system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3577 of 3787

LATCH (LOWER ANCHORS AND TETHER FOR CHILDREN) SYSTEMSB-11

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

LATCH (LOWER ANCHORS AND TE THER FOR CHILDREN) SYSTEM

Removal and InstallationINFOID:0000000005929624

NOTE:

The LATCH (Lower Anchors and Tether fo r Children) system is not serviceable.

Revision: May 2010 2011 Versa

Page 3579 of 3787

SC-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION SC

A

B

SC

N

O P

CONTENTS

STARTING & CHARGING SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BATTERY ............................................................5

How to Handle Battery ........................................ ......5

Trouble Diagnosis with Multitasking Battery Diag-

nostic Station ....................................................... ......

7

Removal and Installation ...........................................7

Required Procedure After Battery Disconnection ......8

STARTING SYSTEM ..........................................9

System Description .............................................. .....9

Wiring Diagram - START - .......................................11

Trouble Diagnosis with Multitasking Battery Diag-

nostic Station ...........................................................

16

Removal and Installation HR16DE ..........................19

Removal and Installation MR18DE ..........................20

CHARGING SYSTEM .......................................21

System Description ..................................................21

Wiring Diagram - CHARGE - ...................................22

Trouble Diagnosis with Multitasking Battery Diag-

nostic Station ...........................................................

