clock NISSAN TIIDA 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1635 of 3787

![NISSAN TIIDA 2011 Service Owners Manual P0456 EVAP CONTROL SYSTEMEC-341

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NO >> Go to

EC-341, "Diagnosis Procedure".

Component Function CheckINFOID:0000000005929999

1.PERFORM C NISSAN TIIDA 2011 Service Owners Manual P0456 EVAP CONTROL SYSTEMEC-341

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NO >> Go to

EC-341, "Diagnosis Procedure".

Component Function CheckINFOID:0000000005929999

1.PERFORM C](/img/5/57396/w960_57396-1634.png)

P0456 EVAP CONTROL SYSTEMEC-341

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NO >> Go to

EC-341, "Diagnosis Procedure".

Component Function CheckINFOID:0000000005929999

1.PERFORM COMPONENT FUNCTION CHECK

With GST

CAUTION:

• Do not use compressed air, doing so may damage the EVAP system.

• Do not start engine.

• Do not exceeded 4.12 kPa (0.042 kg/cm

2, 0.6 psi).

1. Attach the EVAP service port adapter securely to the EVAP service port.

2. Set the pressure pump and a hose.

3. Also set a vacuum gauge via 3-way connector and a hose.

4. Turn ignition switch ON.

5. Connect GST and select Service $08.

6. Using Service $08 control the EVAP canister vent control valve

(close).

7. Apply pressure and make sure the following conditions are sat-

isfied.

Pressure to be applied: 2.7 kPa (0.028 kg/cm

2, 0.39 psi)

Time to be waited after the pressure drawn in to the EVAP

system and the pressure to be dropped: 60 seconds and

the pressure should not be dropped more than 0.4 kPa

(0.004 kg/cm

2, 0.06 psi).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Go to EC-341, "

Diagnosis Procedure".

2.RELEASE PRESSURE

1. Disconnect GST.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Restart engine and let it idle for 90 seconds.

5. Keep engine speed at 2,000 rpm for 30 seconds.

6. Turn ignition switch OFF. NOTE:

For more information, refer to GST Instruction Manual.

>> INSPECTION END

Diagnosis ProcedureINFOID:0000000005930000

1.CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace with genuine NISSAN fuel filler cap. Refer to FL-10, "

Component".

2.CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

SEF462UI

SEF915U

Revision: May 2010 2011 Versa

Page 1860 of 3787

![NISSAN TIIDA 2011 Service Owners Manual EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine NISSAN TIIDA 2011 Service Owners Manual EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine](/img/5/57396/w960_57396-1859.png)

EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-21

or see EC-1033.

2. When the engine is started, the MIL should go off. If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by MIL lighting up when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine cont rol system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected, and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

When any SRT codes are not set, MIL may fl ash without DTC. For the details, refer to EC-542, "Emission-

related Diagnostic Information".

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

•It is better to count the ti me accurately with a clock.

SEF217U

Diagnostic Test

Mode KEY and ENG.

Statu s Function

Explanation of Function

Mode I Ignition switch in

ON position

Engine stopped BULB CHECK

This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION WARNING This is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

• Misfire (Possible three way catalyst damage)

• One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stopped SELF-DIAGNOSTIC

RESULTS

This function allows DTCs an

d 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: May 2010 2011 Versa

Page 1875 of 3787

![NISSAN TIIDA 2011 Service Owners Manual BASIC SERVICE PROCEDUREEC-581

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Electric load switch: OFF

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with NISSAN TIIDA 2011 Service Owners Manual BASIC SERVICE PROCEDUREEC-581

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Electric load switch: OFF

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with](/img/5/57396/w960_57396-1874.png)

BASIC SERVICE PROCEDUREEC-581

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Electric load switch: OFF

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- Models with CONSULT-III (A/T and CVT models)

• Drive vehicle until “FLUID TEMP SE” in “DATA MONI TOR” mode of “A/T” or “CVT” system indicates less

than 0.9 V.

- Models without CONSULT-III (A/T and CVT models) and M/T models

• Drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-III

1. Perform EC-580, "Accelerator Pedal Released Position Learning".

2. Perform EC-580, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEA RN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

7. Make sure that “CMPLT” is displayed on CONSULT-III screen. If “CMPLT” is not displayed, Idle Air Vol-

ume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to

the DIAGNOSTIC PROCEDURE below.

8. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

Refer to EC-574, "

Basic Inspection".

Without CONSULT-III

NOTE:

•It is better to count the time accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform EC-580, "

Accelerator Pedal Released Position Learning".

2. Perform EC-580, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

7. Repeat the following procedure quick ly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

10. Start engine and let it idle.

Item Specification

Idle speed M/T: 700

± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

Ignition timing M/T: 13

± 5 ° BTDC (in Neutral position)

A/T: 13 ± 5° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position)

Revision: May 2010 2011 Versa

Page 2110 of 3787

![NISSAN TIIDA 2011 Service Owners Manual EC-816

< SERVICE INFORMATION >[MR18DE]

DTC P0442 EVAP CONTROL SYSTEM

DTC Confirmation Procedure

INFOID:0000000006341982

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn i NISSAN TIIDA 2011 Service Owners Manual EC-816

< SERVICE INFORMATION >[MR18DE]

DTC P0442 EVAP CONTROL SYSTEM

DTC Confirmation Procedure

INFOID:0000000006341982

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn i](/img/5/57396/w960_57396-2109.png)

EC-816

< SERVICE INFORMATION >[MR18DE]

DTC P0442 EVAP CONTROL SYSTEM

DTC Confirmation Procedure

INFOID:0000000006341982

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

• Perform “DTC WORK SUPPORT” when the fuel level is between 1/4 and 3/4 full, and vehicle is placed

on flat level surface.

• Always perform test at a temperature of 0 to 30 °C (32 to 86 °F).

• Open engine hood before conducting following procedure.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

4. Check the following conditions are met.

COOLAN TEMP/S: 0 - 70 °C (32 - 158° F)

INT/A TEMP SE: 0 - 30 °C (32 - 86° F)

5. Select “EVAP SML LEAK P0442/P1442” of “EV APORATIVE SYSTEM” in “DTC WORK SUPPORT” mode

with CONSULT-III.

Follow the instruction displayed.

NOTE:

If the engine speed cannot be maintained within t he range displayed on the CONSULT-III screen, go to

EC-574, "

Basic Inspection".

6. Make sure that “OK” is displayed. If “NG” is displayed, refer to EC-816, "

Diagnosis Procedure".

NOTE:

Make sure that EVAP hoses are connected to the EVAP canister purge volume control solenoid

valve properly.

WITH GST

NOTE:

Be sure to read the explanation of Driving Pattern on EC-542, "

Emission-related Diagnostic Information"

before driving vehicle.

1. Start engine.

2. Drive vehicle according to Driving Pattern, EC-542, "

Emission-related Diagnostic Information".

3. Stop vehicle.

4. Turn ignition switch OFF and wait at leas t 10 seconds and then turn ignition switch ON.

5. Select Service $07 with GST.

- If P0442 is displayed on the screen, go to EC-816, "

Diagnosis Procedure".

- If P0441 is displayed on the screen, go to EC-811, "

Diagnosis Procedure" for DTC P0441.

Diagnosis ProcedureINFOID:0000000006341983

1.CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

OK or NG

OK >> GO TO 2.

NG >> Replace with genuine NISSAN fuel filler cap.

2.CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened proper ly by rotating the cap clockwise.

SEF915U

Revision: May 2010 2011 Versa

Page 2162 of 3787

![NISSAN TIIDA 2011 Service Owners Manual EC-868

< SERVICE INFORMATION >[MR18DE]

DTC P0455 EVAP CONTROL SYSTEM

Check that the cap is tightened proper

ly by rotating the cap clockwise.

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, the NISSAN TIIDA 2011 Service Owners Manual EC-868

< SERVICE INFORMATION >[MR18DE]

DTC P0455 EVAP CONTROL SYSTEM

Check that the cap is tightened proper

ly by rotating the cap clockwise.

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, the](/img/5/57396/w960_57396-2161.png)

EC-868

< SERVICE INFORMATION >[MR18DE]

DTC P0455 EVAP CONTROL SYSTEM

Check that the cap is tightened proper

ly by rotating the cap clockwise.

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower.

2. Retighten until reteaching sound is heard.

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-528, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one.

