system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3661 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISSRS-27

< SYMPTOM DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

PRE-TEN FRONT LH [OPEN]

[B1086] The circuit for front LH seat belt pre-tensioner is open. 1. Visually check the wiring h NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISSRS-27

< SYMPTOM DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

PRE-TEN FRONT LH [OPEN]

[B1086] The circuit for front LH seat belt pre-tensioner is open. 1. Visually check the wiring h](/img/5/57396/w960_57396-3660.png)

TROUBLE DIAGNOSISSRS-27

< SYMPTOM DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

PRE-TEN FRONT LH [OPEN]

[B1086] The circuit for front LH seat belt pre-tensioner is open. 1. Visually check the wiring harness

connections.

2. Replace the harness if it has visi- ble damage.

3. Replace front LH seat belt pre- tensioner.

4. Replace the air bag diagnosis

sensor unit.

5. Replace the related harness.

PRE-TEN FRONT LH

[VB-SHORT]

[B1087] The circuit for front LH seat belt pre-tensioner is shorted to

some power supply circuit.

PRE-TEN FRONT LH [GND-SHORT] [B1088] The circuit for front LH seat belt pre-tensioner is shorted to

ground.

PRE-TEN FRONT LH [SHORT][B1089] The circuits for the front LH seat belt pre-tensioner are shorted

to each other.

PRE-TEN FRONT RH [OPEN]

[B1081] The circuit for front RH seat belt pre-tensioner is open. 1. Visually check the wiring harness

connections.

2. Replace the harness if it has visi- ble damage.

3. Replace front RH seat belt pre-

tensioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

PRE-TEN FRONT RH

[VB-SHORT][B1082] The circuit for front RH seat belt pre-tensioner is shorted to

some power supply circuit.

PRE-TEN FRONT RH [GND-SHORT][B1083] The circuit for front RH seat belt pre-tensioner is shorted to

ground.

PRE-TEN FRONT RH [SHORT]

[B1084] The circuits for the front RH seat belt pre-tensioner are short-

ed to each other.

CURTAIN MODULE LH [OPEN][B1150] The LH side curtain air bag module circuit is open.

1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi-

ble damage.

3. Replace LH side curtain air bag module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

CURTAIN MODULE LH

[VB-SHORT][B1151] The LH side curtain air bag module circuit is shorted to some

power supply circuits.

CURTAIN MODULE LH [GND-SHORT]

[B1152] The LH side curtain air bag module circuit is shorted to

ground.

CURTAIN MODULE LH [SHORT][B1153] The circuits for the LH side curtain air bag module are shorted

to each other.

CURTAIN MODULE RH [OPEN]

[B1145] The RH side curtain air bag module circuit is open.

1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi- ble damage.

3. Replace RH side curtain air bag

module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

CURTAIN MODULE RH

[VB-SHORT][B1146] The RH side curtain air bag module circuit is shorted to some

power supply circuits.

CURTAIN MODULE RH [GND-SHORT][B1147] The RH side curtain air bag module circuit is shorted to

g

rou

nd.

CURTAIN MODULE RH [SHORT]

[B1148] The circuits for the RH side curtain air bag module are shorted

to each other.

CONTROL UNIT [B1XXX] Air bag diagnosis sensor unit is malfunctioning.

1. Visually check the wiring harness

connection.

2. Replace the air bag diagnosis

sensor unit.

OCCUPANT SENS C/U [UNIT FAIL]

[B1017] or [B1021] The OCS control unit is malfunctioning.

1. Replace RH front seat cushion/

occupant classification system

control unit assembly.

Diagnostic item

Explanation Repair order

Recheck SRS at each replacement

Revision: May 2010 2011 Versa

Page 3681 of 3787

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNITSRS-47

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNIT

Removal and InstallationINFOID:0000000005931220

The occupant classification system control unit, occupant classification system sensor, and bladder are an

integral part of the front passenger seat cushion and are replaced as an assembly. Refer to SE-11

to remove

the seat, and SE-13, "

Disassembly and Assembly" to replace the seat cushion.

