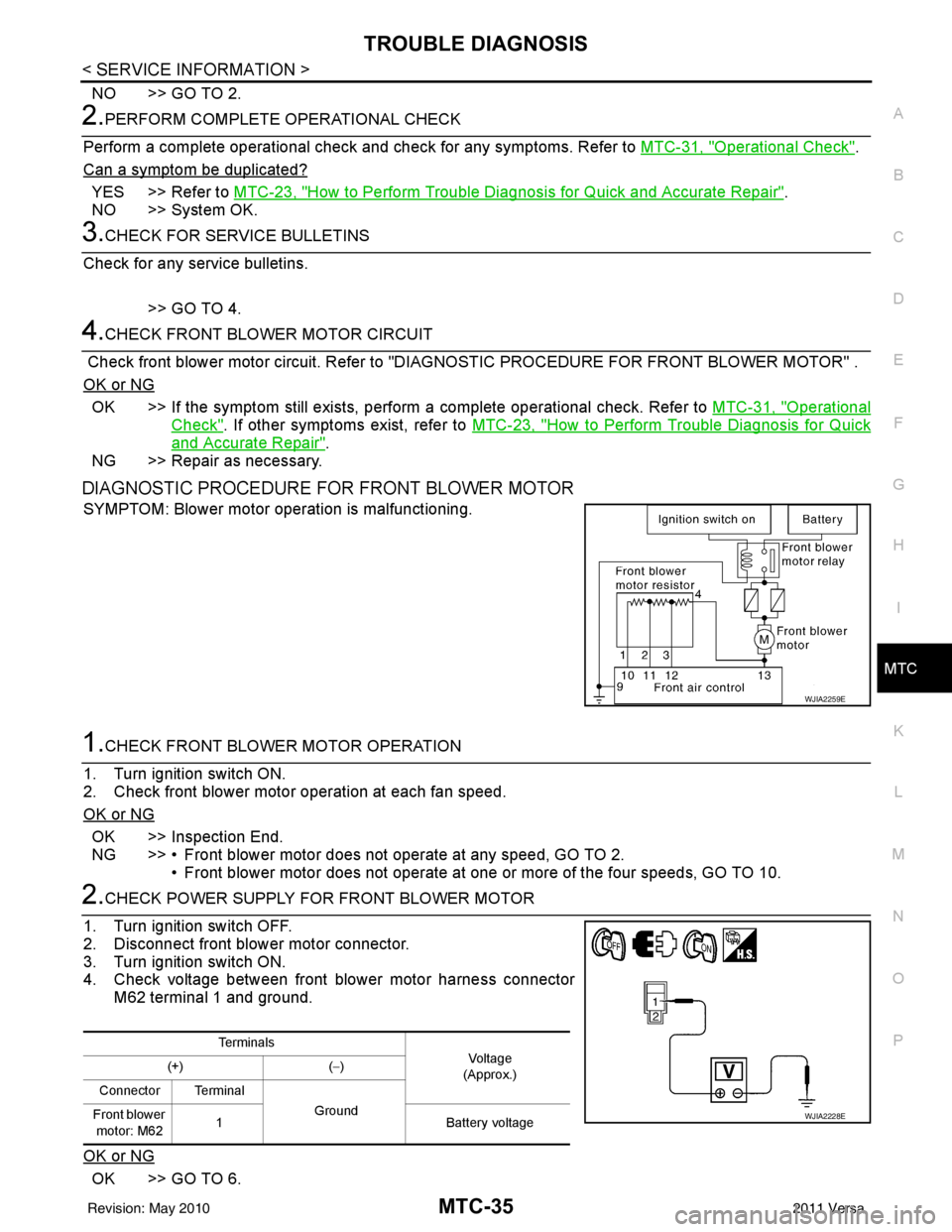

11 .CHECK FAN SWITCH

Check continuity between front air control terminal 9 and 10, 11, 12,

13, 14.

OK or NG

OK >> Replace the front blower motor resistor. Refer to MTC-67, "Removal and Installation".

NG >> Replace front air control. Refer to MTC-59, "

Removal and Installation".

