key NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3 of 3833

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

General Precautions ................................................ 4

Precautions for All Mode 4 × 4 System .................... 5

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 5

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 7

Precautions for Air Conditioning ............................... 7

HOW TO USE THIS MANUAL ................................... 8

Description ............................................................... 8

Terms ....................................................................... 8

Units ......................................................................... 8

Contents ................................................................... 8

Components ............................................................. 8

SYMBOLS ............................................................. 9

How to Follow Trouble Diagnoses ............................ 9

DESCRIPTION ...................................................... 9

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 10

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ........................................ 11

KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 12

How to Read Wiring Diagrams ............................... 14CONNECTOR SYMBOLS ................................... 14

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 15

DESCRIPTION .................................................... 16

Abbreviations .......................................................... 22

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 23

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 23

WORK FLOW ...................................................... 23

INCIDENT SIMULATION TESTS ........................ 23

CIRCUIT INSPECTION ....................................... 26

Control Units and Electrical Parts ........................

... 31

PRECAUTIONS .................................................. 31

CONSULT-II CHECKING SYSTEM .......................... 33

Description .............................................................. 33

Function and System Application ........................... 33

Nickel Metal Hydride Battery Replacement ............ 33

Checking Equipment .............................................. 34

CONSULT-II Data Link Connector (DLC) Circuit .... 34

INSPECTION PROCEDURE .............................. 34

LIFTING POINT ......................................................... 35

Special Service Tools ............................................. 35

Garage Jack and Safety Stand ............................... 35

2-pole Lift ................................................................ 36

Board-on Lift ........................................................... 37

TOW TRUCK TOWING ............................................. 38

Tow Truck Towing ................................................... 38

TOWING AN AUTOMATIC TRANSAXLE

MODEL WITH FOUR WHEELS ON GROUND ... 38

T O W I N G T H E V E H I C L E W I T H R E A R W H E E L S

R A I S E D ( W I T H F R O N T W H E E L S O N G R O U N D )

OR FRONT WHEELS RAISED ........................... 39

Vehicle Recovery (Freeing a stuck vehicle) ............ 39

TIGHTENING TORQUE OF STANDARD BOLTS .... 40

Tightening Torque Table ......................................... 40

IDENTIFICATION INFORMATION ............................ 41

Model Variation ....................................................... 41

IDENTIFICATION NUMBER ................................ 42

IDENTIFICATION PLATE .................................... 43

ENGINE SERIAL NUMBER ................................ 43

Page 7 of 3833

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

●Use approved bonding agent, sealants or their equivalents when required.

●Use tools and recommended special tools where specified for safe and efficient service repairs.

