system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3495 of 3787

PS-1

STEERING

C

DE

F

H I

J

K L

M

SECTION PS

A

B

PS

N

O P

CONTENTS

POWER STEERING SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Steering System .......................... ......3

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

STEERING WHEEL .............................................6

On-Vehicle Inspection and Service ..................... ......6

Removal and Installation ..................................... .....7

STEERING COLUMN ........................................10

Removal and Installation .........................................10

STEERING SHAFT ...........................................13

Removal and Installation .........................................13

POWER STEERING GEAR ..............................15

Removal and Installation .........................................15

Disassembly and Assembly .....................................15

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

20

Steering Wheel ........................................................20

Steering Angle .........................................................20

Steering Column ......................................................20

Steering Outer Socket and Inner Socket .................20

Steering Gear ...................................................... ....21

Revision: May 2010 2011 Versa

Page 3496 of 3787

PS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006409484

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929628

NOTE:

• This procedure is applied only to models with Intel ligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition switch in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3497 of 3787

PRECAUTIONSPS-3

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage).

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Steering SystemINFOID:0000000005929629

• In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehicle

condition, and then check wheel alignment.

• Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might interfere with

their operation.

- Do not reuse non-reusable parts.

- Before assembling, apply the specif ied grease to the directed parts.

Revision: May 2010 2011 Versa

Page 3500 of 3787

PS-6

< SERVICE INFORMATION >

STEERING WHEEL

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000006416714

CHECKING CONDITION OF INSTALLATION

• Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check steering gear assembly bolts and nuts for looseness. Refer to PS-15, "

Removal and Installation".

CHECKING STEERING WHEEL PLAY

• Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the

outer circumference.

• When the measurement value is outside the standard val ue, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

• Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the correct position.

• Perform neutral position inspection after wheel alignment. Refer to PS-2, "

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"".

• Set vehicle to the straight-ahead position and c onfirm steering wheel is in the neutral position.

• Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steer-

ing wheel is not in the neutral position.

