ECM NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 7 of 3833

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

●Use approved bonding agent, sealants or their equivalents when required.

●Use tools and recommended special tools where specified for safe and efficient service repairs.

●When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

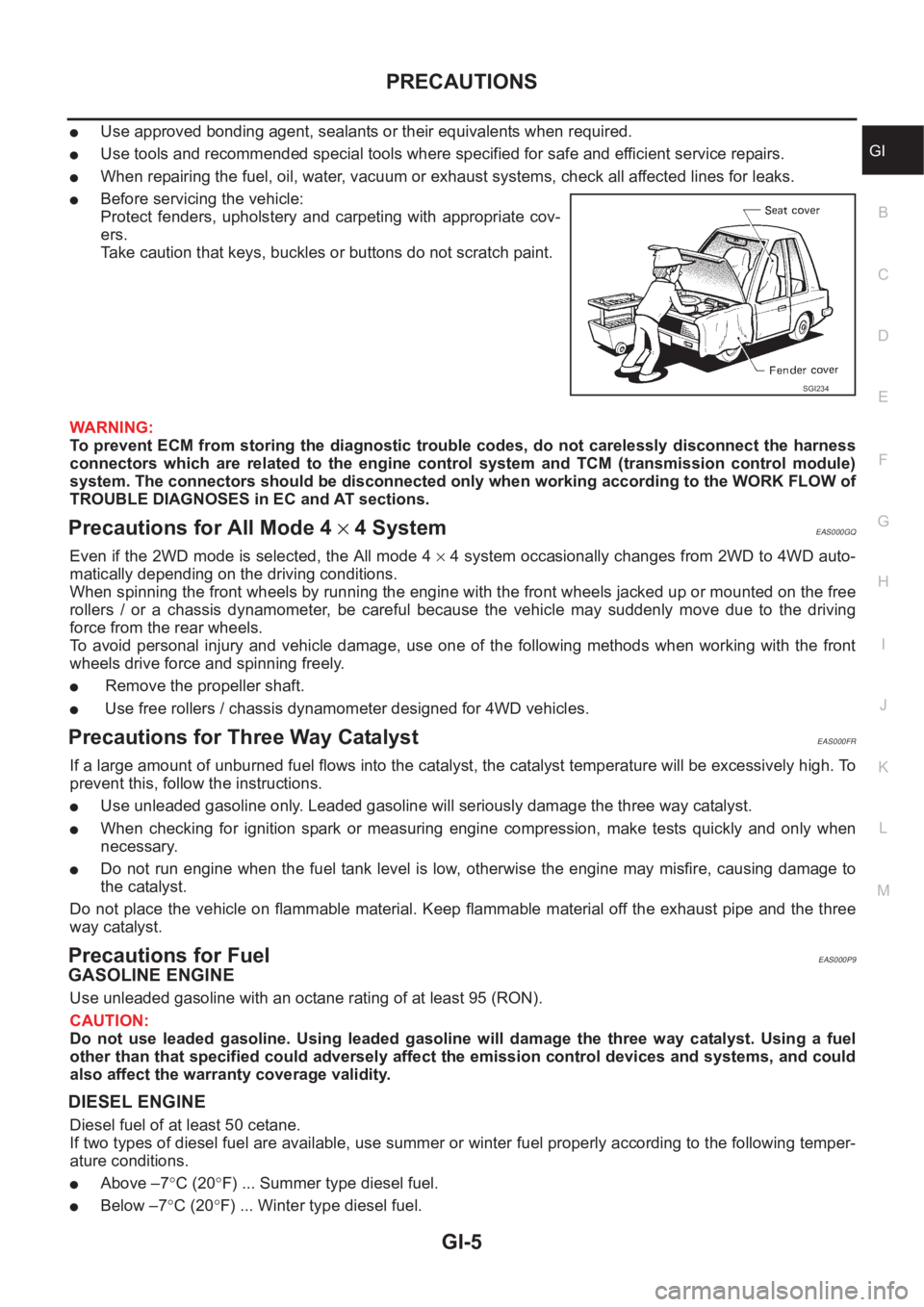

●Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for All Mode 4 × 4 SystemEAS000GQ

Even if the 2WD mode is selected, the All mode 4 × 4 system occasionally changes from 2WD to 4WD auto-

matically depending on the driving conditions.

When spinning the front wheels by running the engine with the front wheels jacked up or mounted on the free

rollers / or a chassis dynamometer, be careful because the vehicle may suddenly move due to the driving

force from the rear wheels.

To avoid personal injury and vehicle damage, use one of the following methods when working with the front

wheels drive force and spinning freely.

● Remove the propeller shaft.

● Use free rollers / chassis dynamometer designed for 4WD vehicles.

Precautions for Three Way CatalystEAS000FR

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

●Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

●When checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

●Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS000P9

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission control devices and systems, and could

also affect the warranty coverage validity.

DIESEL ENGINE

Diesel fuel of at least 50 cetane.

If two types of diesel fuel are available, use summer or winter fuel properly according to the following temper-

ature conditions.

●Above –7°C (20°F) ... Summer type diesel fuel.

●Below –7°C (20°F) ... Winter type diesel fuel.

SGI234

Page 8 of 3833

GI-6

PRECAUTIONS

CAUTION:

●Do not use home heating oil, gasoline or other alternate fuels in your diesel engine. The use of

those can cause engine damage.

●Do not use summer fuel at temperatures below –7°C (20°F). The cold temperatures will cause wax

to form in the fuel. As a result, it may prevent the engine from running smoothly.

●Do not add gasoline or other alternate fuels to diesel fuel.

