system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3442 of 3787

PG-22

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

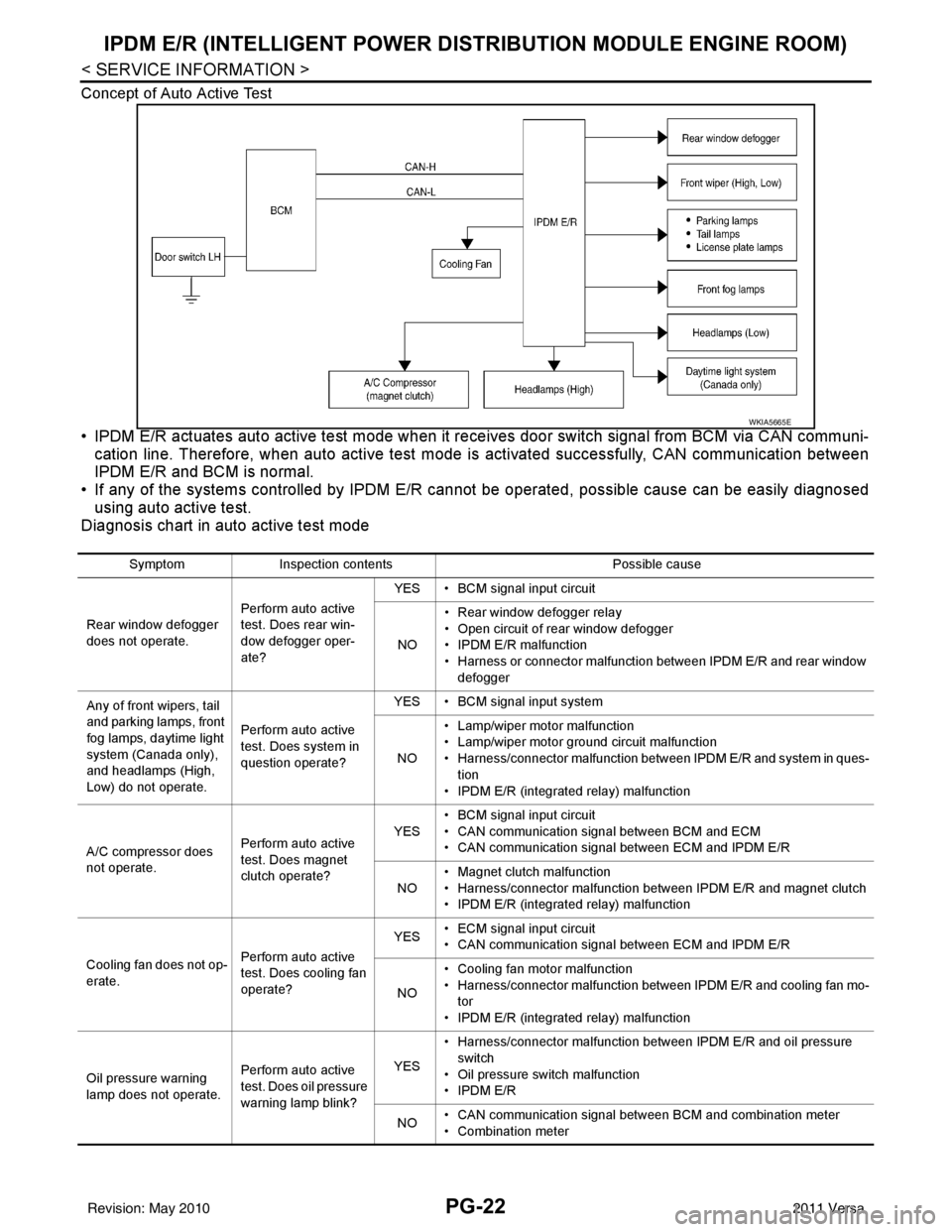

Concept of Auto Active Test

• IPDM E/R actuates auto active test mode when it re ceives door switch signal from BCM via CAN communi-

cation line. Therefore, when auto active test mode is activated successfully, CAN communication between

IPDM E/R and BCM is normal.

• If any of the systems controll ed by IPDM E/R cannot be operated, possible cause can be easily diagnosed

using auto active test.