●When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

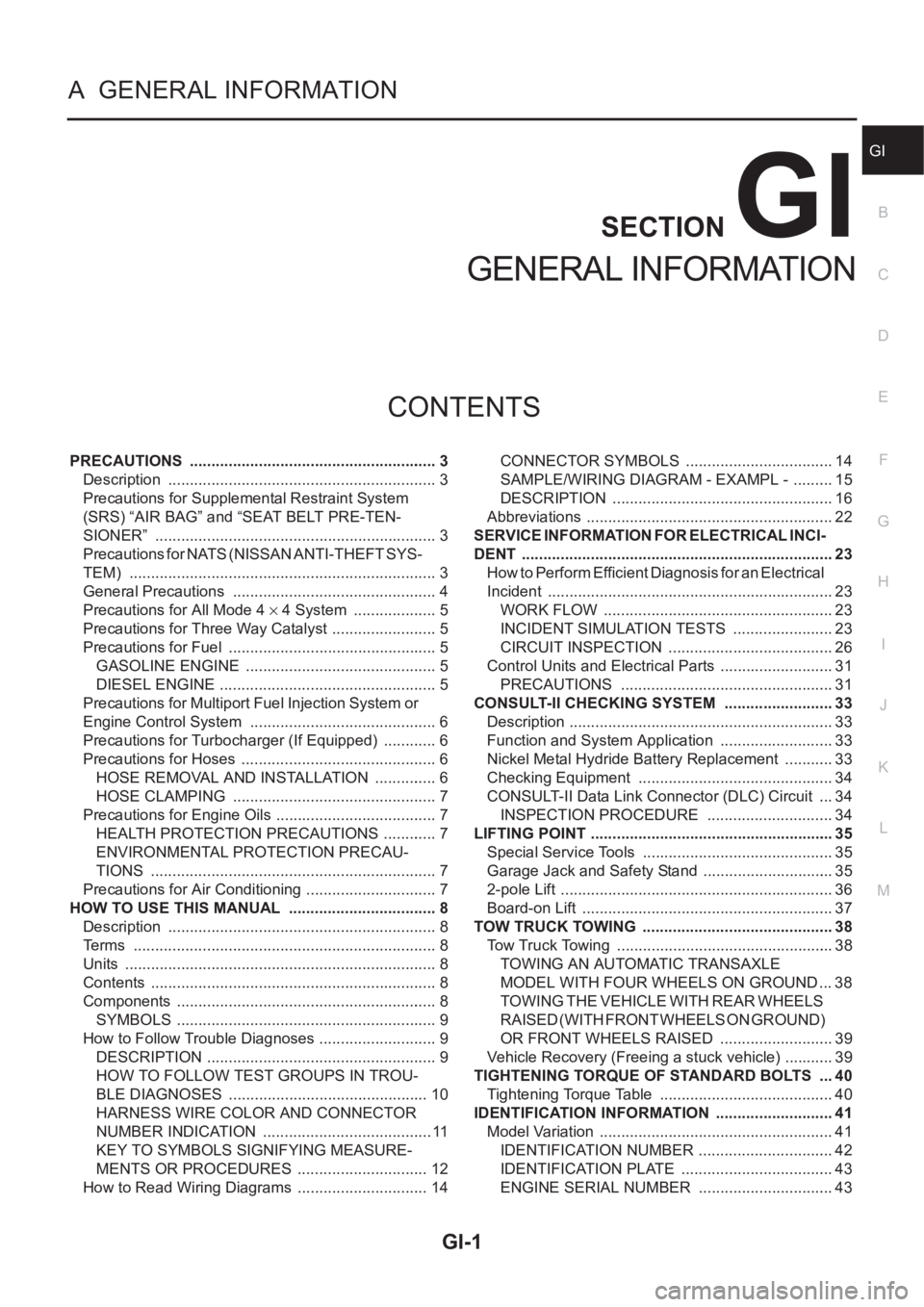

●Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for All Mode 4 × 4 SystemEAS000GQ

Even if the 2WD mode is selected, the All mode 4 × 4 system occasionally changes from 2WD to 4WD auto-

matically depending on the driving conditions.

When spinning the front wheels by running the engine with the front wheels jacked up or mounted on the free

rollers / or a chassis dynamometer, be careful because the vehicle may suddenly move due to the driving

force from the rear wheels.

To avoid personal injury and vehicle damage, use one of the following methods when working with the front

wheels drive force and spinning freely.

● Remove the propeller shaft.

● Use free rollers / chassis dynamometer designed for 4WD vehicles.

Precautions for Three Way CatalystEAS000FR

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

●Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

●When checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

●Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS000P9

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission control devices and systems, and could

also affect the warranty coverage validity.

DIESEL ENGINE

Diesel fuel of at least 50 cetane.

If two types of diesel fuel are available, use summer or winter fuel properly according to the following temper-

ature conditions.

●Above –7°C (20°F) ... Summer type diesel fuel.

●Below –7°C (20°F) ... Winter type diesel fuel.

SGI234

Page 13 of 3833

HOW TO USE THIS MANUAL

GI-11

C

D

E

F

G

H

I

J

K

L

MB

GI

Symbols included in illustrations refer to measurements or procedures. Before diagnosing a problem,

familiarize yourself with each symbol. Refer to "Connector Symbols" in GI Section and "KEY TO SYM-

BOLS SIGNIFYING MEASUREMENTS OR PROCEDURES" below.

4.Action items

Next action for each test group is indicated based on result of each question. Test group number is shown

in the left upper portion of each test group.

