heater NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3340 of 3833

ATC-64

TROUBLE DIAGNOSIS

COMPONENT DESCRIPTION

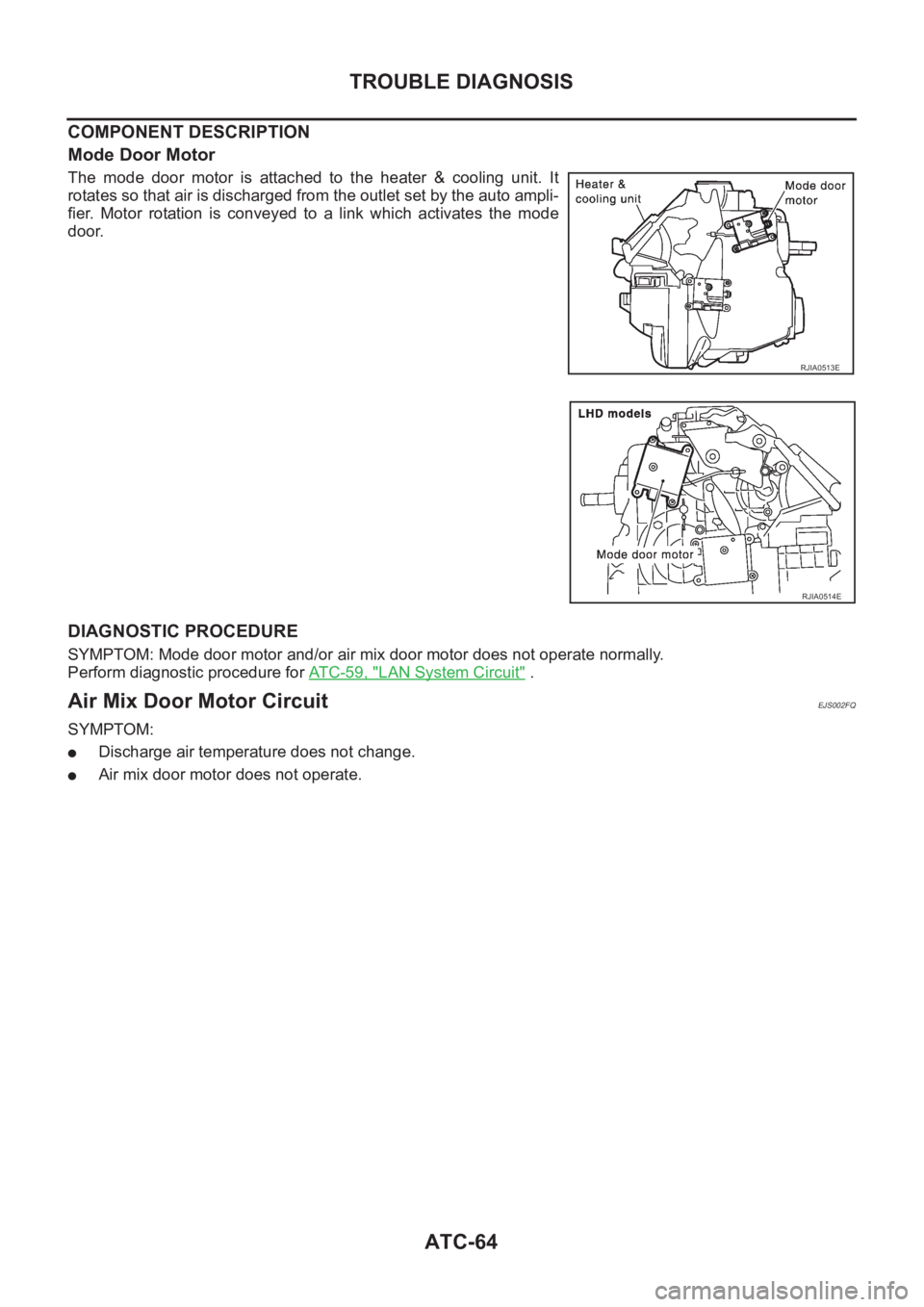

Mode Door Motor

The mode door motor is attached to the heater & cooling unit. It

rotates so that air is discharged from the outlet set by the auto ampli-

fier. Motor rotation is conveyed to a link which activates the mode

door.

DIAGNOSTIC PROCEDURE

SYMPTOM: Mode door motor and/or air mix door motor does not operate normally.

Perform diagnostic procedure for ATC-59, "

LAN System Circuit" .

Air Mix Door Motor CircuitEJS002FQ

SYMPTOM:

●Discharge air temperature does not change.

●Air mix door motor does not operate.

