sensor oxygen NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 48 of 3833

GI-46

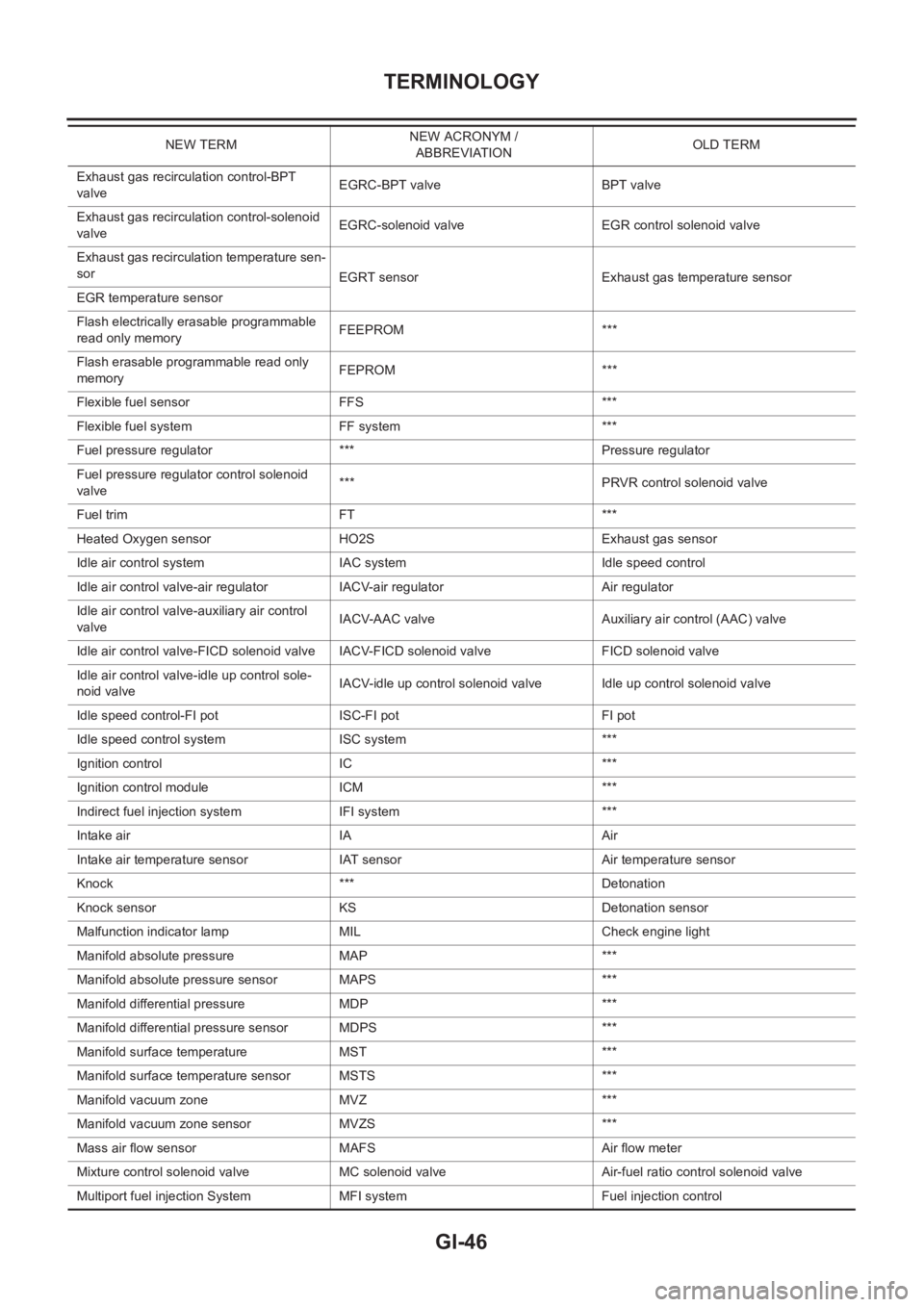

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 49 of 3833

TERMINOLOGY

GI-47

C

D

E

F

G

H

I

J

K

L

MB

GI

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TBThrottle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valveLock-up cancel solenoid

Lock-up solenoid NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 57 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual PREPARATION

EM-7

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

PREPARATIONPFP:00002

Special Service ToolsEBS00L7N

Tool number

To o l n a m eDescription

K V 1 0 1111 0 0

Seal cutterRemoving oil pan and timing chain NISSAN X-TRAIL 2001 Service Repair Manual PREPARATION

EM-7

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

PREPARATIONPFP:00002

Special Service ToolsEBS00L7N

Tool number

To o l n a m eDescription

K V 1 0 1111 0 0

Seal cutterRemoving oil pan and timing chain](/img/5/57405/w960_57405-56.png)