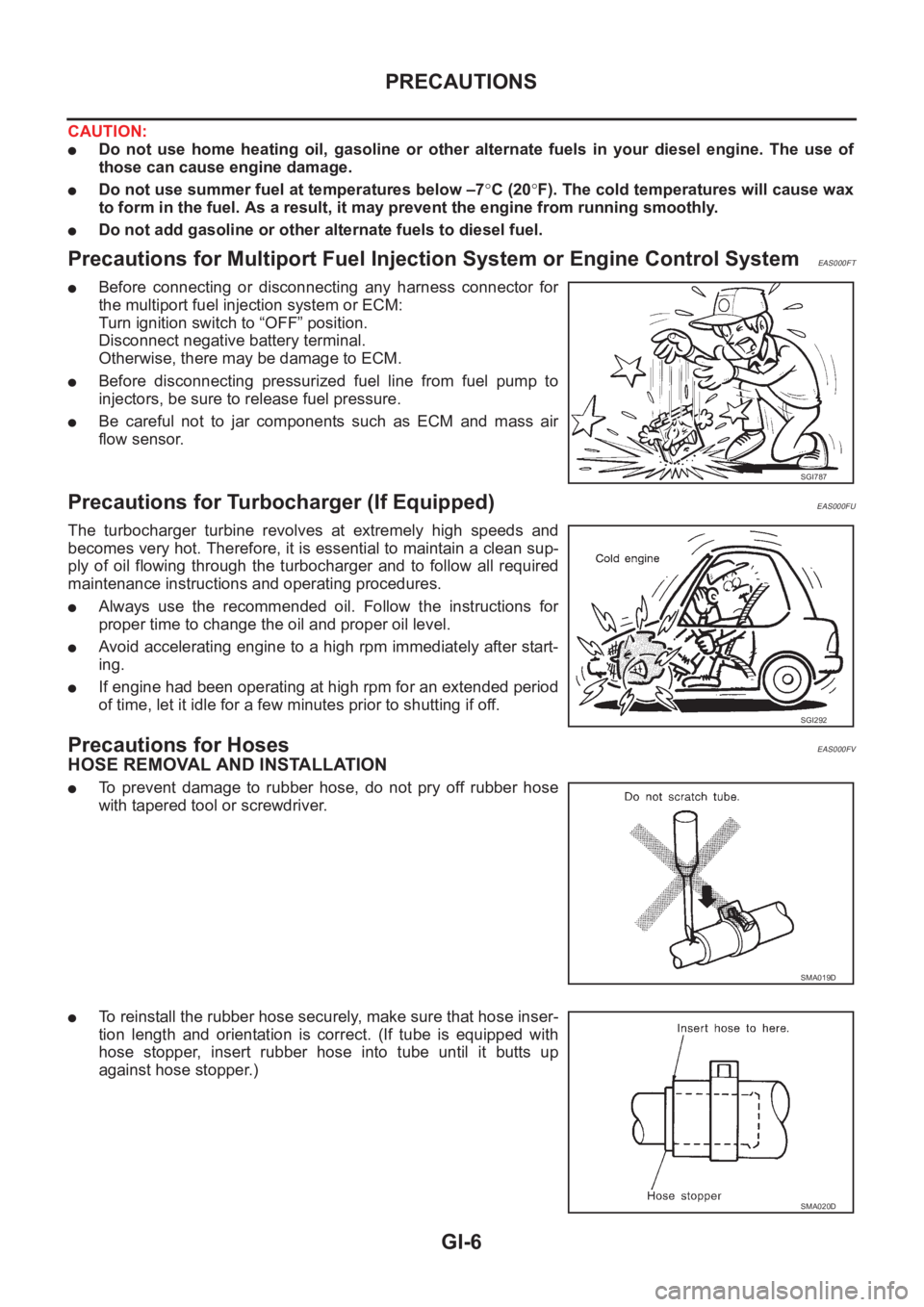

Precautions for Multiport Fuel Injection System or Engine Control SystemEAS000FT

●Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

●Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

●Be careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS000FU

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

●Always use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

●Avoid accelerating engine to a high rpm immediately after start-

ing.

●If engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS000FV

HOSE REMOVAL AND INSTALLATION

●To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

●To reinstall the rubber hose securely, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

SGI787

SGI292

SMA019D

SMA020D

Page 15 of 3833

HOW TO USE THIS MANUAL

GI-13

C

D

E

F

G

H

I

J

K

L

MB

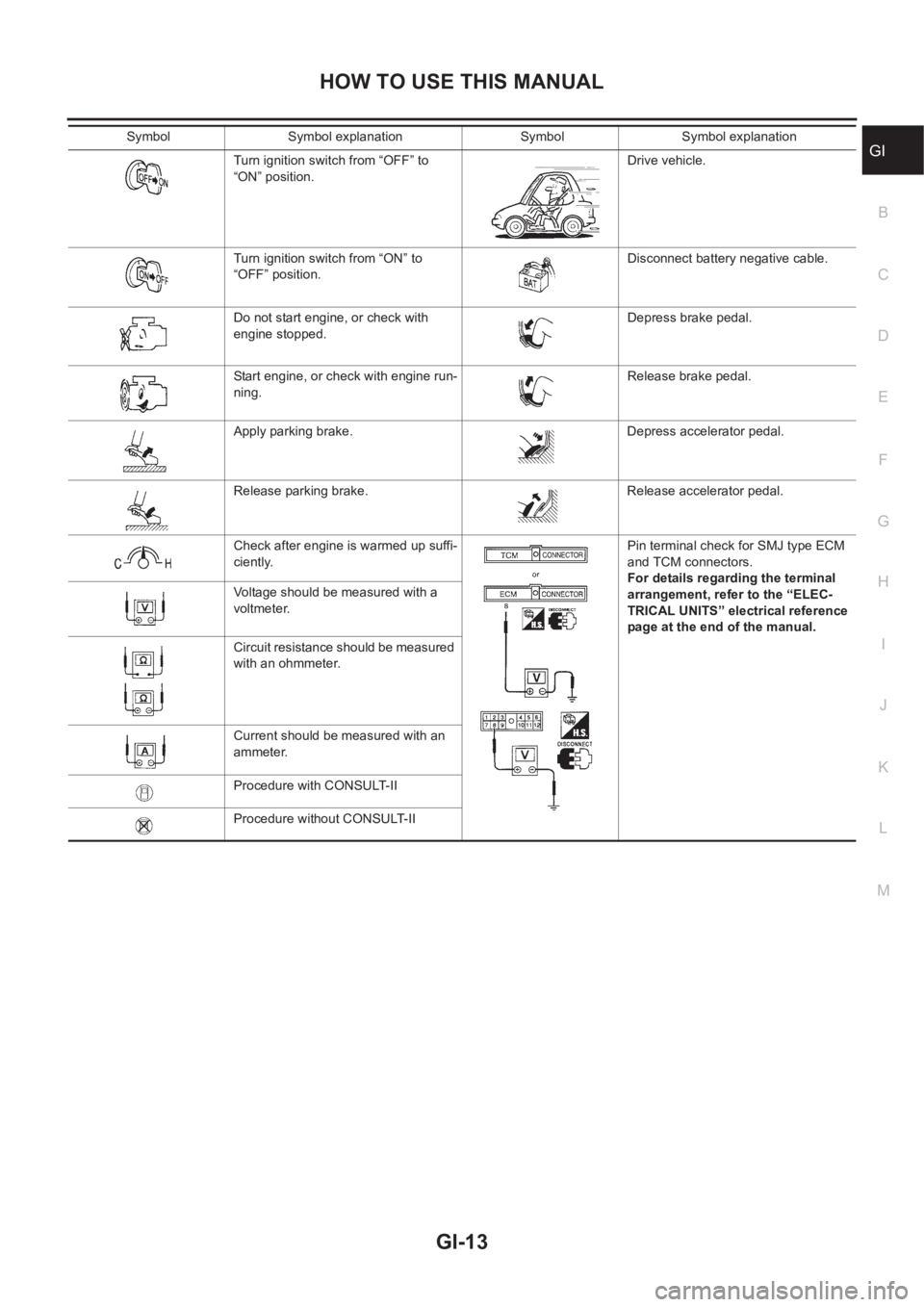

GITurn ignition switch from “OFF” to

“ON” position.Drive vehicle.