Revision: May 2010 2011 Versa

Page 3682 of 3787

SRS-48

< ON-VEHICLE REPAIR >

COLLISION DIAGNOSIS

COLLISION DIAGNOSIS

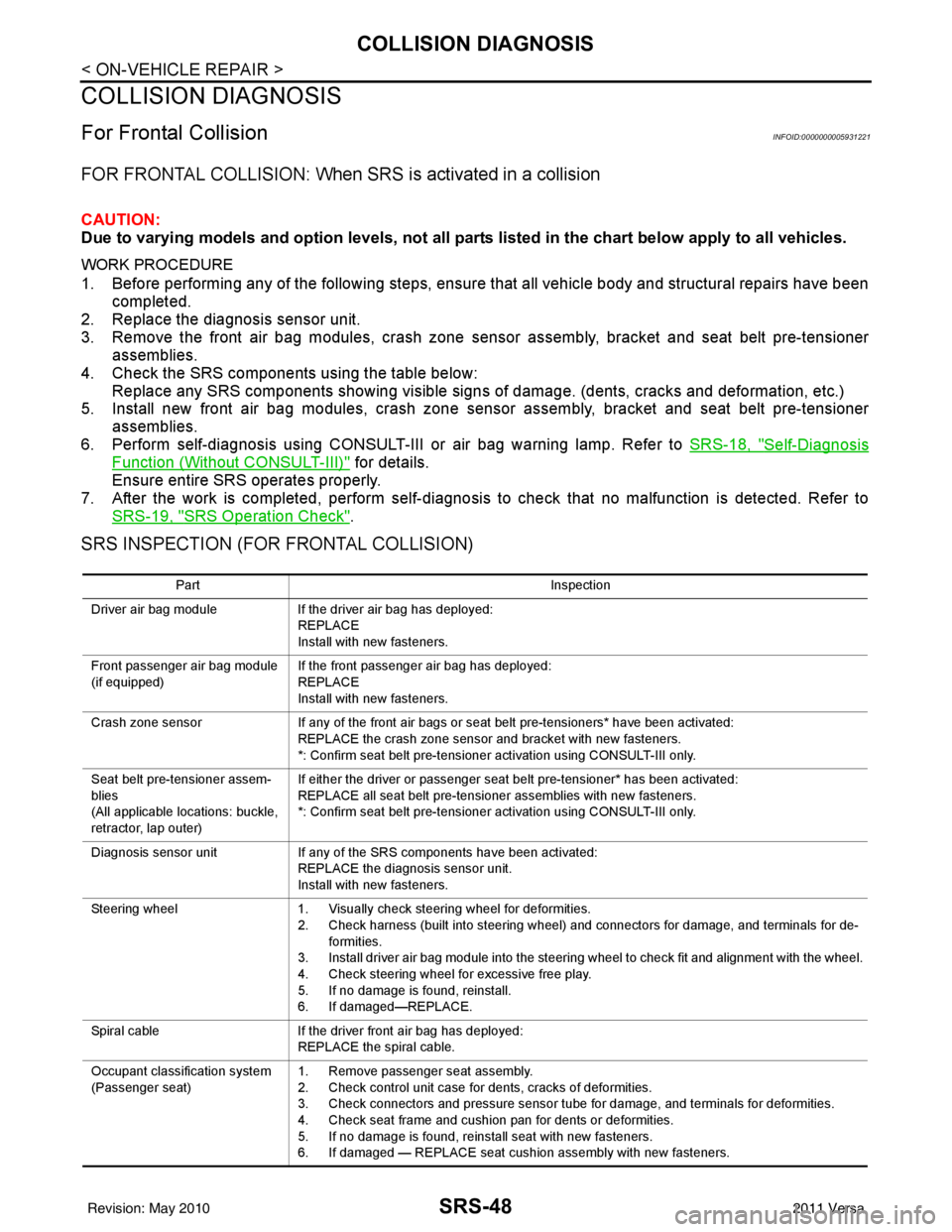

For Frontal CollisionINFOID:0000000005931221

FOR FRONTAL COLLISION: When SRS is activated in a collision

CAUTION:

Due to varying models and option levels, not all parts listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensure that all vehicle body and structural repairs have been

completed.

2. Replace the diagnosis sensor unit.

3. Remove the front air bag modules, crash zone sens or assembly, bracket and seat belt pre-tensioner

assemblies.

4. Check the SRS components using the table below: Replace any SRS components showing visible signs of damage. (dents, cracks and deformation, etc.)

5. Install new front air bag modules, crash zone sens or assembly, bracket and seat belt pre-tensioner

assemblies.

6. Perform self-diagnosis using CONSULT-III or air bag warning lamp. Refer to SRS-18, "

Self-Diagnosis

Function (Without CONSULT-III)" for details.