PREPARATION

EM-7

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

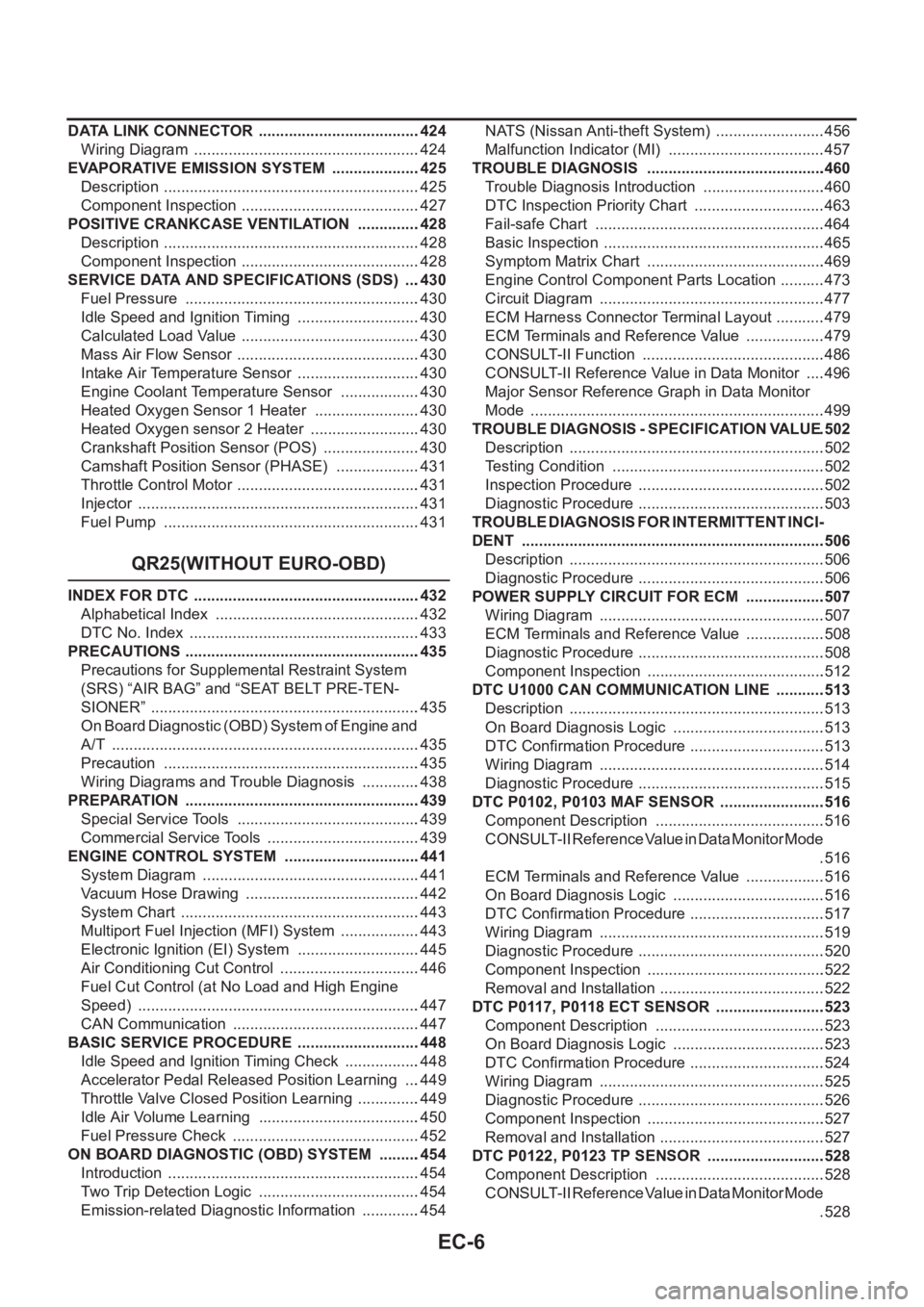

PREPARATIONPFP:00002

Special Service ToolsEBS00L7N

Tool number

To o l n a m eDescription

K V 1 0 1111 0 0

Seal cutterRemoving oil pan and timing chain case

ST0501S000

Engine stand assembly

1. ST05011000

Engine stand

2. ST05012000

BaseDisassembling and assembling

KV10106500

Engine stand shaft

KV10115300

Engine sub-attachment

KV10116200

Valve spring compressor

1. KV10115900

AttachmentDisassembling valve mechanism

KV10112100

Angle wrenchTightening bolts for bearing cap, cylinder

head, etc.

KV10117100

Heated oxygen sensor wrenchLoosening or tightening heated oxygen

sensors with 22 mm (0.87 in) hexagon nut

S-NT046

NT042

NT028

ZZA1078D

NT022

S-NT014

NT379

Page 74 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-24

[QR]

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CATALYST

PFP:14004

Removal and InstallationEBS00KND

REMOVAL

1. Remove heated oxygen sensors.

●Follow below steps to NISSAN X-TRAIL 2001 Service Repair Manual EM-24

[QR]

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CATALYST

PFP:14004

Removal and InstallationEBS00KND

REMOVAL

1. Remove heated oxygen sensors.

●Follow below steps to](/img/5/57405/w960_57405-73.png)

EM-24

[QR]