Turn ignition switch from “ON” to

“OFF” position.Disconnect battery negative cable.

Do not start engine, or check with

engine stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake. Depress accelerator pedal.

Release parking brake. Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.Pin terminal check for SMJ type ECM

and TCM connectors.

For details regarding the terminal

arrangement, refer to the “ELEC-

TRICAL UNITS” electrical reference

page at the end of the manual. Voltage should be measured with a

voltmeter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

Procedure with CONSULT-II

Procedure without CONSULT-II Symbol Symbol explanation Symbol Symbol explanation

Page 21 of 3833

HOW TO USE THIS MANUAL

GI-19

C

D

E

F

G

H

I

J

K

L

MB

GI

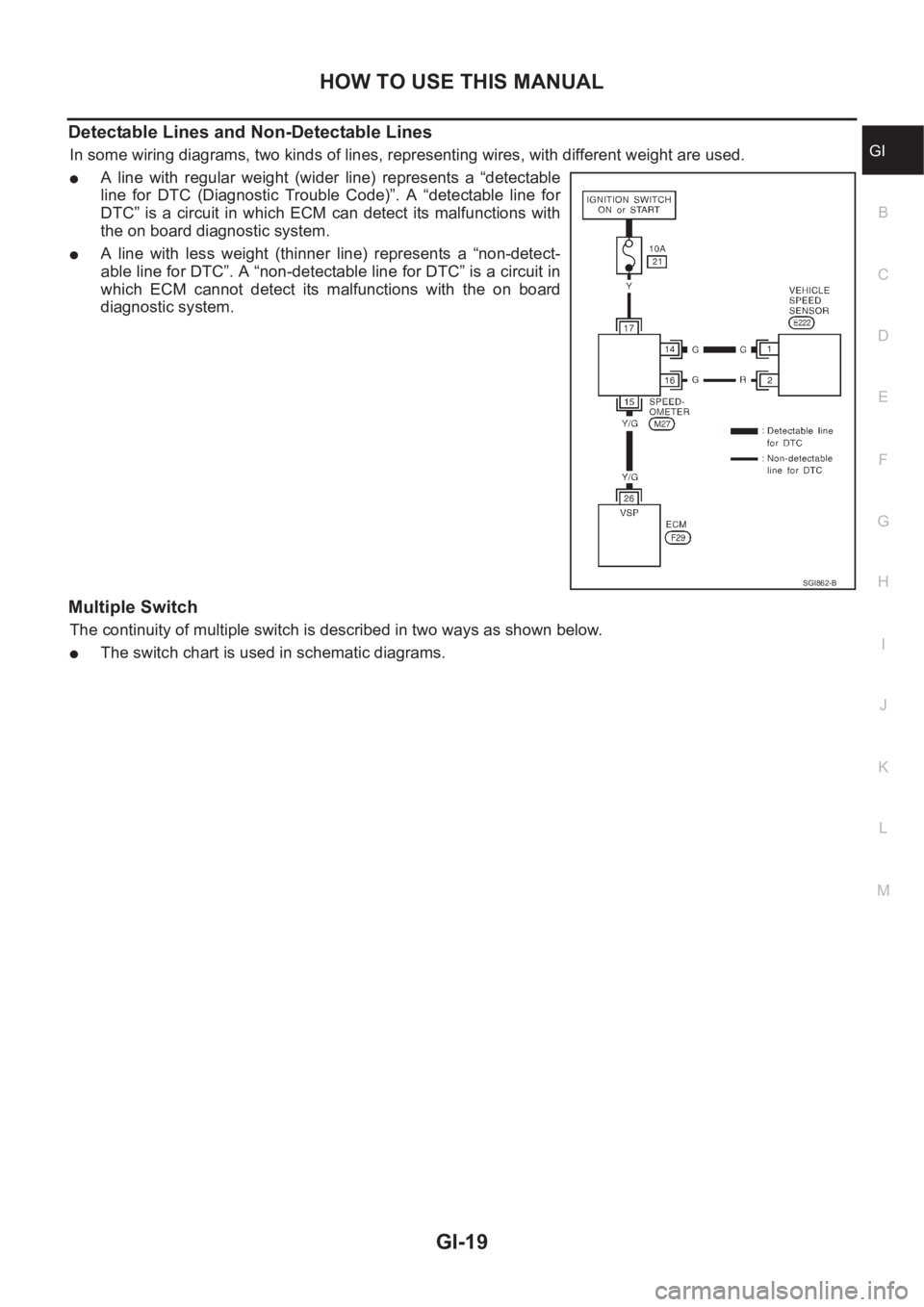

Detectable Lines and Non-Detectable Lines

In some wiring diagrams, two kinds of lines, representing wires, with different weight are used.

●A line with regular weight (wider line) represents a “detectable

line for DTC (Diagnostic Trouble Code)”. A “detectable line for

DTC” is a circuit in which ECM can detect its malfunctions with

the on board diagnostic system.

●A line with less weight (thinner line) represents a “non-detect-

able line for DTC”. A “non-detectable line for DTC” is a circuit in

which ECM cannot detect its malfunctions with the on board

diagnostic system.

Multiple Switch

The continuity of multiple switch is described in two ways as shown below.

●The switch chart is used in schematic diagrams.

