system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3593 of 3787

STARTING SYSTEMSC-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

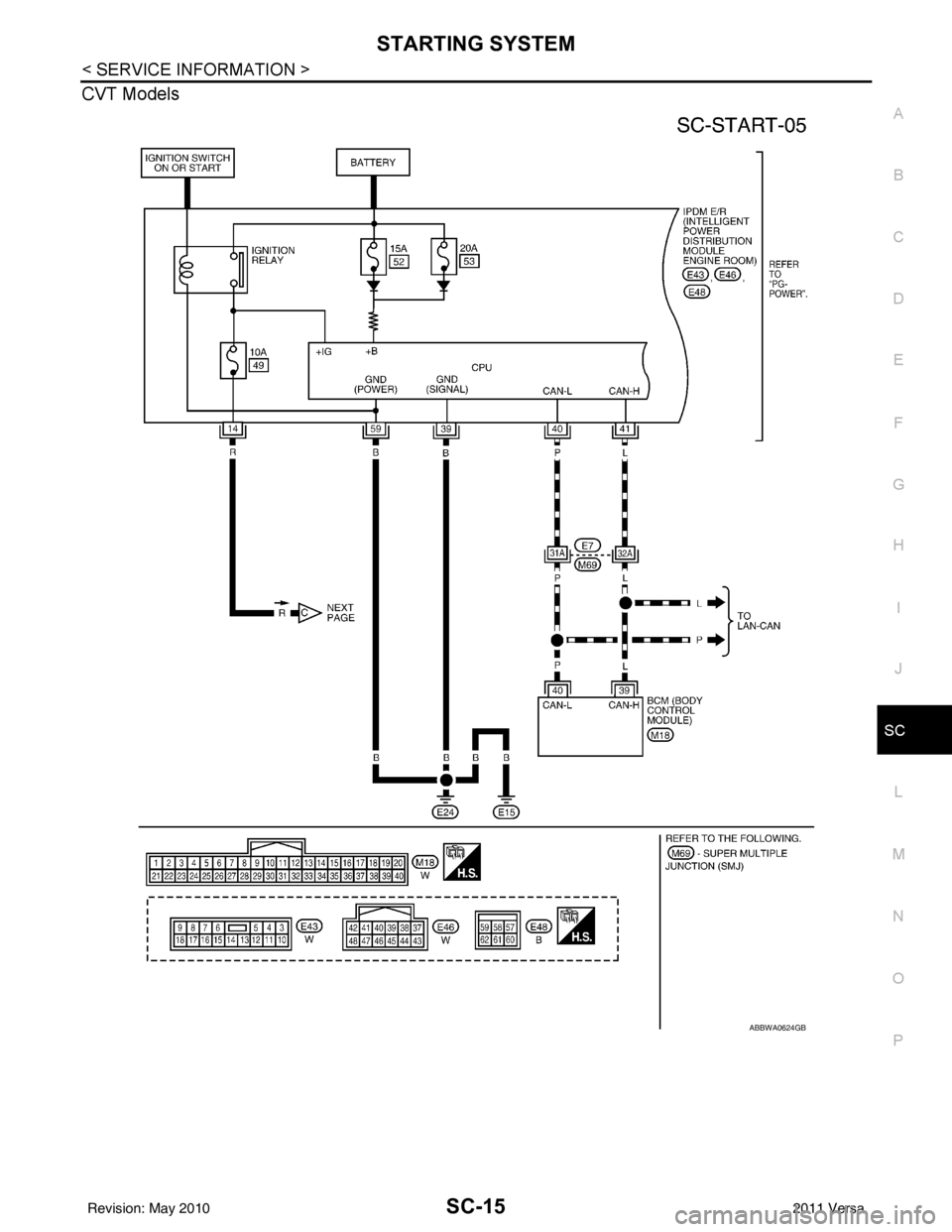

CVT Models

ABBWA0624GB

Revision: May 2010 2011 Versa

Page 3594 of 3787

SC-16

< SERVICE INFORMATION >

STARTING SYSTEM

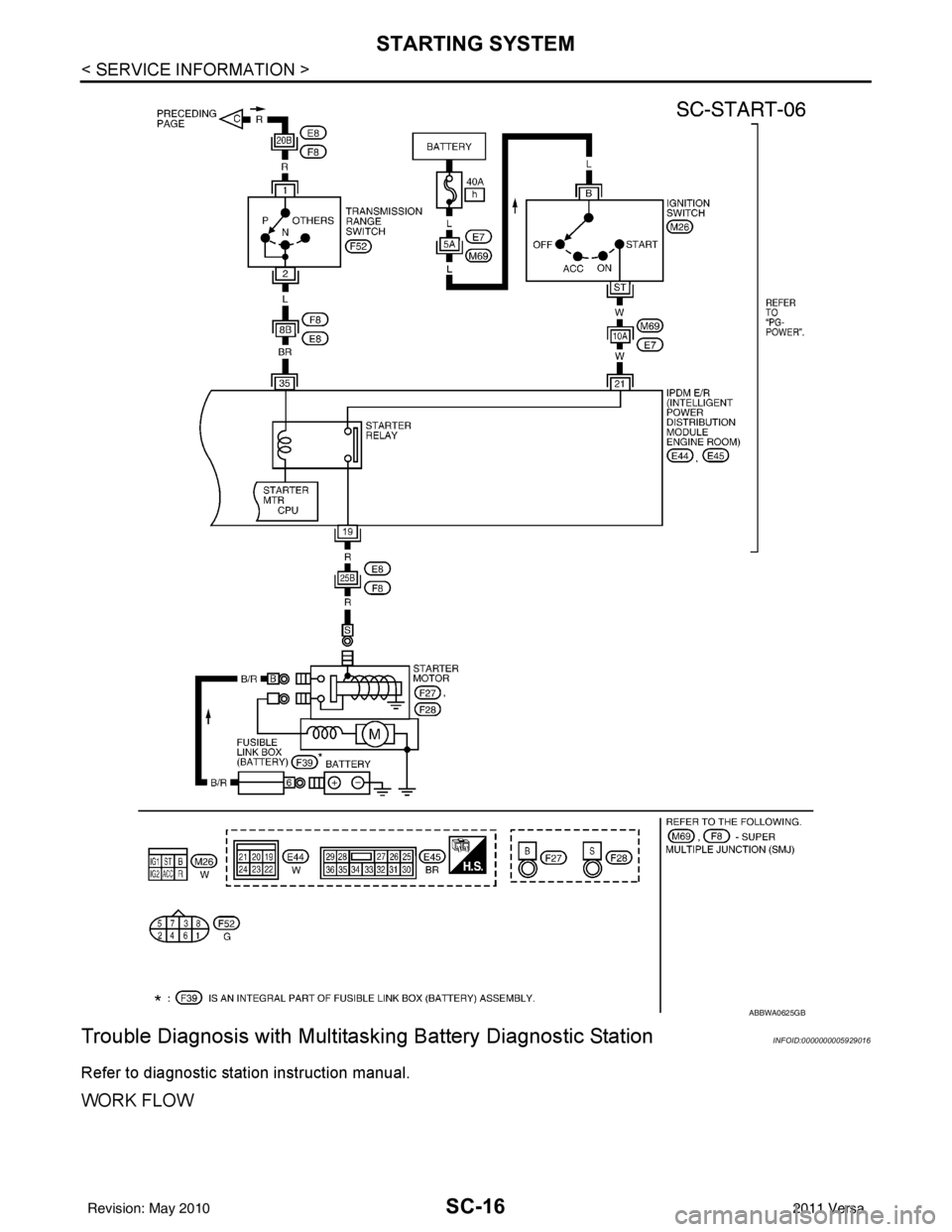

Trouble Diagnosis with Multitas king Battery Diagnostic Station

INFOID:0000000005929016