Diagnosis chart in auto active test mode

WKIA5665E

Symptom Inspection contents Possible cause

Rear window defogger

does not operate. Perform auto active

test. Does rear win-

dow defogger oper-

ate?YES • BCM signal input circuit

NO • Rear window defogger relay

• Open circuit of rear window defogger

•IPDM E/R malfunction

• Harness or connector malfunction between IPDM E/R and rear window

defogger

Any of front wipers, tail

and parking lamps, front

fog lamps, daytime light

system (Canada only),

and headlamps (High,

Low) do not operate. Perform auto active

test. Does system in

question operate?YES • BCM signal input system

NO • Lamp/wiper motor malfunction

• Lamp/wiper motor ground circuit malfunction

• Harness/connector malfunction between IPDM E/R and system in ques-

tion

• IPDM E/R (integrated relay) malfunction

A/C compressor does

not operate. Perform auto active

test. Does magnet

clutch operate?YES

• BCM signal input circuit

• CAN communication signal between BCM and ECM

• CAN communication signal between ECM and IPDM E/R

NO • Magnet clutch malfunction

• Harness/connector malfunction between IPDM E/R and magnet clutch

• IPDM E/R (integrated relay) malfunction

Cooling fan does not op-

erate. Perform auto active

test. Does cooling fan

operate?YES

• ECM signal input circuit

• CAN communication signal between ECM and IPDM E/R

NO • Cooling fan motor malfunction

• Harness/connector malfunction between IPDM E/R and cooling fan mo-

tor

• IPDM E/R (integrated relay) malfunction

Oil pressure warning

lamp does not operate. Perform auto active

test. Does oil pressure

warning lamp blink?YES

• Harness/connector malfunction between IPDM E/R and oil pressure

switch

• Oil pressure switch malfunction

•IPDM E/R

NO • CAN communication signal between BCM and combination meter

• Combination meter

Revision: May 2010

2011 Versa

Page 3445 of 3787

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-25

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

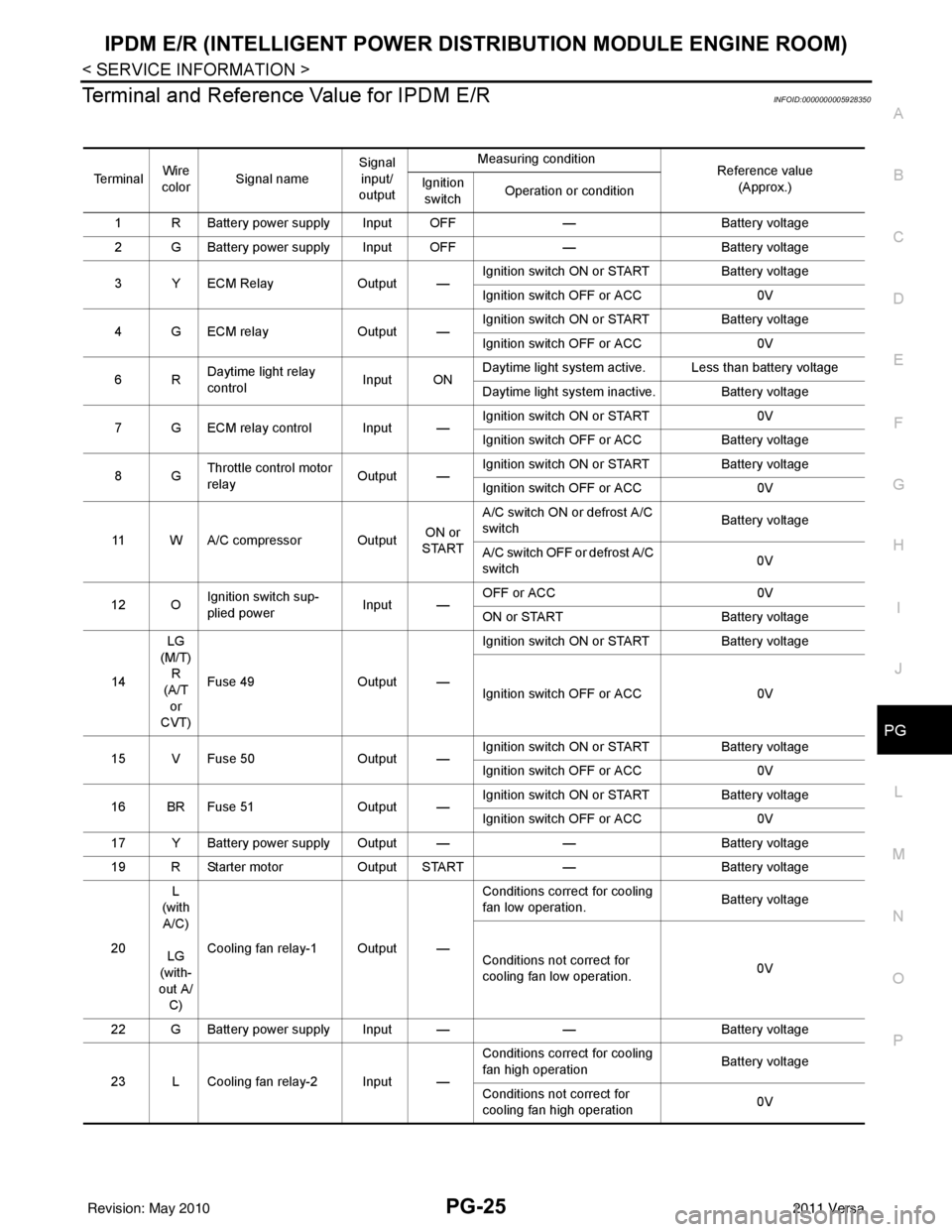

Terminal and Reference Value for IPDM E/RINFOID:0000000005928350

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value

(Approx.)

Ignition

switch Operation or condition

1 R Battery power supply Input OFF —Battery voltage

2 G Battery power supply Input OFF —Battery voltage

3YECM Relay Output— Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

4GECM relay Output— Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

6R Daytime light relay

control Input ON Daytime light system active. Less than battery voltage

Daytime light system inactive. Battery voltage

7 G ECM relay control Input — Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

8G Throttle control motor

relay

Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

11 W A/C compressor Output ON or

START A/C switch ON or defrost A/C

switch

Battery voltage

A/C switch OFF or defrost A/C

switch 0V

12 O Ignition switch sup-

plied power Input —OFF or ACC

0V

ON or START Battery voltage

14 LG

(M/T) R

(A/T or

CVT) Fuse 49

Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

15 V Fuse 50 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

16 BR Fuse 51 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

17 Y Battery power supply Output — —Battery voltage

19 R Starter motor Output START—Battery voltage

20 L

(with A/C)

LG

(with-

out A/

C) Cooling fan relay-1 Output — Conditions correct for cooling

fan low operation.