SGI862-B

Page 35 of 3833

CONSULT-II CHECKING SYSTEM

GI-33

C

D

E

F

G

H

I

J

K

L

MB

GI

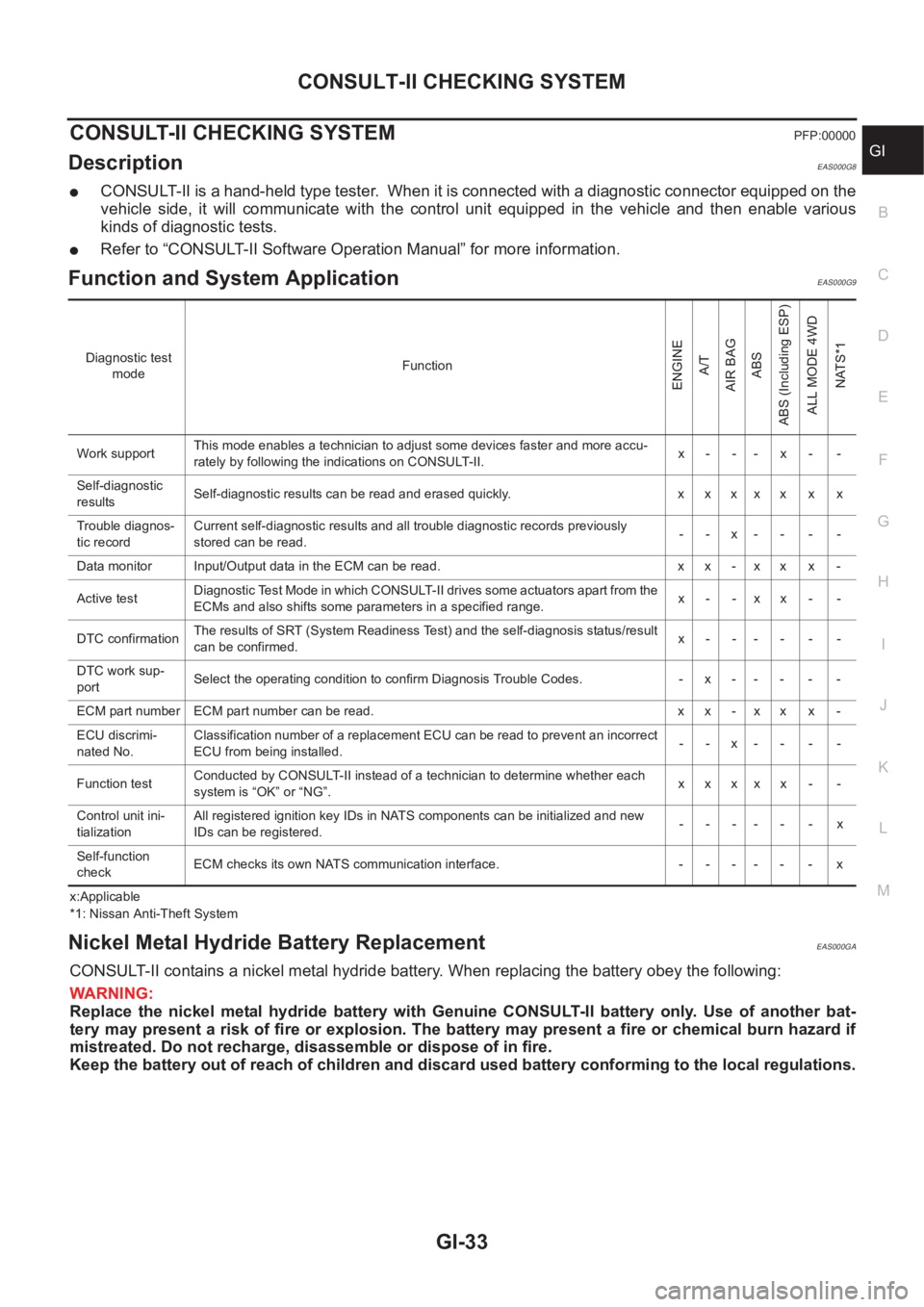

CONSULT-II CHECKING SYSTEMPFP:00000

DescriptionEAS000G8

●CONSULT-II is a hand-held type tester. When it is connected with a diagnostic connector equipped on the

vehicle side, it will communicate with the control unit equipped in the vehicle and then enable various

kinds of diagnostic tests.

●Refer to “CONSULT-II Software Operation Manual” for more information.

Function and System Application EAS000G9

x:Applicable

*1: Nissan Anti-Theft System

Nickel Metal Hydride Battery Replacement EAS000GA

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if

mistreated. Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Diagnostic test

modeFunction

ENGINE

A/T

AIR BAG

ABS

ABS (Including ESP)

ALL MODE 4WD

NATS*1

Work supportThis mode enables a technician to adjust some devices faster and more accu-

rately by following the indications on CONSULT-II.x- -- x- -

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly. x x x x x x x

Trouble diagnos-

tic recordCurrent self-diagnostic results and all trouble diagnostic records previously

stored can be read.--x----

Data monitor Input/Output data in the ECM can be read. x x - x x x -

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from the

ECMs and also shifts some parameters in a specified range.x- -xx- -

DTC confirmationThe results of SRT (System Readiness Test) and the self-diagnosis status/result

can be confirmed.x------

DTC work sup-

portSelect the operating condition to confirm Diagnosis Trouble Codes. -x-----

ECM part number ECM part number can be read. x x - x x x -

ECU discrimi-

nated No.Classification number of a replacement ECU can be read to prevent an incorrect

ECU from being installed.--x----

Function testConducted by CONSULT-II instead of a technician to determine whether each

system is “OK” or “NG”.xxxxx - -

Control unit ini-

tializationAll registered ignition key IDs in NATS components can be initialized and new

