Time NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2758 of 3787

GW-4

< SERVICE INFORMATION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

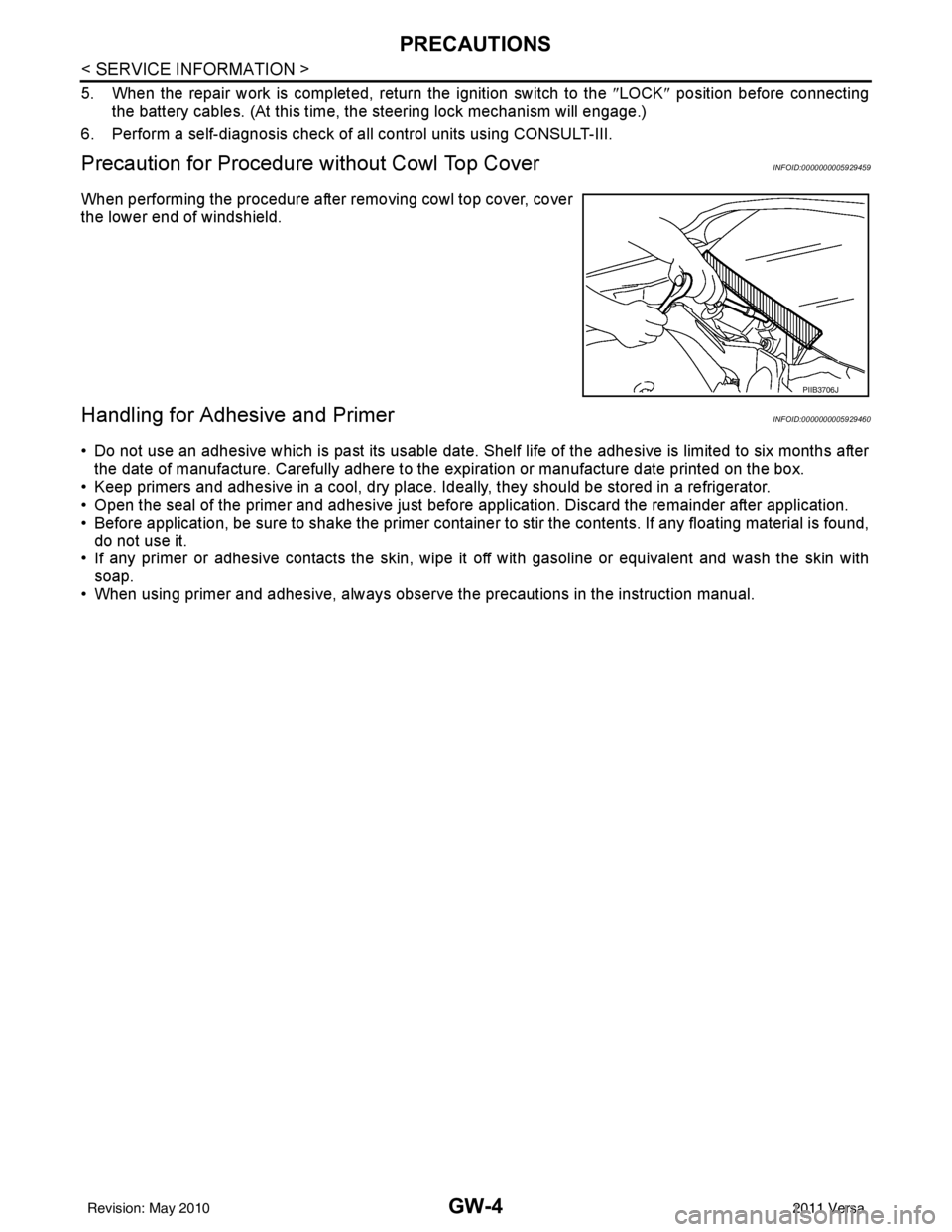

Precaution for Procedure without Cowl Top CoverINFOID:0000000005929459

When performing the procedure after removing cowl top cover, cover

the lower end of windshield.

Handling for Adhesive and PrimerINFOID:0000000005929460

• Do not use an adhesive which is past its usable date. Shel f life of the adhesive is limited to six months after

the date of manufacture. Carefully adhere to the expiration or manufacture date printed on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

• Open the seal of the primer and adhesive just before application. Discard the remainder after application.