Magnet Clutch Circuit (If Equipped)INFOID:0000000005930853

SYMPTOM: Magnet clutch does not engage.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OP ERATIONAL CHECK - MAGNET CLUTCH

1. Turn ignition switch ON.

2. Turn blower control dial to the desired (1 to 4 speed) position.

3. Press the A/C switch. A/C indicator will turn on.

4. Confirm that the compressor clut ch engages (sound or visual inspection).

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check".

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COMPRESSOR BELT TENSION

Check compressor belt tension. Refer to EM-13, "

Checking" (HR16DE) or EM-132, "Checking Drive Belts"

(MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Adjust or replace A/C compressor belt. Refer to EM-14, "

Removal and Installation" (HR16DE) or

EM-132, "

Removal and Installation" (MR18DE).

5.CHECK REFRIGERANT PRESSURE

Check refrigerant pressure with manifold gauge connected. Refer to MTC-46, "

Insufficient Cooling".

OK or NG

OK >> GO TO 6.

NG >> Perform trouble diagnosis for unusual pressure. Refer to MTC-46, "

Insufficient Cooling".

TerminalsConditionContinuity

9 14 Fan control dial: OFF

Ye s

10 Fan control dial: 1-speed

11 Fan control dial: 2-speed

12 Fan control dial: 3-speed

13 Fan control dial: 4-speed

SJIA0732E

Revision: May 2010 2011 Versa

Page 3355 of 3787

TROUBLE DIAGNOSISMTC-39

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

6.CHECK MAGNET CLUTCH CIRCUIT

Perform diagnostic procedure for the magnetic clutch . Refer to "DIAGNOSTIC PROCEDURE FOR MAGNET

CLUTCH".

OK or NG

OK >> If the symptom still exists, perform a complete operational check. Refer to MTC-31, "Operational

Check". If other symptoms exist, refer to MTC-23, "How to Perform Trouble Diagnosis for Quick

and Accurate Repair".

NG >> Repair as necessary.