RJIA0513E

RJIA0514E

Page 3342 of 3833

ATC-66

TROUBLE DIAGNOSIS

SYSTEM DESCRIPTION

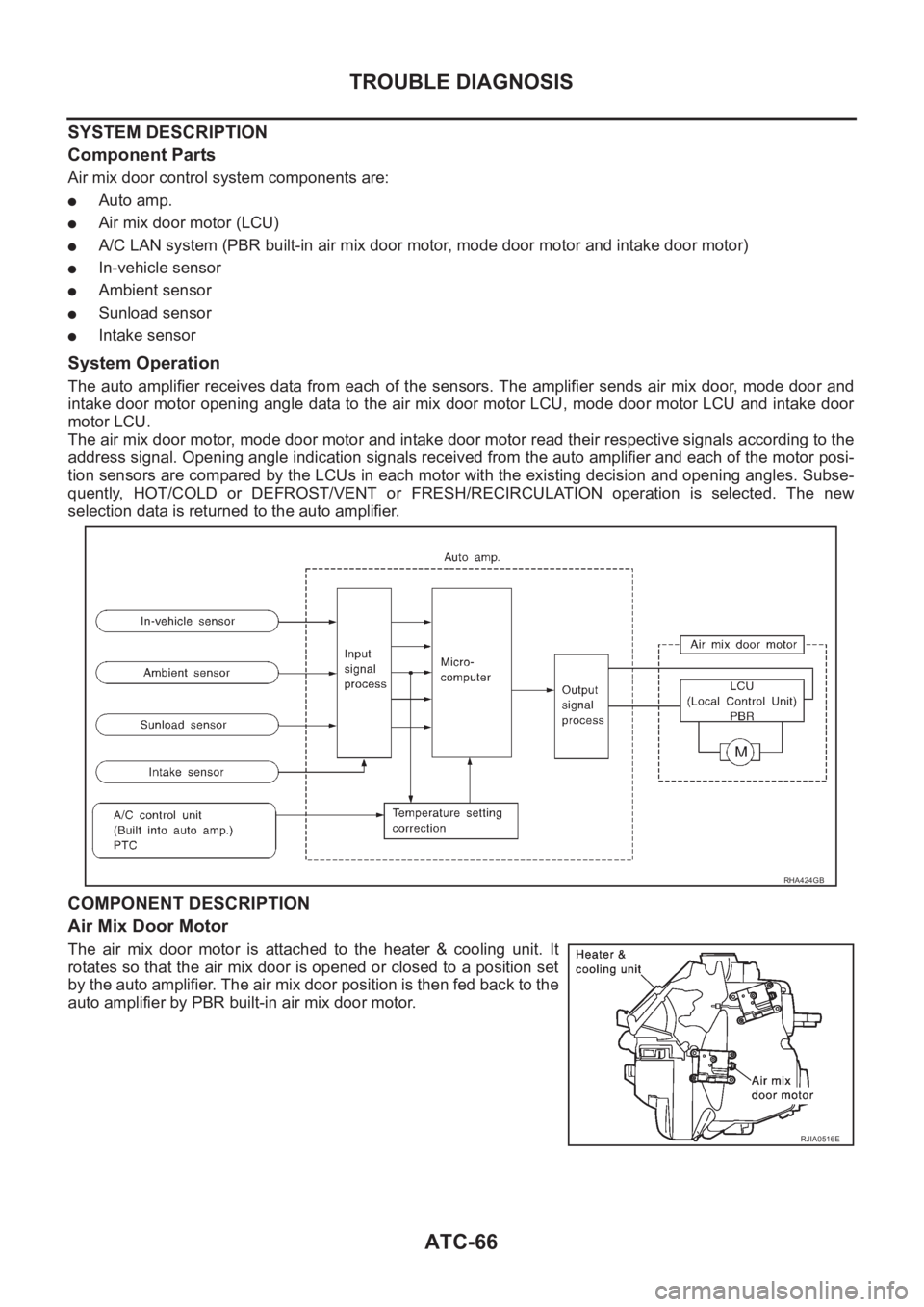

Component Parts

Air mix door control system components are:

●Auto amp.

●Air mix door motor (LCU)

●A/C LAN system (PBR built-in air mix door motor, mode door motor and intake door motor)

●In-vehicle sensor

●Ambient sensor

●Sunload sensor

●Intake sensor

System Operation

The auto amplifier receives data from each of the sensors. The amplifier sends air mix door, mode door and

intake door motor opening angle data to the air mix door motor LCU, mode door motor LCU and intake door

motor LCU.

The air mix door motor, mode door motor and intake door motor read their respective signals according to the

address signal. Opening angle indication signals received from the auto amplifier and each of the motor posi-

tion sensors are compared by the LCUs in each motor with the existing decision and opening angles. Subse-

quently, HOT/COLD or DEFROST/VENT or FRESH/RECIRCULATION operation is selected. The new

selection data is returned to the auto amplifier.

COMPONENT DESCRIPTION

Air Mix Door Motor

The air mix door motor is attached to the heater & cooling unit. It

rotates so that the air mix door is opened or closed to a position set

by the auto amplifier. The air mix door position is then fed back to the

auto amplifier by PBR built-in air mix door motor.