5.CHECK EVAP PURGE LINE

Check EVAP purge line (pipe, rubber tube, fuel tank and EVAP canister) for cracks, improper connection or

disconnection.

Refer to EC-526

.

OK or NG

OK >> GO TO 6.

NG >> Repair or reconnect the hose.

6.CLEAN EVAP PURGE LINE

Clean EVAP purge line (pipe and rubber tube) using air blower.

>> GO TO 7.

7.CHECK DRAIN FILTER

Refer to EC-872, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace drain filter.

8.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following.

• EVAP canister vent control is installed properly. Refer to FL-16, "

Removal and Installation (MR18DE)".

• EVAP canister vent control valve.

Refer to EC-840, "

Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace EVAP cani ster vent control valve and O-ring.

9.INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pressure pump to EVAP service port securely.

For the location of EVAP service port (2), refer to EC-526, "

Description".

• EVAP canister purge volume control solenoid valve (1)

Revision: May 2010 2011 Versa

Page 2169 of 3787

![NISSAN TIIDA 2011 Service Owners Manual DTC P0456 EVAP CONTROL SYSTEMEC-875

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Set the pressure pump and a hose.

3. Also set the pressure pump with pressure gauge to the EVAP

NISSAN TIIDA 2011 Service Owners Manual DTC P0456 EVAP CONTROL SYSTEMEC-875

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Set the pressure pump and a hose.

3. Also set the pressure pump with pressure gauge to the EVAP](/img/5/57396/w960_57396-2168.png)

DTC P0456 EVAP CONTROL SYSTEMEC-875

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Set the pressure pump and a hose.

3. Also set the pressure pump with pressure gauge to the EVAP

service port adapter.

4. Turn ignition switch ON.

5. Connect GST and select Service $08.

6. Using Service $08 control the EVAP canister vent control valve

(close).

7. Apply pressure and make sure the following conditions are sat- isfied.

Pressure to be applied: 2.7 kPa (20 mmHg, 0.79 inHg)

Time to be waited after the pressure drawn in to the EVAP

system and the pressure to be dropped: 60 seconds and

the pressure should not be dropped more than 0.4 kPa (3 mmHg, 0.12 inHg).

If NG, go to EC-875, "

Diagnosis Procedure".

If OK, go to next step.

8. Disconnect GST.

9. Start engine and warm it up to normal operating temperature.

10. Turn ignition switch OFF and wait at least 10 seconds.

11. Restart engine and let it idle for 90 seconds.

12. Keep engine speed at 2,000 rpm for 30 seconds.

13. Turn ignition switch OFF. NOTE:

For more information, refer to GST Instruction Manual.

Diagnosis ProcedureINFOID:0000000006342042

1.CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

OK or NG

OK >> GO TO 2.

NG >> Replace with genuine NISSAN fuel filler cap.

2.CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower. 2. Retighten until reteaching sound is heard.

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-528, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one.