22

Removal and Installation .........................................25

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

27

Battery .....................................................................27

Starter ......................................................................27

Generator ................................................................27

Revision: May 2010 2011 Versa

Page 3580 of 3787

SC-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929006

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929007

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3586 of 3787

SC-8

< SERVICE INFORMATION >

BATTERY

INSTALLATION (All except MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

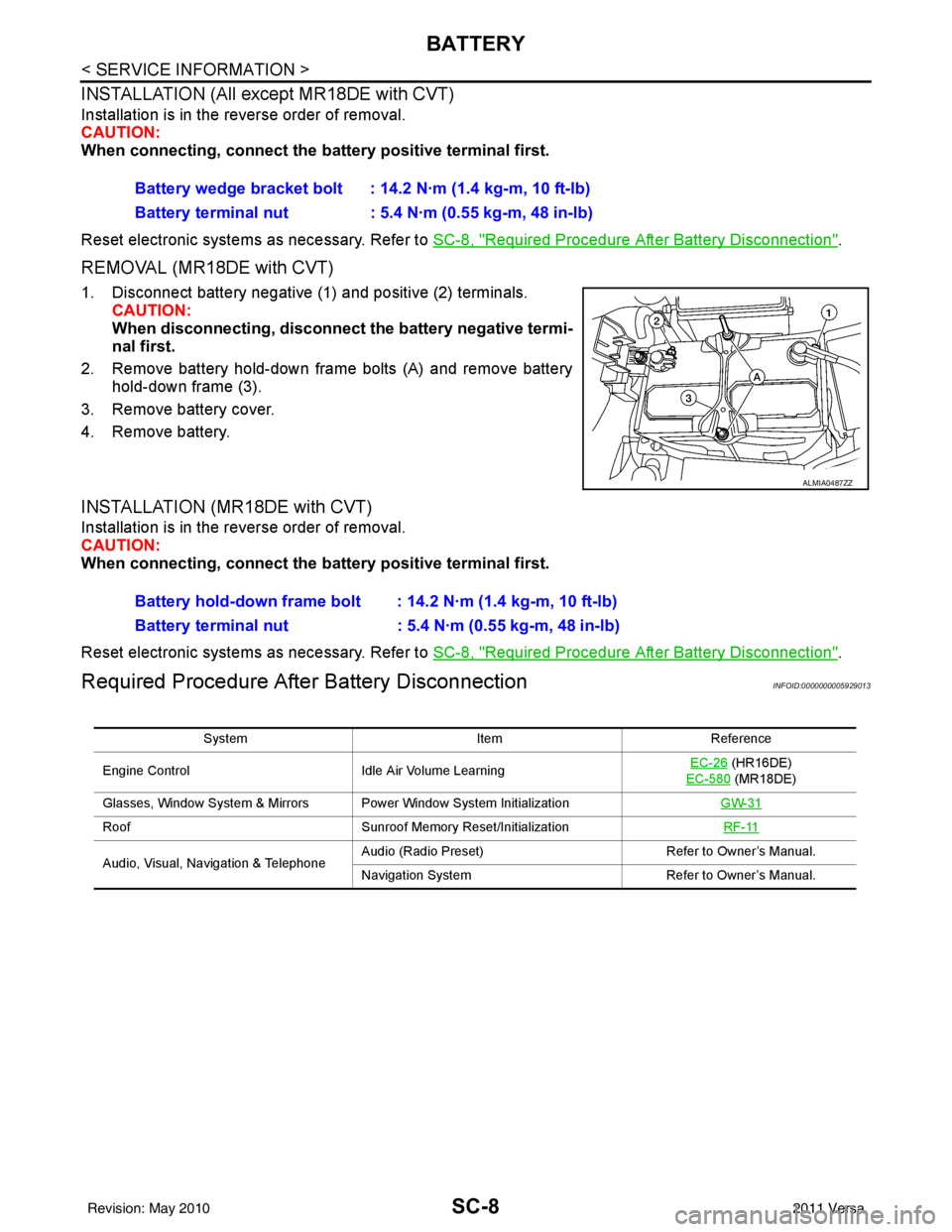

REMOVAL (MR18DE with CVT)

1. Disconnect battery negative (1) and positive (2) terminals.

CAUTION:

When disconnecting, disconnect the battery negative termi-

nal first.

2. Remove battery hold-down frame bolts (A) and remove battery hold-down frame (3).

3. Remove battery cover.

4. Remove battery.

INSTALLATION (MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

Required Procedure After Battery DisconnectionINFOID:0000000005929013

Battery wedge bracket bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

ALMIA0487ZZ

Battery hold-down frame bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

System ItemReference

Engine Control Idle Air Volume Learning EC-26

(HR16DE)

EC-580

(MR18DE)

Glasses, Window System & Mirrors Power Window System Initialization GW-31

RoofSunroof Memory Reset/Initialization RF-11

Audio, Visual, Navigation & TelephoneAudio (Radio Preset)

Refer to Owner’s Manual.

Navigation System Refer to Owner’s Manual.