IDs can be registered.------x

Self-function

checkECM checks its own NATS communication interface. - - - - - - x

Page 47 of 3833

TERMINOLOGY

GI-45

C

D

E

F

G

H

I

J

K

L

MB

GI

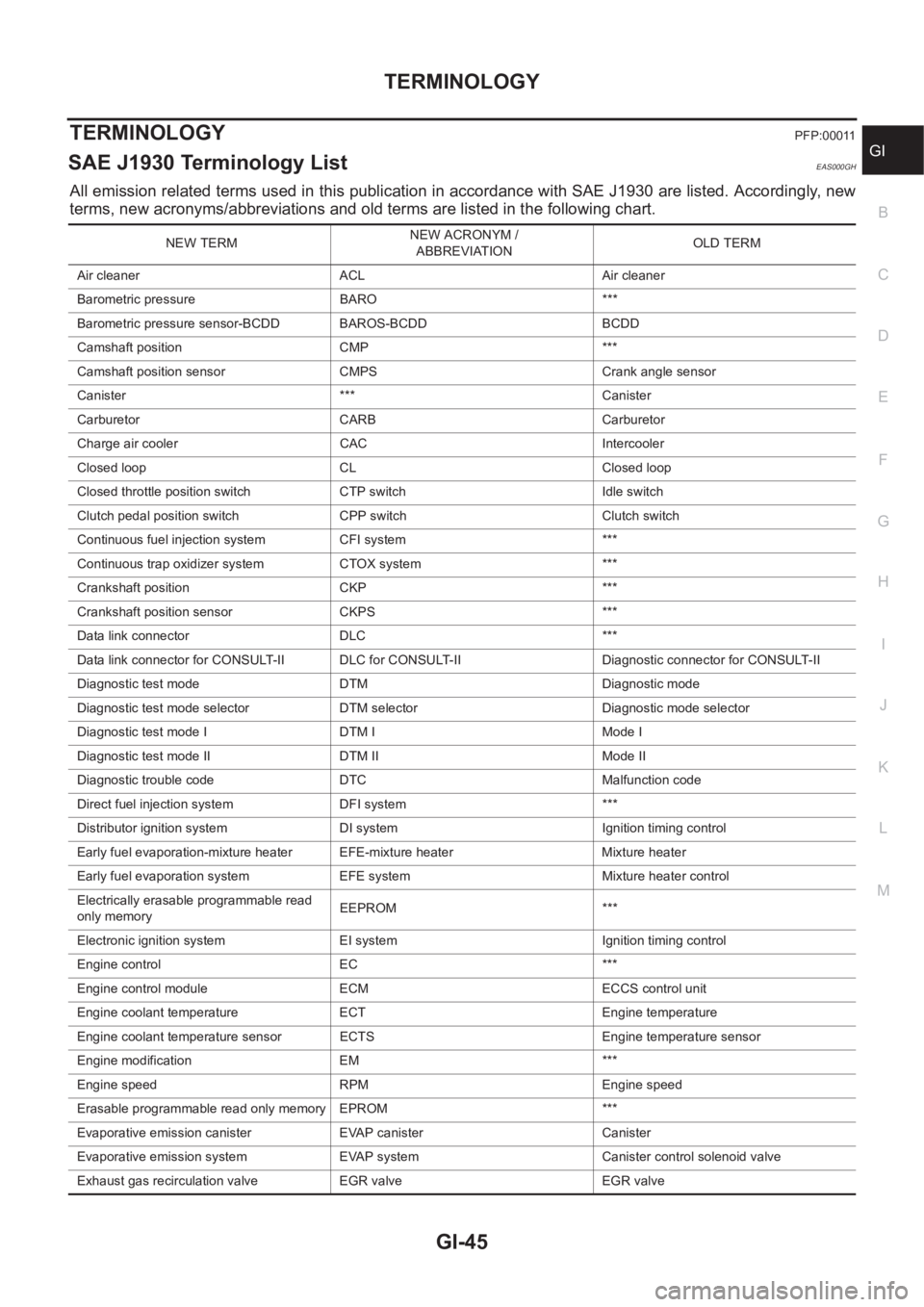

TERMINOLOGYPFP:00011

SAE J1930 Terminology List EAS000GH

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT-II DLC for CONSULT-II Diagnostic connector for CONSULT-II

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

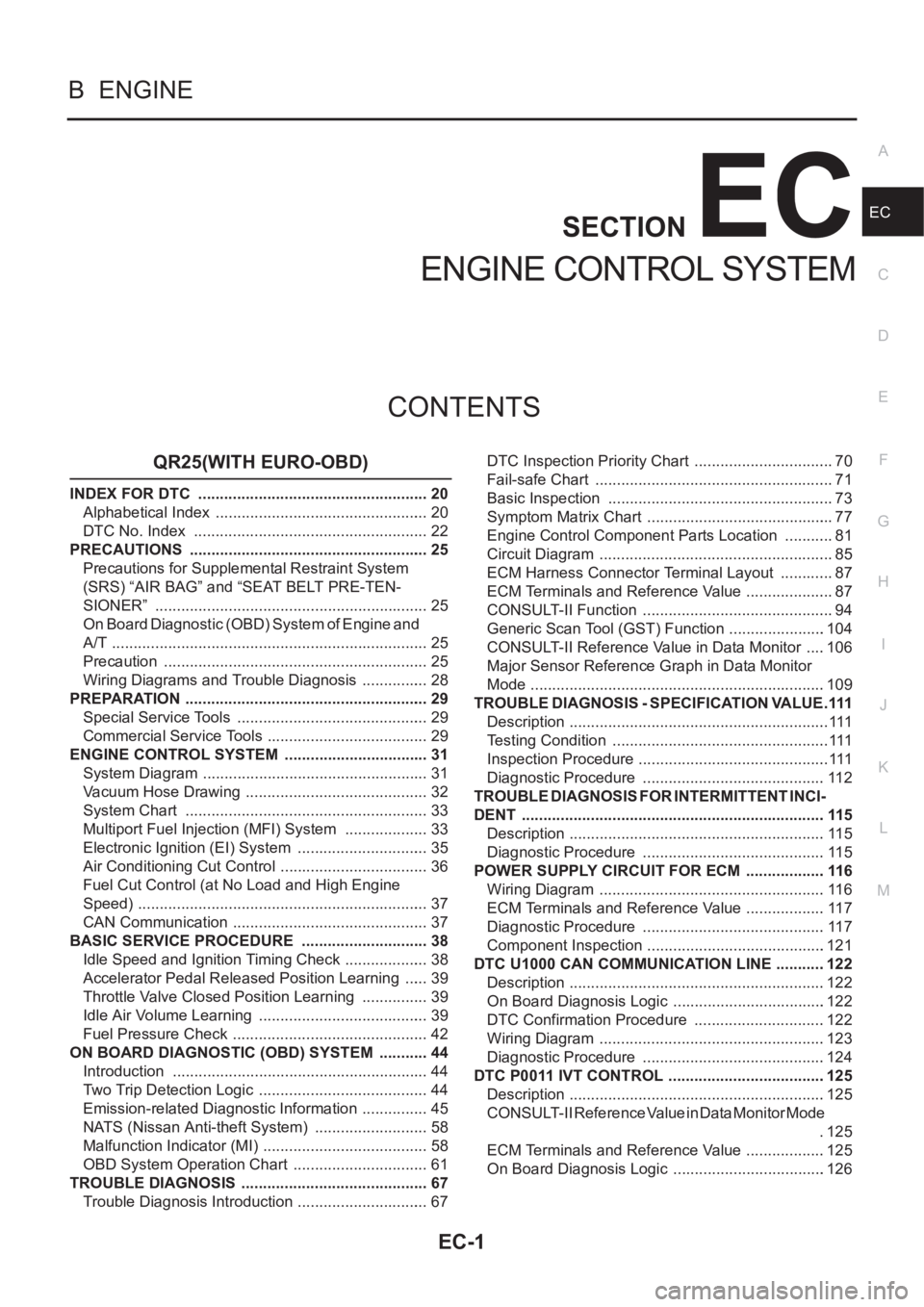

Page 351 of 3833

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QR25(WITH EURO-OBD)