Ensure entire SRS operates properly.

7. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-19, "

SRS Operation Check".

SRS INSPECTION (FOR FRONTAL COLLISION)

Part Inspection

Driver air bag module If the driver air bag has deployed:

REPLACE

Install with new fasteners.

Front passenger air bag module

(if equipped) If the front passenger air bag has deployed:

REPLACE

Install with new fasteners.

Crash zone sensor If any of the front air bags or seat belt pre-tensioners* have been activated:

REPLACE the crash zone sensor and bracket with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If either the driver or passenger seat belt pre-tensioner* has been activated:

REPLACE all seat belt pre-tensioner assemblies with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Diagnosis sensor unit If any of the SRS components have been activated:

REPLACE the diagnosis sensor unit.

Install with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for de- formities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged—REPLACE.

Spiral cable If the driver front air bag has deployed:

REPLACE the spiral cable.

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged — REPLACE seat cushion assembly with new fasteners.

Revision: May 2010

2011 Versa

Page 3684 of 3787

SRS-50

< ON-VEHICLE REPAIR >

COLLISION DIAGNOSIS

For Side and Ro llover Collision

INFOID:0000000005931222

FOR SIDE AND ROLLOVER COLLISION: Wh en SRS is activated in a collision

CAUTION:

Due to varying models and option levels, not all part s listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensure that all vehicle body and structural repairs have been

completed.

2. Replace the following components:

- Front seat back assembly (on the side on which side air bag is activated).

- Door finisher (on the side on which door-mounted curtain air bag is activated).

- Pop-up roll bar assemblies and pop-up roll bar covers.

- Side air bag (satellite) sensor LH/RH (on the side on which side air bag is activated).

- Diagnosis sensor unit.

- Seat belt pre-tensioner assemblies.

3. Check the SRS components and the related parts using the following table. Replace any SRS components and the related parts showing visible signs of damage (dents, cracks,

deformation, etc.).

4. Perform self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRS-19, "

SRS Opera-

tion Check" for details. Make sure entire SRS operates properly.

5. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-18, "

Self-Diagnosis Function (Without CONSULT-III)".

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Diagnosis sensor unit If none of the SRS components have been activated:

1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install diagnosis sensor unit with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for defor- mities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged—REPLACE.

Spiral cable If the driver front air bag has not deployed:

1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged—REPLACE.

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged — REPLACE seat cushion assembly with new fasteners.

Harness and connectors 1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged—REPLACE the damaged harness. Do not attempt to repair, splice or modify any

SRS harness.

Instrument panel assembly If the passenger front air bag has NOT deployed: 1. Visually check instrument panel for damage.

2. If no damage is found, reinstall the instrument panel assembly.

3. If damaged—REPLACE the instrument panel assembly.

Part

Inspection

Revision: May 2010 2011 Versa

Page 3688 of 3787

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

EPS

BASIC INSPECTION ....... .............................

3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

SYSTEM DESCRIPTION ..............................5

EPS SYSTEM ... .............................................. .....5

System Diagram .................................................. ......5

System Description ...................................................5

Component Parts Location ........................................6

Component Description .............................................6

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

.....

8

CONSULT-III Function ........................................ ......8

DTC/CIRCUIT DIAGNOSIS ..........................9

C1601 BATTERY POWER SUPPLY ..................9

Description .......................................................... ......9

DTC Logic .................................................................9

Diagnosis Procedure .................................................9

C1604 TORQUE SENSOR .................................11

Description ..............................................................11

DTC Logic ...............................................................11

Diagnosis Procedure ...............................................11

C1606 EPS MOTOR ...........................................13

Description .......................................................... ....13

DTC Logic ...............................................................13

Diagnosis Procedure ...............................................13

Component Inspection ............................................13

C1607, C1608 EPS CONTROL UNIT ................15

Description .......................................................... ....15

DTC Logic ...............................................................15

Diagnosis Procedure ...............................................15

C1609 VEHICLE SPEED SIGNAL .....................16

Description ........................................................... ....16

DTC Logic ................................................................16

Diagnosis Procedure ...............................................16

C1610 ENGINE STATUS SIGNAL ...................17

Description ...............................................................17

DTC Logic ................................................................17

Diagnosis Procedure ...............................................17

U1000 CAN COMM CIRCUIT ...........................18

Description ...............................................................18

DTC Logic ................................................................18

Diagnosis Procedure ...............................................18

EPS WARNING LAMP ......................................19

Description ...............................................................19

Component Function Check ....................................19

Diagnosis Procedure ...............................................19

ECU DIAGNOSIS INFORMATION ..............20

EPS CONTROL UNIT .......................................20

Reference Value .................................................. ....20

Wiring Diagram - ELECTRONICALLY CON-

TROLLED POWER STEERING SYSTEM - ............