Revision: May 2010 2011 Versa

Page 3587 of 3787

STARTING SYSTEMSC-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

STARTING SYSTEM

System DescriptionINFOID:0000000005929014

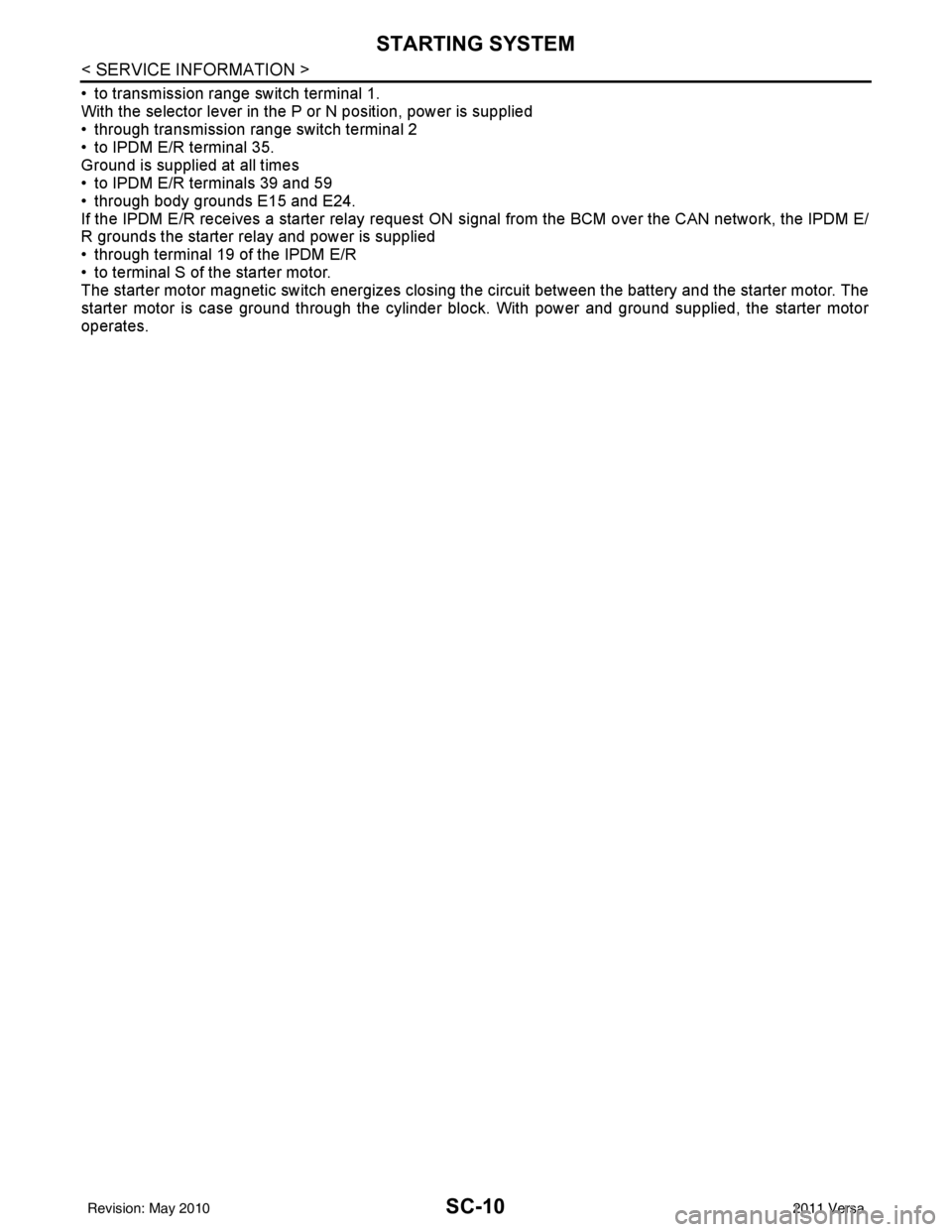

M/T Models

Power is supplied at all times

• to starter motor terminal B, and

• through 40A fusible link (letter h, located in the fuse and fusible link box)

• to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

• from ignition switch terminal ST

• to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 49, located in the IPDM E/R)

• to the clutch interlock switch terminal 1.

With the clutch pedal depressed, power is supplied

• through the clutch interlock switch terminal 2

• to IPDM E/R terminal 35.