Battery voltage

Conditions not correct for

cooling fan low operation. 0V

22 G Battery power supply Input — —Battery voltage

23 L Cooling fan relay-2 Input — Conditions correct for cooling

fan high operation

Battery voltage

Conditions not correct for

cooling fan high operation 0V

Revision: May 2010

2011 Versa

Page 3446 of 3787

PG-26

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

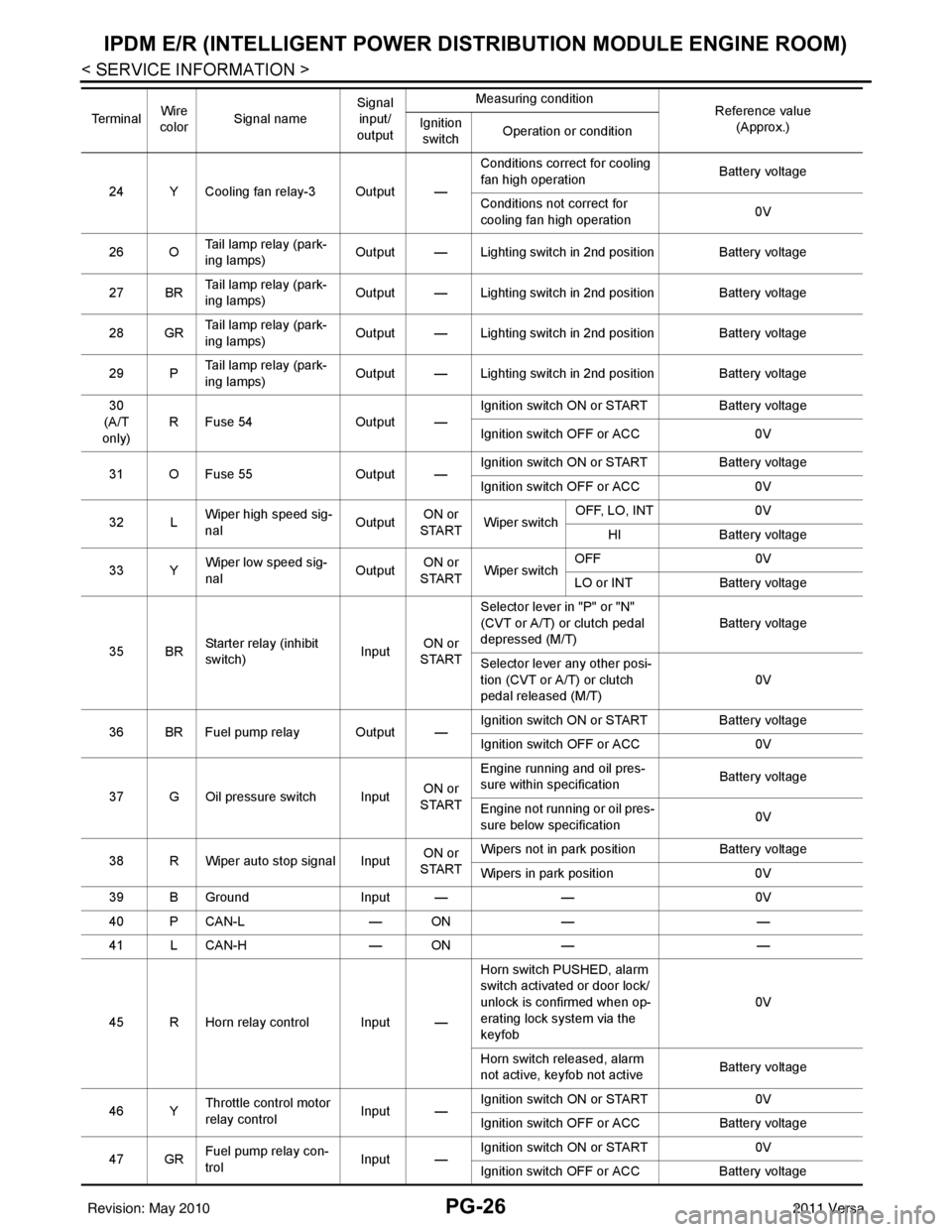

24 Y Cooling fan relay-3 Output — Conditions correct for cooling

fan high operation

Battery voltage

Conditions not correct for

cooling fan high operation 0V

26 O Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

27 BR Tail lamp relay (park-

ing lamps)

Output — Lighting switch in 2nd position Battery voltage

28 GR Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

29 P Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

30

(A/T

only) R Fuse 54

Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

31 O Fuse 55 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

32 L Wiper high speed sig-

nal

OutputON or

START Wiper switch OFF, LO, INT

0V

HI Battery voltage

33 Y Wiper low speed sig-

nal

OutputON or

START Wiper switch OFF

0V

LO or INT Battery voltage

35 BR Starter relay (inhibit

switch) InputON or

START Selector lever in "P" or "N"

(CVT or A/T) or clutch pedal

depressed (M/T)

Battery voltage

Selector lever any other posi-

tion (CVT or A/T) or clutch

pedal released (M/T) 0V

36 BR Fuel pump relay Output — Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

37 G Oil pressure switch Input ON or

START Engine running and oil pres-

sure within specification

Battery voltage

Engine not running or oil pres-

sure below specification 0V

38 R Wiper auto stop signal Input ON or

START Wipers not in park position

Battery voltage

Wipers in park position 0V

39 B Ground Input ——0V

40 P CAN-L — ON— —

41 L CAN-H — ON— —

45 R Horn relay control Input — Horn switch PUSHED, alarm

switch activated or door lock/

unlock is confirmed when op-

erating lock system via the

keyfob

0V

Horn switch released, alarm

not active, keyfob not active Battery voltage

46 Y Throttle control motor

relay control Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

47 GR Fuel pump relay con-

trol Input —Ignition switch ON or START

0V

Ig niti

on switch OFF or ACC Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value

(Approx.)