22

Fail-Safe .............................................................. ....23

DTC Inspection Priority Chart ..................................24

DTC Index ...............................................................24

SYMPTOM DIAGNOSIS ..............................25

EPS WARNING LAMP DOES NOT TURN ON ...25

Description ........................................................... ....25

Diagnosis Procedure ...............................................25

EPS WARNING LAMP DOES NOT TURN

OFF ....................................................................

26

Description ...............................................................26

Diagnosis Procedure ...............................................26

STEERING WHEEL TURNING FORCE IS

HEAVY OR LIGHT ............................................

27

Revision: May 2010 2011 Versa

Page 3689 of 3787

STC-2

Description ..............................................................27

Diagnosis Procedure ..............................................27

UNBALANCE STEERING WHEEL TURNING

FORCE AND RETURN BETWEEN RIGHT

AND LEFT ..........................................................

28

Description ..............................................................28

Diagnosis Procedure ..............................................28

UNBALANCE STEERING WHEEL TURNING

FORCE (TORQUE VARIATION) .......................

29

Description ........................................................... ...29

Diagnosis Procedure ............................................ ...29

PRECAUTION ............................................30

PRECAUTIONS .............................................. ...30

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

30

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

30

Service Notice or Precaution for EPS System ........31

Revision: May 2010 2011 Versa

Page 3690 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS AND REPAIR WORKFLOWSTC-3

< BASIC INSPECTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000005931223

1.OBTAIN INFORMATION ABO NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS AND REPAIR WORKFLOWSTC-3

< BASIC INSPECTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000005931223

1.OBTAIN INFORMATION ABO](/img/5/57396/w960_57396-3689.png)

DIAGNOSIS AND REPAIR WORKFLOWSTC-3

< BASIC INSPECTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000005931223

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much informa tion as possible about the conditions and environment under

which the malfunction occurs.

>> GO TO 2.

2.CHECK DTC

1. Check for DTC.

2. If a DTC exists, perform the following operations.

- Records the DTCs.

- Erase DTCs

- Check that the root cause clarified with DTC matches to the malfunction information described by the cus-

tomer.

3. Check also the related service information or others.

Do malfunction information or DTC exist?

Malfunction information and DTC exist. >>GO TO 3.

Malfunction information exists but no DTC. >>GO TO 4.

No malfunction information, but DTC exists. >>GO TO 5.

3.REPRODUCE THE MALFUNCTION INFORMATION

Check the malfunction described by the customer on the vehicle.

Record the status of each signal when a symptom occurs with “Data Monitor” in CONSULT-III.

Inspect the relation of the information and the condition when it occurs.

>> GO TO 5.

4.CHECK THE MALFUNCTION

Check the malfunction described by the customer on the vehicle.

Record the status of each signal when a symptom occurs with “Data Monitor” in CONSULT-III.

Inspect the relation of the information and the condition when it occurs.

>> GO TO 6.

5.PERFORM “DTC CONFIRMATION PROCEDURE”

Perform the “DTC conformation procedure” to the det ected DTC and check that the DTC is detected again.

Refer to STC-24, "

DTC Inspection Priority Chart" when multiple DTCs are detected, and then judge the order

for performing the diagnosis.

Is any DTC detected?

YES >> GO TO 7.

NO >> Follow GI-9, "

How to Follow Trouble Diagnosis" to check.

6.IDENTIFY MALFUNCTIONING SYST EM WITH “SYMPTOM DIAGNOSIS”

Use the “Symptom diagnosis” from the symptom inspection result in step 4. Then identify where to start per-

forming the diagnosis based on the pos sible causes and the symptoms.

>> GO TO 7.

7.IDENTIFY MALFUNCTIONING PART S WITH “COMPONENT DIAGNOSIS”

Perform the inspection with the “component diagnosis” of the applicable system.

NOTE:

The “component diagnosis” mainly consists of the check for an open circuit.