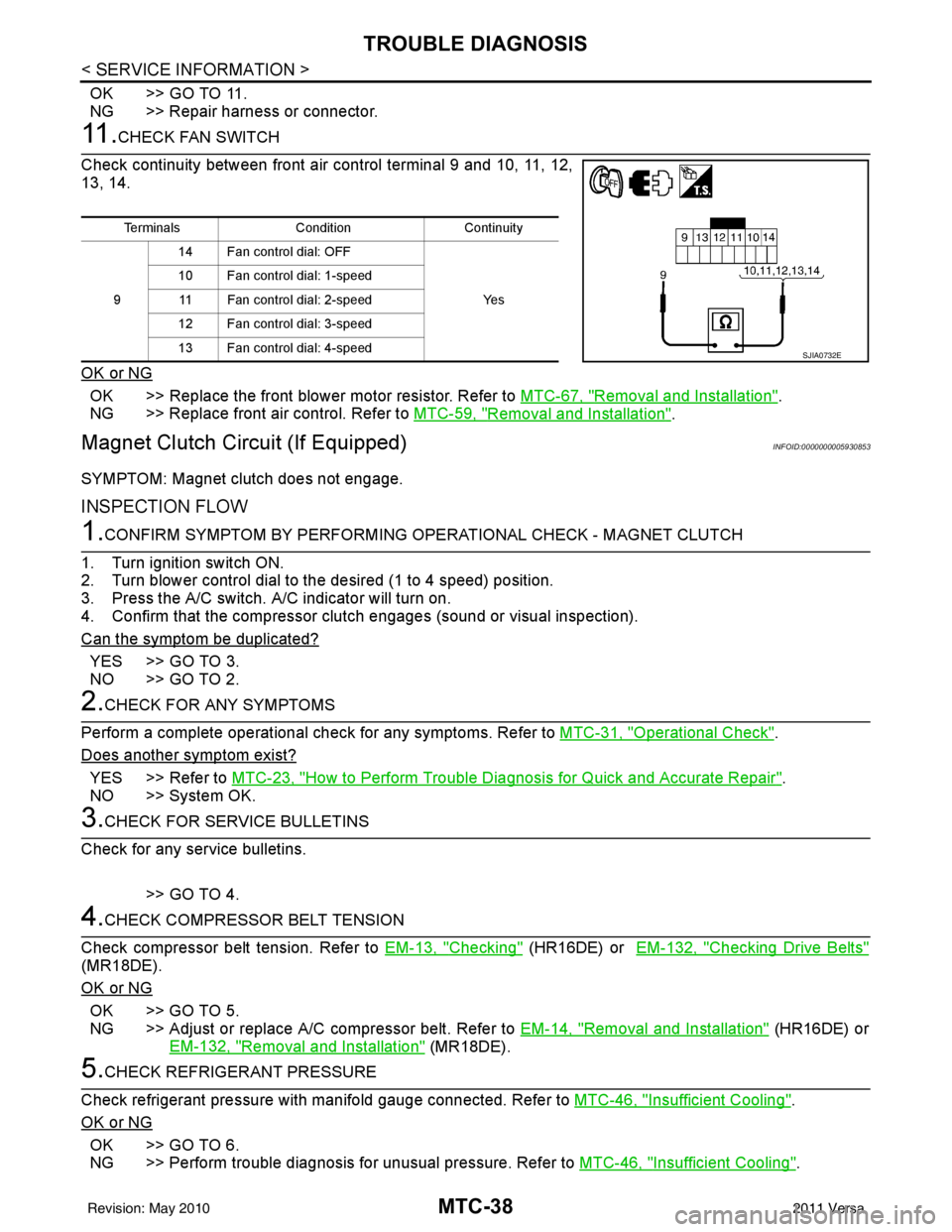

SYSTEM DESCRIPTION

Thermo control amp. controls A/C compressor operation by intake air temperature and signal from ECM.

The defrost A/C switch controls A/C compressor operati on by the BCM when the mode switch is turned to the

(DEF) position.

Low Temperature Protection Control

When intake air temperatures are higher than 4 °C (39° F), the com-

pressor turns ON. The compressor turns OFF when intake air tem-

peratures are lower than 2 °C (36° F).

DIAGNOSTIC PROCEDURE FOR MAGNET CLUTCH

SYMPTOM: Magnet clutch does not engage in A/C, defrost/foot, or defrost mode.

1.PERFORM AUTO ACTIVE TEST

Refer to PG-20, "

Auto Active Test".

Does the magnet clutch operate?

YES >> GO TO 5.

NO >> Check 10A fuse (No. 42, located in the IPDM E/R). Refer to PG-24, "

IPDM E/R Terminal

Arrangement - Type B".

• If fuse is OK, GO TO 2.

• If fuse is NG, replace fuse and check harness for short circuit. Repair or replace if necessary.

2.CHECK POWER SUPPLY FOR IPDM E/R

Check power supply to 10A fuse (No. 42 located in the IPDM E/R).