• Before application, be sure to shake the primer container to stir the contents. If any floating material is found, do not use it.

• If any primer or adhesive contacts the skin, wipe it off with gasoline or equivalent and wash the skin with

soap.

• When using primer and adhesive, always observe the precautions in the instruction manual.

PIIB3706J

Revision: May 2010 2011 Versa

Page 2763 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-9

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 2767 of 3787

WINDSHIELD GLASSGW-13

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

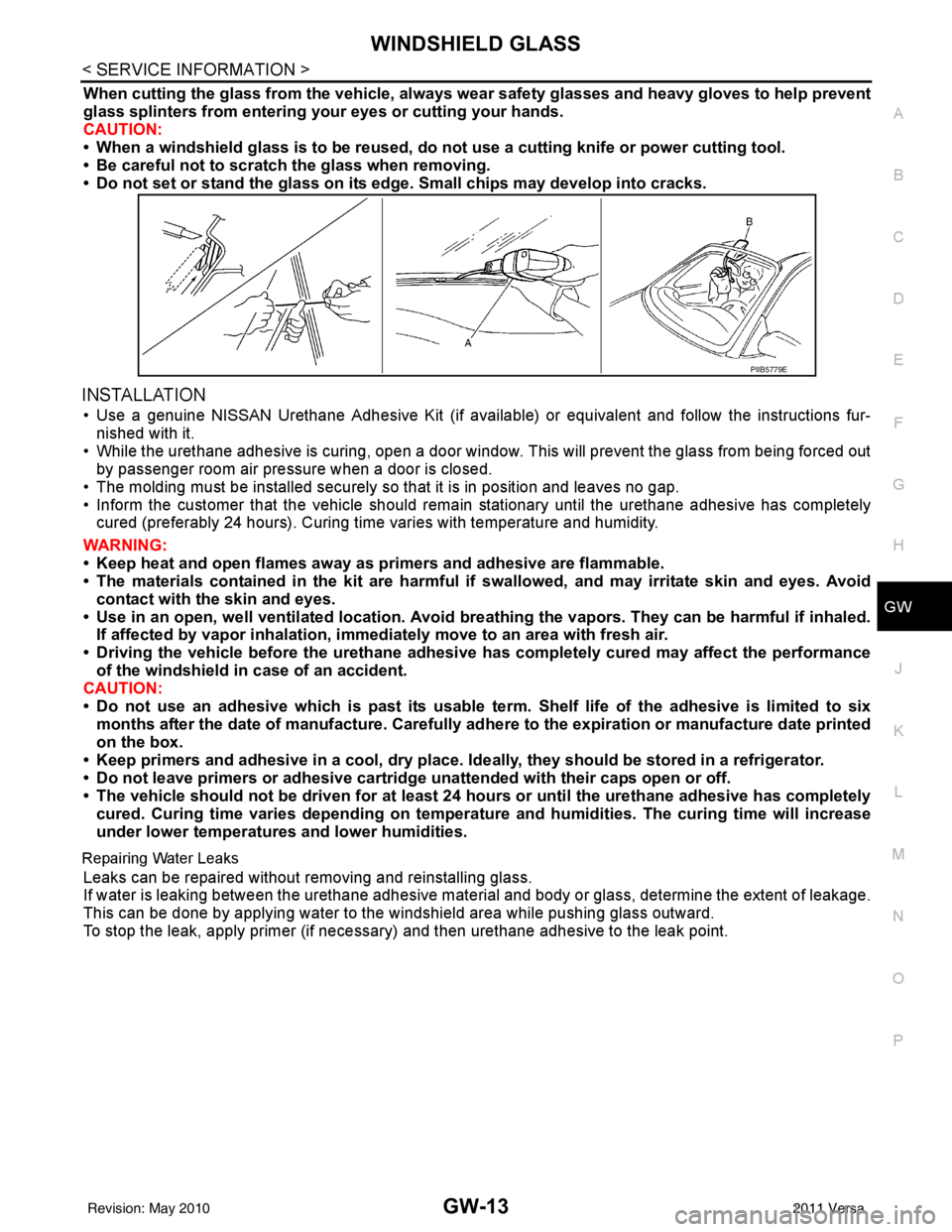

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• When a windshield glass is to be reused, do no t use a cutting knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

INSTALLATION

• Use a genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger room air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated lo cation. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable term. Shelf life of the adhesive is limited to six

months after the date of manufacture. Carefully ad here to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depend ing on temperature and humidities. The curing time will increase

under lower temperatures and lower humidities.