Refer to diagnostic station instruction manual.

WORK FLOW

ABBWA0625GB

Revision: May 2010 2011 Versa

Page 3595 of 3787

STARTING SYSTEMSC-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

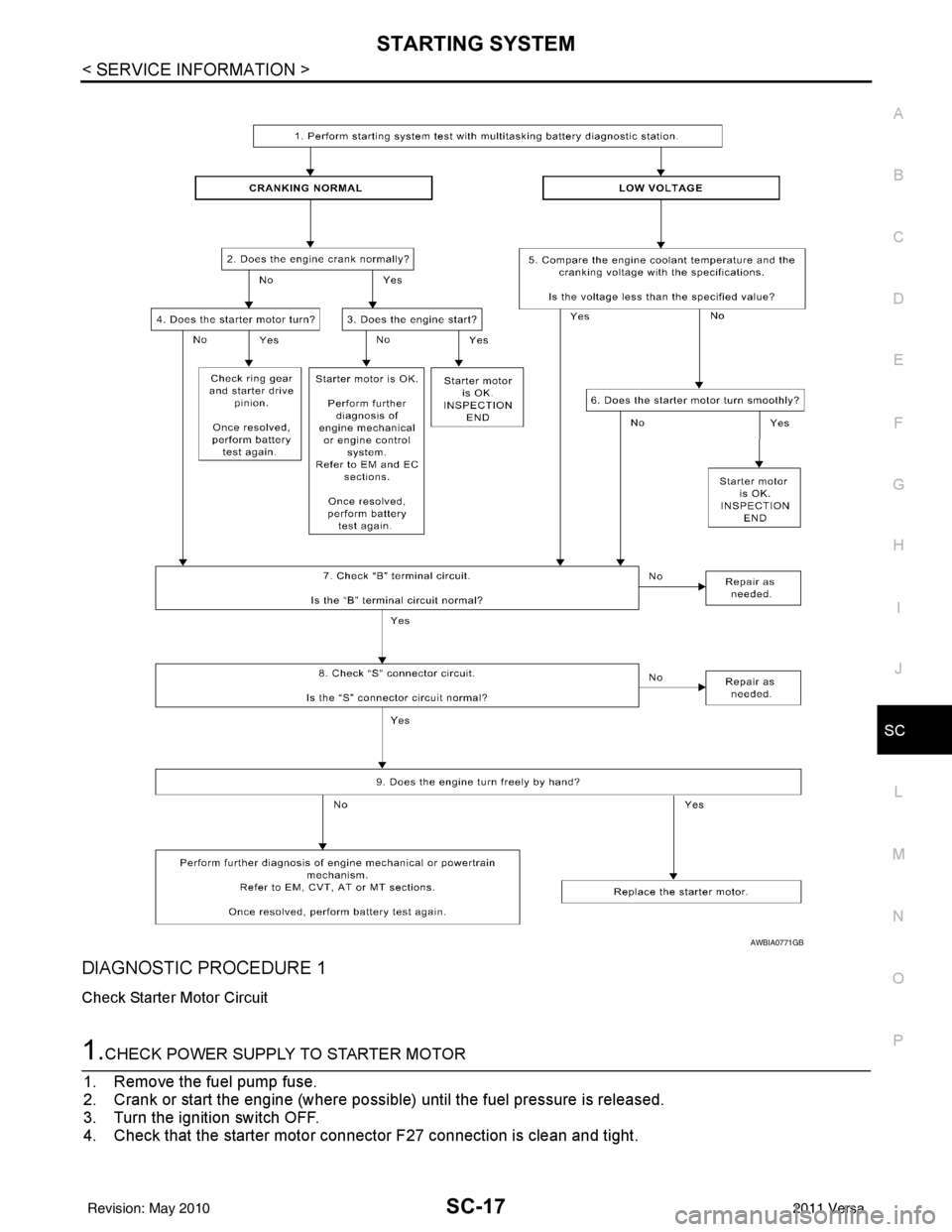

DIAGNOSTIC PROCEDURE 1

Check Starter Motor Circuit

1.CHECK POWER SUPPLY TO STARTER MOTOR

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Check that the starter motor connector F27 connection is clean and tight.