INDEX FOR DTC ...................................................... 20

Alphabetical Index .................................................. 20

DTC No. Index ....................................................... 22

PRECAUTIONS ........................................................ 25

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 25

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 25

Precaution .............................................................. 25

Wiring Diagrams and Trouble Diagnosis ................ 28

PREPARATION ......................................................... 29

Special Service Tools ............................................. 29

Commercial Service Tools ...................................... 29

ENGINE CONTROL SYSTEM .................................. 31

System Diagram ..................................................... 31

Vacuum Hose Drawing ........................................... 32

System Chart ......................................................... 33

Multiport Fuel Injection (MFI) System .................... 33

Electronic Ignition (EI) System ............................... 35

Air Conditioning Cut Control ................................... 36

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 37

CAN Communication .............................................. 37

BASIC SERVICE PROCEDURE .............................. 38

Idle Speed and Ignition Timing Check .................... 38

Accelerator Pedal Released Position Learning ...... 39

Throttle Valve Closed Position Learning ................ 39

Idle Air Volume Learning ........................................ 39

Fuel Pressure Check .............................................. 42

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 44

Introduction ............................................................ 44

Two Trip Detection Logic ........................................ 44

Emission-related Diagnostic Information ................ 45

NATS (Nissan Anti-theft System) ........................... 58

Malfunction Indicator (MI) ....................................... 58

OBD System Operation Chart ................................ 61

TROUBLE DIAGNOSIS ............................................ 67

Trouble Diagnosis Introduction ............................... 67DTC Inspection Priority Chart ................................. 70

Fail-safe Chart ........................................................ 71

Basic Inspection ..................................................... 73

Symptom Matrix Chart ............................................ 77

Engine Control Component Parts Location ............ 81

Circuit Diagram ....................................................... 85

ECM Harness Connector Terminal Layout ............. 87

ECM Terminals and Reference Value ..................