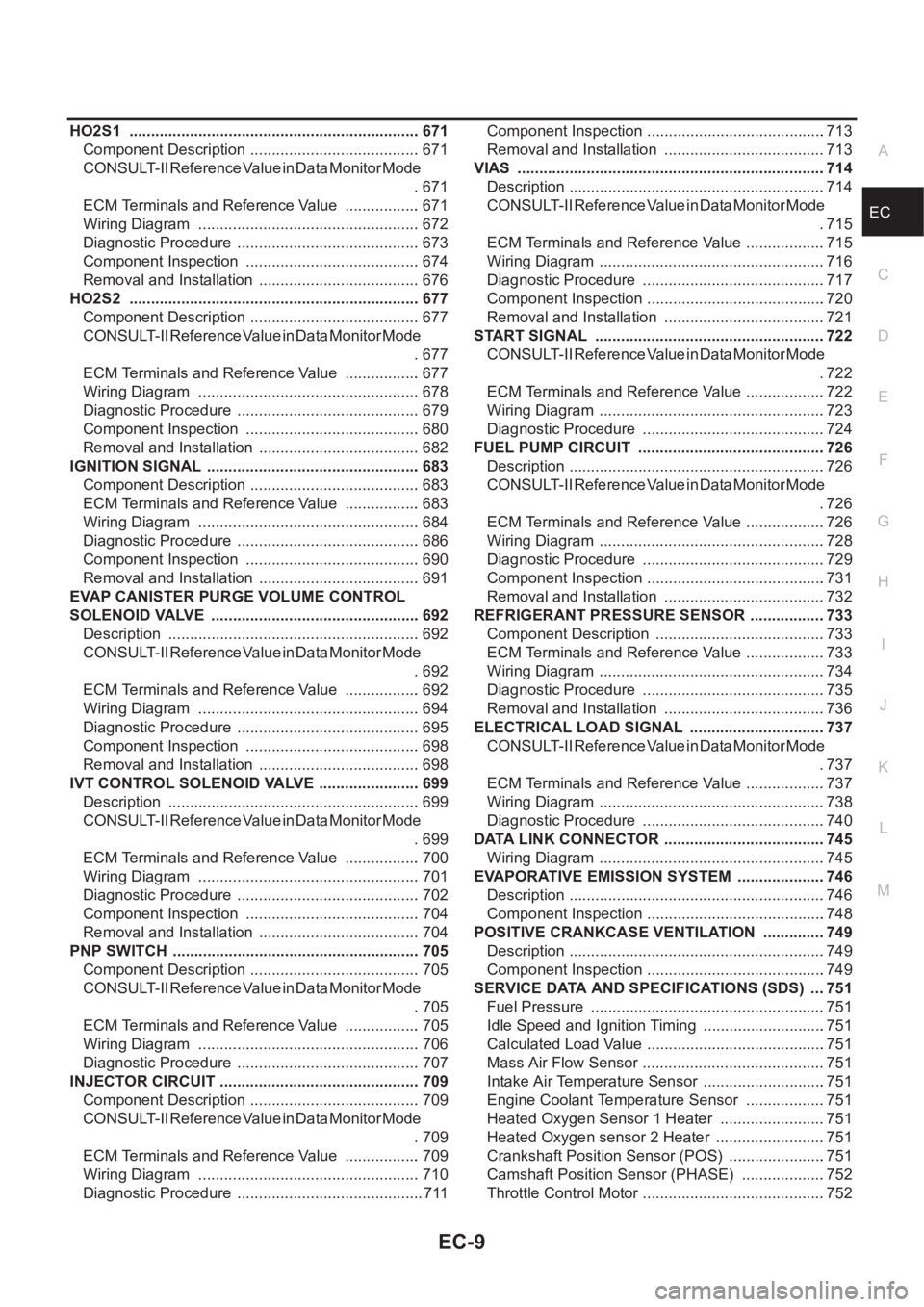

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CATALYST

PFP:14004

Removal and InstallationEBS00KND

REMOVAL

1. Remove heated oxygen sensors.

●Follow below steps to remove each heated oxygen sensor.

a. Remove engine undercover.

b. Disconnect harness connector of each heated oxygen sensor, and harness from bracket and middle

clamp.

c. Using heated oxygen sensor wrench, remove heated oxygen

sensors.

CAUTION:

●Be careful not to damage heated oxygen sensor.

●Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

2. Remove exhaust manifold and three way catalyst assembly.

a. Remove exhaust manifold cover lower.

b. Remove exhaust front tube. Refer to EX-2, "

Removal and Instal-

lation" .

PBIC0279E

1.Exhaust manifold and three way cat-

alyst assembly2. Gasket 3. Exhaust manifold cover

4. Heated oxygen sensor 1 5. Heated oxygen sensor 2

KBIA0094E

Page 75 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Remove exhaust manifold cover upper.

d. Loosen nuts in reverse order of illustration to remove exhaust

manifold NISSAN X-TRAIL 2001 Service Repair Manual EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Remove exhaust manifold cover upper.

d. Loosen nuts in reverse order of illustration to remove exhaust

manifold](/img/5/57405/w960_57405-74.png)

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Remove exhaust manifold cover upper.

d. Loosen nuts in reverse order of illustration to remove exhaust

manifold and catalytic converter.

●Disregard the numerical order No. 6 and 7 when loosening.

3. Remove exhaust manifold and three way catalyst loosening nuts

in reverse order in the figure.

INSPECTION AFTER REMOVAL

Surface Distortion

Use a reliable straightedge and feeler gauge to check the flatness of

exhaust manifold fitting surface.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

Exhaust Manifold Nuts

●Tighten nuts in the numerical order shown in the figure.

●No. 6 and 7 indicate double tightening of bolts No. 1 and 3.

Heated Oxygen Sensor

CAUTION:

Do not over torque the heated oxygen sensor. Doing so may cause damage to the heated oxygen sen-

sor, resulting in the MIL coming on.

KBIA0045E

Standard: 0.3 mm (0.012 in)

KBIA0046E

KBIA0045E

Page 158 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearance NISSAN X-TRAIL 2001 Service Repair Manual EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearance](/img/5/57405/w960_57405-157.png)