Repairing Water Leaks

Leaks can be repaired without removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the windshield area while pushing glass outward.

To stop the leak, apply primer (if necessary ) and then urethane adhesive to the leak point.

PIIB5779E

Revision: May 2010 2011 Versa

Page 2769 of 3787

OPERA WINDOW GLASSGW-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated lo cation. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the side window in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable term. Shelf life of the adhesive is limited to six months after the date of manufacture. Carefully ad here to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely cured. Curing time varies depend ing on temperature and humidities. The curing time will increase

under lower temperature and lower humidity.

Repairing Water Leaks

Leaks can be repaired without removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the side window area while pushing glass outward.

To stop the leak, apply primer (if necessary ) and then urethane adhesive to the leak point.

Revision: May 2010 2011 Versa

Page 2772 of 3787

GW-18

< SERVICE INFORMATION >

REAR WINDOW GLASS AND MOLDING

INSTALLATION

Installation is in the reverse order of removal.

• Use a genuine NISSAN Urethane Adhesive Kit (if available) or equivalent and follow the instructions fur-nished with it.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Check gap along bottom to confirm that glass does not contact sheet metal.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled. If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance of the windshield in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully a dhere to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a c ool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depe nding on temperature and humidity . The curing time will increase

under lower temperatures and lower humidities.

Repairing Water leaks for Rear Window Glass

Leaks can be repaired without removing or reinstalling glass.

If water is leaking between urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the rear window area while pushing glass outward.

To stop leak, apply primer (if necessary) and then urethane adhesive to the leak point.