AWBIA0771GB

Revision: May 2010 2011 Versa

Page 3596 of 3787

SC-18

< SERVICE INFORMATION >

STARTING SYSTEM

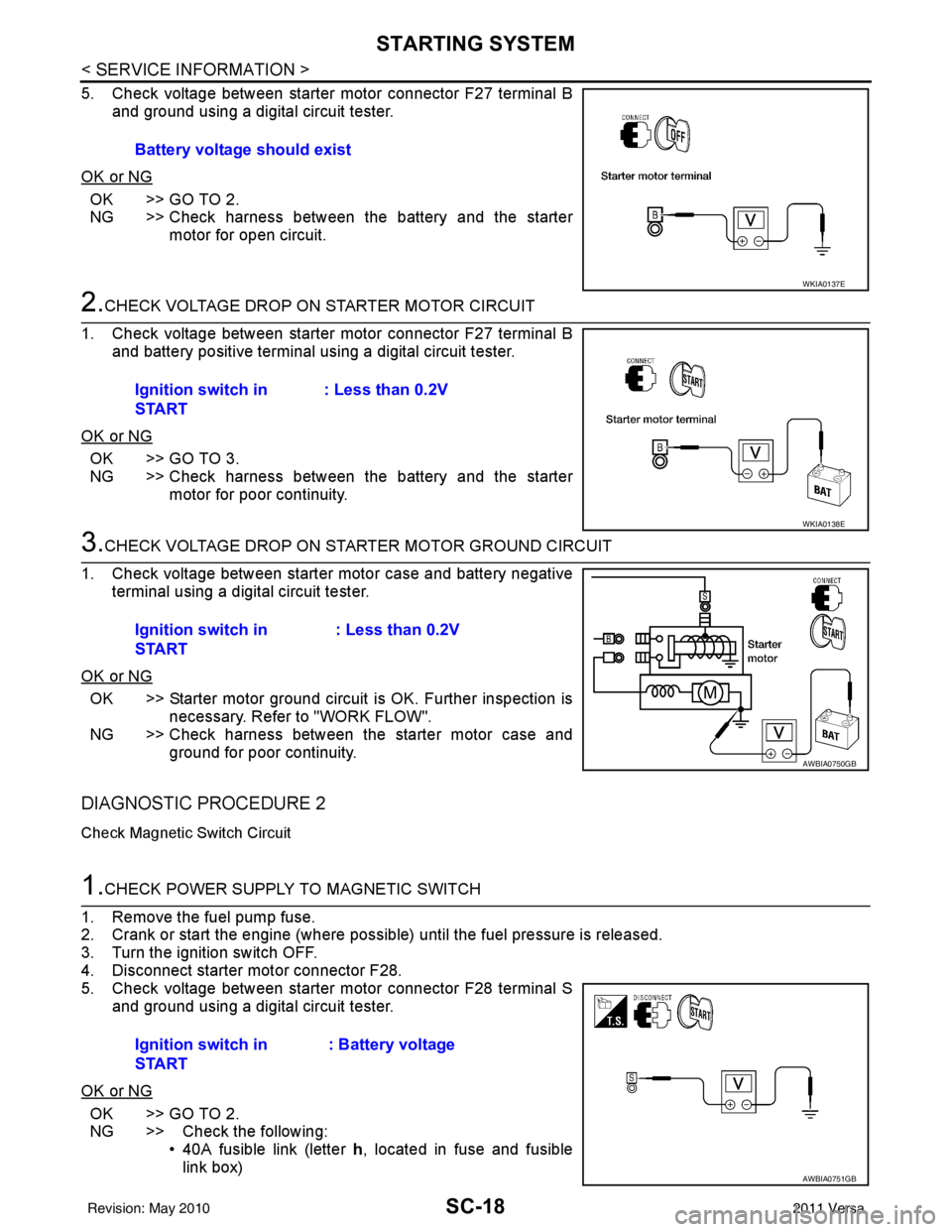

5. Check voltage between starter motor connector F27 terminal Band ground using a digital circuit tester.

OK or NG

OK >> GO TO 2.

NG >> Check harness between the battery and the starter motor for open circuit.

2.CHECK VOLTAGE DROP ON STARTER MOTOR CIRCUIT

1. Check voltage between starter motor connector F27 terminal B and battery positive terminal using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

3.CHECK VOLTAGE DROP ON STARTER MOTOR GROUND CIRCUIT

1. Check voltage between starter motor case and battery negative terminal using a digital circuit tester.

OK or NG

OK >> Starter motor ground circuit is OK. Further inspection is necessary. Refer to "WORK FLOW".

NG >> Check harness between the starter motor case and

ground for poor continuity.

DIAGNOSTIC PROCEDURE 2

Check Magnetic Switch Circuit

1.CHECK POWER SUPPLY TO MAGNETIC SWITCH

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Disconnect starter motor connector F28.

5. Check voltage between starter motor connector F28 terminal S and ground using a digital circuit tester.

OK or NG

OK >> GO TO 2.