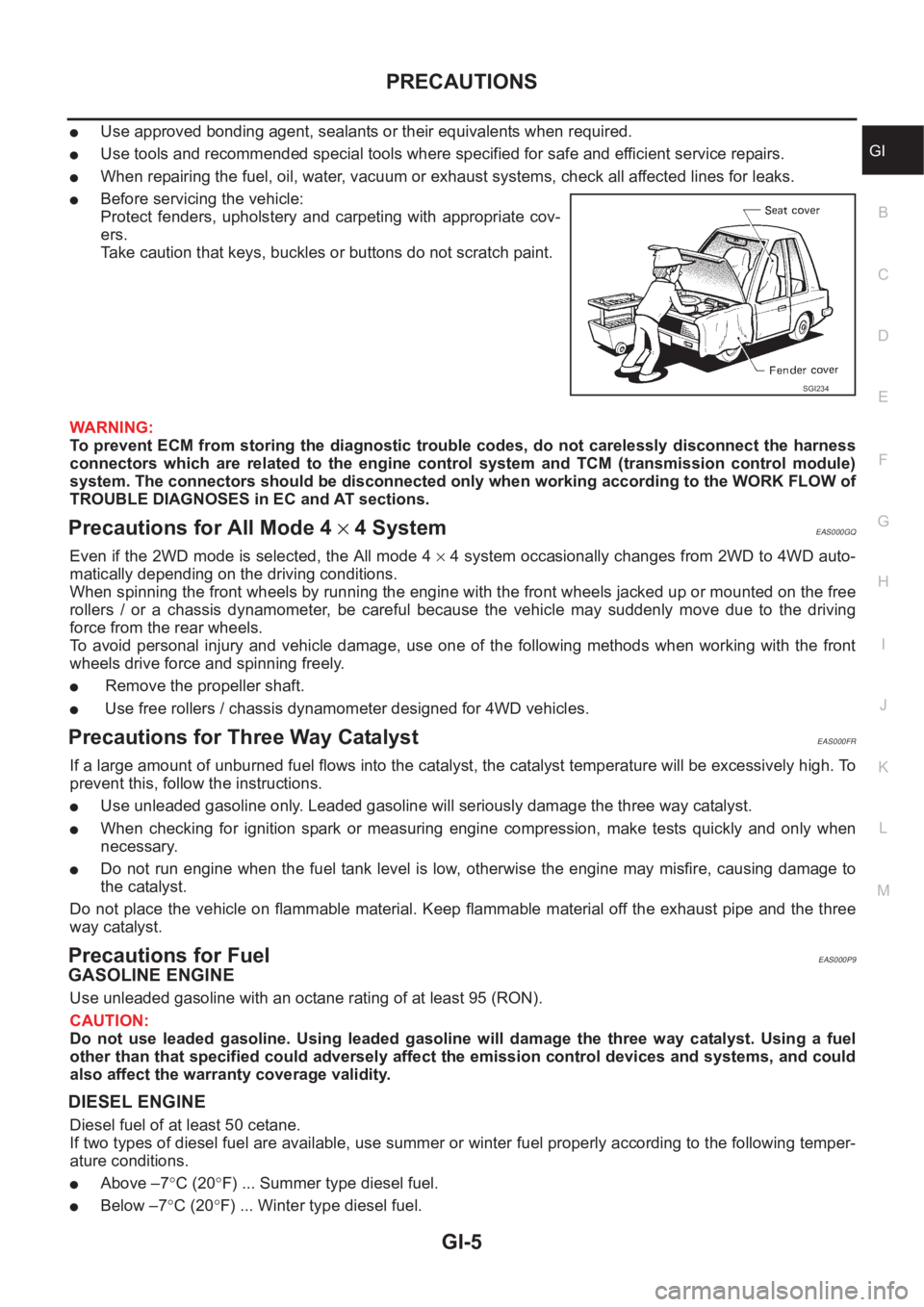

HARNESS WIRE COLOR AND CONNECTOR NUMBER INDICATION

There are two types of harness wire color and connector number indication.

TYPE 1: Harness Wire Color and Connector Number are Shown in Illustration

●Letter designations next to test meter probe indicate harness

wire color.

●Connector numbers in a single circle (e.g. M33) indicate har-

ness connectors.

●Connector numbers in a double circle (e.g. F211) indicate com-

ponent connectors.