RHA424GB

RJIA0516E

Page 3378 of 3833

ATC-102

TROUBLE DIAGNOSIS

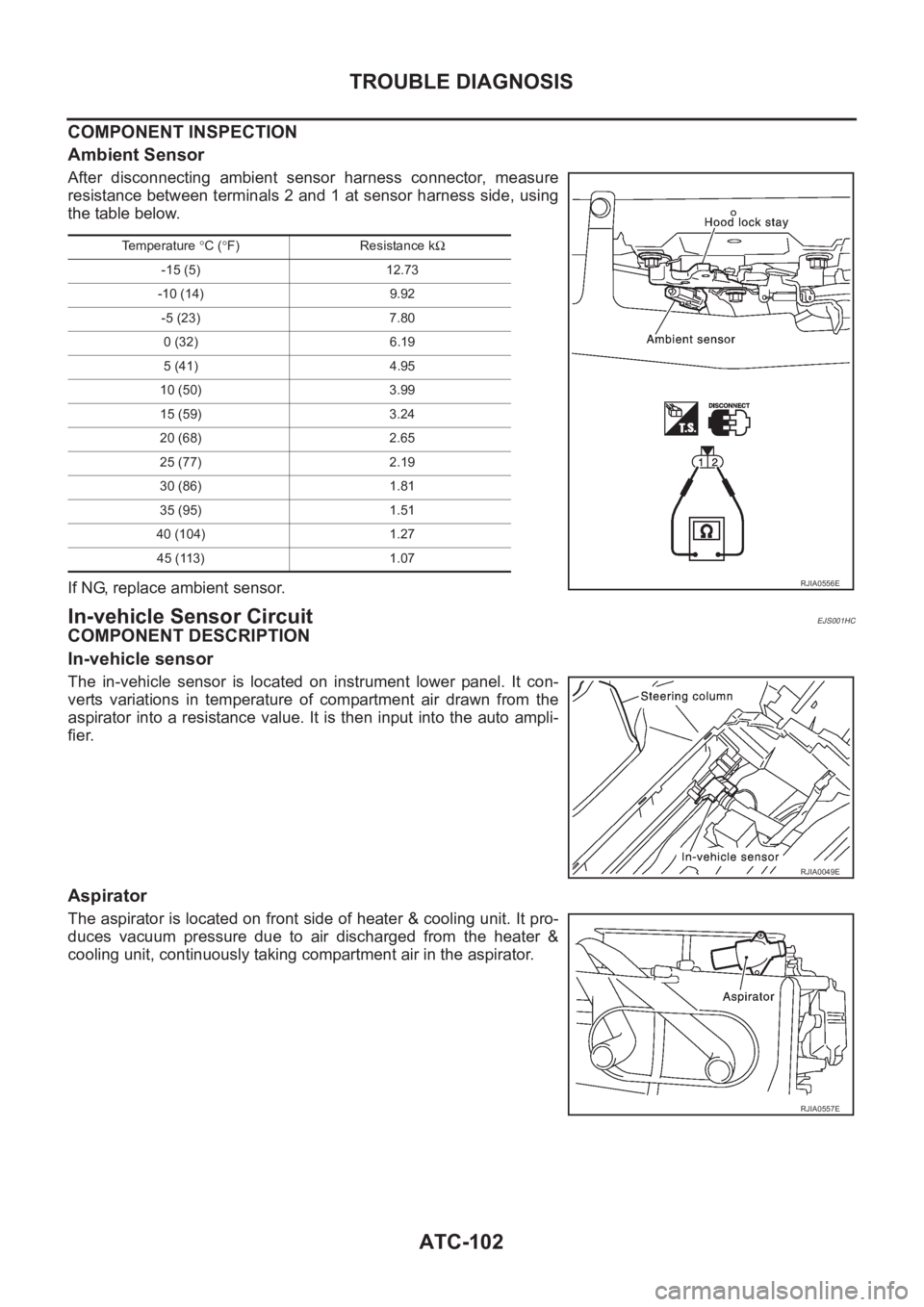

COMPONENT INSPECTION

Ambient Sensor

After disconnecting ambient sensor harness connector, measure

resistance between terminals 2 and 1 at sensor harness side, using

the table below.

If NG, replace ambient sensor.

In-vehicle Sensor CircuitEJS001HC

COMPONENT DESCRIPTION

In-vehicle sensor

The in-vehicle sensor is located on instrument lower panel. It con-

verts variations in temperature of compartment air drawn from the

aspirator into a resistance value. It is then input into the auto ampli-

fier.

Aspirator

The aspirator is located on front side of heater & cooling unit. It pro-

duces vacuum pressure due to air discharged from the heater &

cooling unit, continuously taking compartment air in the aspirator.