Revision: May 2010 2011 Versa

Page 2773 of 3787

POWER WINDOW SYSTEMGW-19

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

POWER WINDOW SYSTEM

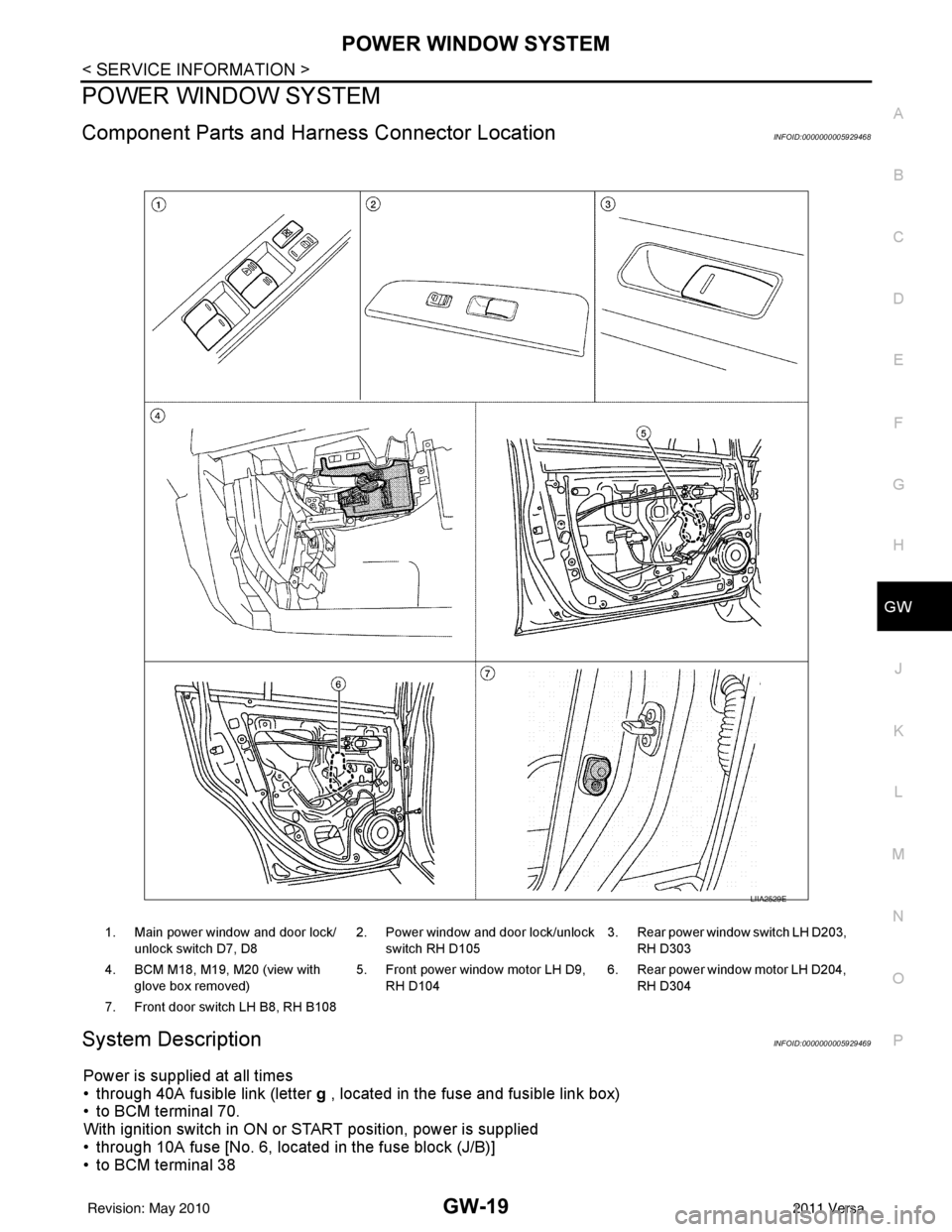

Component Parts and Har ness Connector LocationINFOID:0000000005929468

System DescriptionINFOID:0000000005929469

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70.