... 87

CONSULT-II Function ............................................. 94

Generic Scan Tool (GST) Function .......................104

CONSULT-II Reference Value in Data Monitor .....106

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................109

TROUBLE DIAGNOSIS - SPECIFICATION VALUE ..111

Description .............................................................111

Testing Condition ...................................................111

Inspection Procedure .............................................111

Diagnostic Procedure ...........................................112

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................115

Description ............................................................115

Diagnostic Procedure ...........................................115

POWER SUPPLY CIRCUIT FOR ECM ...................116

Wiring Diagram .....................................................116

ECM Terminals and Reference Value ...................117

Diagnostic Procedure ...........................................117

Component Inspection ..........................................121

DTC U1000 CAN COMMUNICATION LINE ............122

Description ............................................................122

On Board Diagnosis Logic ....................................122

DTC Confirmation Procedure ...............................122

Wiring Diagram .....................................................123

Diagnostic Procedure ...........................................124

DTC P0011 IVT CONTROL .....................................125

Description ............................................................125

CONSULT-II Reference Value in Data Monitor Mode

.125

ECM Terminals and Reference Value ...................125

On Board Diagnosis Logic ....................................126

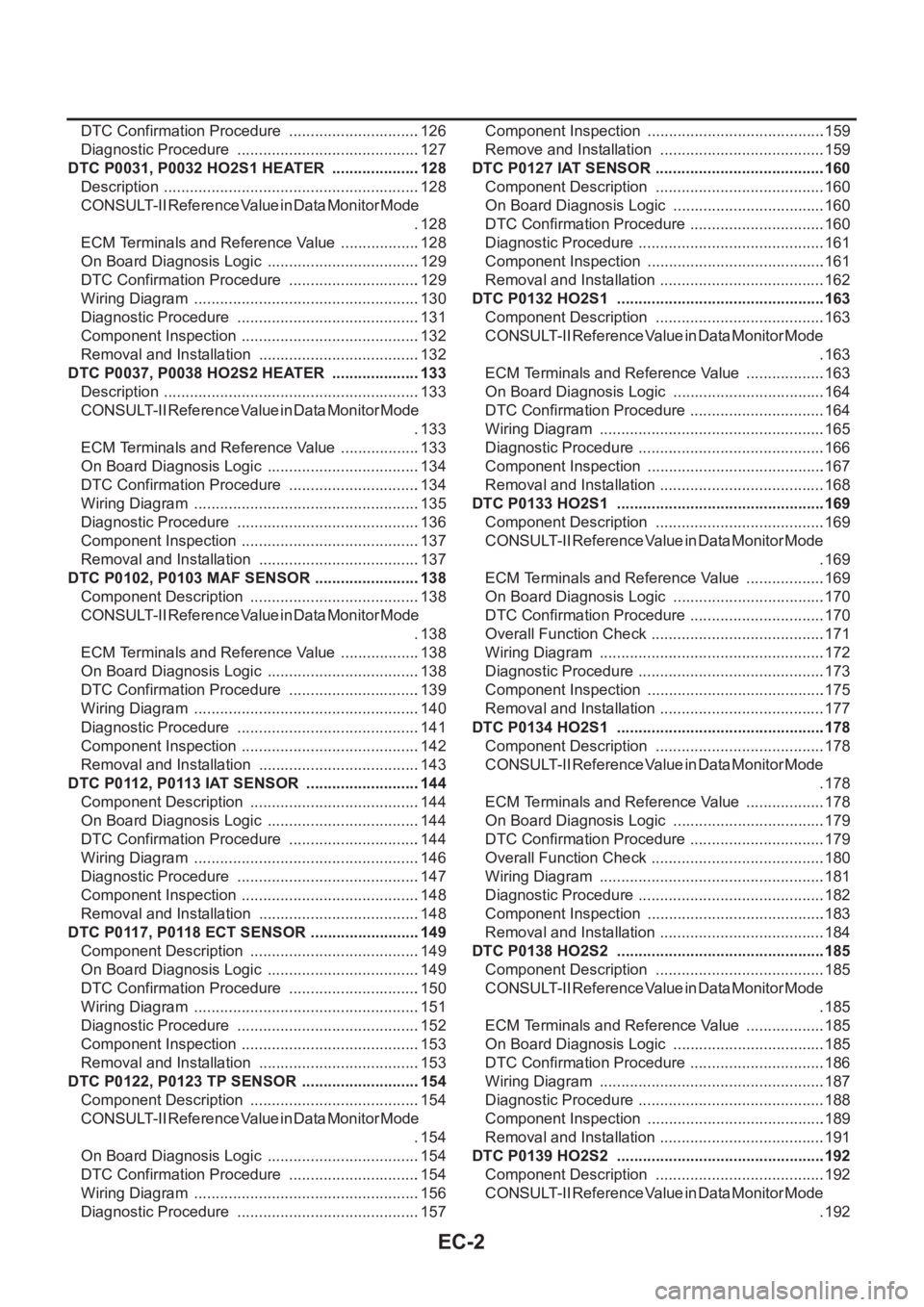

Page 352 of 3833

EC-2

DTC Confirmation Procedure ...............................126

Diagnostic Procedure ...........................................127

DTC P0031, P0032 HO2S1 HEATER .....................128

Description ............................................................128

CONSULT-II Reference Value in Data Monitor Mode

.128

ECM Terminals and Reference Value ...................128

On Board Diagnosis Logic ....................................129

DTC Confirmation Procedure ...............................129

Wiring Diagram .....................................................130

Diagnostic Procedure ...........................................131

Component Inspection ..........................................132

Removal and Installation ......................................132

DTC P0037, P0038 HO2S2 HEATER .....................133

Description ............................................................133

CONSULT-II Reference Value in Data Monitor Mode

.133

ECM Terminals and Reference Value ...................133

On Board Diagnosis Logic ....................................134

DTC Confirmation Procedure ...............................134

Wiring Diagram .....................................................135

Diagnostic Procedure ...........................................136

Component Inspection ..........................................137

Removal and Installation ......................................137

DTC P0102, P0103 MAF SENSOR .........................138

Component Description ........................................138

CONSULT-II Reference Value in Data Monitor Mode

.138

ECM Terminals and Reference Value ...................138

On Board Diagnosis Logic ....................................138

DTC Confirmation Procedure ...............................139

Wiring Diagram .....................................................140

Diagnostic Procedure ...........................................141

Component Inspection ..........................................142

Removal and Installation ......................................143

DTC P0112, P0113 IAT SENSOR ...........................144

Component Description ........................................144

On Board Diagnosis Logic ....................................144

DTC Confirmation Procedure ...............................144

Wiring Diagram .....................................................146

Diagnostic Procedure ...........................................147

Component Inspection ..........................................148

Removal and Installation ......................................148

DTC P0117, P0118 ECT SENSOR ..........................149

Component Description ........................................149

On Board Diagnosis Logic ....................................149

DTC Confirmation Procedure ...............................150

Wiring Diagram .....................................................151

Diagnostic Procedure ...........................................152

Component Inspection ..........................................153

Removal and Installation ......................................153

DTC P0122, P0123 TP SENSOR ............................154

Component Description ........................................154

CONSULT-II Reference Value in Data Monitor Mode

.154

On Board Diagnosis Logic ....................................154

DTC Confirmation Procedure ...............................154

Wiring Diagram .....................................................156

Diagnostic Procedure ...........................................157Component Inspection ..........................................159

Remove and Installation .......................................159

DTC P0127 IAT SENSOR ........................................160

Component Description ........................................160

On Board Diagnosis Logic ....................................160

DTC Confirmation Procedure ................................160

Diagnostic Procedure ............................................161

Component Inspection ..........................................161

Removal and Installation .......................................162

DTC P0132 HO2S1 ................................................ .163

Component Description ........................................163

CONSULT-II Reference Value in Data Monitor Mode

.163

ECM Terminals and Reference Value ...................163

On Board Diagnosis Logic ....................................164

DTC Confirmation Procedure ................................164

Wiring Diagram .....................................................165

Diagnostic Procedure ............................................166

Component Inspection ..........................................167

Removal and Installation .......................................168

DTC P0133 HO2S1 ................................................ .169

Component Description ........................................169

CONSULT-II Reference Value in Data Monitor Mode

.169

ECM Terminals and Reference Value ...................169

On Board Diagnosis Logic ....................................170

DTC Confirmation Procedure ................................170

Overall Function Check .........................................171

Wiring Diagram .....................................................172

Diagnostic Procedure ............................................173

Component Inspection ..........................................175

Removal and Installation .......................................177

DTC P0134 HO2S1 ................................................ .178

Component Description ........................................178

CONSULT-II Reference Value in Data Monitor Mode

.178

ECM Terminals and Reference Value ...................178

On Board Diagnosis Logic ....................................179

DTC Confirmation Procedure ................................179

Overall Function Check .........................................180

Wiring Diagram ....................................................

.181

Diagnostic Procedure ............................................182

Component Inspection ..........................................183

Removal and Installation .......................................184

DTC P0138 HO2S2 ................................................ .185

Component Description ........................................185

CONSULT-II Reference Value in Data Monitor Mode

.185

ECM Terminals and Reference Value ...................185

On Board Diagnosis Logic ....................................185

DTC Confirmation Procedure ................................186

Wiring Diagram .....................................................187

Diagnostic Procedure ............................................188

Component Inspection ..........................................189

Removal and Installation .......................................191

DTC P0139 HO2S2 ................................................ .192

Component Description ........................................192

CONSULT-II Reference Value in Data Monitor Mode

.192

Page 353 of 3833

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA ECM Terminals and Reference Value .................. 192

On Board Diagnosis Logic ................................... 192

DTC Confirmation Procedure ............................... 193

Overall Function Check ........................................ 193

Wiring Diagram .................................................... 195

Diagnostic Procedure ........................................... 196

Component Inspection ......................................... 197

Removal and Installation ...................................... 199

DTC P0171 FUEL INJECTION SYSTEM FUNCTION . 200

On Board Diagnosis Logic ................................... 200

DTC Confirmation Procedure ............................... 200

Wiring Diagram .................................................... 202

Diagnostic Procedure ........................................... 203

DTC P0172 FUEL INJECTION SYSTEM FUNCTION . 206

On Board Diagnosis Logic ................................... 206

DTC Confirmation Procedure ............................... 206

Wiring Diagram .................................................... 208

Diagnostic Procedure ........................................... 209

DTC P0222, P0223 TP SENSOR ........................... 212

Component Description ........................................ 212

CONSULT-II Reference Value in Data Monitor Mode

. 212

ECM Terminals and Reference Value .................. 212

On Board Diagnosis Logic ................................... 213

DTC Confirmation Procedure ............................... 213

Wiring Diagram .................................................... 214

Diagnostic Procedure ........................................... 215

Component Inspection ......................................... 216

Remove and Installation ....................................... 216

DTC P0300 - P0304 MULTIPLE CYLINDER MIS-

FIRE, NO. 1 - 4 CYLINDER MISFIRE ..................... 217

On Board Diagnosis Logic ................................... 217

DTC Confirmation Procedure ............................... 217

Diagnostic Procedure ........................................... 218

DTC P0327, P0328 KS ........................................... 222

Component Description ........................................ 222

ECM Terminals and Reference Value .................. 222

On Board Diagnosis Logic ................................... 222

DTC Confirmation Procedure ............................... 222

Wiring Diagram .................................................... 224

Diagnostic Procedure ........................................... 225

Component Inspection ......................................... 226

Removal and Installation ...................................... 226

DTC P0335 CKP SENSOR (POS) .......................... 227

Component Description ........................................ 227

CONSULT-II Reference Value in Data Monitor Mode

. 227

ECM Terminals and Reference Value .................. 227

On Board Diagnosis Logic ................................... 228

DTC Confirmation Procedure ............................... 228

Wiring Diagram .................................................... 229

Diagnostic Procedure ........................................... 230

Component Inspection ......................................... 231

Removal and Installation ...................................... 232

DTC P0340 CMP SENSOR (PHASE) ..................... 233

Component Description ........................................ 233

ECM Terminals and Reference Value .................. 233

On Board Diagnosis Logic ................................... 233

DTC Confirmation Procedure ............................... 234Wiring Diagram .....................................................235