Revision: May 2010 2011 Versa

Page 3692 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EPS SYSTEMSTC-5

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

SYSTEM DESCRIPTION

EPS SYSTEM

System DiagramINFOID:0000000005931224

System DescriptionINFOID:0000000005931225

• EPS con NISSAN TIIDA 2011 Service Repair Manual EPS SYSTEMSTC-5

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

SYSTEM DESCRIPTION

EPS SYSTEM

System DiagramINFOID:0000000005931224

System DescriptionINFOID:0000000005931225

• EPS con](/img/5/57396/w960_57396-3691.png)

EPS SYSTEMSTC-5

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

SYSTEM DESCRIPTION

EPS SYSTEM

System DiagramINFOID:0000000005931224

System DescriptionINFOID:0000000005931225

• EPS control unit performs an arithmetical operation on data, such as steering wheel turning force (sensor

signal) from the torque sensor, vehicle speed signal, etc. Then it generates an optimum assist torque signal

to the EPS motor according to the driving condition.

• EPS control unit decreases the output signal to EPS mo tor while extremely using the power steering func-

tion (e.g., full steering) consecutively for protec ting EPS motor and EPS control unit (Overload protection

control). While activating overload protection control, the assist torque gradually decreases, and the steering

wheel turning force becomes heavy. The normal assist torque reactivates by no steering.

• In case of an error in the electrical system, the fail- safe function stops output signals to the EPS motor. Then

the previous state is changed to the manual steering state.

• Self-diagnosis can be done with CONSULT-III.

• EPS control unit will decrease assistance under the following 2 conditions.

- Extensive steering at low speed will cause the ECU and MOTOR to heat up, once temperature reaches crit-

ical point ECU will reduce current to reduce heat up. System will recover as temperature lowers (reduced or

no assistance).

- Holding steering on rack-end (full lock) for 1 second will cause the system to engage rack-end protection. This reduces assistance down to 50% in order to prevent heat up. Assistance is immediately returned to

100% when steering released or turned away from rack-end.

- Communicates the signal from each control unit via CAN communication.

WGIA0187E

Control unit Signal status

ECM Transmits mainly the follow

ing signals to EPS control uni t via CAN communication.

Engine status signal

ABS actuator and electric unit

(control unit) Transmits mainly the follow

ing signals to EPS control uni t via CAN communication.

Vehicle speed signal

Revision: May 2010 2011 Versa

Page 3693 of 3787

![NISSAN TIIDA 2011 Service Repair Manual STC-6

< SYSTEM DESCRIPTION >[EPS]

EPS SYSTEM

Component Parts Location

INFOID:0000000005931226

Component DescriptionINFOID:0000000005931227

Combination meter • Transmits mainly the following signals NISSAN TIIDA 2011 Service Repair Manual STC-6

< SYSTEM DESCRIPTION >[EPS]

EPS SYSTEM

Component Parts Location

INFOID:0000000005931226

Component DescriptionINFOID:0000000005931227

Combination meter • Transmits mainly the following signals](/img/5/57396/w960_57396-3692.png)

STC-6

< SYSTEM DESCRIPTION >[EPS]

EPS SYSTEM

Component Parts Location

INFOID:0000000005931226

Component DescriptionINFOID:0000000005931227

Combination meter • Transmits mainly the following signals to EPS control unit via CAN communication.

Vehicle speed signal

• EPS warning lamp si gnal is received from the EPS co ntrol unit via CAN communication.

TCM (Without ABS) Transmits the following si

gnals via CAN communicatio n to EPS control until.

Engine status signal

• Vehicle speed signal

Control unit

Signal status

SGIA1623E

Components parts Reference

EPS control unit STC-15, "

Description"

EPS motorSTC-13, "Description"

Torque sensor STC-11, "Description"

Revision: May 2010 2011 Versa

Page 3694 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EPS SYSTEMSTC-7

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

Reduction gear Reduction gear increa

ses the assist torque provided from EPS

motor with worm gears, and outputs to the c NISSAN TIIDA 2011 Service Repair Manual EPS SYSTEMSTC-7

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

Reduction gear Reduction gear increa

ses the assist torque provided from EPS

motor with worm gears, and outputs to the c](/img/5/57396/w960_57396-3693.png)

EPS SYSTEMSTC-7

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

Reduction gear Reduction gear increa

ses the assist torque provided from EPS

motor with worm gears, and outputs to the column shaft.

EPS warning lamp STC-19, "

Description"

Components partsReference

Revision: May 2010 2011 Versa