Temperature °C (°F) Resistance kΩ

-15 (5) 12.73

-10 (14) 9.92

-5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

RJIA0556E

RJIA0049E

RJIA0557E

Page 3384 of 3833

ATC-108

TROUBLE DIAGNOSIS

Intake Sensor Circuit

EJS001HE

COMPONENT DESCRIPTION

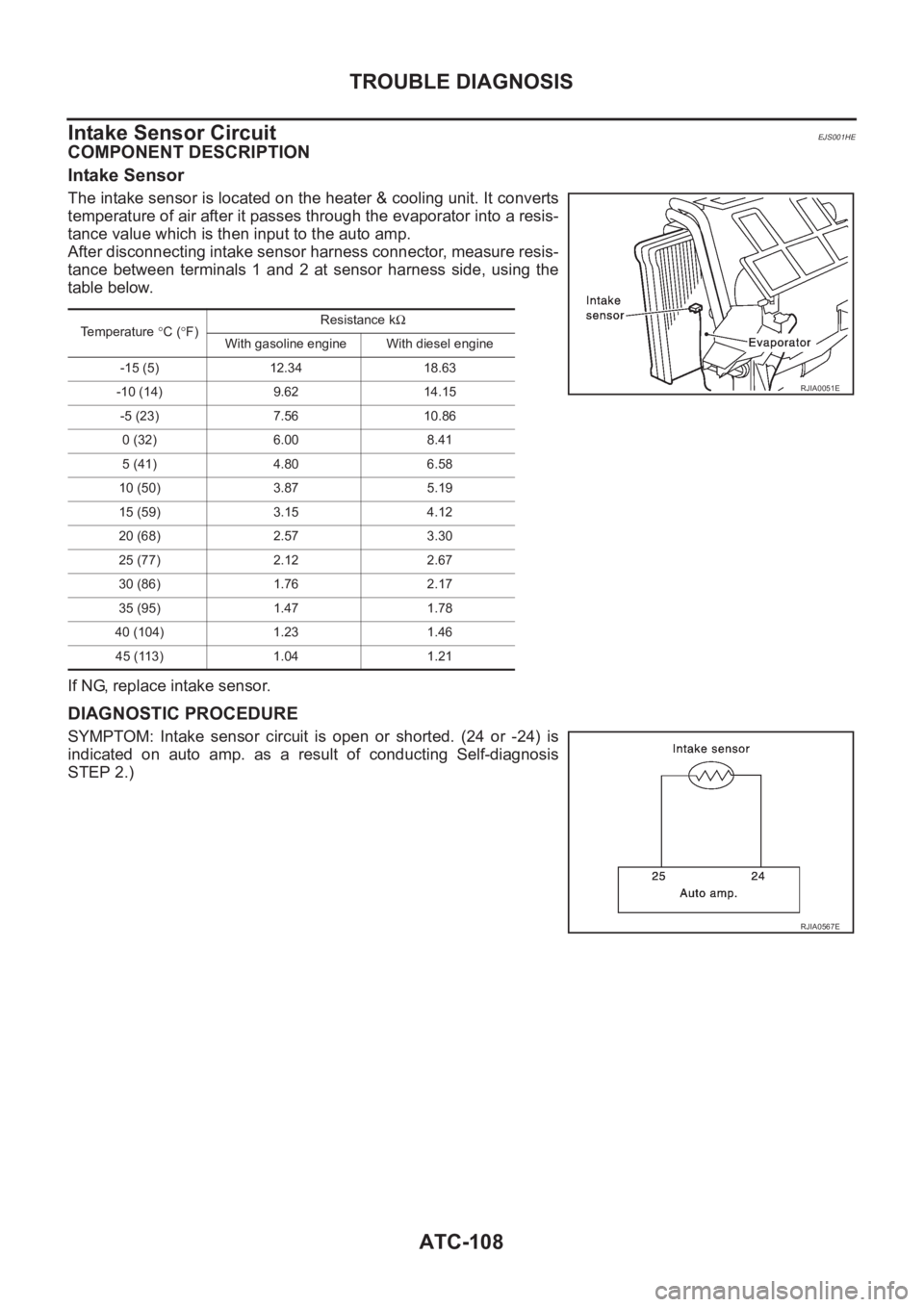

Intake Sensor

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the auto amp.

After disconnecting intake sensor harness connector, measure resis-

tance between terminals 1 and 2 at sensor harness side, using the

table below.

If NG, replace intake sensor.

DIAGNOSTIC PROCEDURE

SYMPTOM: Intake sensor circuit is open or shorted. (24 or -24) is

indicated on auto amp. as a result of conducting Self-diagnosis

STEP 2.)

Temperature °C (°F)Resistance kΩ

With gasoline engine With diesel engine

-15 (5) 12.34 18.63

-10 (14) 9.62 14.15

-5 (23) 7.56 10.86

0 (32) 6.00 8.41

5 (41) 4.80 6.58

10 (50) 3.87 5.19

15 (59) 3.15 4.12

20 (68) 2.57 3.30

25 (77) 2.12 2.67

30 (86) 1.76 2.17

35 (95) 1.47 1.78

40 (104) 1.23 1.46

45 (113) 1.04 1.21

RJIA0051E

RJIA0567E

Page 3398 of 3833

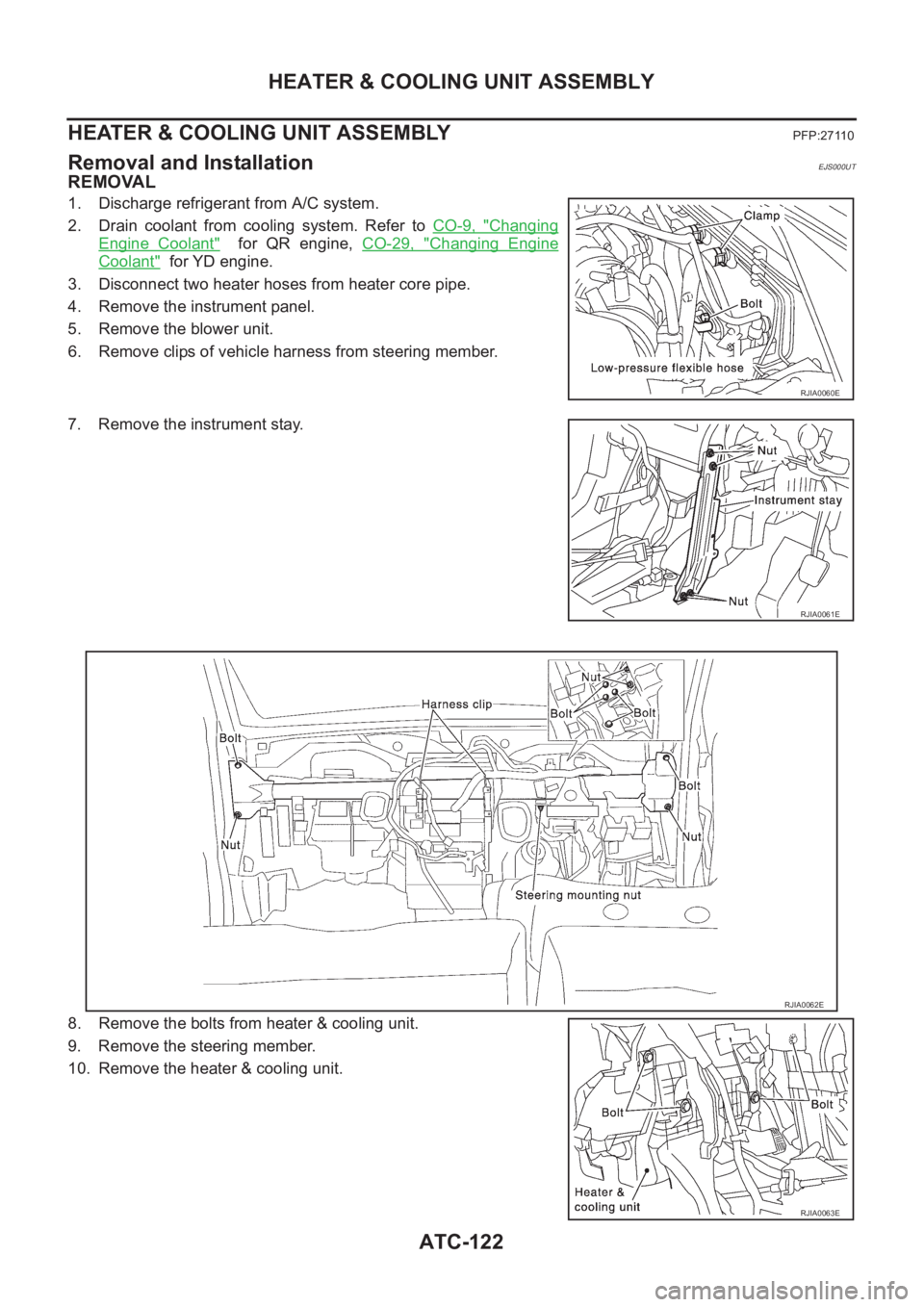

ATC-122

HEATER & COOLING UNIT ASSEMBLY

HEATER & COOLING UNIT ASSEMBLY

PFP:27110

Removal and InstallationEJS000UT

REMOVAL

1. Discharge refrigerant from A/C system.

2. Drain coolant from cooling system. Refer to CO-9, "

Changing

Engine Coolant" for QR engine, CO-29, "Changing Engine

Coolant" for YD engine.