Ignition

switch Operation or condition

Revision: May 2010

2011 Versa

Page 3448 of 3787

PG-28

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

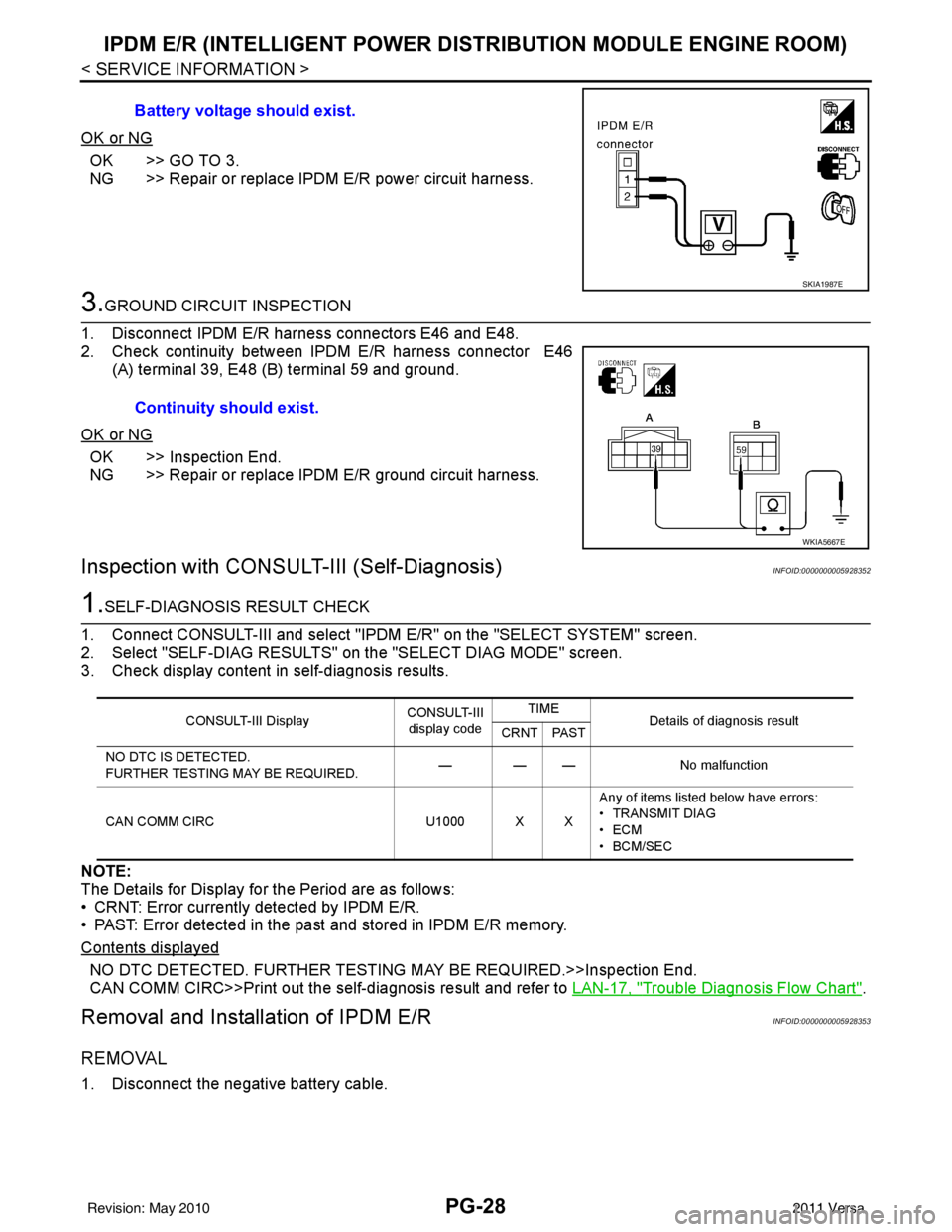

OK or NG

OK >> GO TO 3.

NG >> Repair or replace IPDM E/R power circuit harness.

3.GROUND CIRCUIT INSPECTION

1. Disconnect IPDM E/R harness connectors E46 and E48.

2. Check continuity between IPDM E/R harness connector E46 (A) terminal 39, E48 (B) terminal 59 and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or replace IPDM E/R ground circuit harness.

Inspection with CONSULT-III (Self-Diagnosis)INFOID:0000000005928352

1.SELF-DIAGNOSIS RESULT CHECK

1. Connect CONSULT-III and select "IPDM E/R" on the "SELECT SYSTEM" screen.

2. Select "SELF-DIAG RESULTS" on the "SELECT DIAG MODE" screen.

3. Check display content in self-diagnosis results.

NOTE:

The Details for Display for the Period are as follows:

• CRNT: Error currently detected by IPDM E/R.

• PAST: Error detected in the past and stored in IPDM E/R memory.

Contents displayed

NO DTC DETECTED. FURTHER TESTING MAY BE REQUIRED.>>Inspection End.

CAN COMM CIRC>>Print out the self-diagnosis result and refer to LAN-17, "

Trouble Diagnosis Flow Chart".

Removal and Installation of IPDM E/RINFOID:0000000005928353

REMOVAL

1. Disconnect the negative battery cable. Battery voltage should exist.

SKIA1987E

Continuity should exist.

WKIA5667E

CONSULT-III Display

CONSULT-III

display code TIME

Details of diagnosis result

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED. — — —

No malfunction

CAN COMM CIRC U1000 X XAny of items listed below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