NG >> Check the following: • 40A fusible link (letter h, located in fuse and fusible

link box)

Battery voltage should exist

WKIA0137E

Ignition switch in

START

: Less than 0.2V

WKIA0138E

Ignition switch in

START : Less than 0.2V

AWBIA0750GB

Ignition switch in

START: Battery voltage

AWBIA0751GB

Revision: May 2010

2011 Versa

Page 3597 of 3787

STARTING SYSTEMSC-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

• 10A fuse (No. 49, M/T model s, located in the IPDM E/R)

• 15A fuse (No. 52, located in the IPDM E/R)

• 20A fuse (No. 53, located in the IPDM E/R)

• Transmission range switch, clutch interlock switch or TCM depending on equipment

• Ignition switch

• Ignition relay IPDM E/R

• Starter relay IPDM E/R

• Starter relay request ON signal from BCM

• Harness for open or short circuit

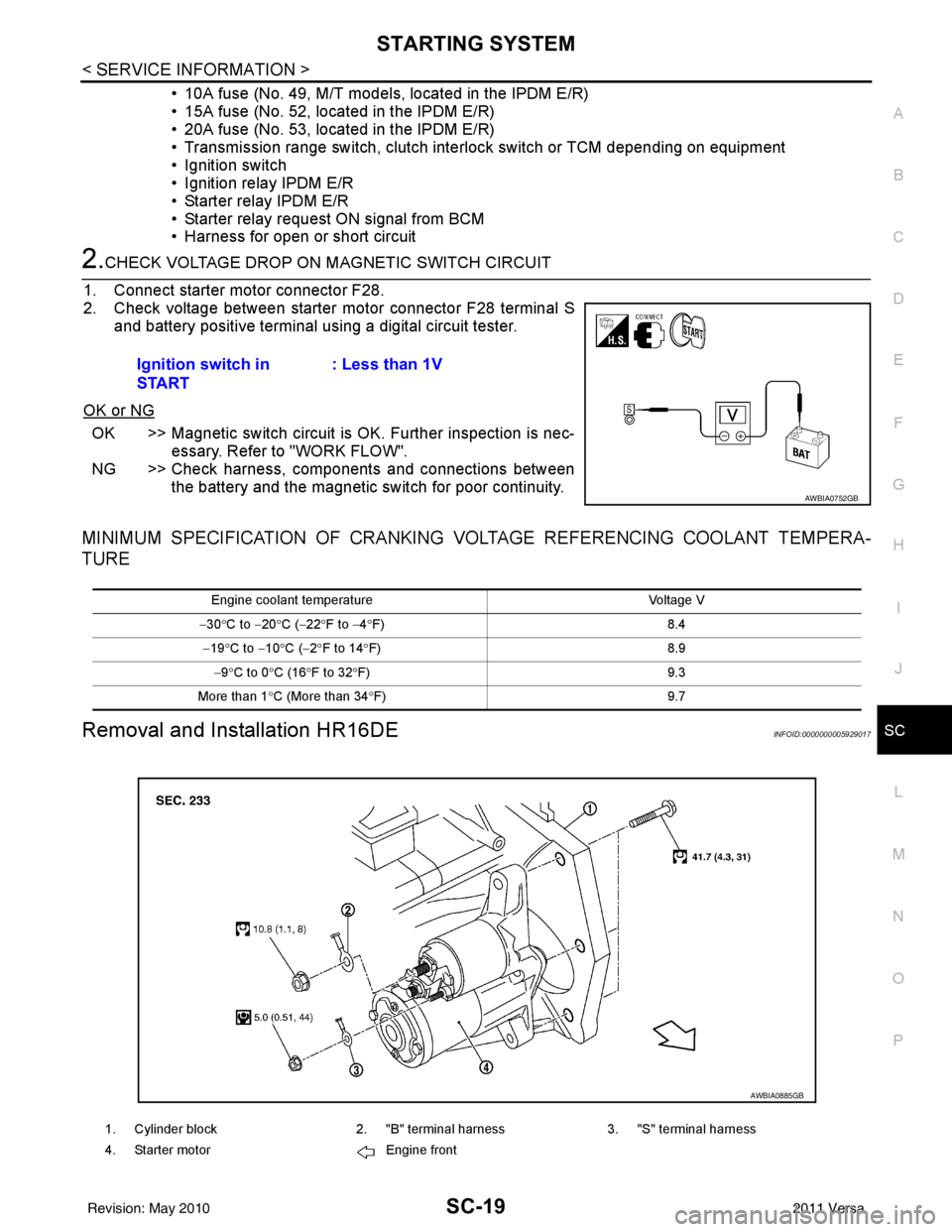

2.CHECK VOLTAGE DROP ON MAGNETIC SWITCH CIRCUIT

1. Connect starter motor connector F28.

2. Check voltage between starter motor connector F28 terminal S and battery positive terminal using a digital circuit tester.

OK or NG

OK >> Magnetic switch circuit is OK. Further inspection is nec-

essary. Refer to "WORK FLOW".

NG >> Check harness, components and connections between the battery and the magnetic switch for poor continuity.