With ignition switch in ON or START position, power is supplied

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38

1. Main power window and door lock/

unlock switch D7, D8 2. Power window and door lock/unlock

switch RH D105 3. Rear power window switch LH D203,

RH D303

4. BCM M18, M19, M20 (view with glove box removed) 5. Front power window motor LH D9,

RH D104 6. Rear power window motor LH D204,

RH D304

7. Front door switch LH B8, RH B108

LIIA2529E

Revision: May 2010 2011 Versa

Page 2783 of 3787

POWER WINDOW SYSTEMGW-29

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

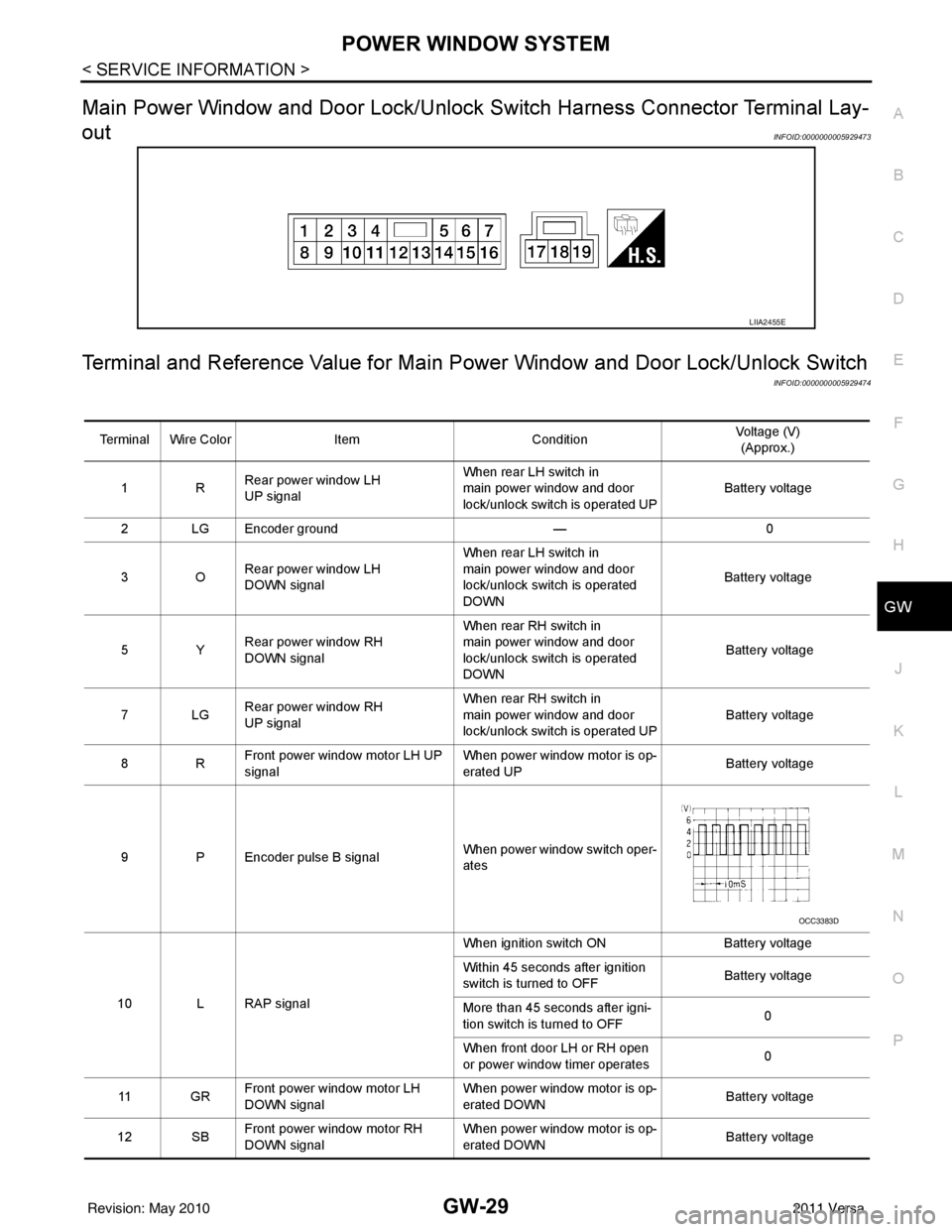

Main Power Window and Door Lock/Unlock Switch Harness Connector Terminal Lay-

out

INFOID:0000000005929473

Terminal and Reference Value for Main Po wer Window and Door Lock/Unlock Switch

INFOID:0000000005929474

LIIA2455E

Terminal Wire ColorItemCondition Voltage (V)

(Approx.)