Revision: May 2010

2011 Versa

Page 3470 of 3787

PG-50

< SERVICE INFORMATION >

HARNESS

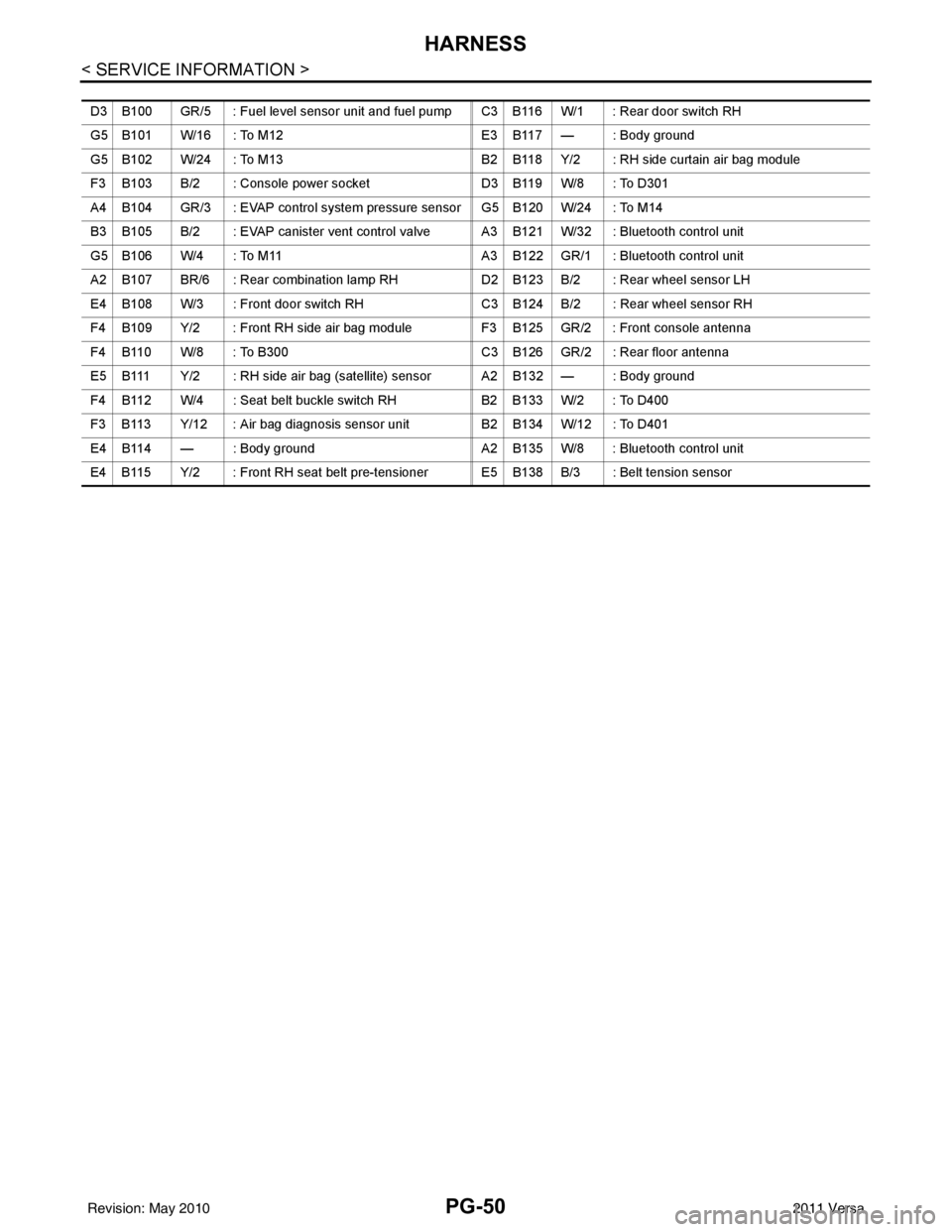

D3 B100 GR/5 : Fuel level sensor unit and fuel pump C3 B116 W/1 : Rear door switch RH

G5 B101 W/16 : To M12E3 B117 — : Body ground

G5 B102 W/24 : To M13 B2 B118 Y/2 : RH side curtain air bag module

F3 B103 B/2 : Console power socket D3 B119 W/8 : To D301

A4 B104 GR/3 : EVAP control system pressure sensor G5 B120 W/24 : To M14

B3 B105 B/2 : EVAP canister vent control valve A3 B121 W/32 : Bluetooth control unit