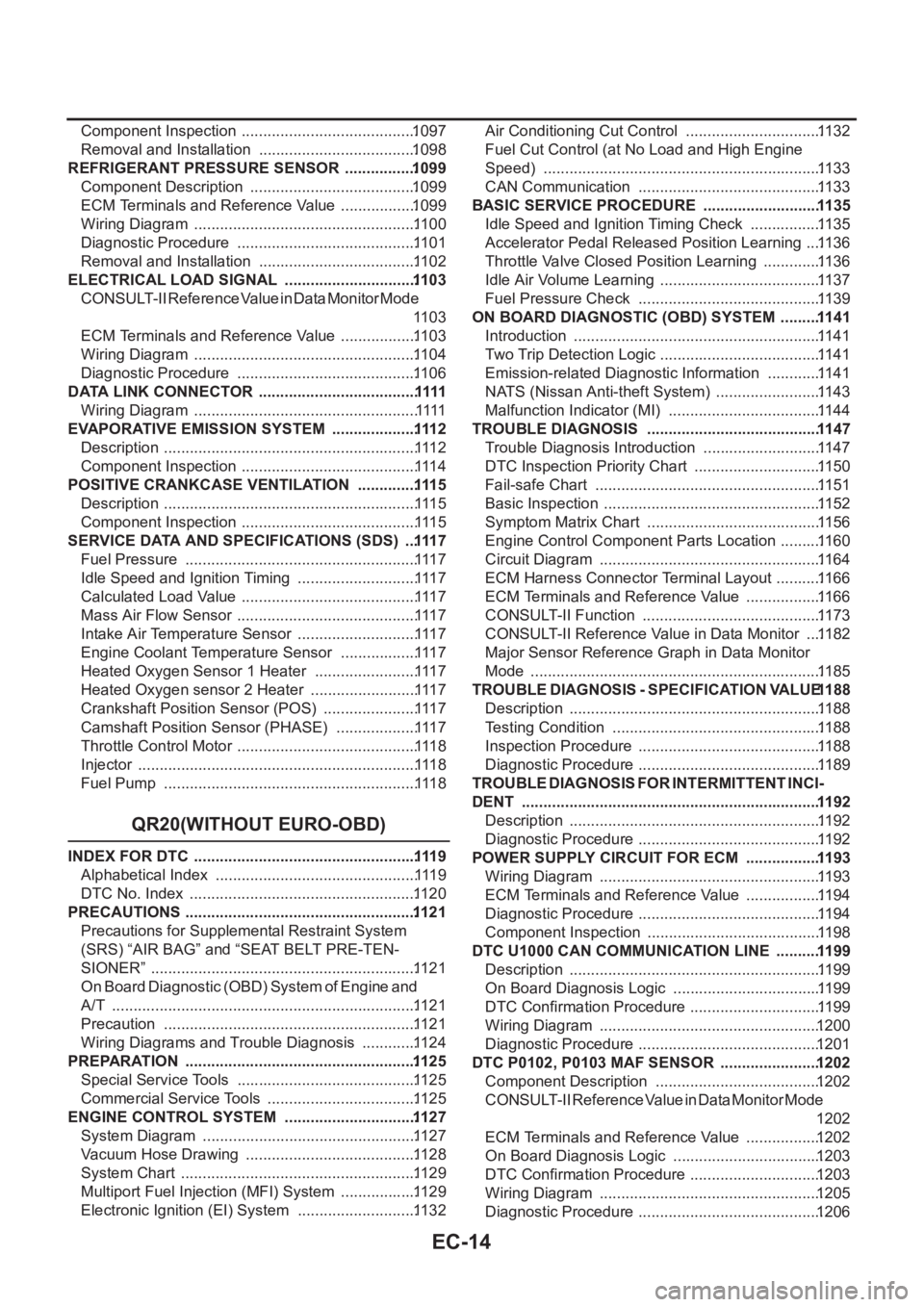

EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearanceStandard 0.028 - 0.045 (0.0011 - 0.0018)

Limit 0.10 (0.0039)

*1: Parts to be tightened in particular orders.

1)-: Order of tightening when tightening two or more times separately.

Auto-tensioner 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Mass air flow sensor

3.8 - 4.5 (0.39 - 0.46, 34 - 39) *

2

Resonator

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*2

Air cleaner case lower

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*2

*1 Intake manifold17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Intake manifold collector 17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Intake manifold support 17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Electric throttle control actuator

7.2 - 9.6 (0.74 - 0.98, 64 - 84) *

2

EVAP canister purge volume control solenoid valve

4.3 - 5.8 (0.44 - 0.59, 38 - 51) *2

*1 Exhaust manifold 39.2 - 44.1 (4.0 - 4.5, 29 - 32)

Exhaust manifold cover

5.1 - 6.5 (0.52 - 0.66, 46 - 57) *

2

Heated oxygen sensor 40 - 50 (4.1 - 5.1, 30 - 36)

*1 Oil pan upper M6 bolt

8.1 - 9.5 (0.83 - 0.97, 72 - 84) *

2

M8 bolt 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Oil pan upper to transmission joint bolts 39.2 - 46.1 (4.0 - 4.7, 29 - 34)

*1 Oil pan lower

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Oil pan drain plug29.4 - 39.2 (3.0 - 4.0, 22 - 28)

Rear plate cover

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Oil strainer M6 bolt

8.1 - 9.5 (0.83 - 0.97, 72 - 84) *2

M8 bolt 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Oil level gauge guide 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Ignition coil

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *

2

Spark plug19.6 - 29.4 (2.0 - 3.0, 15 - 21)

*1 Fuel tube1)

2)9.3 - 10.8 (0.95 - 1.1, 0.7 - 0.8) *

2

20.6 - 26.5 (2.1 - 2.7, 16 - 19)

*1 Rocker cover1)

2)0.98 - 2.9 (0.1 - 0.3, 9 - 25) *

2

7.4 - 9.3 (0.75 - 0.95, 66 - 82) *2

PCV valve

1.96 - 2.94 (0.20 - 0.30, 18 - 26) *2

Intake valve timing control solenoid valve

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *2

*1 Intake valve timing control cover 11.8 - 13.7 (1.2 - 1.4, 9 - 10)

Camshaft position sensor (PHASE)

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *

2

Camshaft sprocket (Intake and Exhaust) 127- 157 (13.0 - 16.0, 94 - 115)