1R Rear power window LH

UP signal When rear LH switch in

main power window and door

lock/unlock switch is operated UP

Battery voltage

2 LG Encoder ground — 0

3O Rear power window LH

DOWN signal When rear LH switch in

main power window and door

lock/unlock switch is operated

DOWN

Battery voltage

5Y Rear power window RH

DOWN signal When rear RH switch in

main power window and door

lock/unlock switch is operated

DOWN

Battery voltage

7LG Rear power window RH

UP signal When rear RH switch in

main power window and door

lock/unlock switch is operated UP

Battery voltage

8R Front power window motor LH UP

signal When power window motor is op-

erated UP

Battery voltage

9 P Encoder pulse B signal When power window switch oper-

ates

10 L RAP signal When ignition switch ON

Battery voltage

Within 45 seconds after ignition

switch is turned to OFF Battery voltage

More than 45 seconds after igni-

tion switch is turned to OFF 0

When front door LH or RH open

or power window timer operates 0

11 G R Front power window motor LH

DOWN signal When power window motor is op-

erated DOWN

Battery voltage

12 SB Front power window motor RH

DOWN signal When power window motor is op-

erated DOWN

Battery voltage

OCC3383D

Revision: May 2010

2011 Versa

Page 2784 of 3787

GW-30

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

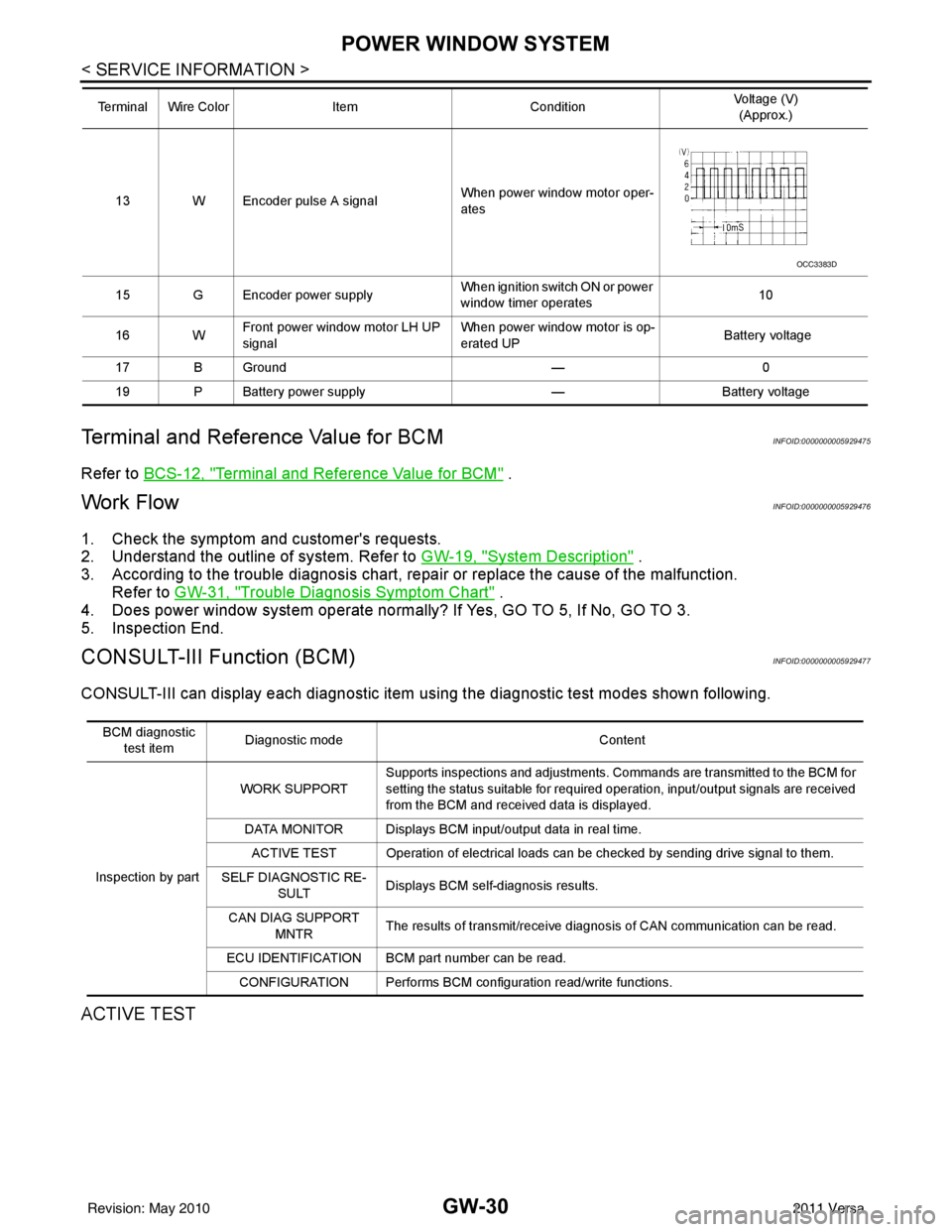

Terminal and Reference Value for BCM

INFOID:0000000005929475

Refer to BCS-12, "Terminal and Reference Value for BCM" .

Work FlowINFOID:0000000005929476

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-19, "

System Description" .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to GW-31, "

Trouble Diagnosis Symptom Chart" .

4. Does power window system operate normally? If Yes, GO TO 5, If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM)INFOID:0000000005929477

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

ACTIVE TEST

13 W Encoder pulse A signal When power window motor oper-

ates

15 G Encoder power supply When ignition switch ON or power

window timer operates10

16 W Front power window motor LH UP

signal When power window motor is op-

erated UP

Battery voltage

17 B Ground —0

19 P Battery power supply —Battery voltage

Terminal Wire Color

ItemCondition Voltage (V)

(Approx.)

OCC3383D

BCM diagnostic

test item Diagnostic mode

Content

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RE- SULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ECU IDENTIFICATION BCM part number can be read. CONFIGURATION Performs BCM configuration read/write functions.