SJIA0741E

WJIA2250E

Revision: May 2010 2011 Versa

Page 3362 of 3787

MTC-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

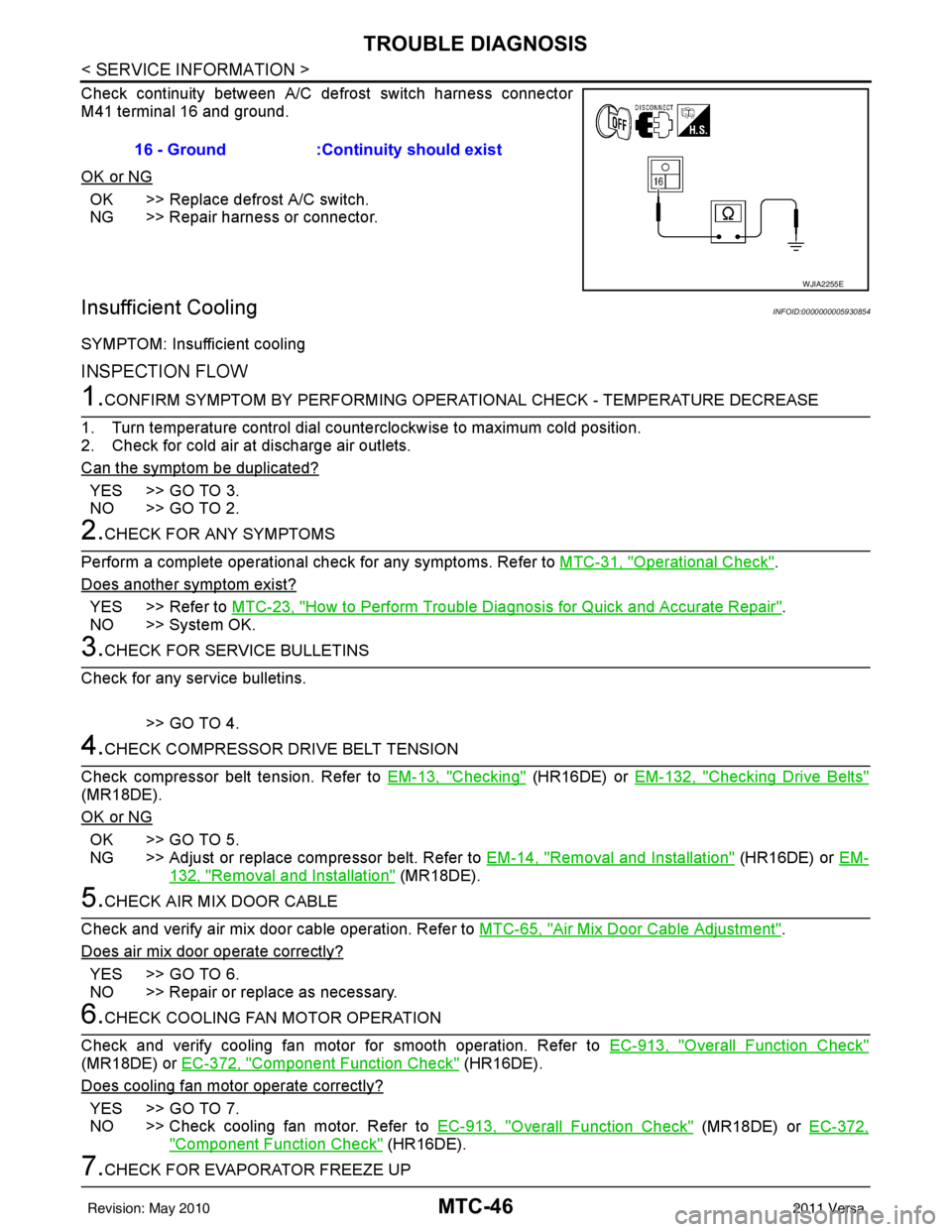

Check continuity between A/C defrost switch harness connector

M41 terminal 16 and ground.

OK or NG

OK >> Replace defrost A/C switch.

NG >> Repair harness or connector.

Insufficient CoolingINFOID:0000000005930854

SYMPTOM: Insufficient cooling

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE DECREASE

1. Turn temperature control dial counterclockwise to maximum cold position.

2. Check for cold air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check".

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COMPRESSOR DRIVE BELT TENSION

Check compressor belt tension. Refer to EM-13, "

Checking" (HR16DE) or EM-132, "Checking Drive Belts"

(MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Adjust or replace compressor belt. Refer to EM-14, "

Removal and Installation" (HR16DE) or EM-

132, "Removal and Installation" (MR18DE).

5.CHECK AIR MIX DOOR CABLE

Check and verify air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment".

Does air mix door operate correctly?

YES >> GO TO 6.

NO >> Repair or replace as necessary.

6.CHECK COOLING FAN MOTOR OPERATION

Check and verify cooling fan motor for smooth operation. Refer to EC-913, "

Overall Function Check"

(MR18DE) or EC-372, "Component Function Check" (HR16DE).

Does cooling fan motor operate correctly?

YES >> GO TO 7.

NO >> Check cooling fan motor. Refer to EC-913, "

Overall Function Check" (MR18DE) or EC-372,

"Component Function Check" (HR16DE).