Chain tensioner

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Page 356 of 3833

EC-6

DATA LINK CONNECTOR ......................................424

Wiring Diagram .....................................................424

EVAPORATIVE EMISSION SYSTEM .....................425

Description ............................................................425

Component Inspection ..........................................427

POSITIVE CRANKCASE VENTILATION ...............428

Description ............................................................428

Component Inspection ..........................................428

SERVICE DATA AND SPECIFICATIONS (SDS) ....430

Fuel Pressure .......................................................430

Idle Speed and Ignition Timing .............................430

Calculated Load Value ..........................................430

Mass Air Flow Sensor ...........................................430

Intake Air Temperature Sensor .............................430

Engine Coolant Temperature Sensor ...................430

Heated Oxygen Sensor 1 Heater .........................430

Heated Oxygen sensor 2 Heater ..........................430

Crankshaft Position Sensor (POS) .......................430

Camshaft Position Sensor (PHASE) ....................431

Throttle Control Motor ...........................................431

Injector ..................................................................431

Fuel Pump ............................................................431

QR25(WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................432

Alphabetical Index ................................................432

DTC No. Index ......................................................433

PRECAUTIONS .......................................................435

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................435

On Board Diagnostic (OBD) System of Engine and

A/T ........................................................................435

Precaution ............................................................435

Wiring Diagrams and Trouble Diagnosis ..............438

PREPARATION .......................................................439

Special Service Tools ...........................................439

Commercial Service Tools ....................................439

ENGINE CONTROL SYSTEM ................................441

System Diagram ...................................................441

Vacuum Hose Drawing .........................................442

System Chart ........................................................443

Multiport Fuel Injection (MFI) System ...................443

Electronic Ignition (EI) System .............................445

Air Conditioning Cut Control .................................446

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................447

CAN Communication ............................................447

BASIC SERVICE PROCEDURE .............................448

Idle Speed and Ignition Timing Check ..................448

Accelerator Pedal Released Position Learning ....449

Throttle Valve Closed Position Learning ...............449

Idle Air Volume Learning ......................................450

Fuel Pressure Check ............................................452

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........454

Introduction ...........................................................454

Two Trip Detection Logic ......................................454

Emission-related Diagnostic Information ..............454NATS (Nissan Anti-theft System) ..........................456

Malfunction Indicator (MI) .....................................457

TROUBLE DIAGNOSIS ..........................................460

Trouble Diagnosis Introduction .............................460

DTC Inspection Priority Chart ...............................463

Fail-safe Chart ......................................................464

Basic Inspection ....................................................465

Symptom Matrix Chart ..........................................469

Engine Control Component Parts Location ...........473

Circuit Diagram .....................................................477

ECM Harness Connector Terminal Layout ............479

ECM Terminals and Reference Value ...................479

CONSULT-II Function ...........................................486

CONSULT-II Reference Value in Data Monitor .....496

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................499

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .502

Description ............................................................502

Testing Condition ..................................................502

Inspection Procedure ........................................... .502

Diagnostic Procedure ............................................503

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................506

Description ............................................................506

Diagnostic Procedure ............................................506

POWER SUPPLY CIRCUIT FOR ECM ...................507

Wiring Diagram .....................................................507

ECM Terminals and Reference Value ...................508

Diagnostic Procedure ............................................508

Component Inspection ..........................................512

DTC U1000 CAN COMMUNICATION LINE ............513

Description ............................................................513

On Board Diagnosis Logic ....................................513

DTC Confirmation Procedure ................................513

Wiring Diagram .....................................................514

Diagnostic Procedure ............................................515

DTC P0102, P0103 MAF SENSOR .........................516

Component Description ........................................516

CONSULT-II Reference Value in Data Monitor Mode

.516

ECM Terminals and Reference Value ...................516

On Board Diagnosis Logic ....................................516

DTC Confirmation Procedure ................................517

Wiring Diagram .....................................................519

Diagnostic Procedure ............................................520

Component Inspection ..........................................522

Removal and Installation .......................................522

DTC P0117, P0118 ECT SENSOR ..........................523

Component Description ........................................523

On Board Diagnosis Logic ....................................523

DTC Confirmation Procedure ................................524

Wiring Diagram .....................................................525

Diagnostic Procedure ............................................526

Component Inspection ..........................................527

Removal and Installation .......................................527

DTC P0122, P0123 TP SENSOR ............................528

Component Description ........................................528

CONSULT-II Reference Value in Data Monitor Mode

.528

Page 359 of 3833

EC-9

C

D

E

F

G

H

I

J

K

L

M

ECA HO2S1 .................................................................... 671

Component Description ........................................ 671

CONSULT-II Reference Value in Data Monitor Mode

. 671

ECM Terminals and Reference Value .................. 671

Wiring Diagram .................................................... 672

Diagnostic Procedure ........................................... 673

Component Inspection ......................................... 674

Removal and Installation ...................................... 676

HO2S2 .................................................................... 677

Component Description ........................................ 677

CONSULT-II Reference Value in Data Monitor Mode

. 677

ECM Terminals and Reference Value .................. 677

Wiring Diagram .................................................... 678

Diagnostic Procedure ........................................... 679

Component Inspection ......................................... 680

Removal and Installation ...................................... 682

IGNITION SIGNAL .................................................. 683

Component Description ........................................ 683

ECM Terminals and Reference Value .................. 683

Wiring Diagram .................................................... 684

Diagnostic Procedure ........................................... 686

Component Inspection ......................................... 690

Removal and Installation ...................................... 691

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE ................................................. 692

Description ........................................................... 692

CONSULT-II Reference Value in Data Monitor Mode

. 692

ECM Terminals and Reference Value .................. 692

Wiring Diagram .................................................... 694

Diagnostic Procedure ........................................... 695

Component Inspection ......................................... 698

Removal and Installation ...................................... 698

IVT CONTROL SOLENOID VALVE ........................ 699

Description ........................................................... 699

CONSULT-II Reference Value in Data Monitor Mode

. 699

ECM Terminals and Reference Value .................. 700

Wiring Diagram .................................................... 701

Diagnostic Procedure ........................................... 702

Component Inspection ......................................... 704

Removal and Installation ...................................... 704

PNP SWITCH .......................................................... 705

Component Description ........................................ 705

CONSULT-II Reference Value in Data Monitor Mode

. 705

ECM Terminals and Reference Value .................. 705

Wiring Diagram ...................................................