3. Disconnect two heater hoses from heater core pipe.

4. Remove the instrument panel.

5. Remove the blower unit.

6. Remove clips of vehicle harness from steering member.

7. Remove the instrument stay.

8. Remove the bolts from heater & cooling unit.

9. Remove the steering member.

10. Remove the heater & cooling unit.

RJIA0060E

RJIA0061E

RJIA0062E

RJIA0063E

Page 3399 of 3833

HEATER & COOLING UNIT ASSEMBLY

ATC-123

C

D

E

F

G

H

I

K

L

MA

B

AT C

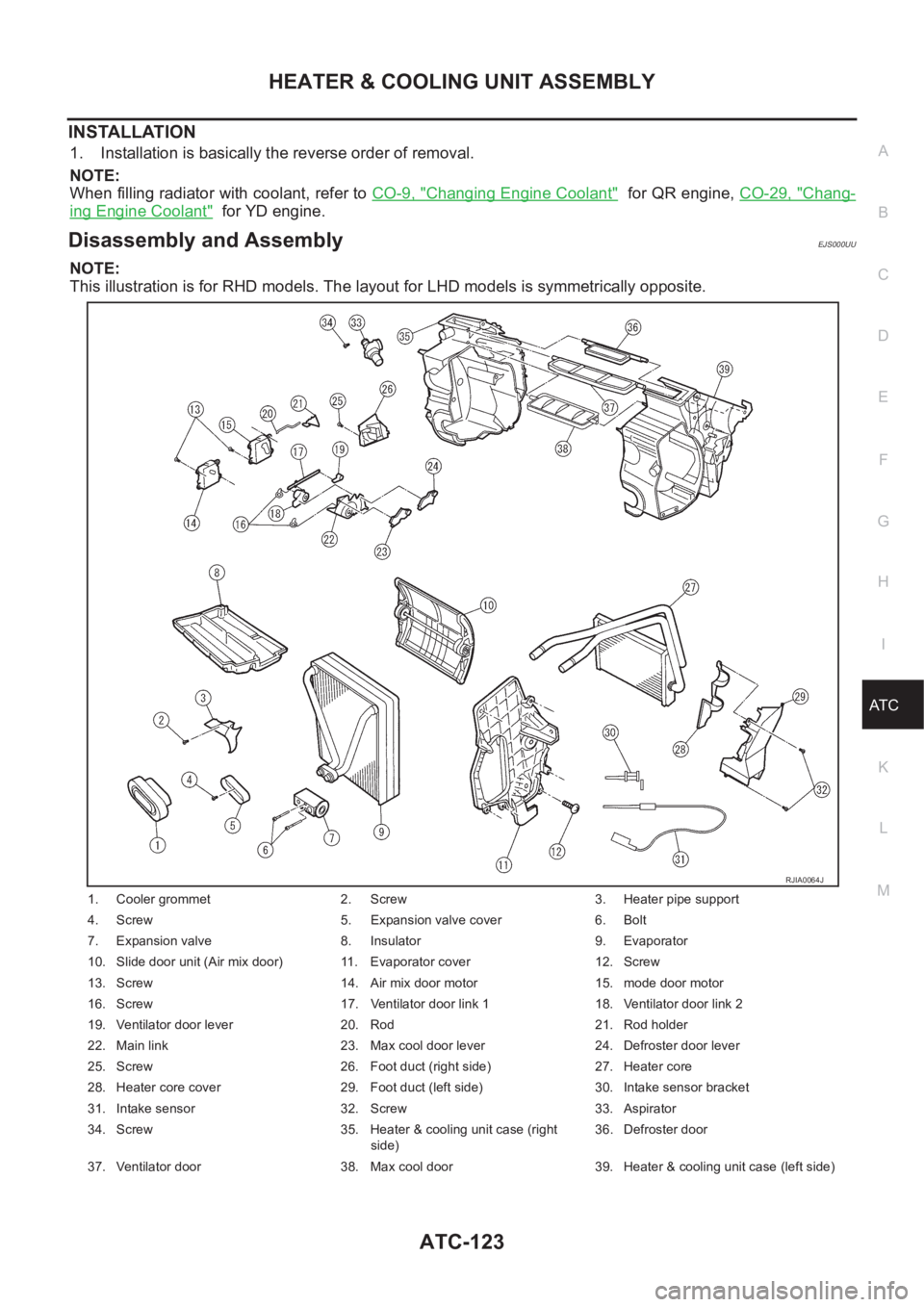

INSTALLATION

1. Installation is basically the reverse order of removal.

NOTE:

When filling radiator with coolant, refer to CO-9, "

Changing Engine Coolant" for QR engine, CO-29, "Chang-

ing Engine Coolant" for YD engine.