7.CHECK FOR EVAPORATOR FREEZE UP16 - Ground :Continuity should exist

WJIA2255E

Revision: May 2010

2011 Versa

Page 3364 of 3787

MTC-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

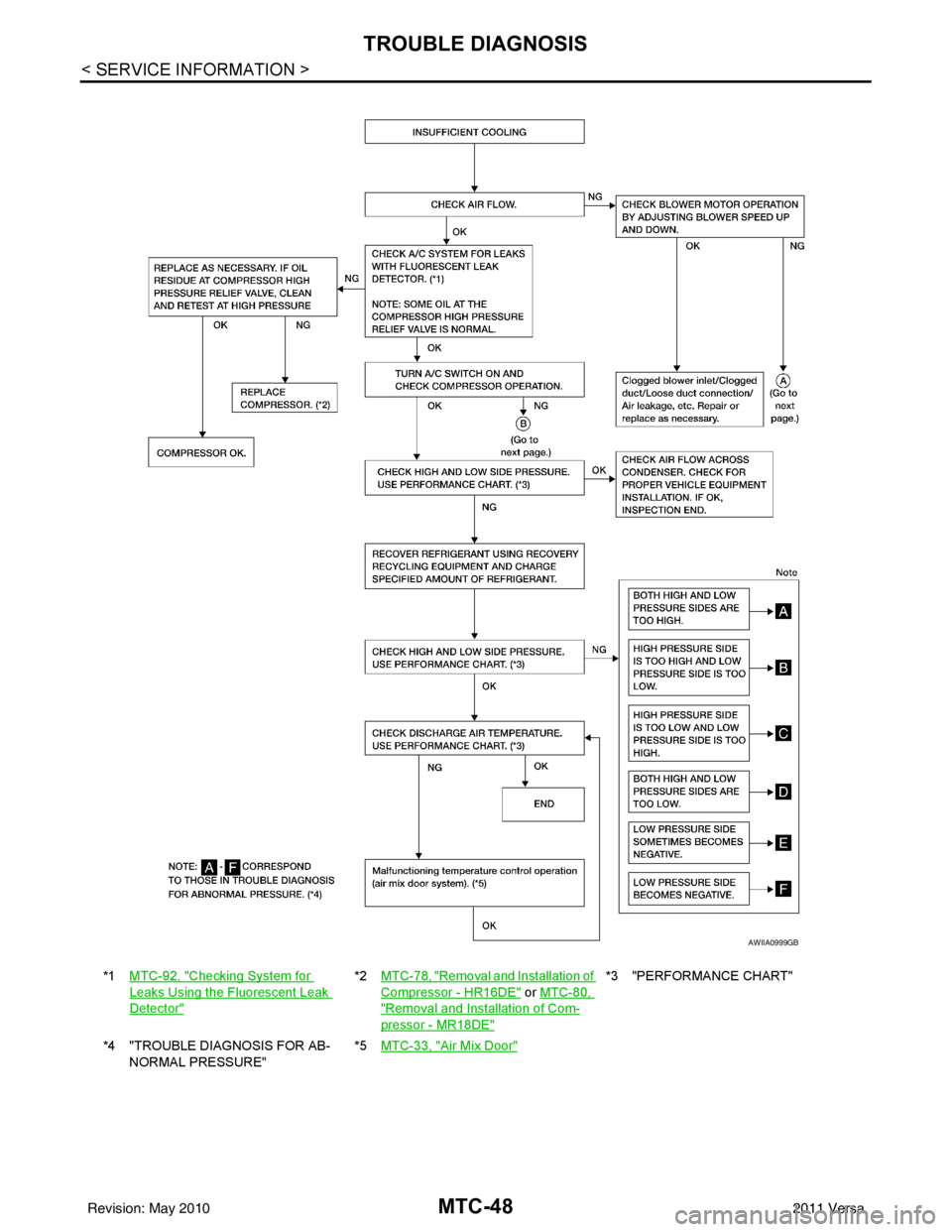

*1MTC-92, "Checking System for

Leaks Using the Fluorescent Leak

Detector"

*2MTC-78, "Removal and Installation of

Compressor - HR16DE" or MTC-80,

"Removal and Installation of Com-

pressor - MR18DE"

*3 "PERFORMANCE CHART"

*4 "TROUBLE DIAGNOSIS FOR AB- NORMAL PRESSURE" *5

MTC-33, "

Air Mix Door"