G5 B106 W/4 : To M11 A3 B122 GR/1 : Bluetooth control unit

A2 B107 BR/6 : Rear combination lamp RH D2 B123 B/2 : Rear wheel sensor LH

E4 B108 W/3 : Front door switch RH C3 B124 B/2 : Rear wheel sensor RH

F4 B109 Y/2 : Front RH side air bag module F3 B125 GR/2 : Front console antenna

F4 B110 W/8 : To B300 C3 B126 GR/2 : Rear floor antenna

E5 B111 Y/2 : RH side air bag (satellite) sensor A2 B132 — : Body ground

F4 B112 W/4 : Seat belt buckle switch RH B2 B133 W/2 : To D400

F3 B113 Y/12 : Air bag diagnosis sensor unit B2 B134 W/12 : To D401

E4 B114 — : Body ground A2 B135 W/8 : Bluetooth control unit

E4 B115 Y/2 : Front RH seat belt pre-tensioner E5 B138 B/3 : Belt tension sensor

Revision: May 2010 2011 Versa

Page 3471 of 3787

HARNESSPG-51

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

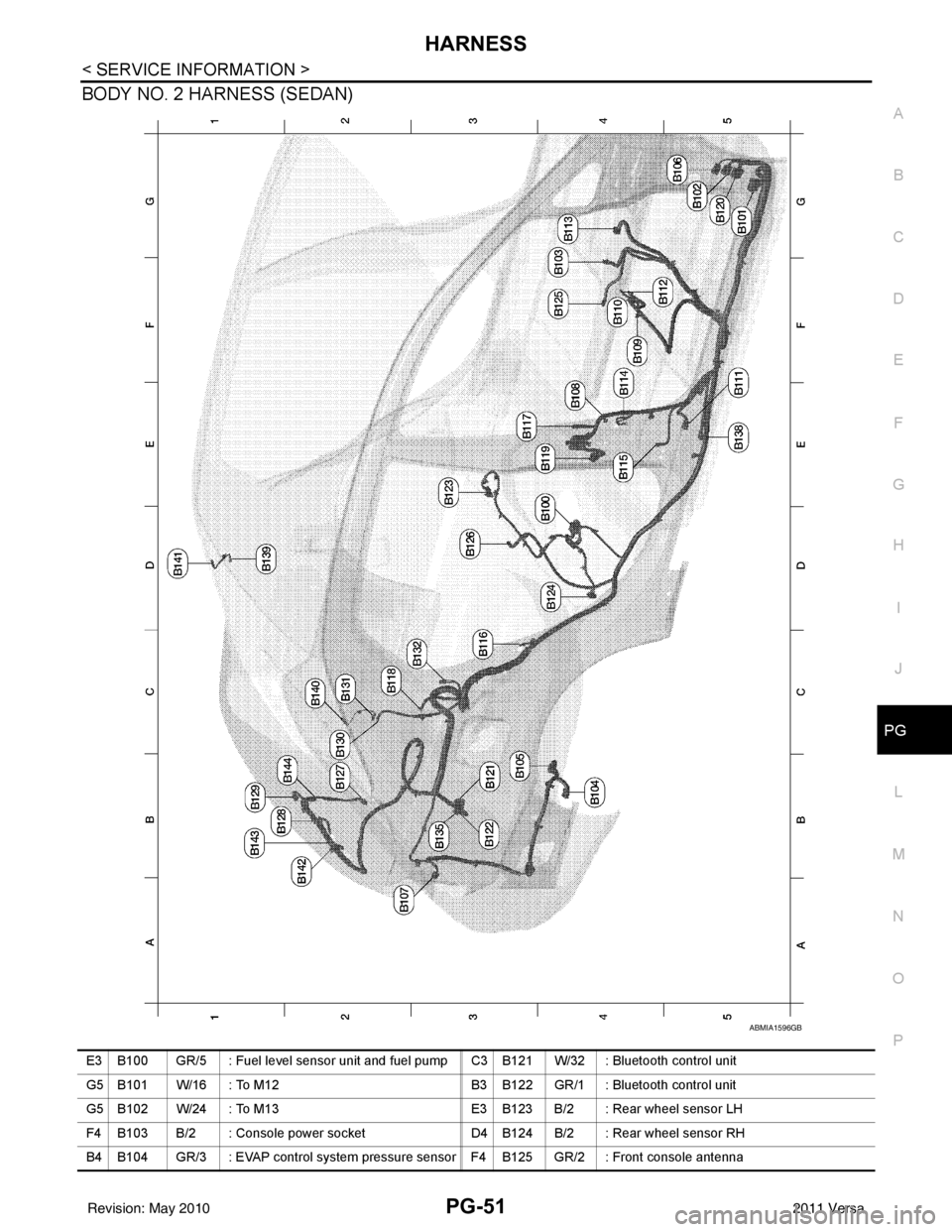

BODY NO. 2 HARNESS (SEDAN)

ABMIA1596GB

E3 B100 GR/5 : Fuel level sensor unit and fuel pump C3 B121 W/32 : Bluetooth control unit

G5 B101 W/16 : To M12 B3 B122 GR/1 : Bluetooth control unit

G5 B102 W/24 : To M13 E3 B123 B/2 : Rear wheel sensor LH

F4 B103 B/2 : Console power socket D4 B124 B/2 : Rear wheel sensor RH

B4 B104 GR/3 : EVAP control system pressure sensor F4 B125 GR/2 : Front console antenna

Revision: May 2010 2011 Versa

Page 3478 of 3787

PG-58

< SERVICE INFORMATION >

HARNESS

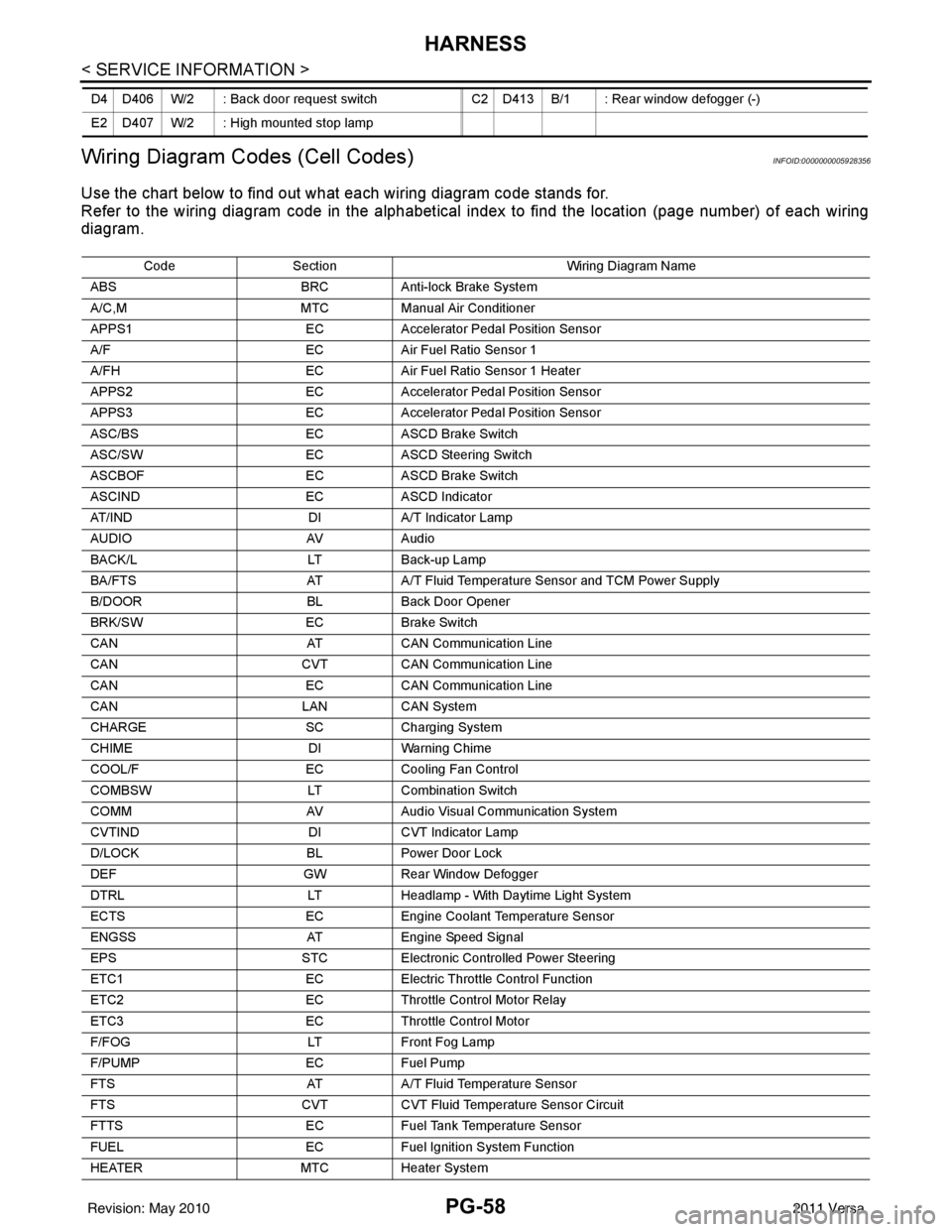

Wiring Diagram Codes (Cell Codes)