MINIMUM SPECIFICATION OF CRANKING VO LTAGE REFERENCING COOLANT TEMPERA-

TURE

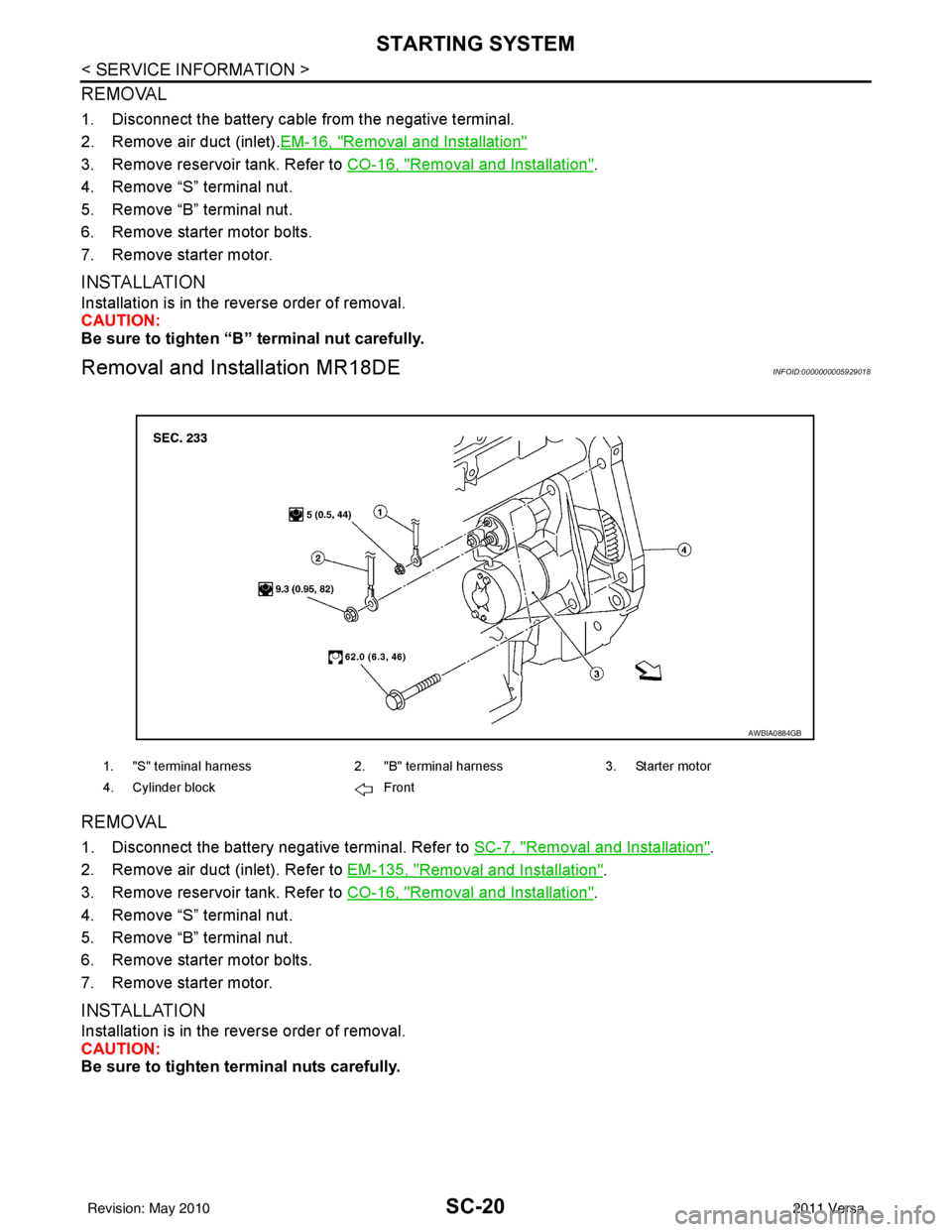

Removal and Installation HR16DEINFOID:0000000005929017

Ignition switch in

START : Less than 1V

AWBIA0752GB

Engine coolant temperature

Voltage V

− 30 °C to − 20°C ( −22 °F to −4 °F) 8.4

− 19 °C to − 10°C ( −2°F to 14 °F) 8.9

− 9 °C to 0 °C (16 °F to 32 °F) 9.3

More than 1 °C (More than 34 °F) 9.7

1. Cylinder block2. "B" terminal harness3. "S" terminal harness

4. Starter motor Engine front

AWBIA0885GB

Revision: May 2010 2011 Versa

Page 3598 of 3787

SC-20

< SERVICE INFORMATION >

STARTING SYSTEM

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Remove air duct (inlet).EM-16, "

Removal and Installation"