SEF462UI

SEF915U

Revision: May 2010 2011 Versa

Page 2336 of 3787

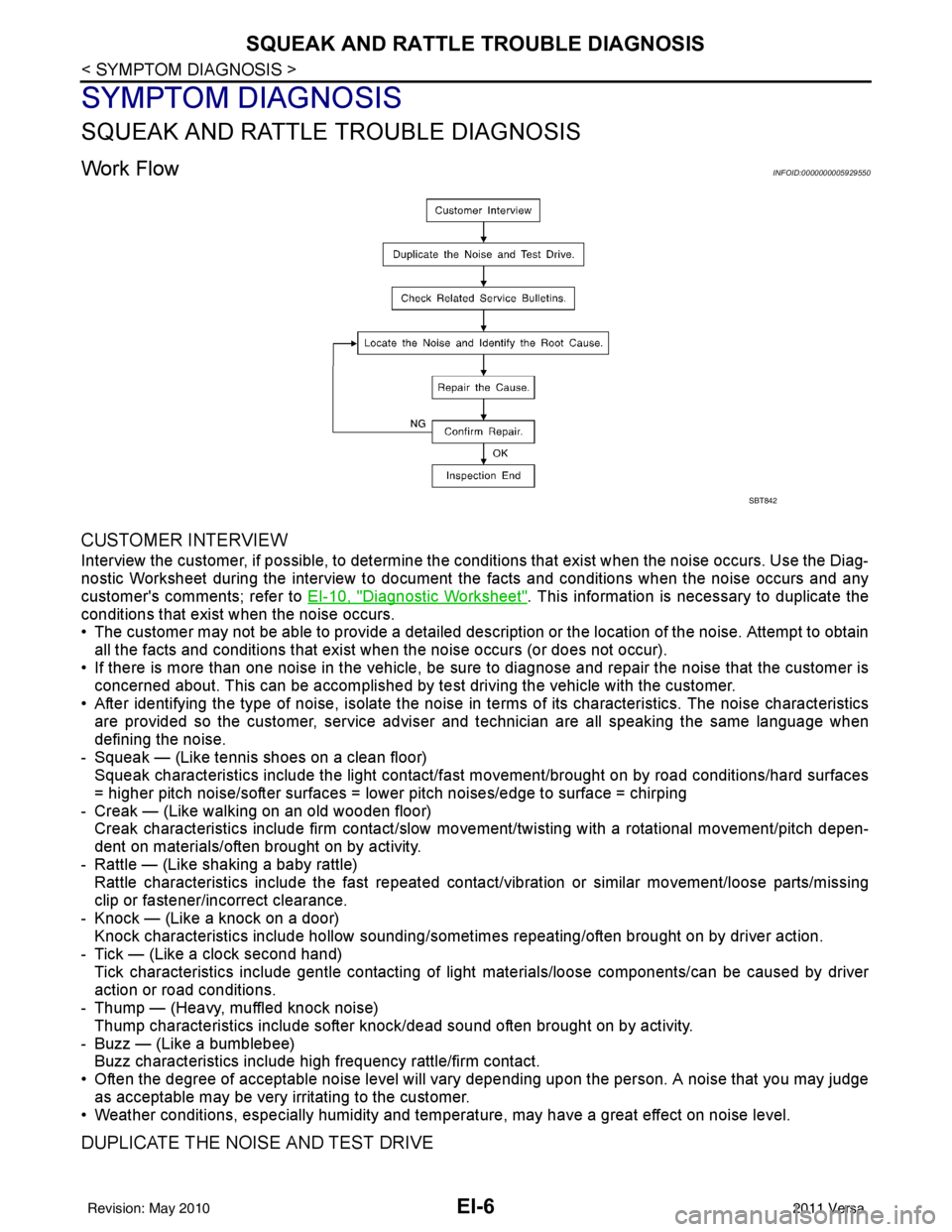

EI-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Work FlowINFOID:0000000005929550

CUSTOMER INTERVIEW

Interview the customer, if possible, to determine the conditions that exis t when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to EI-10, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by te st driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

- Squeak — (Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

- Creak — (Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

- Rattle — (Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

- Knock — (Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

- Tick — (Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

- Thump — (Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

- Buzz — (Like a bumblebee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: May 2010 2011 Versa

Page 2403 of 3787

![NISSAN TIIDA 2011 Service Owners Manual DRIVE BELTSEM-13

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

ON-VEHICLE MAINTENANCE

DRIVE BELTS

CheckingINFOID:0000000005930924

• Inspection should be done only when engine i NISSAN TIIDA 2011 Service Owners Manual DRIVE BELTSEM-13

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

ON-VEHICLE MAINTENANCE

DRIVE BELTS

CheckingINFOID:0000000005930924

• Inspection should be done only when engine i](/img/5/57396/w960_57396-2402.png)

DRIVE BELTSEM-13

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

ON-VEHICLE MAINTENANCE

DRIVE BELTS

CheckingINFOID:0000000005930924

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belts for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley two times clockwise, and make sure tension on all pulleys is equal before doing the test.

• When measuring deflection, apply 98 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency with acous tic tension gauge at the ( ) marked point.

CAUTION:

• When the tension and frequency are measured, the acoustic tension gauge should be used.

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, re-adjust to the sp ecified value to avoid variation in deflection

between pulleys.

Tension AdjustmentINFOID:0000000005930925

CAUTION:

• When belt is replaced with new one, adjust belt te nsion to the value for “New belt”, because new belt

will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

• When installing a belt, make sure it is correctly engaged with the pulley groove.

• Never allow oil or engine coolant to get on the belt.

• Never twist or bend the belt strongly.