INFOID:0000000005928356

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D4 D406 W/2 : Back door request switch C2 D413 B/1 : Rear window defogger (-)

E2 D407 W/2 : High mounted stop lamp

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

HEATER MTC Heater System

Revision: May 2010 2011 Versa

Page 3479 of 3787

HARNESSPG-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

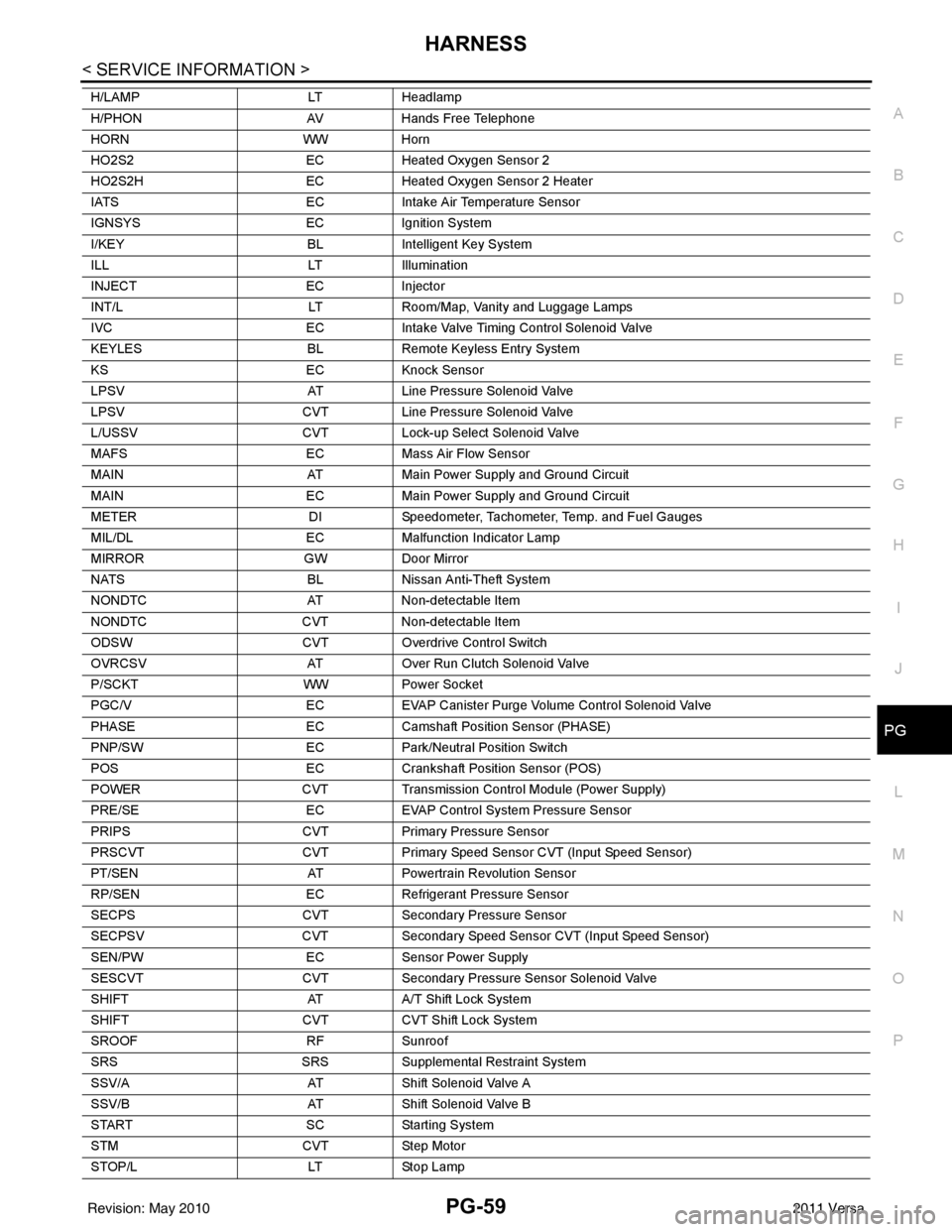

H/LAMP LT Headlamp

H/PHON AV Hands Free Telephone

HORN WW Horn

HO2S2 EC Heated Oxygen Sensor 2

HO2S2H EC Heated Oxygen Sensor 2 Heater

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

I/KEY BL Intelligent Key System

ILL LT Illumination

INJECT EC Injector

INT/L LT Room/Map, Vanity and Luggage Lamps

IVC EC Intake Valve Timing Control Solenoid Valve

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

LPSV AT Line Pressure Solenoid Valve

LPSV CVT Line Pressure Solenoid Valve

L/USSV CVT Lock-up Select Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp

MIRROR GW Door Mirror

NATS BL Nissan Anti-Theft System

NONDTC AT Non-detectable Item

NONDTC CVT Non-detectable Item

ODSW CVT Overdrive Control Switch

OVRCSV AT Over Run Clutch Solenoid Valve

P/SCKT WW Power Socket

PGC/V EC EVAP Canister Purge Vo lume Control Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER CVT Transmission Control Module (Power Supply)

PRE/SE EC EVAP Control System Pressure Sensor

PRIPS CVT Primary Pressure Sensor

PRSCVT CVT Primary Speed Sensor CVT (Input Speed Sensor)

PT/SEN AT Powertrain Revolution Sensor

RP/SEN EC Refrigerant Pressure Sensor

SECPS CVT Secondary Pressure Sensor

SECPSV CVT Secondary Speed Sensor CVT (Input Speed Sensor)