AGI070

Page 14 of 3833

GI-12

HOW TO USE THIS MANUAL

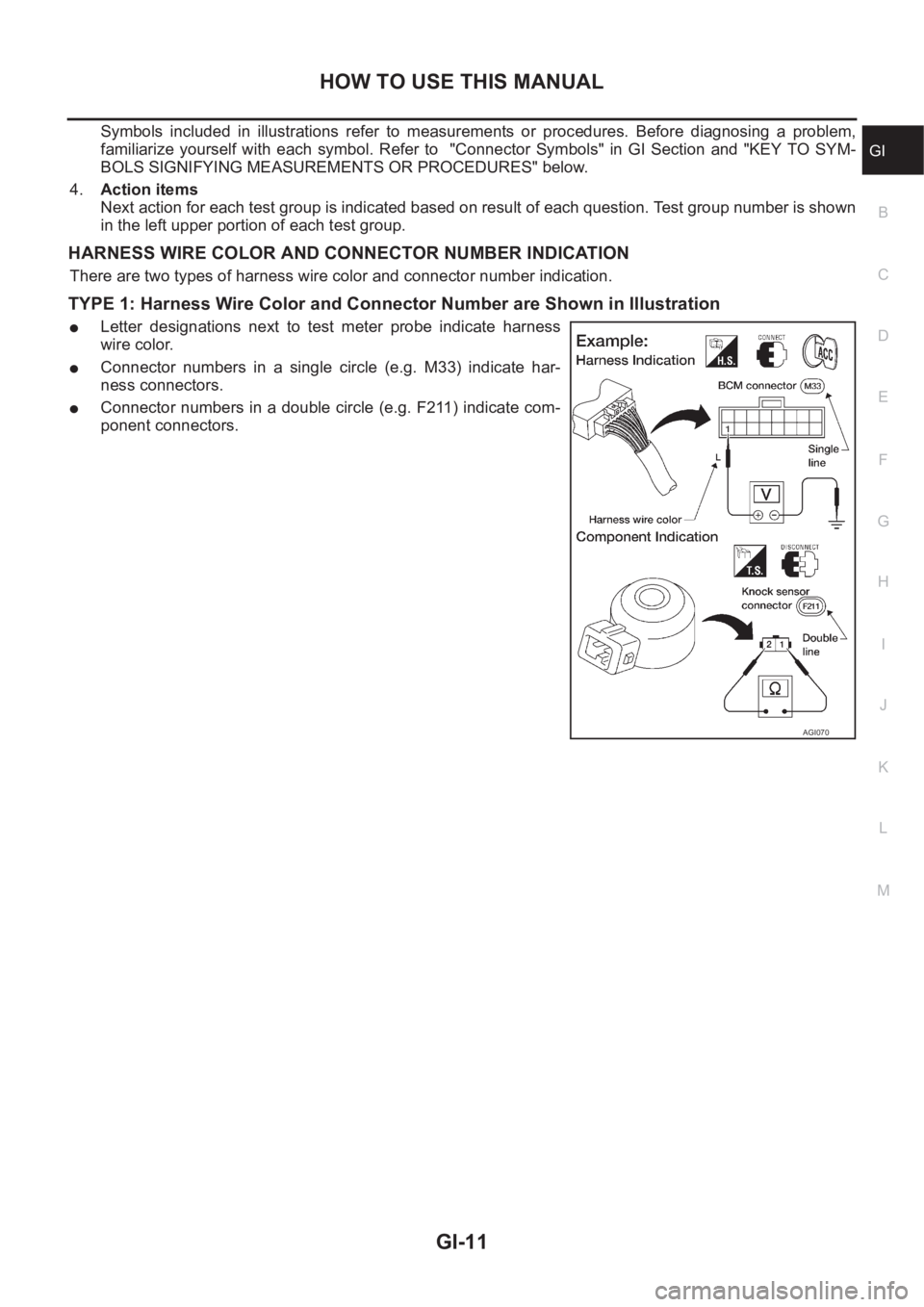

TYPE 2: Harness Wire Color and Connector Number are Shown in Text

KEY TO SYMBOLS SIGNIFYING MEASUREMENTS OR PROCEDURES

SGI144A

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connec-

tor to be measured.Procedure with Generic Scan Tool

(GST, OBD-II scan tool)

Check after connecting the connector

to be measured.Procedure without CONSULT, CON-

SULT-II or GST

Insert key into ignition switch. A/C switch is “OFF”.

Remove key from ignition switch. A/C switch is “ON”.

Turn ignition switch to “OFF” position. REC switch is “ON”.

Turn ignition switch to “ON” position. REC switch is “OFF”.

Turn ignition switch to “START” posi-

tion.Fan switch is “ON”. (At any position

except for “OFF” position)

Turn ignition switch from “OFF” to

“ACC” position.Fan switch is “OFF”.

Turn ignition switch from “ACC” to

“OFF” position.Apply positive voltage from battery

with fuse directly to components.