Ground is supplied at all times

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

• through terminal 19 of the IPDM E/R

• to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

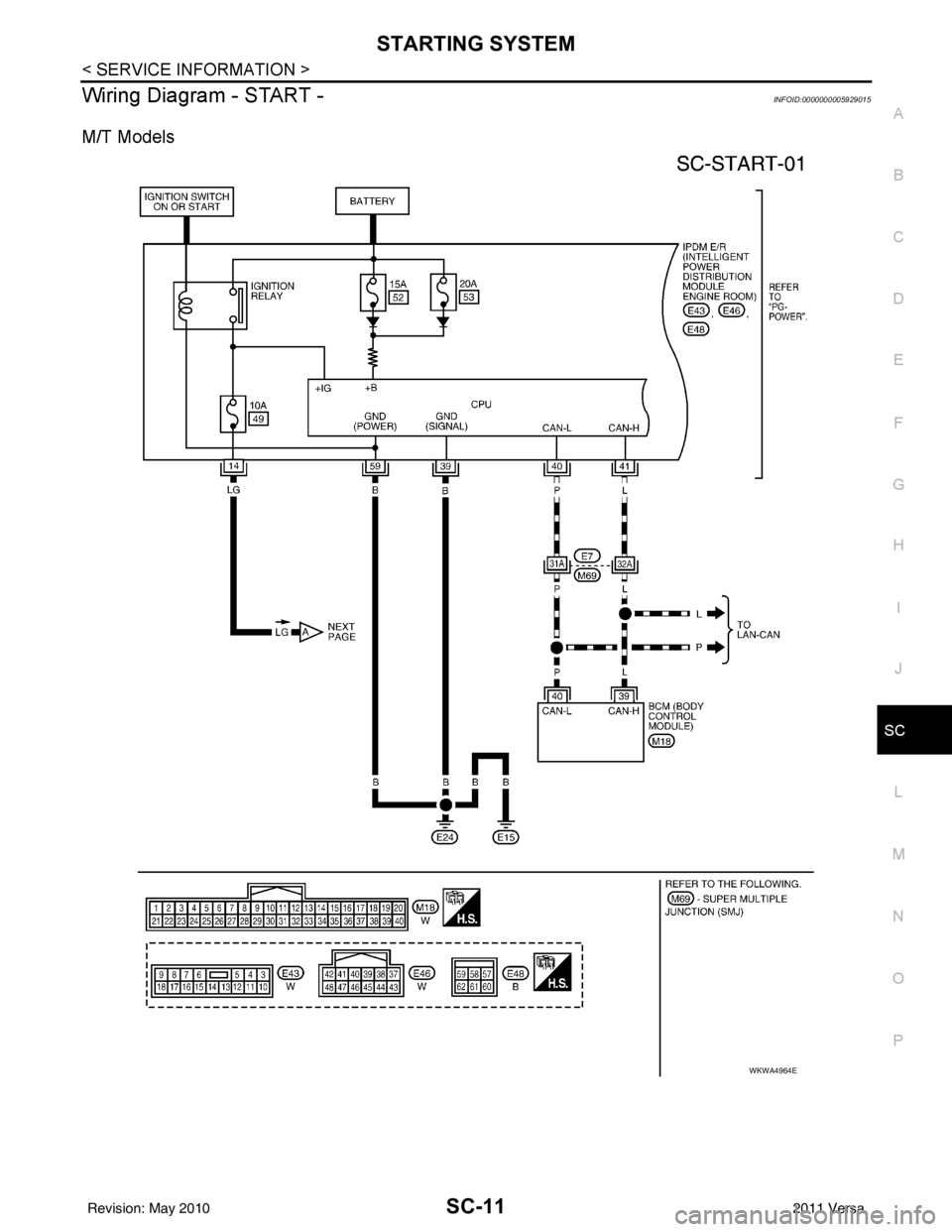

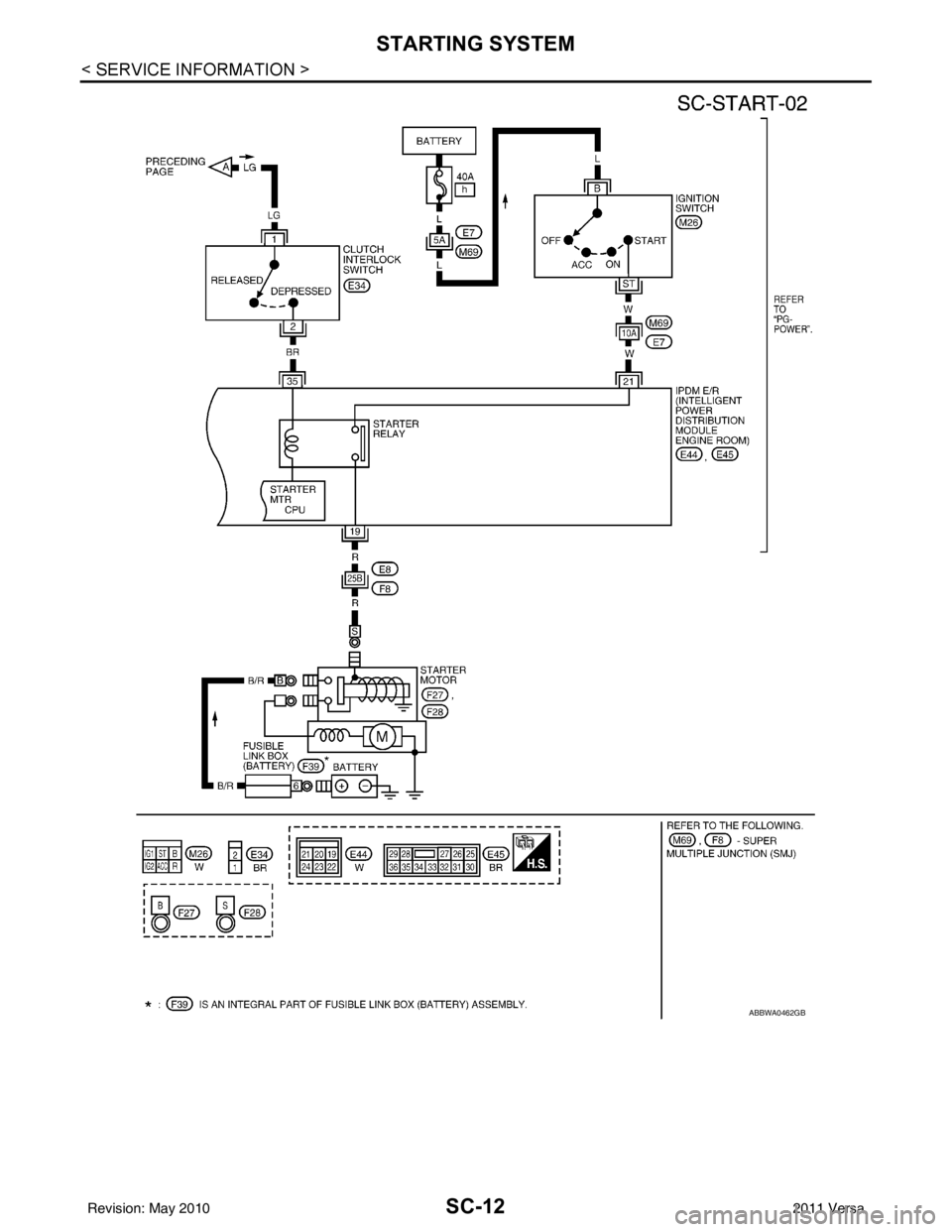

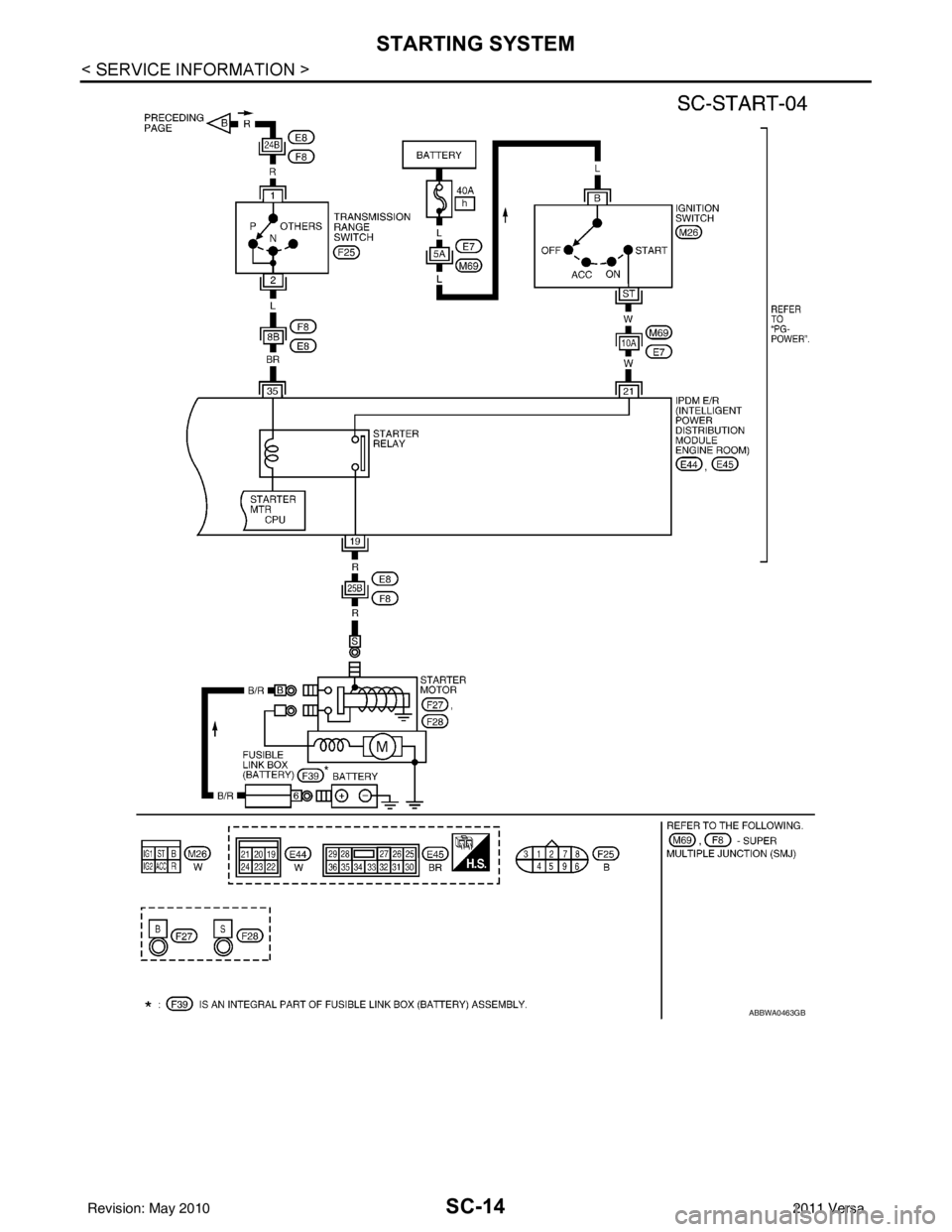

A/T Models

Power is supplied at all times

• to starter motor terminal B, and

• through 40A fusible link (letter h, located in the fuse and fusible link box)

• to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

• from ignition switch terminal ST

• to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 54, located in the IPDM E/R)

• to transmission range switch terminal 1.

With the selector lever in the P or N position, power is supplied

• through transmission range switch terminal 2

• to IPDM E/R terminal 35.

Ground is supplied at all times

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

• through terminal 19 of the IPDM E/R

• to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

CVT Models

Power is supplied at all times

• to starter motor terminal B, and

• through 40A fusible link (letter h, located in the fuse and fusible link box)

• to ignition switch terminal B.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 49, located in the IPDM E/R)

Revision: May 2010 2011 Versa

Page 3588 of 3787

SC-10

< SERVICE INFORMATION >

STARTING SYSTEM

• to transmission range switch terminal 1.

With the selector lever in the P or N position, power is supplied

• through transmission range switch terminal 2

• to IPDM E/R terminal 35.