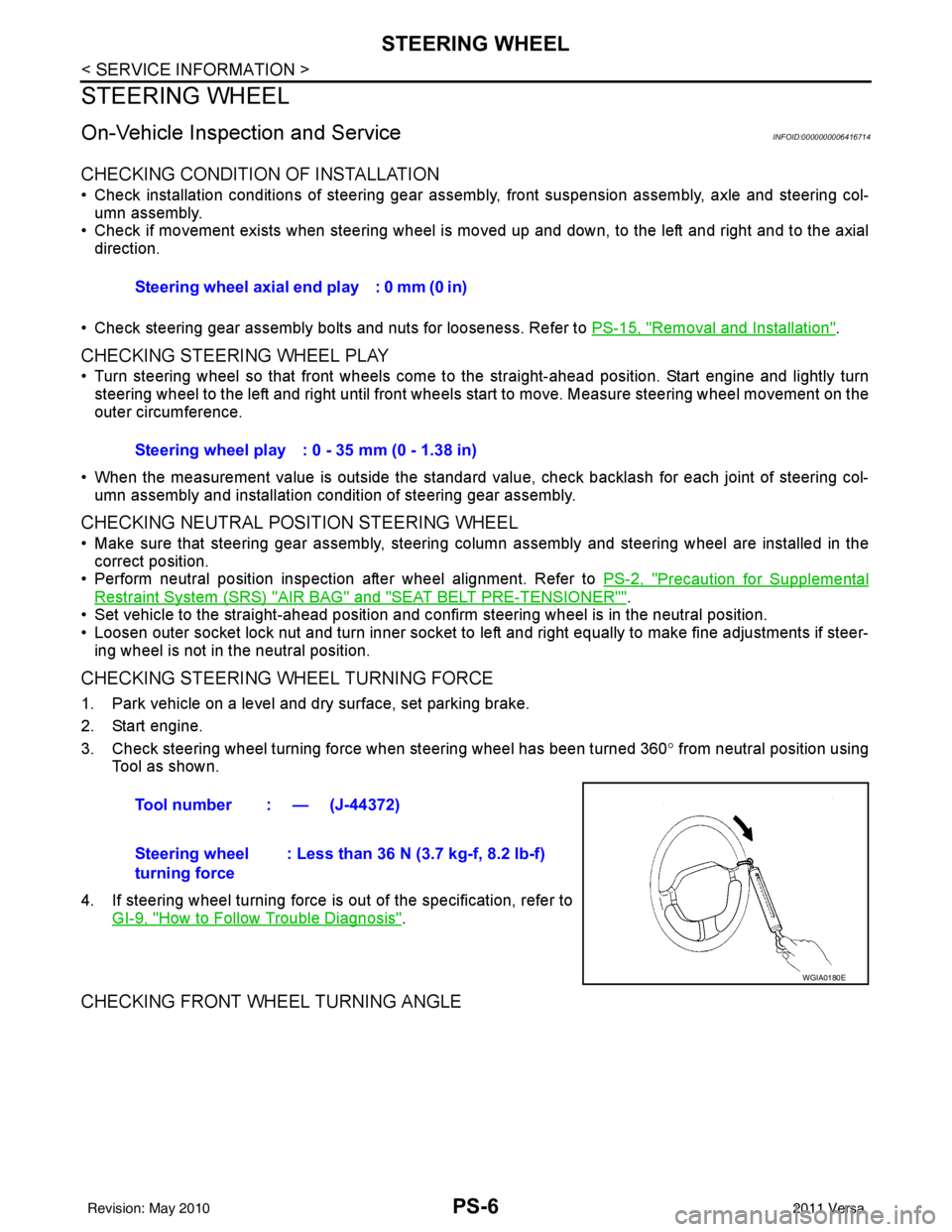

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Check steering wheel turning force when steering wheel has been turned 360 ° from neutral position using

Tool as shown.

4. If steering wheel turning force is out of the specification, refer to GI-9, "

How to Follow Trouble Diagnosis".

CHECKING FRONT WHEEL TURNING ANGLE

Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Tool number : — (J-44372)

Steering wheel

turning force : Less than 36 N (3.7 kg-f, 8.2 lb-f)

WGIA0180E

Revision: May 2010

2011 Versa

Page 3516 of 3787

RAX-1

DRIVELINE/AXLE

CEF

G H

I

J

K L

M

SECTION RAX

A

B

RAX

N

O P

CONTENTS

REAR AXLE

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Commercial Service Tool .................................... ......4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

5

NVH Troubleshooting Chart ................................ .....5

WHEEL HUB ......................................................6

On-Vehicle Inspection and Service ..........................6

Removal and Installation ..........................................6

SERVICE DATA AND SPECIFICATIONS

(SDS) ..................................................................

8

Wheel Bearing ..........................................................8

Revision: May 2010 2011 Versa

Page 3517 of 3787

RAX-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928711

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005928712

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3524 of 3787

RF-1

BODY

C

DE

F

G H

J

K L

M

SECTION RF

A

B

RF

N

O P

CONTENTS

ROOF

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution .................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

SYMPTOM DIAGNOSIS ...............................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

5

Work Flow ........................................................... ......5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

FUNCTION DIAGNOSIS ..............................11

TROUBLE DIAGNOSIS ................................. ....11

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

11

System Description ..................................................11

CAN Communication System Description ...............13

Wiring Diagram - SROOF - ......................................14

Terminal and Reference Value for BCM ..................15

Terminal and Reference Value for Sunroof Motor

Assembly ............................................................. ....

16

Work Flow ................................................................16

CONSULT-III Function (BCM) .................................16

Work Support ....................................................... ....17

Active Test ...............................................................17

Data Monitor ............................................................17

Trouble Diagnosis Chart by Symptom .....................17

BCM Power Supply and Ground Circuit Inspection

....

17

Sunroof Switch System Inspection ..........................17

Sunroof Motor Assembly Power Supply and

Ground Circuit Inspection ........................................