Diagnostic Procedure ...........................................236

Component Inspection ..........................................238

Removal and Installation ......................................238

DTC P0420 THREE WAY CATALYST FUNCTION . 239

On Board Diagnosis Logic ....................................239

DTC Confirmation Procedure ...............................239

Overall Function Check ........................................240

Diagnostic Procedure ...........................................241

DTC P0444, P0445 EVAP CANISTER PURGE VOL-

UME CONTROL SOLENOID VALVE ......................244

Description ............................................................244

CONSULT-II Reference Value in Data Monitor Mode

.244

ECM Terminals and Reference Value ...................244

On Board Diagnosis Logic ....................................245

DTC Confirmation Procedure ...............................245

Wiring Diagram .....................................................246

Diagnostic Procedure ...........................................247

Component Inspection ..........................................248

Removal and Installation ......................................249

DTC P0500 VSS ......................................................250

Component Description ........................................250

ECM Terminals and Reference Value ...................250

On Board Diagnosis Logic ....................................250

DTC Confirmation Procedure ...............................250

Overall Function Check ........................................251

Wiring Diagram .....................................................252

Diagnostic Procedure ...........................................254

DTC P0550 PSP SENSOR .....................................255

Component Description ........................................255

CONSULT-II Reference Value in Data Monitor Mode

.255

ECM Terminals and Reference Value ...................255

On Board Diagnosis Logic ....................................255

DTC Confirmation Procedure ...............................255

Wiring Diagram .....................................................257

Diagnostic Procedure ...........................................258

Component Inspection ..........................................259

DTC P0605 ECM .....................................................260

Component Description ........................................260

On Board Diagnosis Logic ....................................260

DTC Confirmation Procedure ...............................260

Diagnostic Procedure ...........................................261

DTC P0650 MI .........................................................263

Component Description ........................................263

On Board Diagnosis Logic ....................................263

DTC Confirmation Procedure ...............................263

Wiring Diagram .....................................................264

Diagnostic Procedure ...........................................265

DTC P1065 ECM POWER SUPPLY .......................267

Component Description ........................................267

On Board Diagnosis Logic ....................................267

DTC Confirmation Procedure ...............................267

Wiring Diagram .....................................................268

Diagnostic Procedure ...........................................269

DTC P1111 IVT CONTROL SOLENOID VALVE .....271

Component Description ........................................271

CONSULT-II Reference Value in Data Monitor Mode

Page 354 of 3833

EC-4

.271

ECM Terminals and Reference Value ...................271

On Board Diagnosis Logic ....................................271

DTC Confirmation Procedure ...............................272

Wiring Diagram .....................................................273

Diagnostic Procedure ...........................................274

Component Inspection ..........................................275

Removal and Installation ......................................275

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR .............................................................276

Description ............................................................276

On Board Diagnosis Logic ....................................276

DTC Confirmation Procedure ...............................276

Diagnostic Procedure ...........................................277

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION ..............................................................278

Description ............................................................278

CONSULT-II Reference Value in Data Monitor Mode

.278

ECM Terminals and Reference Value ...................278

On Board Diagnosis Logic ....................................279

DTC Confirmation Procedure ...............................279

Wiring Diagram .....................................................280

Diagnostic Procedure ...........................................281

Remove and Installation .......................................284

DTC P1124, P1126 THROTTLE CONTROL MOTOR

RELAY .....................................................................285

Component Description ........................................285

CONSULT-II Reference Value in Data Monitor Mode

.285

ECM Terminals and Reference Value ...................285

On Board Diagnosis Logic ....................................285

DTC Confirmation Procedure ...............................285

Wiring Diagram .....................................................287

Diagnostic Procedure ...........................................288

Component Inspection ..........................................289

DTC P1128 THROTTLE CONTROL MOTOR .........290

Component Description ........................................290

ECM Terminals and Reference Value ...................290

On Board Diagnosis Logic ....................................290

DTC Confirmation Procedure ...............................290

Wiring Diagram .....................................................292

Diagnostic Procedure ...........................................293

Component Inspection ..........................................294

Remove and Installation .......................................294

DTC P1143 HO2S1 .................................................295

Component Description ........................................295

CONSULT-II Reference Value in Data Monitor Mode

.295

ECM Terminals and Reference Value ...................295

On Board Diagnosis Logic ....................................296

DTC Confirmation Procedure ...............................296

Overall Function Check ........................................297

Diagnostic Procedure ...........................................297

Component Inspection ..........................................299

Removal and Installation ......................................300

DTC P1144 HO2S1 .................................................301

Component Description ........................................301

CONSULT-II Reference Value in Data Monitor Mode .301

ECM Terminals and Reference Value ...................301

On Board Diagnosis Logic ....................................302

DTC Confirmation Procedure ................................302

Overall Function Check .........................................303

Diagnostic Procedure ............................................303

Component Inspection ..........................................305

Removal and Installation .......................................306

DTC P1146 HO2S2 ..................................................307

Component Description ........................................307

CONSULT-II Reference Value in Data Monitor Mode

.307

ECM Terminals and Reference Value ...................307

On Board Diagnosis Logic ....................................307

DTC Confirmation Procedure ................................308

Overall Function Check .........................................308

Wiring Diagram .....................................................310

Diagnostic Procedure ............................................311

Component Inspection ..........................................312

Removal and Installation .......................................314

DTC P1147 HO2S2 ..................................................315

Component Description ........................................315

CONSULT-II Reference Value in Data Monitor Mode

.315

ECM Terminals and Reference Value ...................315

On Board Diagnosis Logic ....................................315

DTC Confirmation Procedure ................................316

Overall Function Check .........................................316

Wiring Diagram .....................................................318

Diagnostic Procedure ............................................319

Component Inspection ..........................................320

Removal and Installation .......................................322

DTC P1217 ENGINE OVER TEMPERATURE ........323

System Description ...............................................323

CONSULT-II Reference Value in Data Monitor Mode

.323

ECM Terminals and Reference Value ...................324

On Board Diagnosis Logic ....................................324

Overall Function Check .........................................325

Wiring Diagram .....................................................327

Diagnostic Procedure ............................................328

Main 12 Causes of Overheating ...........................335

Component Inspection ..........................................336

DTC P1225 TP SENSOR ........................................337

Component Description ........................................337

On Board Diagnosis Logic ....................................337

DTC Confirmation Procedure ................................337

Diagnostic Procedure ............................................338

Remove and Installation .......................................338

DTC P1226 TP SENSOR ........................................339

Component Description ........................................339

On Board Diagnosis Logic ....................................339

DTC Confirmation Procedure ................................339

Diagnostic Procedure ............................................340

Remove and Installation .......................................340

DTC P1229 SENSOR POWER SUPPLY ................341

On Board Diagnosis Logic ....................................341

DTC Confirmation Procedure ................................341