AWIIA0999GB

Revision: May 2010 2011 Versa

Page 3366 of 3787

MTC-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

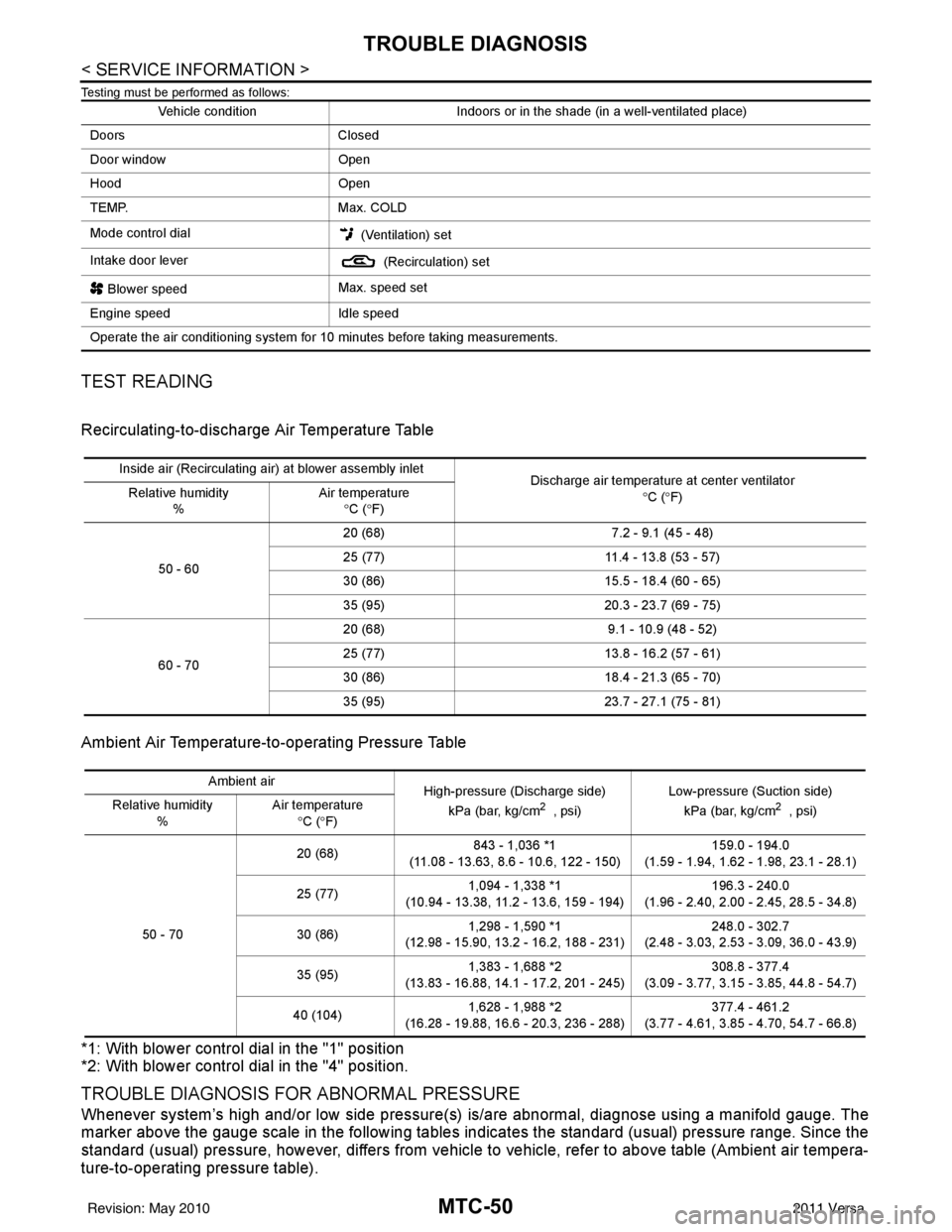

Testing must be performed as follows:

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

*1: With blower control dial in the "1" position

*2: With blower control dial in the "4" position.