3. Remove reservoir tank. Refer to CO-16, "Removal and Installation".

4. Remove “S” terminal nut.

5. Remove “B” terminal nut.

6. Remove starter motor bolts.

7. Remove starter motor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

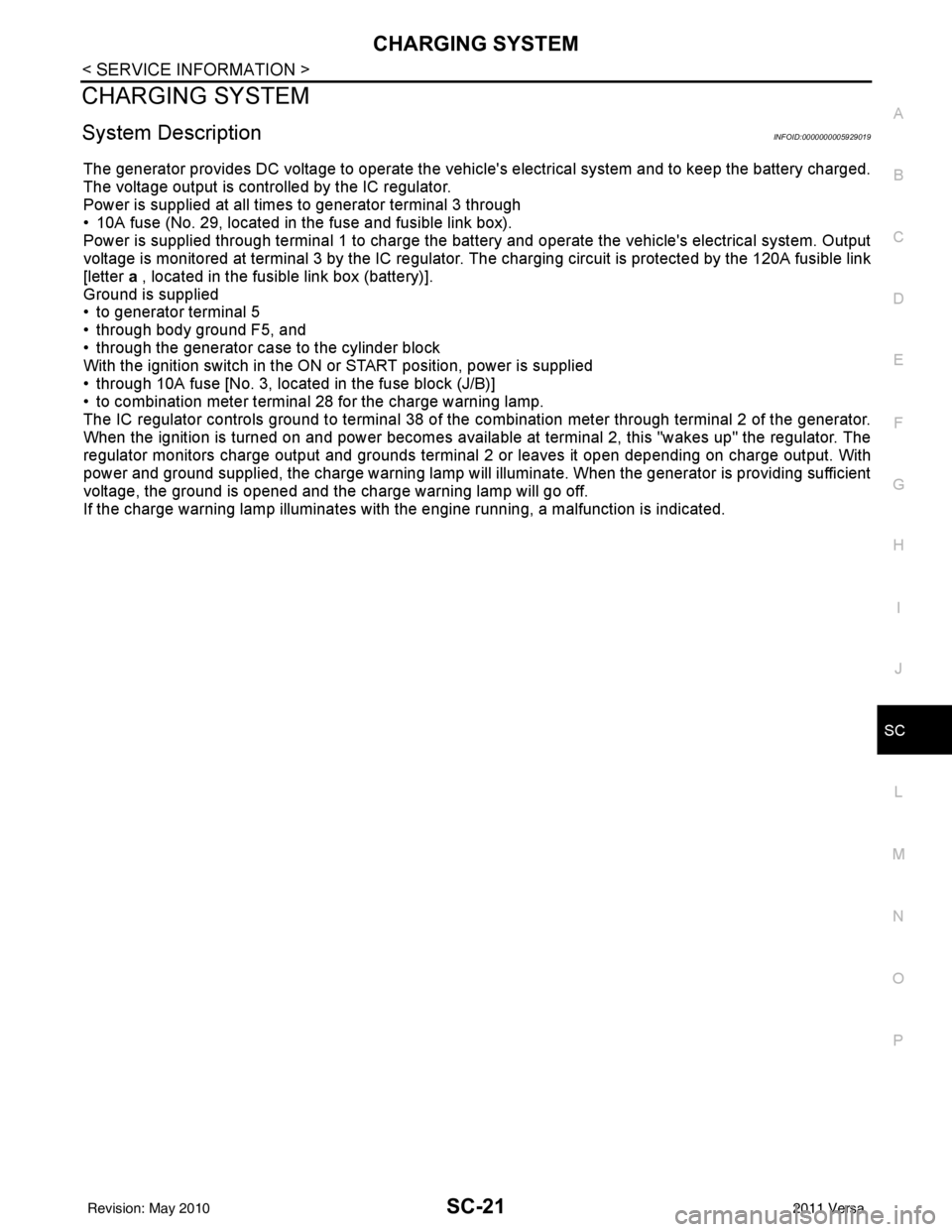

Removal and Installation MR18DEINFOID:0000000005929018

REMOVAL

1. Disconnect the battery negative terminal. Refer to SC-7, "Removal and Installation".

2. Remove air duct (inlet). Refer to EM-135, "

Removal and Installation".

3. Remove reservoir tank. Refer to CO-16, "

Removal and Installation".

4. Remove “S” terminal nut.

5. Remove “B” terminal nut.

6. Remove starter motor bolts.

7. Remove starter motor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Be sure to tighten terminal nuts carefully.

1. "S" terminal harness 2. "B" terminal harness 3. Starter motor

4. Cylinder block Front

AWBIA0884GB

Revision: May 2010 2011 Versa

Page 3599 of 3787

CHARGING SYSTEMSC-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

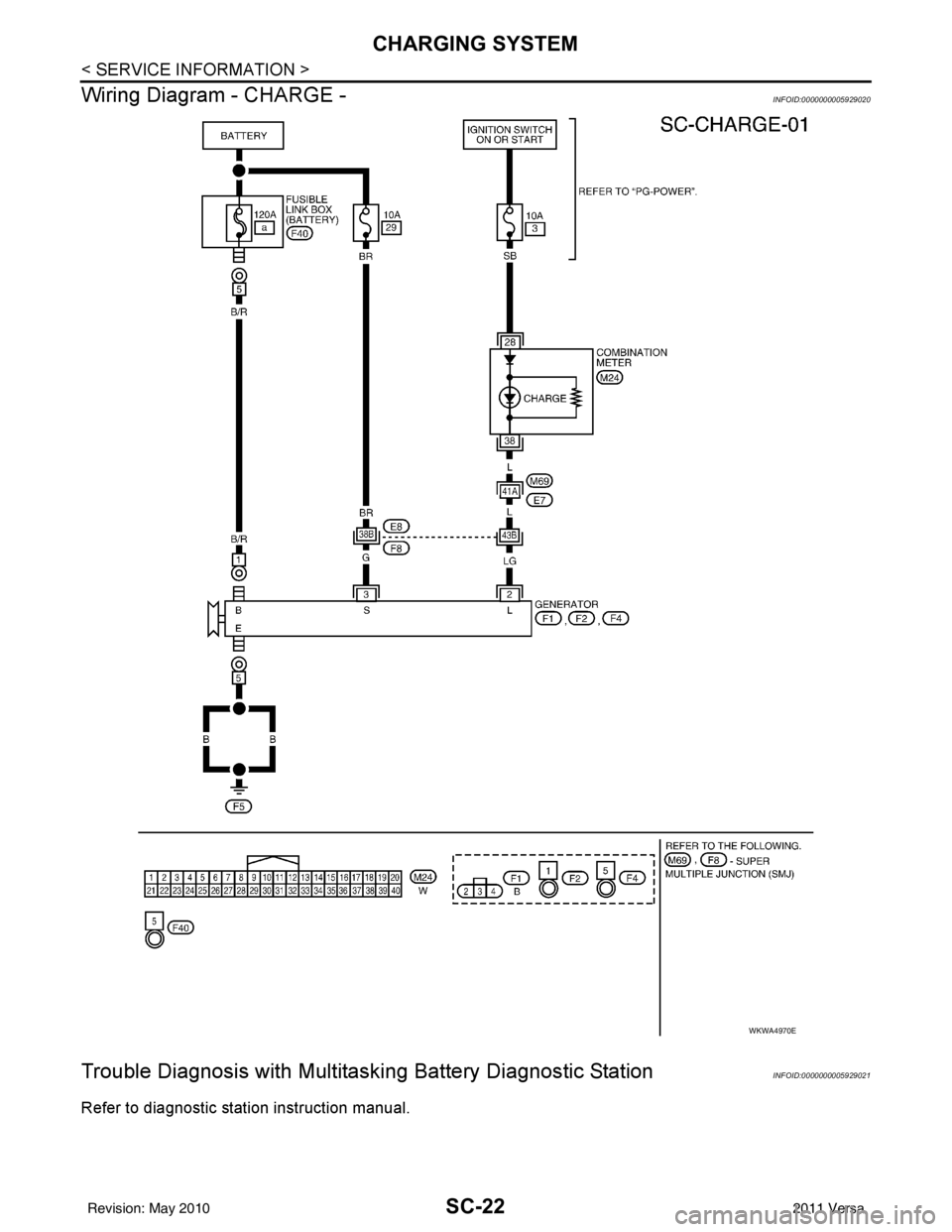

CHARGING SYSTEM

System DescriptionINFOID:0000000005929019

The generator provides DC voltage to operate the vehicl e's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal 3 through

• 10A fuse (No. 29, located in the fuse and fusible link box).