Disassembly and AssemblyEJS000UU

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

1. Cooler grommet 2. Screw 3. Heater pipe support

4. Screw 5. Expansion valve cover 6. Bolt

7. Expansion valve 8. Insulator 9. Evaporator

10. Slide door unit (Air mix door) 11. Evaporator cover 12. Screw

13. Screw 14. Air mix door motor 15. mode door motor

16. Screw 17. Ventilator door link 1 18. Ventilator door link 2

19. Ventilator door lever 20. Rod 21. Rod holder

22. Main link 23. Max cool door lever 24. Defroster door lever

25. Screw 26. Foot duct (right side) 27. Heater core

28. Heater core cover 29. Foot duct (left side) 30. Intake sensor bracket

31. Intake sensor 32. Screw 33. Aspirator

34. Screw 35. Heater & cooling unit case (right

side)36. Defroster door

37. Ventilator door 38. Max cool door 39. Heater & cooling unit case (left side)

RJIA0064J

Page 3402 of 3833

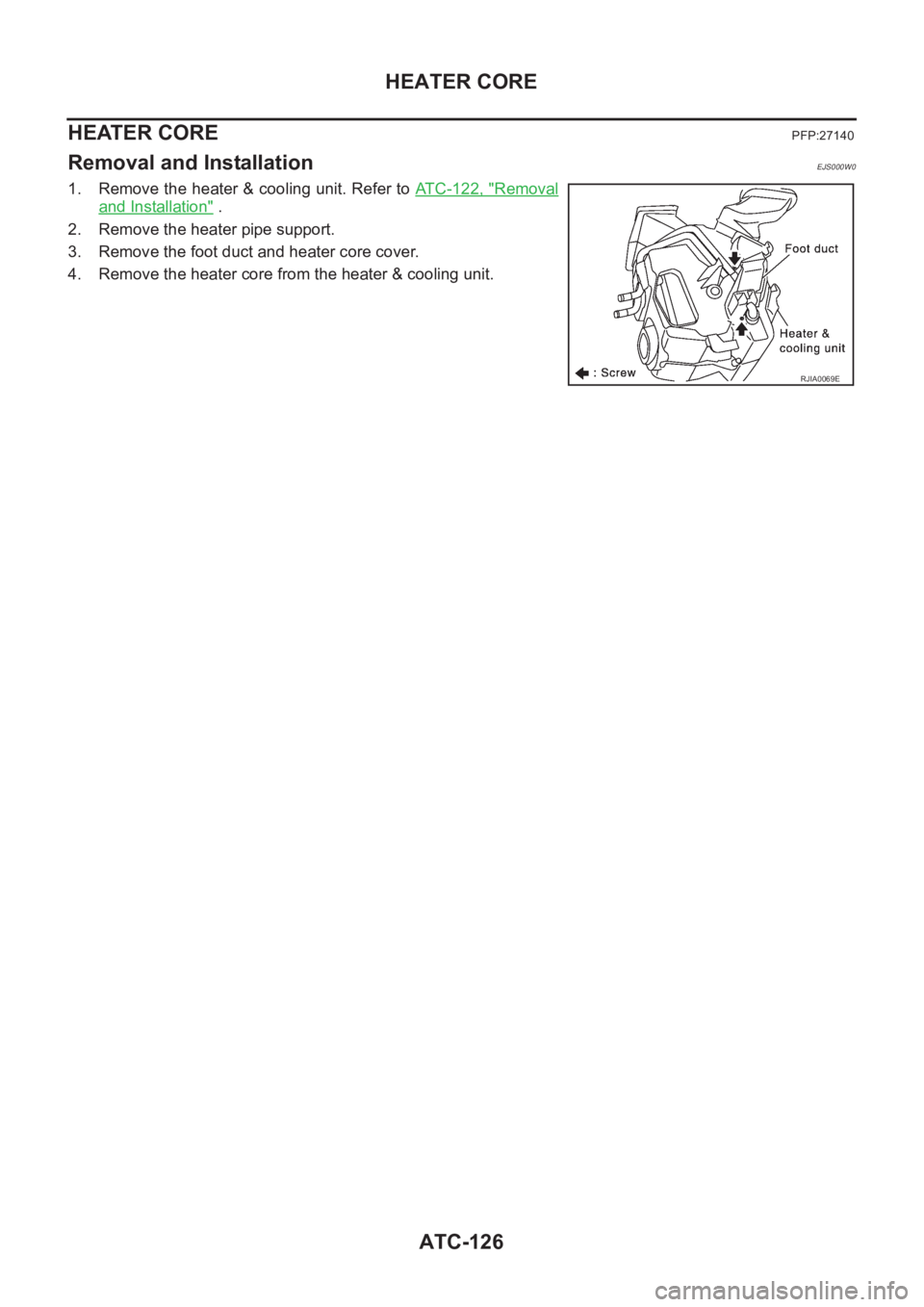

ATC-126

HEATER CORE

HEATER CORE

PFP:27140

Removal and InstallationEJS000W0

1. Remove the heater & cooling unit. Refer to ATC-122, "Removal

and Installation" .