TROUBLE DIAGNOSIS FOR ABNORMAL PRESSURE

Whenever system’s high and/or low side pressure(s) is/are abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode control dial (Ventilation) set

Intake door lever (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68)

7.2 - 9.1 (45 - 48)

25 (77) 11.4 - 13.8 (53 - 57)

30 (86) 15.5 - 18.4 (60 - 65)

35 (95) 20.3 - 23.7 (69 - 75)

60 - 70 20 (68)

9.1 - 10.9 (48 - 52)

25 (77) 13.8 - 16.2 (57 - 61)

30 (86) 18.4 - 21.3 (65 - 70)

35 (95) 23.7 - 27.1 (75 - 81)

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2 , psi) Low-pressure (Suction side)

kPa (bar, kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

843 - 1,036 *1

(11.08 - 13.63, 8.6 - 10.6, 122 - 150) 159.0 - 194.0

(1.59 - 1.94, 1.62 - 1.98, 23.1 - 28.1)

25 (77) 1,094 - 1,338 *1

(10.94 - 13.38, 11.2 - 13.6, 159 - 194) 196.3 - 240.0

(1.96 - 2.40, 2.00 - 2.45, 28.5 - 34.8)

30 (86) 1,298 - 1,590 *1

(12.98 - 15.90, 13.2 - 16.2, 188 - 231) 248.0 - 302.7

(2.48 - 3.03, 2.53 - 3.09, 36.0 - 43.9)

35 (95) 1,383 - 1,688 *2

(13.83 - 16.88, 14.1 - 17.2, 201 - 245) 308.8 - 377.4

(3.09 - 3.77, 3.15 - 3.85, 44.8 - 54.7)

40 (104) 1,628 - 1,988 *2

(16.28 - 19.88, 16.6 - 20.3, 236 - 288) 377.4 - 461.2

(3.77 - 4.61, 3.85 - 4.70, 54.7 - 66.8)