1. Loosen the idler pulley lock nut (A) from the tightening position with the specified torque by 45 degrees.

CAUTION:

1 : Generator

2 : Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6: Drive belt

Belt Deflection / Belt Tension and Frequency : Refer to EM-111, "Drive Belts".

PBIC3642E

LocationLocation of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

1 : Generator

2: Water pump

3 : Crankshaft pulley

4 : A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6: Drive belt

A : Idler pulley lock nut

B : Adjusting bolt

PBIC3643E

Revision: May 2010 2011 Versa

Page 2409 of 3787

![NISSAN TIIDA 2011 Service Owners Manual CAMSHAFT VALVE CLEARANCEEM-19

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000005930930

INSPECTION

Perform inspectio NISSAN TIIDA 2011 Service Owners Manual CAMSHAFT VALVE CLEARANCEEM-19

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000005930930

INSPECTION

Perform inspectio](/img/5/57396/w960_57396-2408.png)

CAMSHAFT VALVE CLEARANCEEM-19

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000005930930

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to EM-46, "

Exploded View".

2. Measure the valve clearance with the following procedure:

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (2) clockwise and align TDC mark(without paint mark) (A) to timing indicator (1) on front cover.

• At the same time, make sure that both intake and exhaust cam noses of No. 1 cylinder face inside as shown.

• If they do not face inside, rotate crankshaft pulley once more (360 degrees) and align as shown.

b. Use a feeler gauge, measure the clearance between valve lifter and camshaft.

• Measure the valve clearances at locations marked “× ” as

shown in the table below [locations indicated with black arrow

( ) as shown] with a feeler gauge.

B : White paint mark (Not use for service)

PBIC3673E

1 : Camshaft (INT)

2 : Camshaft (EXH)

: Engine front

PBIC3359J

Valve Clearance: Refer to EM-112, "Camshaft".

SEM139D

A : No. 1 cylinder compression TDC

: Engine front

Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 4 CYL.

Measurement po-

sition EXH

× ×

INT × ×

PBIC3707E

Revision: May 2010 2011 Versa

Page 2440 of 3787

![NISSAN TIIDA 2011 Service Owners Manual EM-50

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

4. Remove the following parts.

• Intake manifold: Refer to EM-27, "

Exploded View".

• Drive belt: Refer to EM-14, "

Removal and Installation".

• NISSAN TIIDA 2011 Service Owners Manual EM-50

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

4. Remove the following parts.

• Intake manifold: Refer to EM-27, "

Exploded View".

• Drive belt: Refer to EM-14, "

Removal and Installation".

•](/img/5/57396/w960_57396-2439.png)

EM-50

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

4. Remove the following parts.

• Intake manifold: Refer to EM-27, "

Exploded View".

• Drive belt: Refer to EM-14, "

Removal and Installation".

• Water pump pulley: Refer to CO-20, "

Exploded View".

• Ground cable (RH)

5. Support the bottom surface of engine using a tr ansmission jack, and then remove the engine mounting

bracket and insulator (RH). Refer to EM-82, "

Exploded View".

6. Remove rocker cover. Refer to EM-46, "

Exploded View".

7. Set No. 1 cylinder at TDC of its compression stroke with the following procedure:

a. Rotate crankshaft pulley (2) clockwise and align TDC mark (without paint mark) (A) to timing indicator (1) on front cover.

b. Make sure the matching marks on each camshaft sprocket are positioned as shown.

• If not, rotate crankshaft pulley one more turn to align matching

marks to the positions.

8. Remove crankshaft pulley with the following procedure:

a. Secure crankshaft pulley (1) using a suitable tool (A).

b. Loosen and pull out crankshaft pulley bolts. CAUTION:

Never remove the bolts as they are used as a supporting

point for the pulley puller.

c. Attach Tool (A) in the M 6 thread hole on crankshaft pulley, and remove crankshaft pulley.

B : White paint mark (Not use for service)

PBIC3673E

1 : Camshaft sprocket (EXH)

2 : Camshaft sprocket (INT)

A : Matching mark (stamp)

B : Matching mark (peripheral stamp line)

PBIC3872E

PBIC3710E

B: M6 bolt

Tool number : KV11103000 ( — )

PBIC3711E

Revision: May 2010 2011 Versa