SEN/PW EC Sensor Power Supply

SESCVT CVT Secondary Pressure Sensor Solenoid Valve

SHIFT AT A/T Shift Lock System

SHIFT CVT CVT Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STM CVT Step Motor

STOP/L LT Stop Lamp

Revision: May 2010 2011 Versa

Page 3480 of 3787

PG-60

< SERVICE INFORMATION >

HARNESS

TCVAT Torque Converter Clutch Solenoid Valve

TCV CVT Torque Converter Clutch Solenoid Valve

T/LID BL Trunk Lid Opener

T/WARN WT Low Tire Pressure Warning System

TAIL/L LT Parking, License and Tail Lamps

TPS1 EC Throttle Position Sensor

TPS2 EC Throttle Position Sensor

TPS3 EC Throttle Position Sensor

TR/SW AT Transmission Range Switch

TR/SW CVT Transmission Range Switch

TURN LT Turn Signal and Hazard Warning Lamps

VDC BRC Vehicle Dynamic Control System

VEHSEC BL Vehicle Security (Theft Warning) System

VENT/V EC EVAP Canister Vent Control Valve

VSSA/T AT Vehicle Speed Sensor A/T (Input Speed Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN DI Warning Lamps

WINDOW GW Power Window

WIP/R WW Rear Wiper and Washer

WIPER WW Front Wiper and Washer

Revision: May 2010 2011 Versa

Page 3485 of 3787

HARNESS CONNECTORPG-65

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

HARNESS CONNECTOR

DescriptionINFOID:0000000005928358

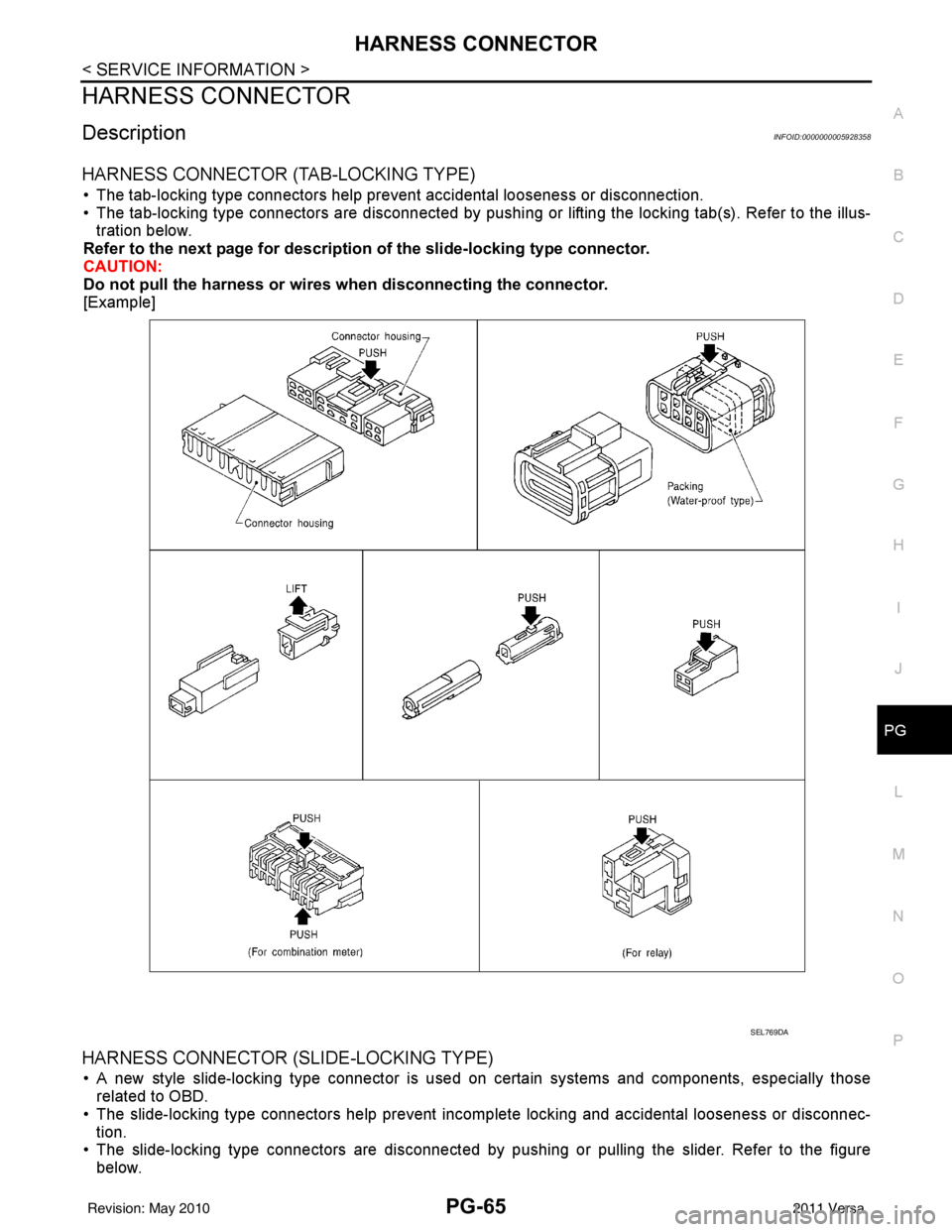

HARNESS CONNECTOR (TAB-LOCKING TYPE)

• The tab-locking type connectors help prevent accidental looseness or disconnection.

• The tab-locking type connectors are disconnected by pushi ng or lifting the locking tab(s). Refer to the illus-

tration below.

Refer to the next page for description of the slide-locking type connector.

CAUTION:

Do not pull the harness or wires when disconnecting the connector.

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

• A new style slide-locking type connector is used on certain systems and components, especially those related to OBD.

• The slide-locking type connectors help prevent incomplete locking and accidental looseness or disconnec- tion.

• The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the figure

below.

SEL769DA

Revision: May 2010 2011 Versa