19

Door Switch Check ..................................................20

ON-VEHICLE REPAIR .................................22

SUNROOF .........................................................22

Removal and Installation ..................................... ....22

Fitting Adjustment ....................................................27

Inspection ................................................................28

Revision: May 2010 2011 Versa

Page 3525 of 3787

RF-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929517

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929518

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3534 of 3787

TROUBLE DIAGNOSISRF-11

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

FUNCTION DIAGNOSIS

TROUBLE DIAGNOSIS

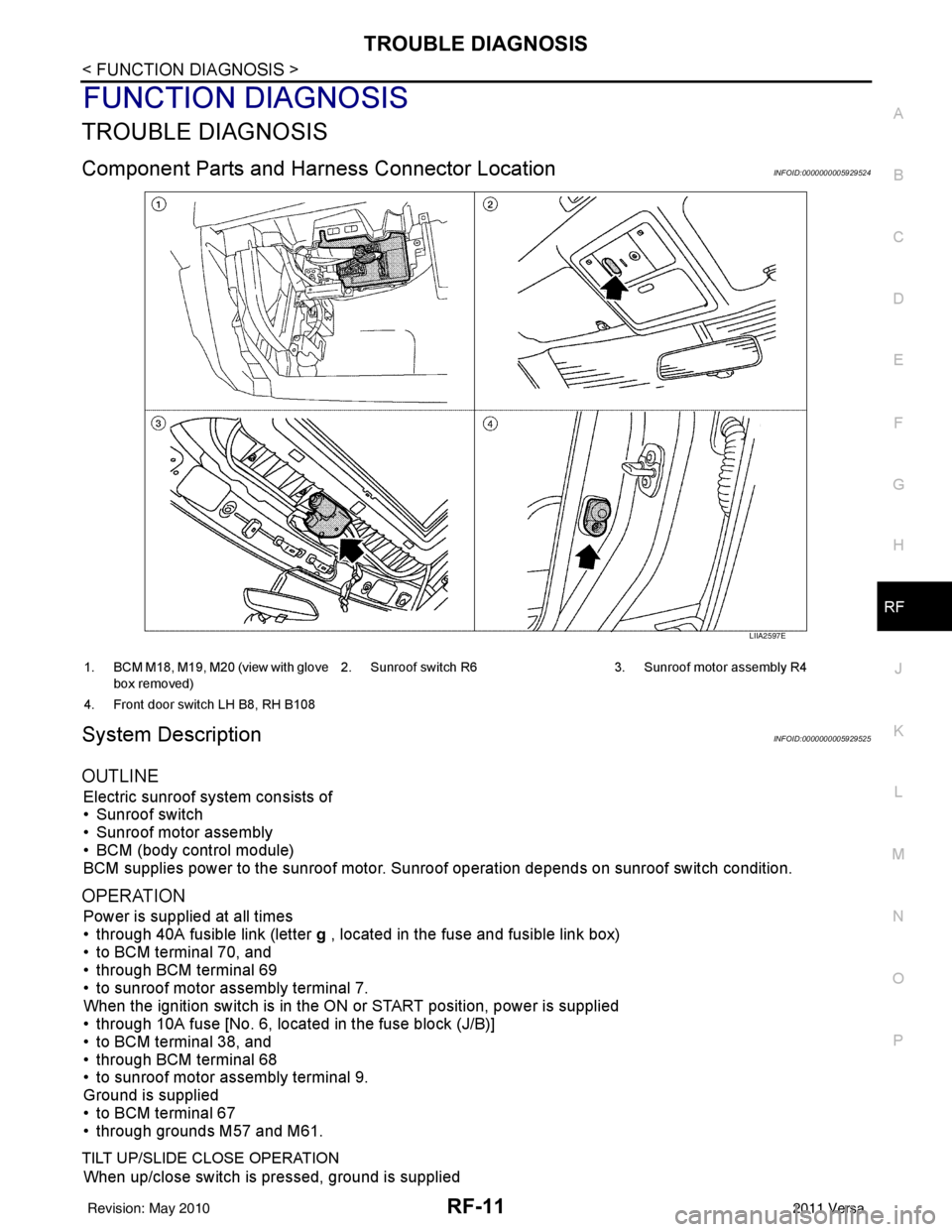

Component Parts and Har ness Connector LocationINFOID:0000000005929524

System DescriptionINFOID:0000000005929525

OUTLINE

Electric sunroof system consists of

• Sunroof switch

• Sunroof motor assembly

• BCM (body control module)

BCM supplies power to the sunroof motor. S unroof operation depends on sunroof switch condition.