. 706

Diagnostic Procedure ........................................... 707

INJECTOR CIRCUIT ............................................... 709

Component Description ........................................ 709

CONSULT-II Reference Value in Data Monitor Mode

. 709

ECM Terminals and Reference Value .................. 709

Wiring Diagram .................................................... 710

Diagnostic Procedure ............................................ 711Component Inspection ..........................................713

Removal and Installation ......................................713

VIAS ........................................................................714

Description ............................................................714

CONSULT-II Reference Value in Data Monitor Mode

.715

ECM Terminals and Reference Value ...................715

Wiring Diagram .....................................................716

Diagnostic Procedure ...........................................717

Component Inspection ..........................................720

Removal and Installation ......................................721

START SIGNAL ......................................................722

CONSULT-II Reference Value in Data Monitor Mode

.722

ECM Terminals and Reference Value ...................722

Wiring Diagram .....................................................723

Diagnostic Procedure ...........................................724

FUEL PUMP CIRCUIT ............................................726

Description ............................................................726

CONSULT-II Reference Value in Data Monitor Mode

.726

ECM Terminals and Reference Value ...................726

Wiring Diagram .....................................................728

Diagnostic Procedure ...........................................729

Component Inspection ..........................................731

Removal and Installation ......................................732

REFRIGERANT PRESSURE SENSOR ..................733

Component Description ........................................733

ECM Terminals and Reference Value ...................733

Wiring Diagram .....................................................734

Diagnostic Procedure ...........................................735

Removal and Installation ......................................736

ELECTRICAL LOAD SIGNAL ................................737

CONSULT-II Reference Value in Data Monitor Mode

.737

ECM Terminals and Reference Value ...................737

Wiring Diagram .....................................................738

Diagnostic Procedure ...........................................740

DATA LINK CONNECTOR ......................................745

Wiring Diagram .....................................................745

EVAPORATIVE EMISSION SYSTEM .....................746

Description ...................................................

.........746

Component Inspection ..........................................748

POSITIVE CRANKCASE VENTILATION ...............749

Description ............................................................749

Component Inspection ..........................................749

SERVICE DATA AND SPECIFICATIONS (SDS) ....751

Fuel Pressure .......................................................751

Idle Speed and Ignition Timing .............................751

Calculated Load Value ..........................................751

Mass Air Flow Sensor ...........................................751

Intake Air Temperature Sensor .............................751

Engine Coolant Temperature Sensor ...................751

Heated Oxygen Sensor 1 Heater .........................751

Heated Oxygen sensor 2 Heater ..........................751

Crankshaft Position Sensor (POS) .......................751

Camshaft Position Sensor (PHASE) ....................752

Throttle Control Motor ...........................................752

Page 364 of 3833

EC-14

Component Inspection .........................................1097

Removal and Installation .....................................1098

REFRIGERANT PRESSURE SENSOR .................1099

Component Description .......................................1099

ECM Terminals and Reference Value ..................1099

Wiring Diagram ....................................................11 0 0

Diagnostic Procedure ..........................................11 0 1

Removal and Installation .....................................11 0 2

ELECTRICAL LOAD SIGNAL ...............................110 3

CONSULT-II Reference Value in Data Monitor Mode

11 0 3

ECM Terminals and Reference Value ..................11 0 3

Wiring Diagram ....................................................11 0 4

Diagnostic Procedure ..........................................11 0 6

DATA LINK CONNECTOR .....................................1111

Wiring Diagram ....................................................1111

EVAPORATIVE EMISSION SYSTEM ....................111 2

Description ...........................................................111 2

Component Inspection .........................................111 4

POSITIVE CRANKCASE VENTILATION ..............111 5

Description ...........................................................111 5

Component Inspection .........................................111 5

SERVICE DATA AND SPECIFICATIONS (SDS) ...111 7

Fuel Pressure ......................................................111 7

Idle Speed and Ignition Timing ............................111 7

Calculated Load Value .........................................111 7

Mass Air Flow Sensor ..........................................111 7

Intake Air Temperature Sensor ............................111 7

Engine Coolant Temperature Sensor ..................111 7

Heated Oxygen Sensor 1 Heater ........................111 7

Heated Oxygen sensor 2 Heater .........................111 7

Crankshaft Position Sensor (POS) ......................111 7

Camshaft Position Sensor (PHASE) ...................111 7

Throttle Control Motor ..........................................111 8

Injector .................................................................111 8

Fuel Pump ...........................................................111 8

QR20(WITHOUT EURO-OBD)

INDEX FOR DTC ....................................................111 9

Alphabetical Index ...............................................111 9

DTC No. Index .....................................................11 2 0

PRECAUTIONS ......................................................112 1

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ..............................................................11 2 1

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................11 2 1

Precaution ...........................................................11 2 1

Wiring Diagrams and Trouble Diagnosis .............11 2 4

PREPARATION ......................................................112 5

Special Service Tools .......................................... 11 2 5

Commercial Service Tools ...................................11 2 5

ENGINE CONTROL SYSTEM ...............................112 7

System Diagram ..................................................11 2 7

Vacuum Hose Drawing ........................................11 2 8

System Chart .......................................................11 2 9

Multiport Fuel Injection (MFI) System ..................11 2 9

Electronic Ignition (EI) System ............................11 3 2Air Conditioning Cut Control ................................11 3 2