Revision: May 2010 2011 Versa

Page 3367 of 3787

TROUBLE DIAGNOSISMTC-51

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

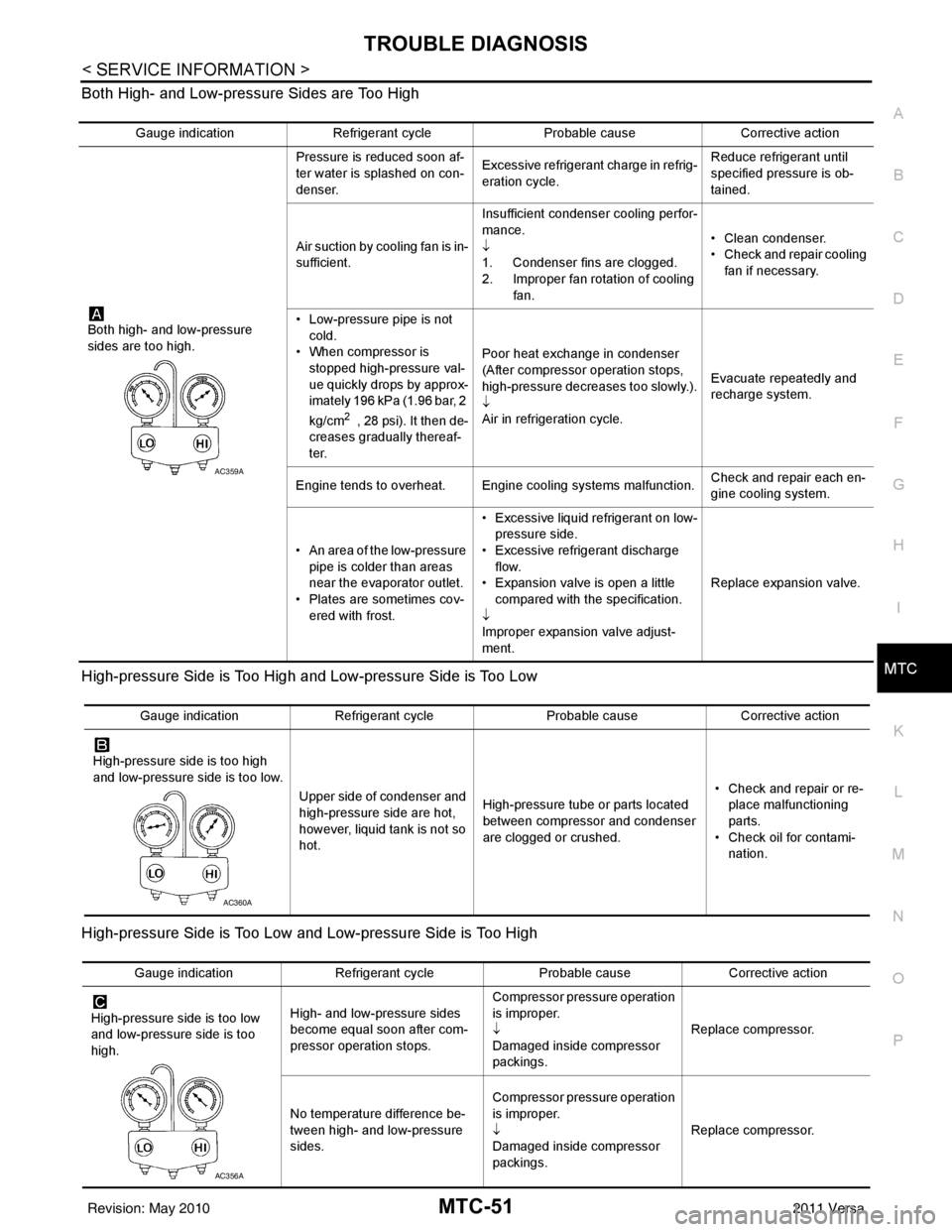

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication

Refrigerant cycle Probable causeCorrective action

Both high- and low-pressure

sides are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in refrig-

eration cycle. Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. • Clean condenser.

• Check and repair cooling

fan if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2 , 28 psi). It then de-

creases gradually thereaf-

ter. Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.

Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction. Check and repair each en-

gine cooling system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant on low-

pressure side.

• Excessive refrigerant discharge flow.

• Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment. Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycle Probable causeCorrective action

High-pressure side is too high

and low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. • Check and repair or re-

place malfunctioning

parts.

• Check oil for contami- nation.

AC360A

Gauge indication Refrigerant cycle Probable causeCorrective action

High-pressure side is too low

and low-pressure side is too

high. High- and low-pressure sides

become equal soon after com-

pressor operation stops. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Revision: May 2010

2011 Versa

Page 3368 of 3787

MTC-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable causeCorrective action

Both high- and low-pressure

sides are too low. • There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

• Liquid tank inlet and expan- sion valve are frosted. Liquid tank inside is slightly

clogged.

• Replace liquid tank.

• Check oil for contamination.

• Temperature of expansion valve inlet is extremely low as

compared with areas near liq-

uid tank.

• Expansion valve inlet may be

frosted.

• Temperature difference oc- curs somewhere in high-pres-

sure side. High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged.

• Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched. Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to

MTC-92, "

Checking of

Refrigerant Leaks" .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted. Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion valve.

3. Outlet and inlet may be clogged. • Remove foreign particles by

using compressed air.

• Replace expansion valve.

• Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet. Low-pressure pipe is clogged or

crushed.• Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Air flow volume is not enough or

is too low. Evaporator is frozen.• Check thermo control amp.

Refer to MTC-38, "

Magnet

Clutch Circuit (If Equipped)"

.

• Replace compressor.

• Repair evaporator fins.

• Replace evaporator.

•Refer to MTC-34, "

Front

Blower Motor Circuit" .

AC353A

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side sometimes be-

comes negative. • Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

• The system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted. Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant.

• Drain water from refrigerant

or replace refrigerant.

• Replace liquid tank.

AC354A

Revision: May 2010 2011 Versa

Page 3369 of 3787

TROUBLE DIAGNOSISMTC-53

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Insufficient HeatingINFOID:0000000005930855

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to maximum heat position.

2. Check for hot air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check" .

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COOLANT SYSTEM

1. Check engine coolant level. Refer to CO-11, "

Inspection" (HR16DE) or CO-36, "Inspection" (MR18DE).

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to CO-14, "

Checking Radiator Cap" HR16DE or CO-39, "Checking Radiator

Cap" (MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Repair/replace as necessary.

5.CHECK AIR MIX DOOR CABLE

Check air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

OK or NG

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: May 2010 2011 Versa