Ground is supplied at all times

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN network, the IPDM E/

R grounds the starter relay and power is supplied

• through terminal 19 of the IPDM E/R

• to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

Revision: May 2010 2011 Versa

Page 3589 of 3787

STARTING SYSTEMSC-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

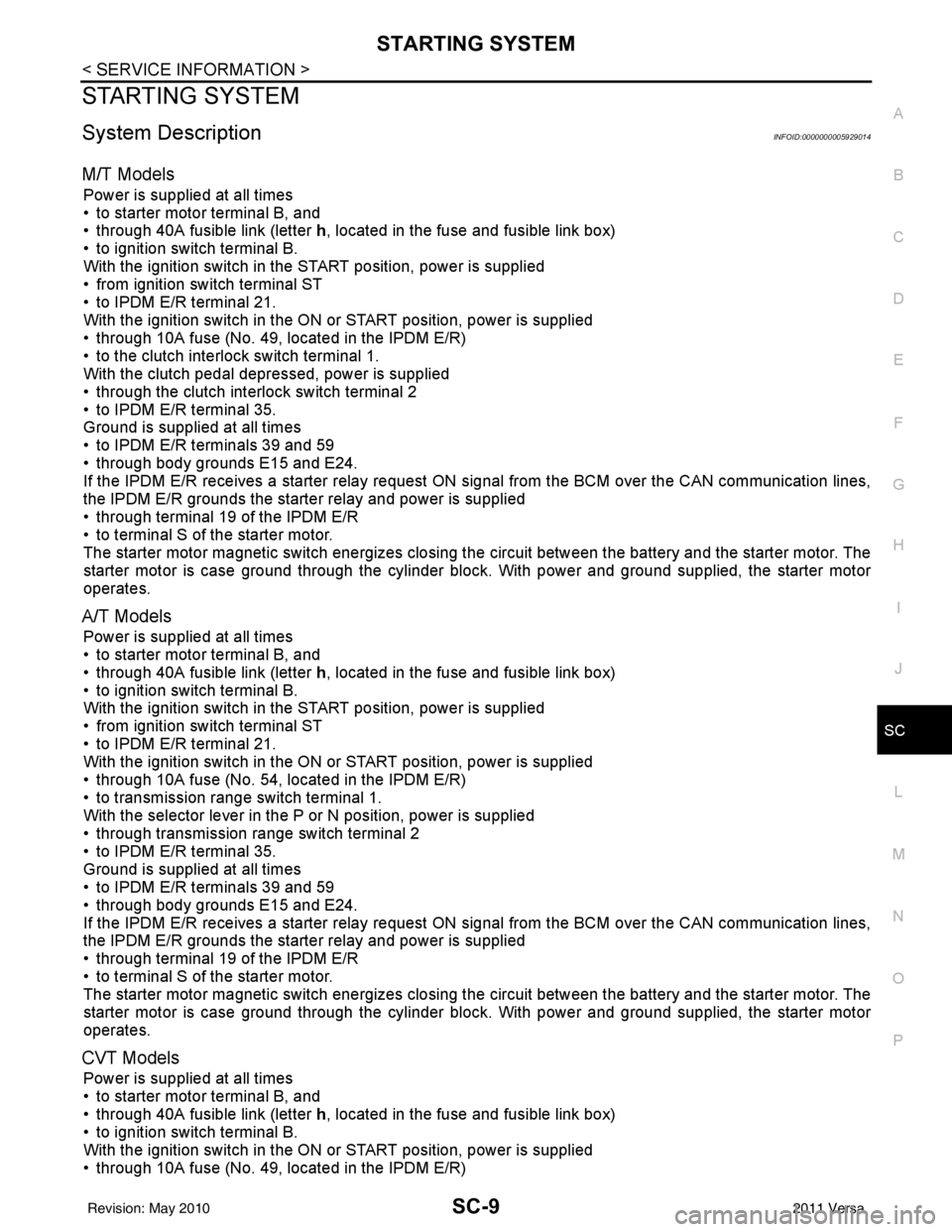

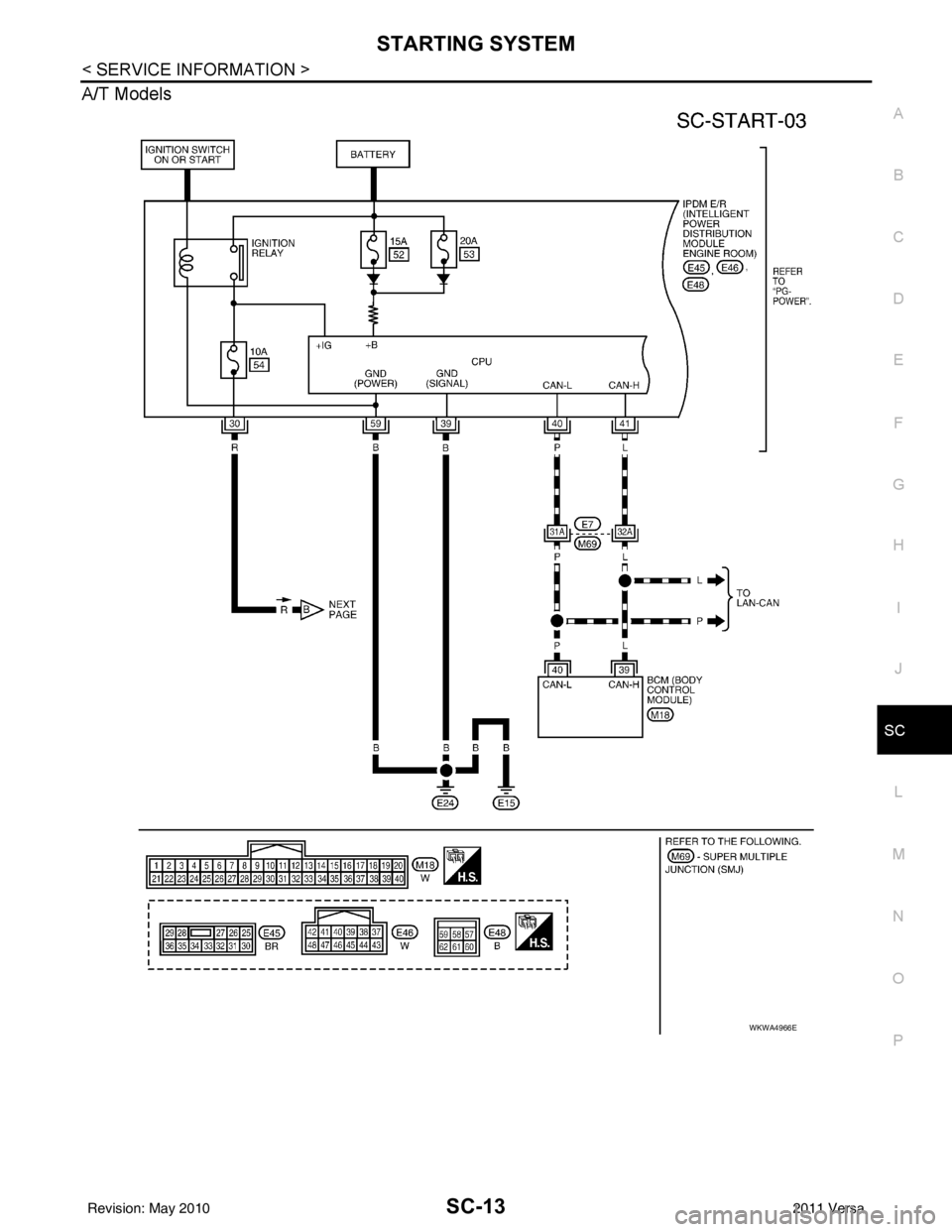

Wiring Diagram - START -INFOID:0000000005929015

M/T Models

WKWA4964E

Revision: May 2010 2011 Versa

Page 3590 of 3787

SC-12

< SERVICE INFORMATION >

STARTING SYSTEM

ABBWA0462GB

Revision: May 20102011 Versa

Page 3591 of 3787

STARTING SYSTEMSC-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

A/T Models

WKWA4966E

Revision: May 2010 2011 Versa

Page 3592 of 3787

SC-14

< SERVICE INFORMATION >

STARTING SYSTEM

ABBWA0463GB

Revision: May 20102011 Versa