OPERATION

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70, and

• through BCM terminal 69

• to sunroof motor assembly terminal 7.

When the ignition switch is in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38, and

• through BCM terminal 68

• to sunroof motor assembly terminal 9.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61.

TILT UP/SLIDE CLOSE OPERATION

When up/close switch is pressed, ground is supplied

LIIA2597E

1. BCM M18, M19, M20 (view with glove

box removed) 2. Sunroof switch R6 3. Sunroof motor assembly R4

4. Front door switch LH B8, RH B108

Revision: May 2010 2011 Versa

Page 3535 of 3787

RF-12

< FUNCTION DIAGNOSIS >

TROUBLE DIAGNOSIS

• to sunroof motor assembly terminal 1

• through sunroof switch terminal 3

• through sunroof switch terminal 2

• through grounds M57 and M61.

Then the sunroof will tilt up/slide closed.

TILT DOWN/SLIDE OPEN OPERATION

When down/open switch is pressed, ground is supplied

• to sunroof motor assembly terminal 5

• through sunroof switch terminal 1

• through sunroof switch terminal 2

• through grounds M57 and M61.

Then the sunroof will tilt down/slide open.

AUTO OPERATION

The power sunroof AUTO feature makes it possible to slide open and slide closed or tilt up and tilt down the

sunroof without holding the sunroof switch in the UP/CLOSE or DOWN/OPEN position.

RETAINED POWER OPERATION

When the ignition switch is turned to OFF position from ON position, power is supplied for 45 seconds

• through BCM terminal 68

• to sunroof motor assembly terminal 9.

When power is supplied, the sunroof can be operated.

The retained power operation is canceled when the front door LH or RH is opened.

RAP signal period can be changed by CONSULT-III. Refer to RF-17, "

Work Support" .

ANTI-PINCH FUNCTION

The CPU (central processing unit) of sunroof motor as sembly monitors the sunroof motor operation and the

sunroof position (fully-closed or other ) by the signals from sunroof motor.

When sunroof motor detects an interruption during the following slide close and tilt down operation, sunroof

switch controls the motor for open and the sunroof will oper ate until it reaches full up position (during tilt down

operation) or 125 mm (4.92 in) or more in an open direction (during slide close operation).

• close operation and tilt down when igniti on switch is in the ON position.

• close operation and tilt down during retained power operation.

INITIALIZATION FAILURE CONDITIONS

Initialization and teaching of system should be conducted if the following conditions exist:

• sunroof will only move in the UP/CLOSE direction, having a step by step motion

• sunroof does not have any auto operation.

INITIALIZATION PROCEDURE

If the sunroof does not open or close automatically, use the following procedure to return sunroof operation to

normal.

NOTE:

If the sunroof switch is released at any time during step 3, the procedure must be started over again. Leave

the ignition switch ON for at least 2 seconds after this procedure.

1. Push the ignition switch to the ON position.

2. Hold the sunroof switch in the tilt up position. Release the switch when the s unroof has reached the full tilt

up position.

3. Within 5 seconds of releasing the switch in step 2, hold the sunroof switch in the tilt up position again. The sunroof will move from the open position and back to t he close position. Release the switch only when

the sunroof has reached the full closed position.

RE-TEACHING CONDITIONS

Re-teaching of system should be conducted if any of the following conditions exist:

• the sunroof is manually operated using the sunroof wrench with the battery discharged or disconnected.

• the sunroof is manually operated using the sunroof wrench with the key switch in the OFF position and

retained power timed out (after approximat ely 45 seconds or with a front door open).

• the sunroof motor assembly is replaced with a new one.

• the sunroof motor is removed from the sunroof assembly and operated before it is reinstalled.

• the sunroof motor is removed from the sunroof assembly and the glass panel position is changed.

RE-TEACHING PROCEDURE

1. Using the UP/CLOSE switch, move the sunroof toward the tilt position until it stops.

Revision: May 2010 2011 Versa