Power is supplied through terminal 1 to charge the batte ry and operate the vehicle's electrical system. Output

voltage is monitored at terminal 3 by the IC regulator. The charging circuit is protected by the 120A fusible link

[letter a , located in the fusible link box (battery)].

Ground is supplied

• to generator terminal 5

• through body ground F5, and

• through the generator case to the cylinder block

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28 for the charge warning lamp.

The IC regulator controls ground to terminal 38 of the combination meter through terminal 2 of the generator.

When the ignition is turned on and power becomes availabl e at terminal 2, this "wakes up" the regulator. The

regulator monitors charge output and grounds terminal 2 or leaves it open depending on charge output. With

power and ground supplied, the charge warning lamp will il luminate. When the generator is providing sufficient

voltage, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Revision: May 2010 2011 Versa

Page 3600 of 3787

SC-22

< SERVICE INFORMATION >

CHARGING SYSTEM

Wiring Diagram - CHARGE -

INFOID:0000000005929020

Trouble Diagnosis with Multitas king Battery Diagnostic StationINFOID:0000000005929021

Refer to diagnostic station instruction manual.

WKWA4970E

Revision: May 2010 2011 Versa

Page 3601 of 3787

CHARGING SYSTEMSC-23

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

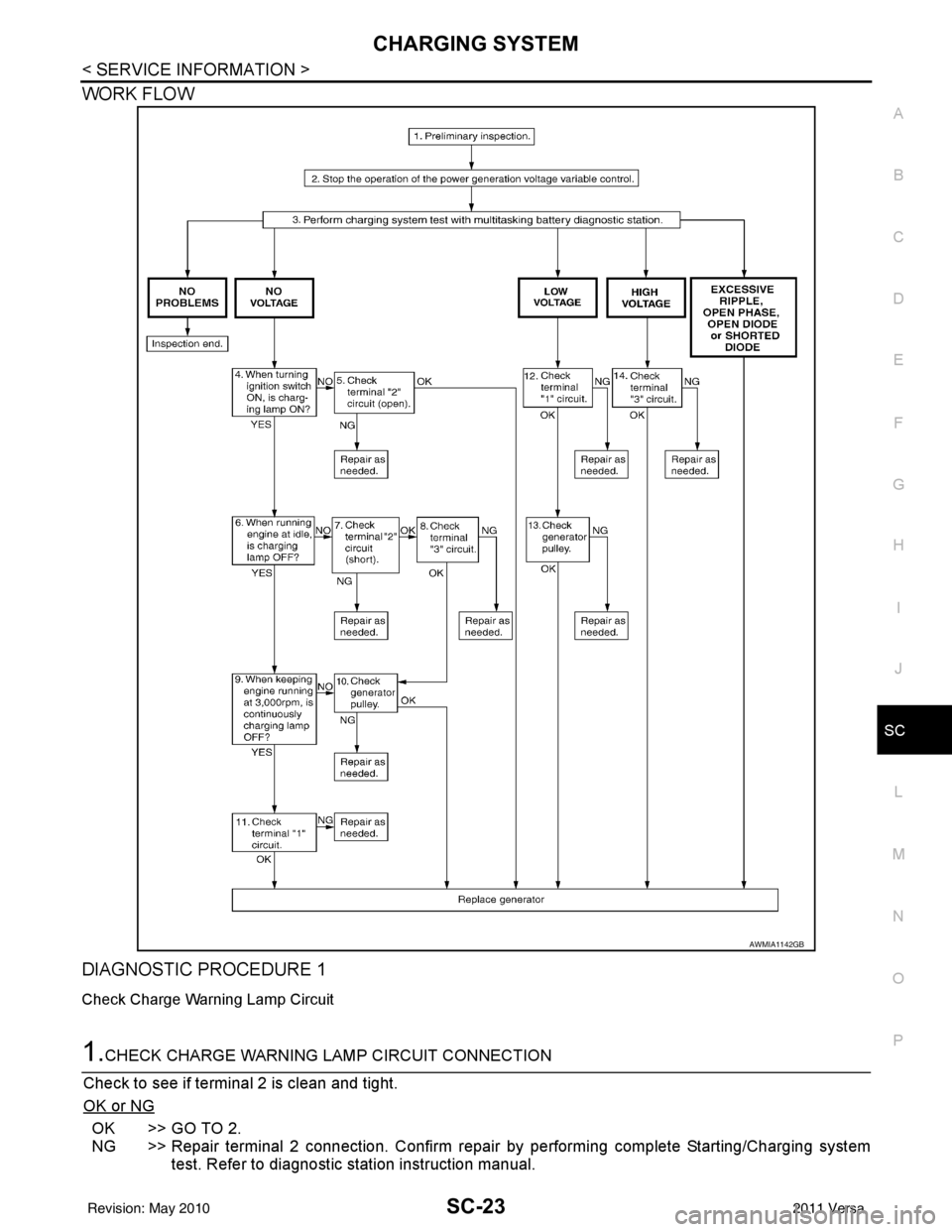

WORK FLOW

DIAGNOSTIC PROCEDURE 1

Check Charge Warning Lamp Circuit

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Check to see if terminal 2 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal 2 connection. Confirm repair by performing complete Starting/Charging system test. Refer to diagnostic station instruction manual.