Revision: May 2010 2011 Versa

Page 2785 of 3787

POWER WINDOW SYSTEMGW-31

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

WORK SUPPORT

DATA MONITOR

Power Window Auto Operation InitializationINFOID:0000000005929478

1. Turn the ignition switch ON.

2. Open the window—all the way DOWN.

3. Pull all the way UP on the switch and hold (close the window). • Continue holding the switch all the way UP for 4 seconds after the window is closed.

4. Confirm the window is now operating correctly. NOTE:

• If the window is still not operating correctly, refer to GW-31, "

Trouble Diagnosis Symptom Chart".

• The above initialization procedure must be performed if any of the following occur:

- Battery cable is disconnected

- Power window switch connector is disconnected

- Power window regulator is replaced

- Power window motor is replaced

- Window glass is removed

- Window glass run rubber is replaced

- Power window fuse is blown

- Window is partly opened and/or closed many times without being fully closed.

Trouble Diagnosis Symptom ChartINFOID:0000000005929479

Check that other systems us ing the signal of the following systems operate normally.

Test Item Description

RETAINED PWR This test is able to supply RAP signal (powe

r) from BCM (body control module) to power window

system and power sunroof system (if equipped). Those systems can be operated when turning on

“RETAINED PWR” on CONSULT-III screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-III can be operated with ignition switch in OFF position. “RETAINED

PWR” should be turned “ON” or “OFF” on CONSULT-III screen when ignition switch is ON. Then

turn ignition switch OFF to check retained power operation. CONSULT-III might be stuck if “RE-

TAINED PWR” is turned “ON” or “OFF” on CONSULT-III screen when ignition switch is OFF.

Work item Description

RETAINED PWR RAP signal’s power supply period can be changed by mode setting. Selects RAP signal’s power

supply period between three steps

• MODE1 (45 sec.)/MODE2 (OFF)/MODE3 (2 min.).

Work item

Description

IGN ON SW Indicates (ON/OFF) condition of ignition switch

DOOR SW-DR Indicates (ON/OFF) condition of front door switch LH

DOOR SW-AS Indicates (ON/OFF) condition of front door switch RH

Symptom Repair orderRefer to page

None of the power windows can be operated using any switch 1. BCM power supply and ground circuit check

BCS-16

2. Main power window and door lock/unlock

power supply and ground circuit check GW-32

3. Replace main power window and door lock/

unlock switch

EI-36

Front power window LH alone does not operate 1. Front power window motor LH circuit check

GW-332. Replace main power window and door lock/

unlock switch EI-36

Revision: May 2010

2011 Versa

Page 2806 of 3787

GW-52

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

Power is supplied at all times

• through 15A fuses (No. 46 and 47, located in the IPDM E/R)

• to rear window defogger relay

• through 10A fuse [No. 5 (with heated mirrors), located in the fuse block (J/B)]

• to heated mirror relay terminal 3

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch turned to ON or START position, power is supplied

• through ignition relay

• to rear window defogger relay (located in the IPDM E/R)

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to front air control terminal 8

• through body grounds M57 and M61

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

When front air control (rear window defogger switch) is turned to ON, ground is supplied

• to BCM terminal 9

• through front air control terminal 3

• through front air control terminal 8

• through body grounds M57 and M61.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R via CAN communication (CAN-H, CAN-L).

When IPDM E/R receives rear window defogger switch signals, ground is supplied

• to rear window defogger relay (located in the IPDM E/R)

• through IPDM E/R terminals 39 and 59

• through body grounds E15 and E24

Then rear window defogger relay is energized.

With power and ground supplied, rear window def ogger filaments heat and defog the rear window.

When rear window defogger relay is turned to ON (with heated mirrors), power is supplied

• through heated mirror relay terminal 5

• to door mirror (LH and RH) terminal 1.

Door mirror (LH and RH) is grounded through body grounds M57 and M61.

With power and ground supplied, rear window defogger filaments heat and defog the rear window and door

mirror filaments heat and defog the mirrors.

CAN Communication System DescriptionINFOID:0000000005929499

Refer to LAN-7, "System Description".

Revision: May 2010 2011 Versa