Page 25 of 3833

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-23

C

D

E

F

G

H

I

J

K

L

MB

GI

SERVICE INFORMATION FOR ELECTRICAL INCIDENTPFP:00000

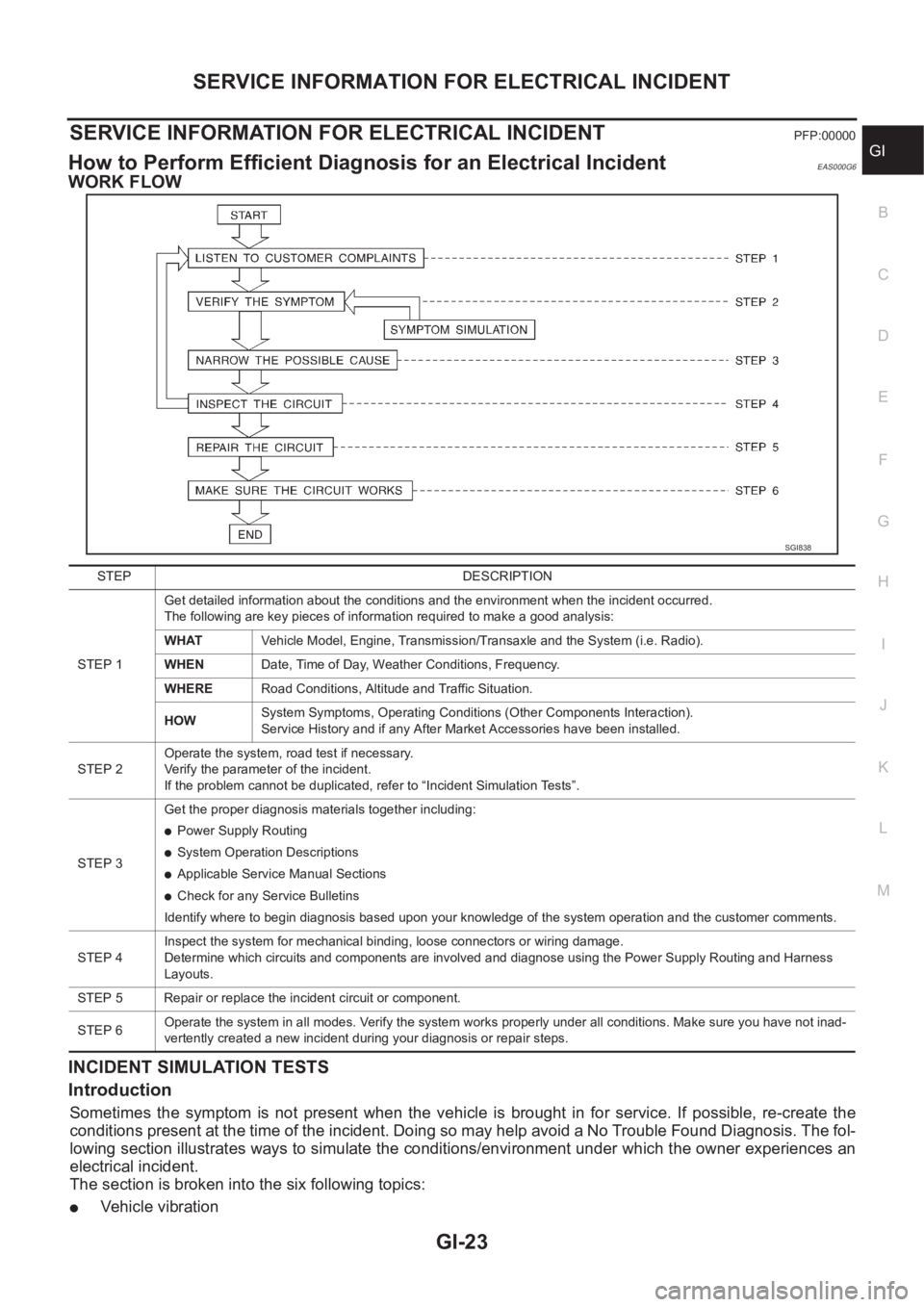

How to Perform Efficient Diagnosis for an Electrical IncidentEAS000G6

WORK FLOW

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

●Vehicle vibration

SGI838

STEP DESCRIPTION

STEP 1Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3Get the proper diagnosis materials together including:

●Power Supply Routing

●System Operation Descriptions

●Applicable Service Manual Sections

●Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Page 29 of 3833

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-27

C

D

E

F

G

H

I

J

K

L

MB

GI

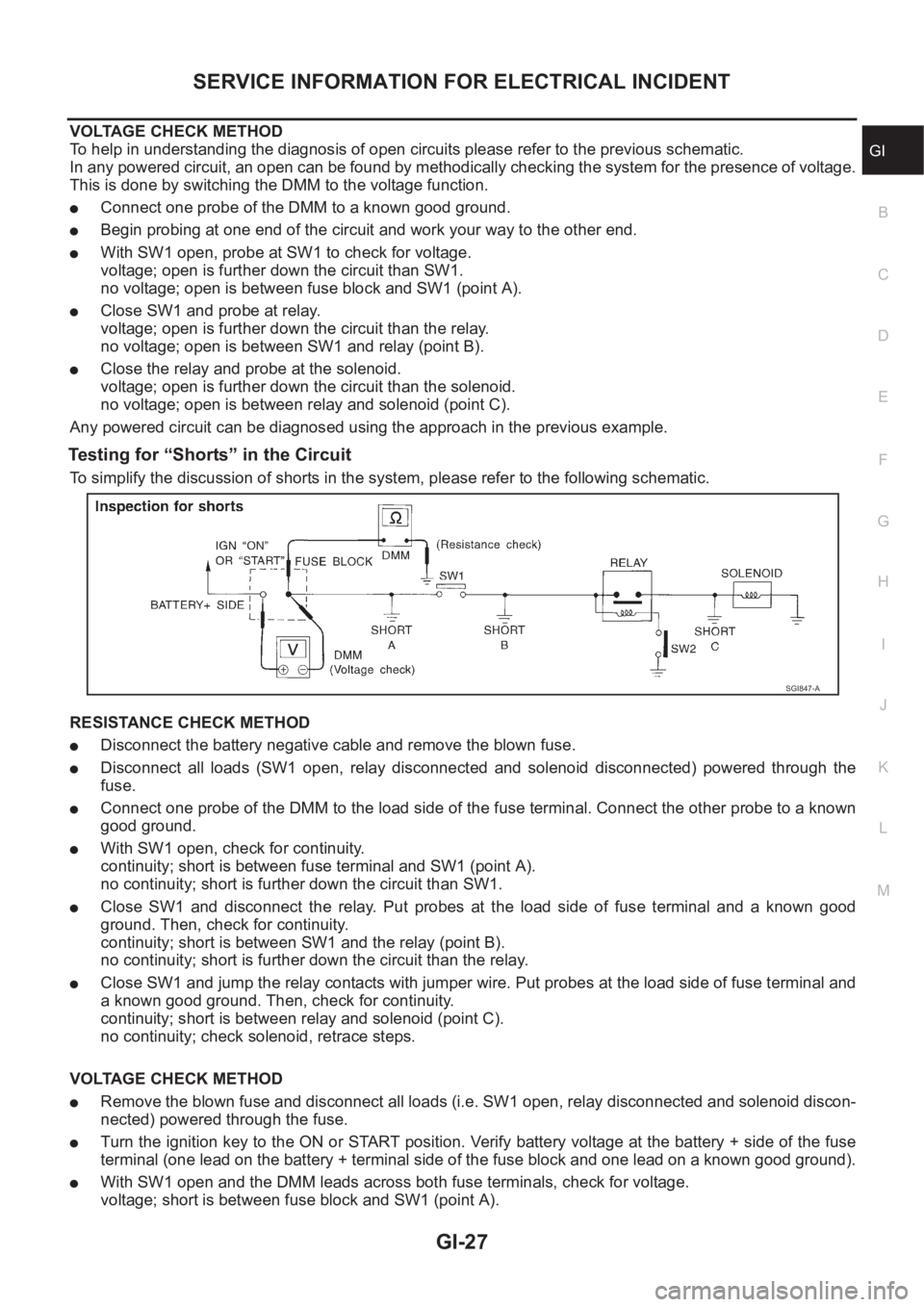

VOLTAGE CHECK METHOD

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodically checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

●Connect one probe of the DMM to a known good ground.

●Begin probing at one end of the circuit and work your way to the other end.

●With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

●Close SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

●Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

●Disconnect the battery negative cable and remove the blown fuse.

●Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the

fuse.

●Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

●With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

●Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

●Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and

a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

●Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

●Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse

terminal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

●With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

SGI847-A

Page 35 of 3833

CONSULT-II CHECKING SYSTEM

GI-33

C

D

E

F

G

H

I

J

K

L

MB

GI

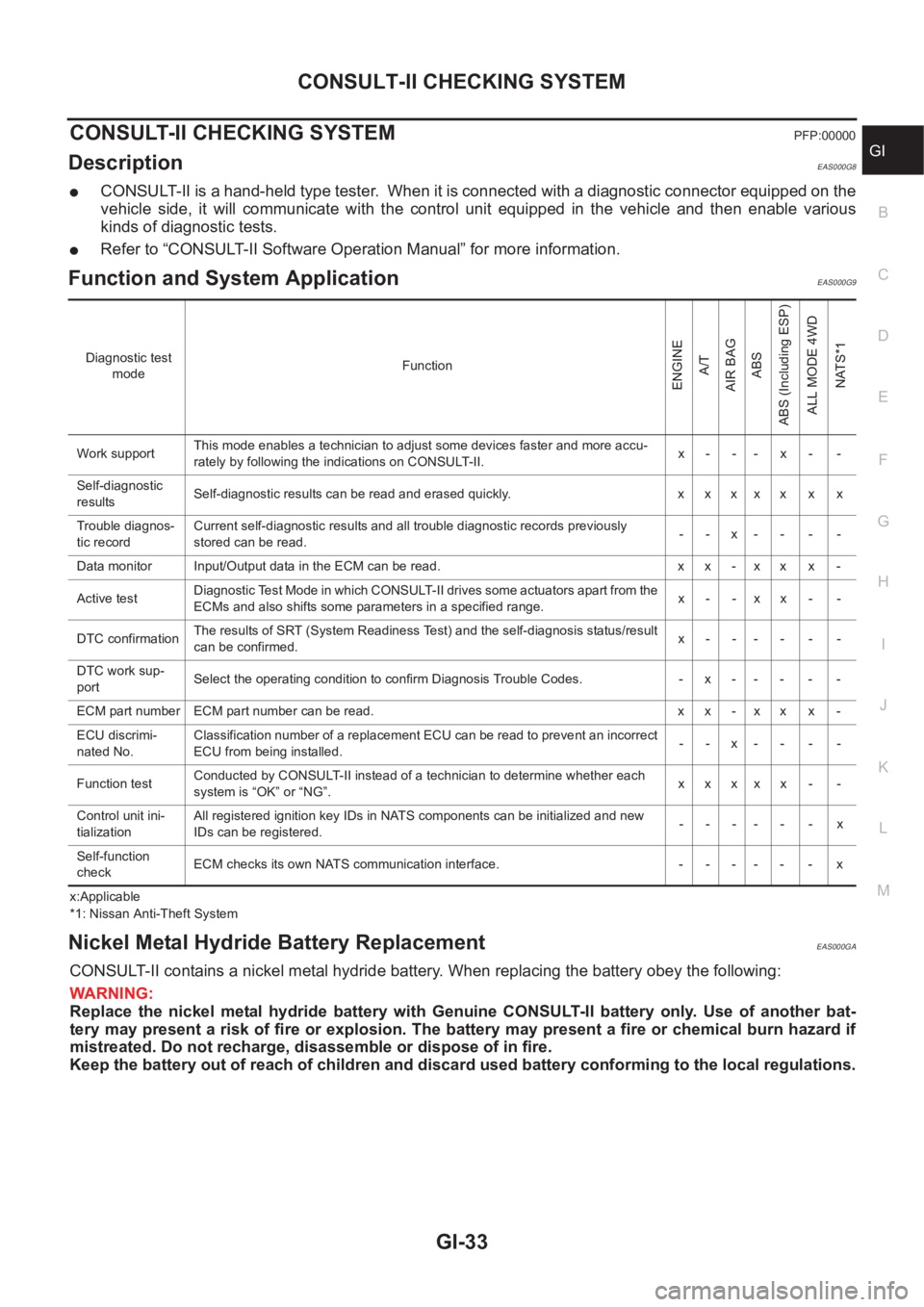

CONSULT-II CHECKING SYSTEMPFP:00000

DescriptionEAS000G8

●CONSULT-II is a hand-held type tester. When it is connected with a diagnostic connector equipped on the

vehicle side, it will communicate with the control unit equipped in the vehicle and then enable various

kinds of diagnostic tests.

●Refer to “CONSULT-II Software Operation Manual” for more information.

Function and System Application EAS000G9

x:Applicable

*1: Nissan Anti-Theft System

Nickel Metal Hydride Battery Replacement EAS000GA

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if

mistreated. Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Diagnostic test

modeFunction

ENGINE

A/T

AIR BAG

ABS

ABS (Including ESP)

ALL MODE 4WD

NATS*1

Work supportThis mode enables a technician to adjust some devices faster and more accu-

rately by following the indications on CONSULT-II.x- -- x- -

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly. x x x x x x x

Trouble diagnos-

tic recordCurrent self-diagnostic results and all trouble diagnostic records previously

stored can be read.--x----

Data monitor Input/Output data in the ECM can be read. x x - x x x -

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from the

ECMs and also shifts some parameters in a specified range.x- -xx- -

DTC confirmationThe results of SRT (System Readiness Test) and the self-diagnosis status/result

can be confirmed.x------

DTC work sup-

portSelect the operating condition to confirm Diagnosis Trouble Codes. -x-----

ECM part number ECM part number can be read. x x - x x x -

ECU discrimi-

nated No.Classification number of a replacement ECU can be read to prevent an incorrect

ECU from being installed.--x----

Function testConducted by CONSULT-II instead of a technician to determine whether each

system is “OK” or “NG”.xxxxx - -

Control unit ini-

tializationAll registered ignition key IDs in NATS components can be initialized and new

IDs can be registered.------x

Self-function

checkECM checks its own NATS communication interface. - - - - - - x

Page 91 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TIMING CHAIN

EM-41

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

INSPECTION AFTER REMOVAL

Timing Chain

Check timing chain for cracks or serious wear. If a malfunction is

detected, replace it.

Balancer Unit NISSAN X-TRAIL 2001 Service Repair Manual TIMING CHAIN

EM-41

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

INSPECTION AFTER REMOVAL

Timing Chain

Check timing chain for cracks or serious wear. If a malfunction is

detected, replace it.