AWMIA1142GB

Revision: May 2010 2011 Versa

Page 3602 of 3787

SC-24

< SERVICE INFORMATION >

CHARGING SYSTEM

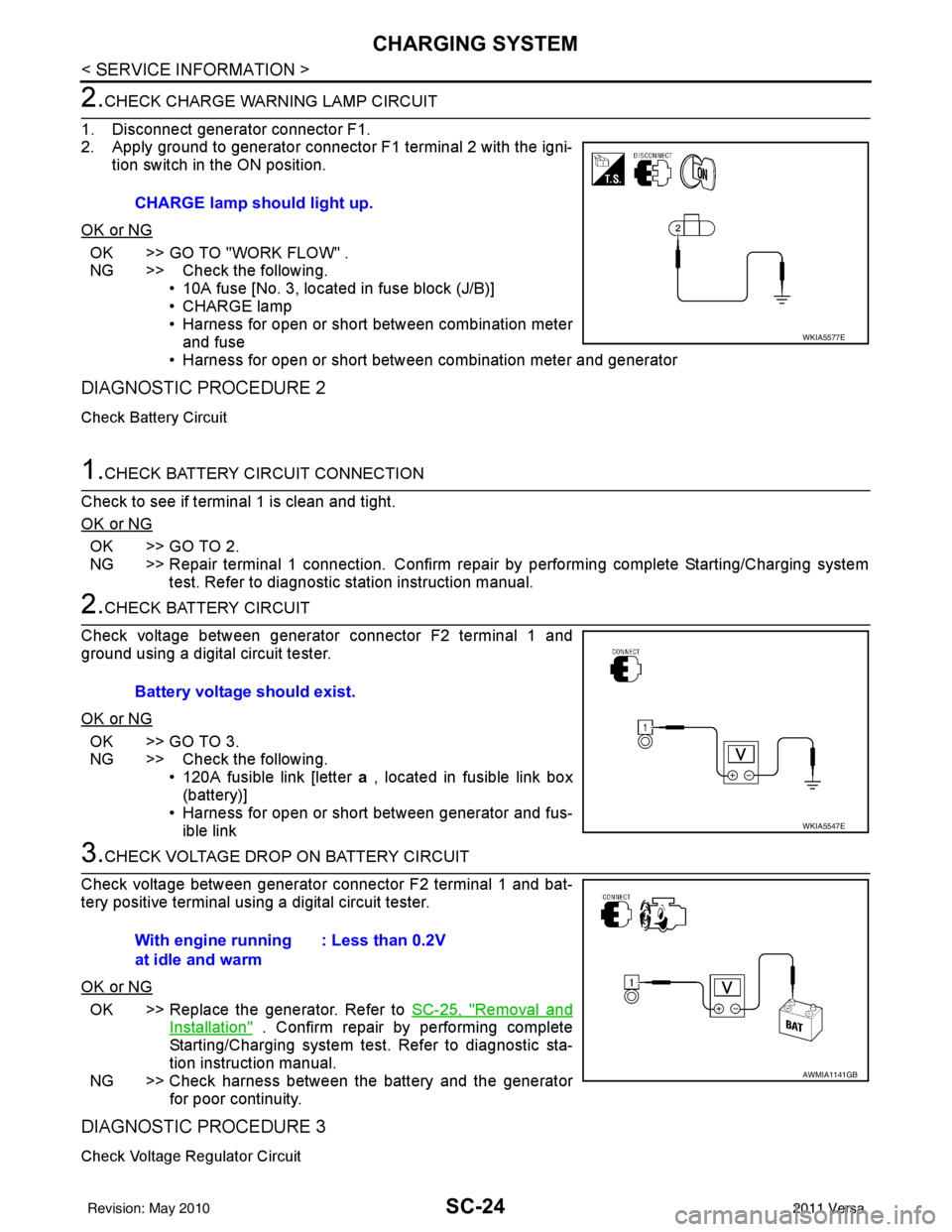

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F1.

2. Apply ground to generator connector F1 terminal 2 with the igni- tion switch in the ON position.

OK or NG

OK >> GO TO "WORK FLOW" .

NG >> Check the following. • 10A fuse [No. 3, located in fuse block (J/B)]

• CHARGE lamp

• Harness for open or short between combination meterand fuse

• Harness for open or short between combination meter and generator

DIAGNOSTIC PROCEDURE 2

Check Battery Circuit

1.CHECK BATTERY CIRCUIT CONNECTION

Check to see if terminal 1 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal 1 connection. Confirm repair by performing complete Starting/Charging system test. Refer to diagnostic station instruction manual.

2.CHECK BATTERY CIRCUIT

Check voltage between generator connector F2 terminal 1 and

ground using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check the following. • 120A fusible link [letter a , located in fusible link box

(battery)]

• Harness for open or short between generator and fus- ible link

3.CHECK VOLTAGE DROP ON BATTERY CIRCUIT

Check voltage between generator connector F2 terminal 1 and bat-

tery positive terminal using a digital circuit tester.

OK or NG

OK >> Replace the generator. Refer to SC-25, "Removal and

Installation" . Confirm repair by performing complete

Starting/Charging system test. Refer to diagnostic sta-

tion instruction manual.

NG >> Check harness between the battery and the generator for poor continuity.

DIAGNOSTIC PROCEDURE 3

Check Voltage Regulator Circuit

CHARGE lamp should light up.

WKIA5577E

Battery voltage should exist.

WKIA5547E

With engine running

at idle and warm : Less than 0.2V

AWMIA1141GB

Revision: May 2010

2011 Versa