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................11 3 3

CAN Communication ...........................................11 3 3

BASIC SERVICE PROCEDURE ............................11 35

Idle Speed and Ignition Timing Check .................11 3 5

Accelerator Pedal Released Position Learning ....11 3 6

Throttle Valve Closed Position Learning ..............11 3 6

Idle Air Volume Learning ......................................11 3 7

Fuel Pressure Check ...........................................11 3 9

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........11 41

Introduction ..........................................................11 4 1

Two Trip Detection Logic ......................................11 4 1

Emission-related Diagnostic Information .............11 4 1

NATS (Nissan Anti-theft System) .........................11 4 3

Malfunction Indicator (MI) ....................................11 4 4

TROUBLE DIAGNOSIS .........................................11 47

Trouble Diagnosis Introduction ............................11 4 7

DTC Inspection Priority Chart ..............................11 5 0

Fail-safe Chart .....................................................11 5 1

Basic Inspection ...................................................11 5 2

Symptom Matrix Chart .........................................11 5 6

Engine Control Component Parts Location ..........11 6 0

Circuit Diagram ....................................................11 6 4

ECM Harness Connector Terminal Layout ...........11 6 6

ECM Terminals and Reference Value ..................11 6 6

CONSULT-II Function ..........................................

11 7 3

CONSULT-II Reference Value in Data Monitor ....11 8 2

Major Sensor Reference Graph in Data Monitor

Mode ....................................................................11 8 5

TROUBLE DIAGNOSIS - SPECIFICATION VALUE 11 88

Description ...........................................................11 8 8

Testing Condition .................................................11 8 8

Inspection Procedure ........................................... 11 8 8

Diagnostic Procedure ........................................... 11 8 9

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ......................................................................11 92