Balancer Unit](/img/5/57405/w960_57405-90.png)

TIMING CHAIN

EM-41

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

INSPECTION AFTER REMOVAL

Timing Chain

Check timing chain for cracks or serious wear. If a malfunction is

detected, replace it.

Balancer Unit Mounting Bolt Outer Diameter.

●Measure outer diameters (d1, d2) at the two positions shown in

the figure.

●Measure d2 within the range A.

●If the value difference (d1 – d2) exceeds the limit (a dimension

difference is large), replace it with a new one.

INSTALLATION

NOTE:

●The figure shows the relationship between the mating mark on

each timing chain and that on the corresponding sprocket, with

the components installed.

●Because of parallel manufacture, there are two types of mark

(link colors) for timing chain.

1. Make suer that crankshaft key points straight up.

PBIC0282E

Limit: 0.15 mm (0. 0059in) or more.

PBIC1137E

SBIA0265E

Page 94 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-44

[QR]

TIMING CHAIN

d. Tighten mounting bolts in the numerical order shown in the fig-

ure.

e. After all bolts are tightened, retighten them to specified torque.

CAUTION:

Be sure to w NISSAN X-TRAIL 2001 Service Repair Manual EM-44

[QR]

TIMING CHAIN

d. Tighten mounting bolts in the numerical order shown in the fig-

ure.

e. After all bolts are tightened, retighten them to specified torque.

CAUTION:

Be sure to w](/img/5/57405/w960_57405-93.png)

EM-44

[QR]

TIMING CHAIN

d. Tighten mounting bolts in the numerical order shown in the fig-

ure.

e. After all bolts are tightened, retighten them to specified torque.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking to

surface for fitting oil pan.

8. Install chain guide between camshaft sprockets.

9. Install intake valve timing control cover with the following procedure.

a. Install intake valve timing control solenoid valves to intake valve timing control cover.

b. Install oil rings to the intake camshaft sprocket insertion points on intake valve timing control backside

cover.

c. Install O-ring to front cover.

d. Apply liquid gasket to the positions in the figure.

Use Genuine Liquid gasket or equivalent.

e. Tighten mounting bolts in the numerical order shown in the fig-

ure.

10. Insert crankshaft pulley by aligning with crankshaft key.

●Tap its center with a plastic hammer to insert.

●Do not tap belt hook.

11. Tighten crankshaft pulley mounting bolt.

KBIA0083E

SBIA0260E

KBIA0085E

Page 228 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-178

[YD22DDTi]

PRIMARY TIMING CHAIN

b. Install four O-rings to the grooves of the cylinder block and fuel

supply pump bracket.

c. Install rear chain case.

●When installing, align the dowel pin wi NISSAN X-TRAIL 2001 Service Repair Manual EM-178

[YD22DDTi]

PRIMARY TIMING CHAIN

b. Install four O-rings to the grooves of the cylinder block and fuel

supply pump bracket.

c. Install rear chain case.

●When installing, align the dowel pin wi](/img/5/57405/w960_57405-227.png)

EM-178

[YD22DDTi]

PRIMARY TIMING CHAIN

b. Install four O-rings to the grooves of the cylinder block and fuel

supply pump bracket.

c. Install rear chain case.

●When installing, align the dowel pin with the pin hole.

d. Tighten bolts in the numerical order shown in the figure.

●Install the following four types of bolts, referring to the figure.

●The shank length under the bolt neck above is the length of

threaded part (pilot portion not included).

e. After tightening all the bolts, re-tighten in the same order.

2. Install power steering pump.

3. Install fuel supply pump.

●Before installing, make sure the notch on the fuel supply

pump flange and the hole 6 mm (0.24 in) in diameter on the

pump body are aligned.

4. Install chain guide and tension guides.

5. Install crankshaft sprocket, aligning it with the crankshaft key on

the far side.

6. Install primary timing chain with fuel supply pump sprocket.

●When installing, match the alignment marks on sprockets with

color coded alignment marks (colored links) on the chain.

●Install fuel supply pump sprocket washer with the surface

marked “F” (front mark) facing the front of the engine.

7. Install timing chain onto power steering pump sprocket and

through chain guide.

JEM141G

16 mm (0.63 in) : Bolt No. 1, 2, 16, 17, 18, 19, 20, 21, 22

20 mm (0.79 in) : Bolt No. 3, 4, 6, 9, 10, 11, 13, 14

25 mm (0.98 in) : Bolt No. 12, 15

35 mm (1.38 in) : Bolt No. 5, 7, 8

SBIA0211E

SBIA0210E

JEM136G