2. Remove the heater pipe support.

3. Remove the foot duct and heater core cover.

4. Remove the heater core from the heater & cooling unit.

RJIA0069E

Page 3404 of 3833

ATC-128

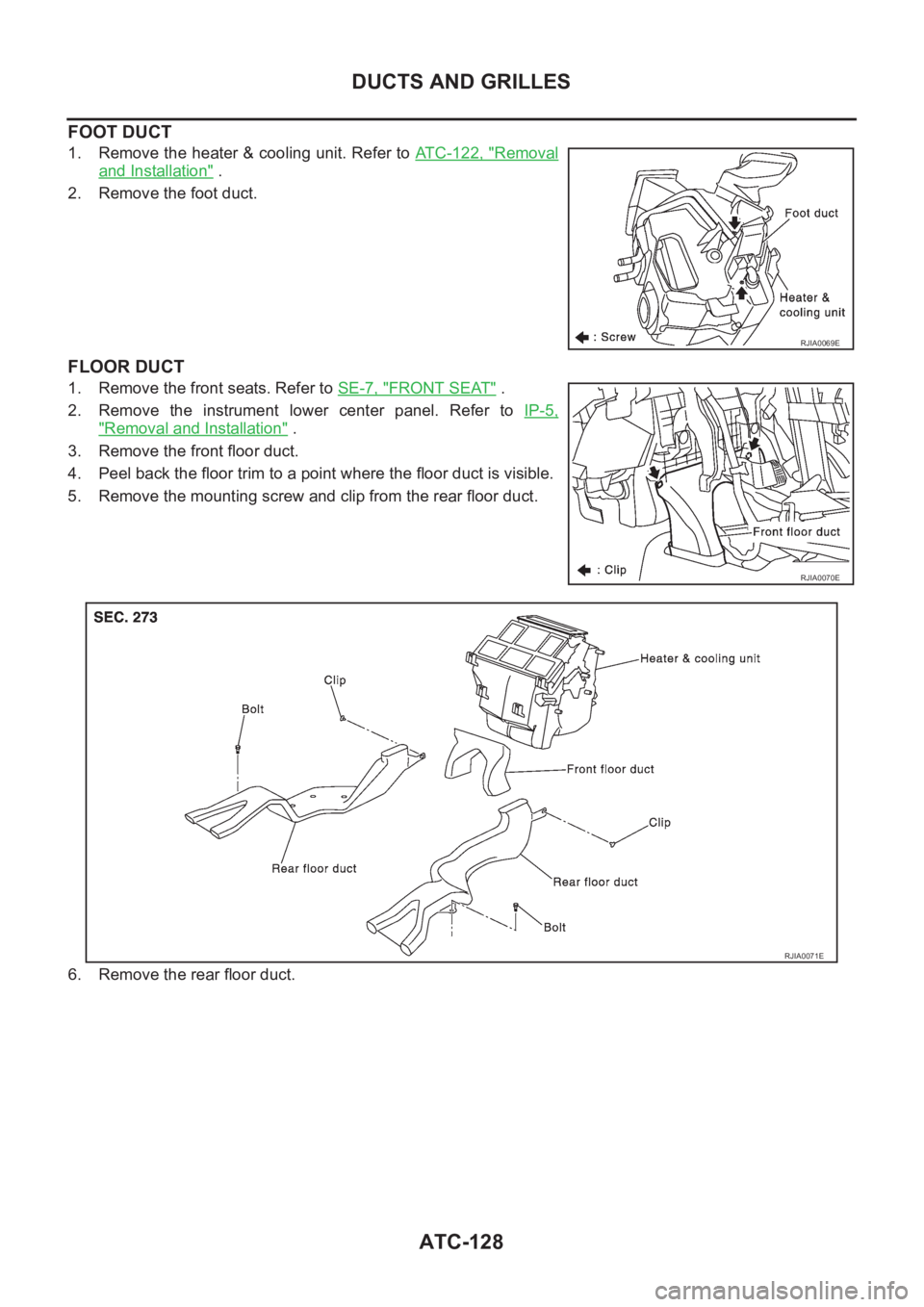

DUCTS AND GRILLES

FOOT DUCT

1. Remove the heater & cooling unit. Refer to ATC-122, "Removal

and Installation" .

2. Remove the foot duct.

FLOOR DUCT

1. Remove the front seats. Refer to SE-7, "FRONT SEAT" .

2. Remove the instrument lower center panel. Refer to IP-5,

"Removal and Installation" .