Description ...........................................................11 9 2

Diagnostic Procedure ........................................... 11 9 2

POWER SUPPLY CIRCUIT FOR ECM ..................11 93

Wiring Diagram ....................................................11 9 3

ECM Terminals and Reference Value ..................11 9 4

Diagnostic Procedure ........................................... 11 9 4

Component Inspection .........................................11 9 8

DTC U1000 CAN COMMUNICATION LINE ...........11 99

Description ...........................................................11 9 9

On Board Diagnosis Logic ...................................11 9 9

DTC Confirmation Procedure ...............................11 9 9

Wiring Diagram ....................................................1200

Diagnostic Procedure ........................................... 1201

DTC P0102, P0103 MAF SENSOR ........................1202

Component Description .......................................1202

CONSULT-II Reference Value in Data Monitor Mode

1202

ECM Terminals and Reference Value ..................1202

On Board Diagnosis Logic ...................................1203

DTC Confirmation Procedure ...............................1203

Wiring Diagram ....................................................1205

Diagnostic Procedure ........................................... 1206

Page 367 of 3833

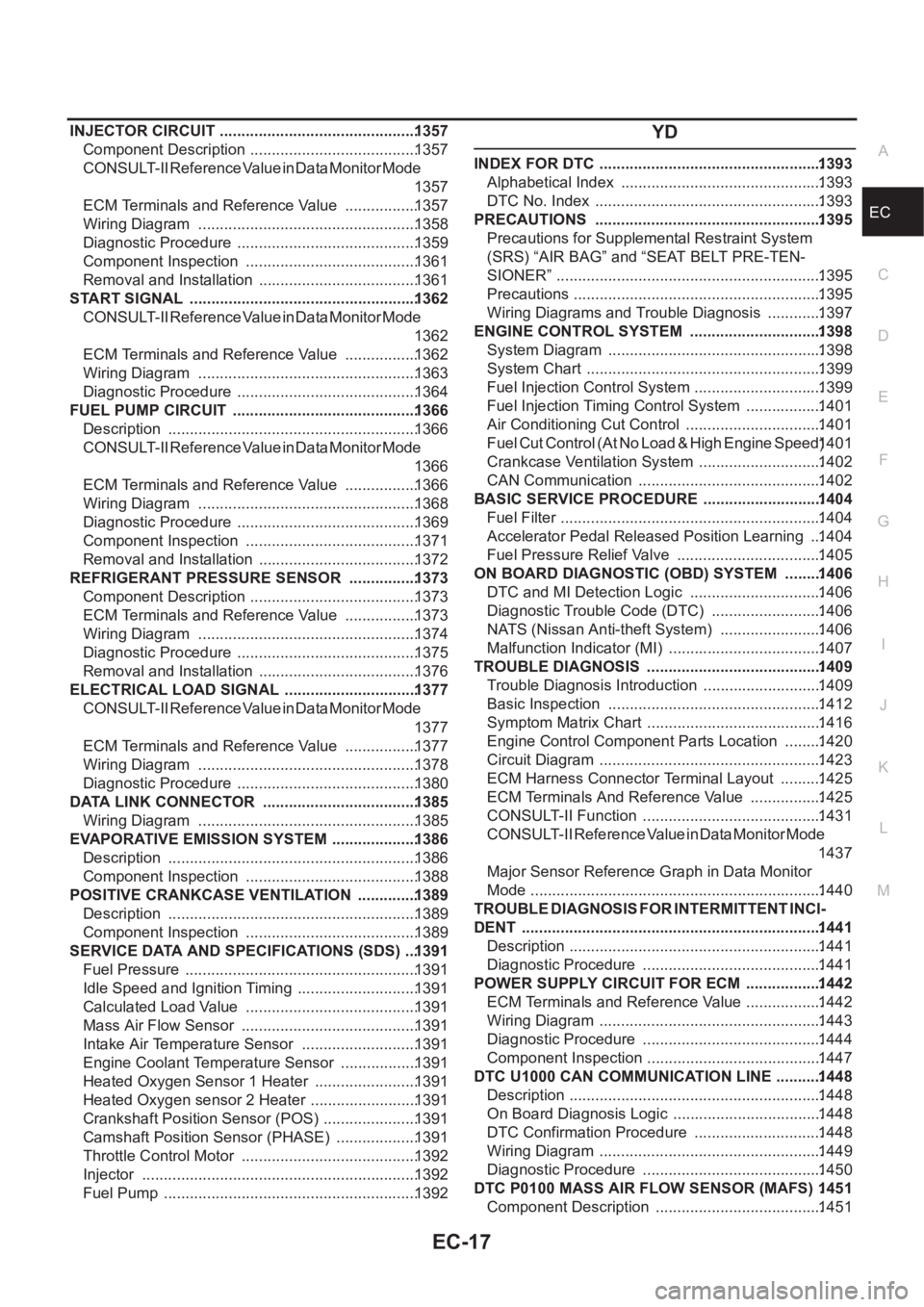

EC-17

C

D

E

F

G

H

I

J

K

L

M

ECA INJECTOR CIRCUIT ..............................................1357

Component Description .......................................1357

CONSULT-II Reference Value in Data Monitor Mode

1357

ECM Terminals and Reference Value .................1357

Wiring Diagram ...................................................1358

Diagnostic Procedure ..........................................1359

Component Inspection ........................................1361

Removal and Installation .....................................1361

START SIGNAL .....................................................1362

CONSULT-II Reference Value in Data Monitor Mode

1362

ECM Terminals and Reference Value .................1362

Wiring Diagram ...................................................1363

Diagnostic Procedure ..........................................1364

FUEL PUMP CIRCUIT ...........................................1366

Description ..........................................................1366

CONSULT-II Reference Value in Data Monitor Mode

1366

ECM Terminals and Reference Value .................1366

Wiring Diagram ...................................................1368

Diagnostic Procedure ..........................................1369

Component Inspection ........................................1371

Removal and Installation .....................................1372

REFRIGERANT PRESSURE SENSOR ................1373

Component Description .......................................1373

ECM Terminals and Reference Value .................1373

Wiring Diagram ...................................................1374

Diagnostic Procedure ..........................................1375

Removal and Installation .....................................1376

ELECTRICAL LOAD SIGNAL ...............................1377

CONSULT-II Reference Value in Data Monitor Mode

1377

ECM Terminals and Reference Value .................1377

Wiring Diagram ...................................................1378

Diagnostic Procedure ..........................................1380

DATA LINK CONNECTOR ....................................1385

Wiring Diagram ...................................................1385

EVAPORATIVE EMISSION SYSTEM ....................1386

Description ..........................................................1386

Component Inspection ........................................1388

POSITIVE CRANKCASE VENTILATION ..............1389

Description ..........................................................1389

Component Inspection ........................................1389

SERVICE DATA AND SPECIFICATIONS (SDS) ...1391

Fuel Pressure ......................................................1391

Idle Speed and Ignition Timing ............................1391

Calculated Load Value ........................................1391

Mass Air Flow Sensor .........................................1391

Intake Air Temperature Sensor ...........................1391

Engine Coolant Temperature Sensor ..................1391

Heated Oxygen Sensor 1 Heater ........................1391

Heated Oxygen sensor 2 Heater .........................1391

Crankshaft Position Sensor (POS) ......................1391

Camshaft Position Sensor (PHASE) ...................1391

Throttle Control Motor ......................................... 1392

Injector ................................................................1392

Fuel Pump ...........................................................1392

YD

INDEX FOR DTC ....................................................1393

Alphabetical Index ...............................................1393

DTC No. Index .....................................................1393

PRECAUTIONS .....................................................1395

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ..............................................................1395

Precautions ..........................................................1395

Wiring Diagrams and Trouble Diagnosis .............1397

ENGINE CONTROL SYSTEM ...............................1398

System Diagram ..................................................1398

System Chart .......................................................1399

Fuel Injection Control System ..............................1399

Fuel Injection Timing Control System ..................1401

Air Conditioning Cut Control ................................1401

F u e l C u t C o n t r o l ( A t N o L o a d & H i g h E n g i n e S p e e d ) 1401

Crankcase Ventilation System .............................1402

CAN Communication ...........................................1402

BASIC SERVICE PROCEDURE ............................1404

Fuel Filter .............................................................1404

Accelerator Pedal Released Position Learning ...1404

Fuel Pressure Relief Valve ..................................1405

ON BOARD DIAGNOSTIC (OBD) SYSTEM .........1406

DTC and MI Detection Logic ...............................1406

Diagnostic Trouble Code (DTC) ..........................1406

NATS (Nissan Anti-theft System) ........................1406

Malfunction Indicator (MI) ....................................1407

TROUBLE DIAGNOSIS .........................................1409

Trouble Diagnosis Introduction ............................1409

Basic Inspection ..................................................1412

Symptom Matrix Chart .........................................1416

Engine Control Component Parts Location .........1420

Circuit Diagram ....................................................1423

ECM Harness Connector Terminal Layout ..........1425

ECM Terminals And Reference Value .................1425

CONSULT-II Function ..........................................1431

CONSULT-II Reference Value in Data Monitor Mode

1437

Major Sensor Reference Graph in Data Monitor

Mode ....................................................................1440

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ......................................................................1441

Description ...........................................................1441

Diagnostic Procedure ..........................................1441

POWER SUPPLY CIRCUIT FOR ECM ..................1442

ECM Terminals and Reference Value ..................1442

Wiring Diagram ....................................................1443

Diagnostic Procedure ..........................................1444

Component Inspection .........................................1447

DTC U1000 CAN COMMUNICATION LINE ...........1448

Description ...........................................................1448

On Board Diagnosis Logic ...................................1448

DTC Confirmation Procedure ..............................1448

Wiring Diagram ....................................................1449

Diagnostic Procedure ..........................................1450

DTC P0100 MASS AIR FLOW SENSOR (MAFS) .1451

Component Description .......................................1451