3. Remove the front floor duct.

4. Peel back the floor trim to a point where the floor duct is visible.

5. Remove the mounting screw and clip from the rear floor duct.

6. Remove the rear floor duct.

RJIA0069E

RJIA0070E

RJIA0071E

Page 3407 of 3833

REFRIGERANT LINES

ATC-131

C

D

E

F

G

H

I

K

L

MA

B

AT C

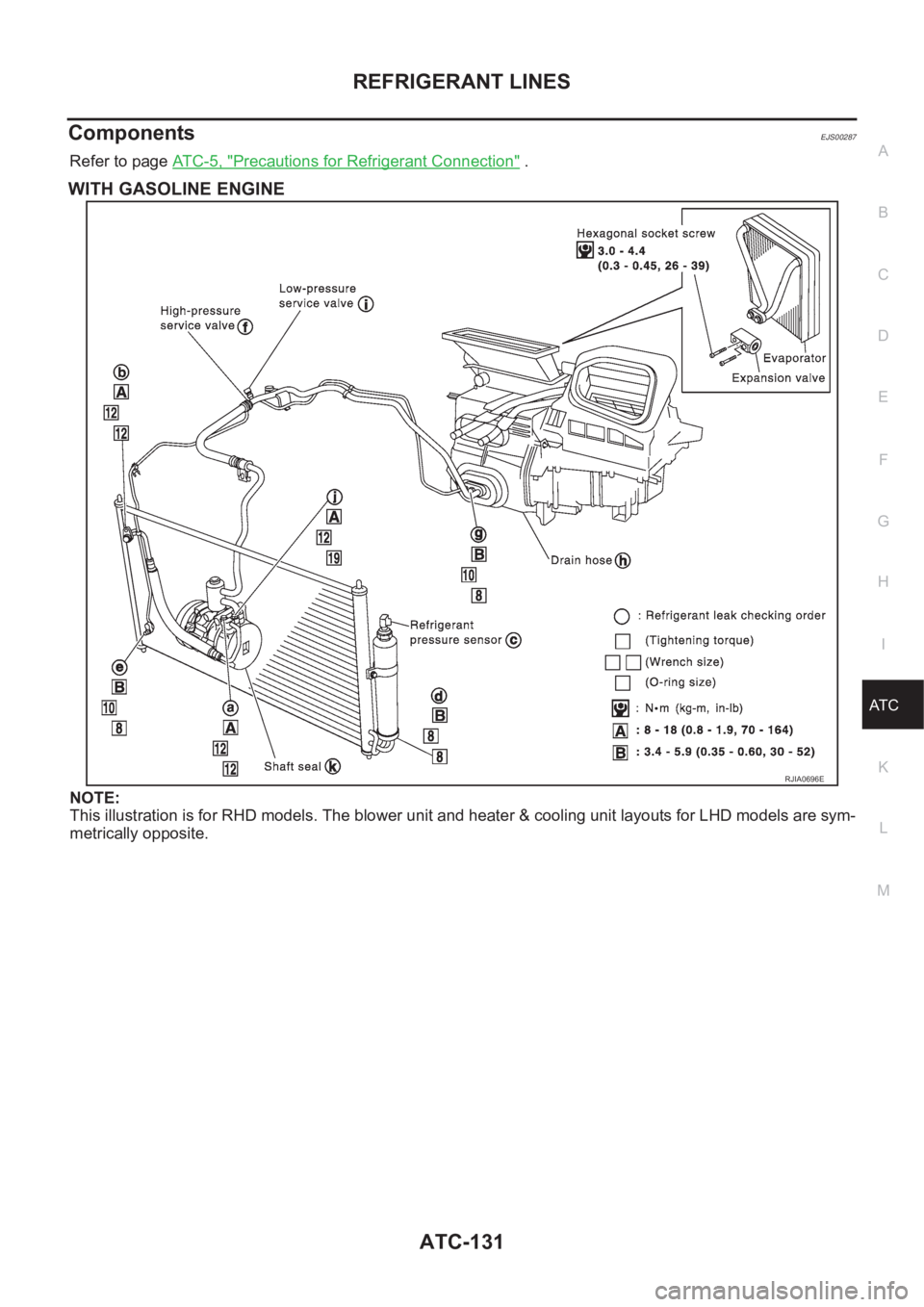

ComponentsEJS00287

Refer to page AT C - 5 , "Precautions for Refrigerant Connection" .

WITH GASOLINE ENGINE

NOTE:

This illustration is for RHD models. The blower unit and heater & cooling unit layouts for LHD models are sym-

metrically opposite.

RJIA0696E

Page 3408 of 3833

ATC-132

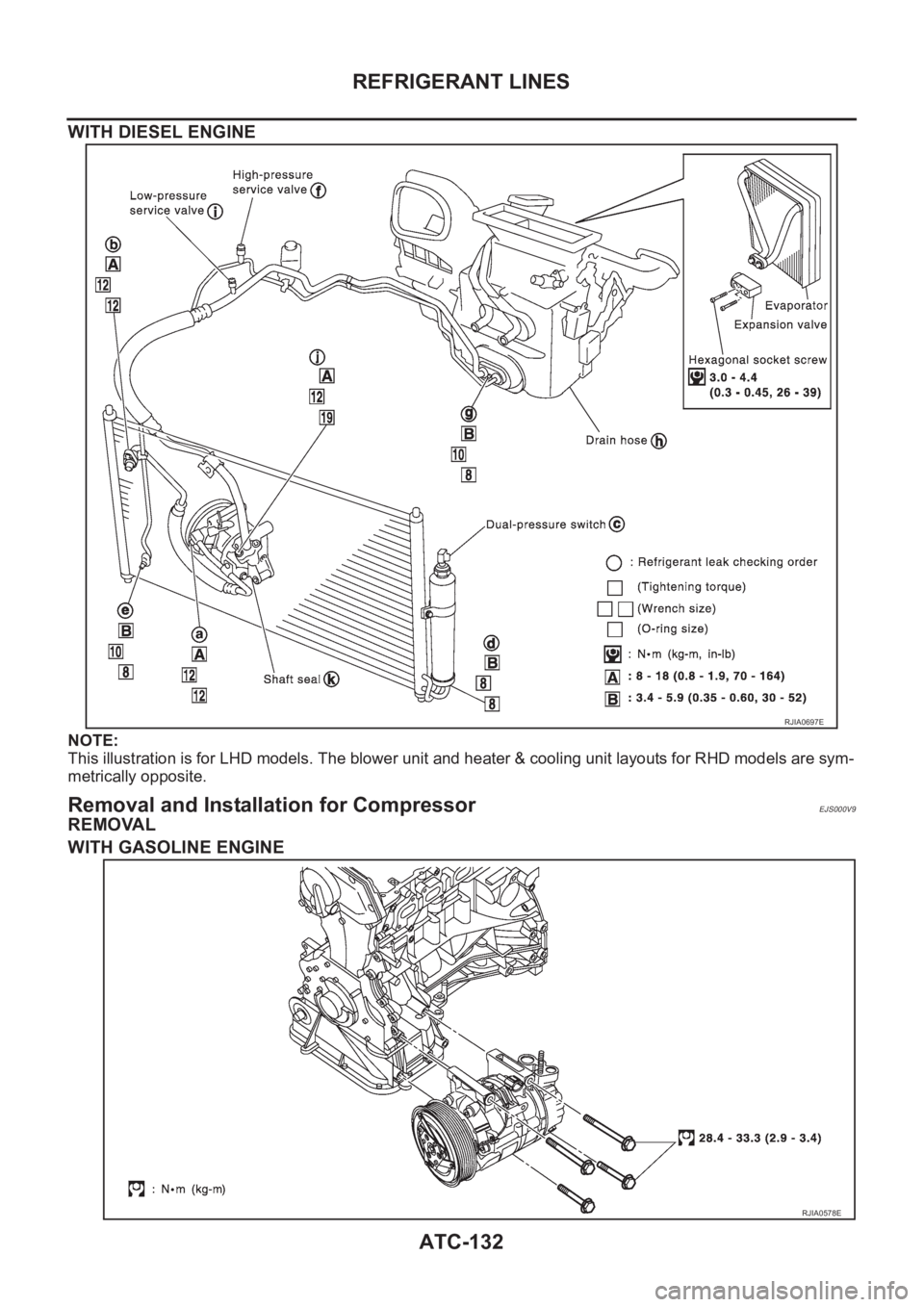

REFRIGERANT LINES

WITH DIESEL ENGINE

NOTE:

This illustration is for LHD models. The blower unit and heater & cooling unit layouts for RHD models are sym-

metrically opposite.

Removal and Installation for CompressorEJS000V9

REMOVAL

WITH GASOLINE ENGINE

RJIA0697E

RJIA0578E