key NISSAN X-TRAIL 2001 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2085 of 3833

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

●After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DURE”.

The DTC should not be displayed in the “DTC CONFIRMA-

TION PROCEDURE” if the repair is completed.

●Before proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

●Disassembly should be done in a clean work area.

●Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transaxle.

●Place disassembled parts in order for easier and proper assembly.

●All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

●Gaskets, seals and O-rings should be replaced any time the transaxle is disassembled.

●It is very important to perform functional tests whenever they are indicated.

●The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

●Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

●Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

●Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

●After overhaul, refill the transaxle with new ATF.

●When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

to “Changing A/T Fluid”, AT-13, "

A/T FLUID" .

Service Notice or PrecautionsECS004Q3

FA I L - S A F E

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

When the ignition key is turned “ON” following Fail-Safe operation, O/D OFF indicator lamp blinks for about 8

seconds. Refer to AT- 2 5 3 , "

SELF-DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-II)" (EXCEPT FOR

EURO-OBD) or AT-51, "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)" (EURO-OBD).

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW”, refer to AT-262, "

Work Flow" (EXCEPT FOR Euro-OBD) or AT- 6 0 , "Work

Flow" (Euro-OBD).

The SELF-DIAGNOSIS results will be as follows:

●The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

●During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

●External leaks in the hub weld area.

●Converter hub is scored or damaged.

●Converter pilot is broken, damaged or fits poorly into crankshaft.

●Steel particles are found after flushing the cooler and cooler lines.

●Pump is damaged or steel particles are found in the converter.

●Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

SAT652J

Page 2135 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-57

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

●WHAT..... Vehicle & A/T model

●WHEN..... Date, Frequencies

NISSAN X-TRAIL 2001 Service Service Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-57

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

●WHAT..... Vehicle & A/T model

●WHEN..... Date, Frequencies](/img/5/57405/w960_57405-2134.png)

TROUBLE DIAGNOSIS — INTRODUCTION

AT-57

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

●WHAT..... Vehicle & A/T model

●WHEN..... Date, Frequencies

●WHERE..... Road conditions

●HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

Frequency❏ Continuous❏ Intermittent ( times a day)

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → O/D)

❏ No down-shift (❏ O/D → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lockup malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ Lockup❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

O/D OFF indicator lamp Blinks for about 8 seconds.

❏ Continuously lit❏ Not lit

Malfunction indicator lamp (MIL)❏ Continuously lit❏ Not lit

Page 2337 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-259

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

●WHAT..... Vehicle & A/T model

●WHEN..... Date, Frequ NISSAN X-TRAIL 2001 Service Service Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-259

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

●WHAT..... Vehicle & A/T model

●WHEN..... Date, Frequ](/img/5/57405/w960_57405-2336.png)

TROUBLE DIAGNOSIS — INTRODUCTION

AT-259

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

●WHAT..... Vehicle & A/T model

●WHEN..... Date, Frequencies

●WHERE..... Road conditions

●HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

Frequency❏ Continuous❏ Intermittent ( times a day)

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → O/D)

❏ No down-shift (❏ O/D → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lockup malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ Lockup❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

O/D OFF indicator lamp Blinks for about 8 seconds.

❏ Continuously lit❏ Not lit

Page 2484 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual AT-406

[ALL]

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

DescriptionECS00405

●The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the se NISSAN X-TRAIL 2001 Service Service Manual AT-406

[ALL]

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

DescriptionECS00405

●The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the se](/img/5/57405/w960_57405-2483.png)

AT-406

[ALL]

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

DescriptionECS00405

●The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from “P” (parking) to any other posi-

tion unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from “P” to any other position.

The key cannot be removed unless the selector lever is placed in “P”.

●The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationECS00406

SCIA0781E

Page 2486 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual AT-408

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

●Selector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

●Selec NISSAN X-TRAIL 2001 Service Service Manual AT-408

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

●Selector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

●Selec](/img/5/57405/w960_57405-2485.png)

AT-408

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

●Selector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

●Selector lever can be moved from “P” position with key in ON position and brake pedal released.

●Selector lever can be moved from “P” position when key is removed from key cylinder.

SYMPTOM 2:

●Ignition key cannot be removed when selector lever is set to “P” position.

●Ignition key can be removed when selector lever is set to any position except “P”.

1. CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK >> GO TO 2.

NG >> Repair key interlock cable. Refer to AT- 4 1 2 , "

KEY INTERLOCK CABLE" .

2. CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK >> GO TO 3.

NG >> Check selector lever. Refer to AT- 4 1 6 , "

Park/Neutral Position (PNP) Switch Adjustment" .

3. CHECK POWER SOURCE

1. Turn ignition switch to “ON” position.

(Do not start engine.)

2. Check voltage between A/T device harness connector M58 ter-

minal 5 (G) and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4. DETECT MALFUNCTIONING ITEM

Check the following items:

1. Harness for short or open between ignition switch and A/T device harness terminal 5

2. Fuse

3. Ignition switch (Refer to PG-2, "

POWER SUPPLY ROUTING" .)

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.Voltage: Battery voltage

SCIA1165E

Page 2490 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual AT-412

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

●Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

fer NISSAN X-TRAIL 2001 Service Service Manual AT-412

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

●Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

fer](/img/5/57405/w960_57405-2489.png)

AT-412

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

●Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

ference with adjacent parts.

●After installing key interlock cable to control device, make sure that casing cap and bracket are

firmly secured in their positions.

RemovalECS0040A

1. Unlock slider by squeezing lock tabs on slider from adjuster

holder and remove interlock rod from cable.

SAT996J

SAT853J

Page 2491 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual KEY INTERLOCK CABLE

AT-413

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Remove lock plate from steering lock assembly and remove key

interlock cable.

InstallationECS0040B

1. Turn ignition key to lock position.

NISSAN X-TRAIL 2001 Service Service Manual KEY INTERLOCK CABLE

AT-413

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Remove lock plate from steering lock assembly and remove key

interlock cable.

InstallationECS0040B

1. Turn ignition key to lock position.](/img/5/57405/w960_57405-2490.png)

KEY INTERLOCK CABLE

AT-413

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Remove lock plate from steering lock assembly and remove key

interlock cable.

InstallationECS0040B

1. Turn ignition key to lock position.

2. Set A/T selector lever to P position.

3. Set key interlock cable to steering lock assembly and install lock

plate.

4. Clamp cable to steering column and fix to control cable with

band.

5. Insert interlock rod into adjuster holder.

6. Install casing cap to bracket.

7. Move slider in order to fix adjuster holder to interlock rod.

SAT854J

SAT854J

SAT804E

SAT805E

Page 2920 of 3833

PS-10

STEERING COLUMN

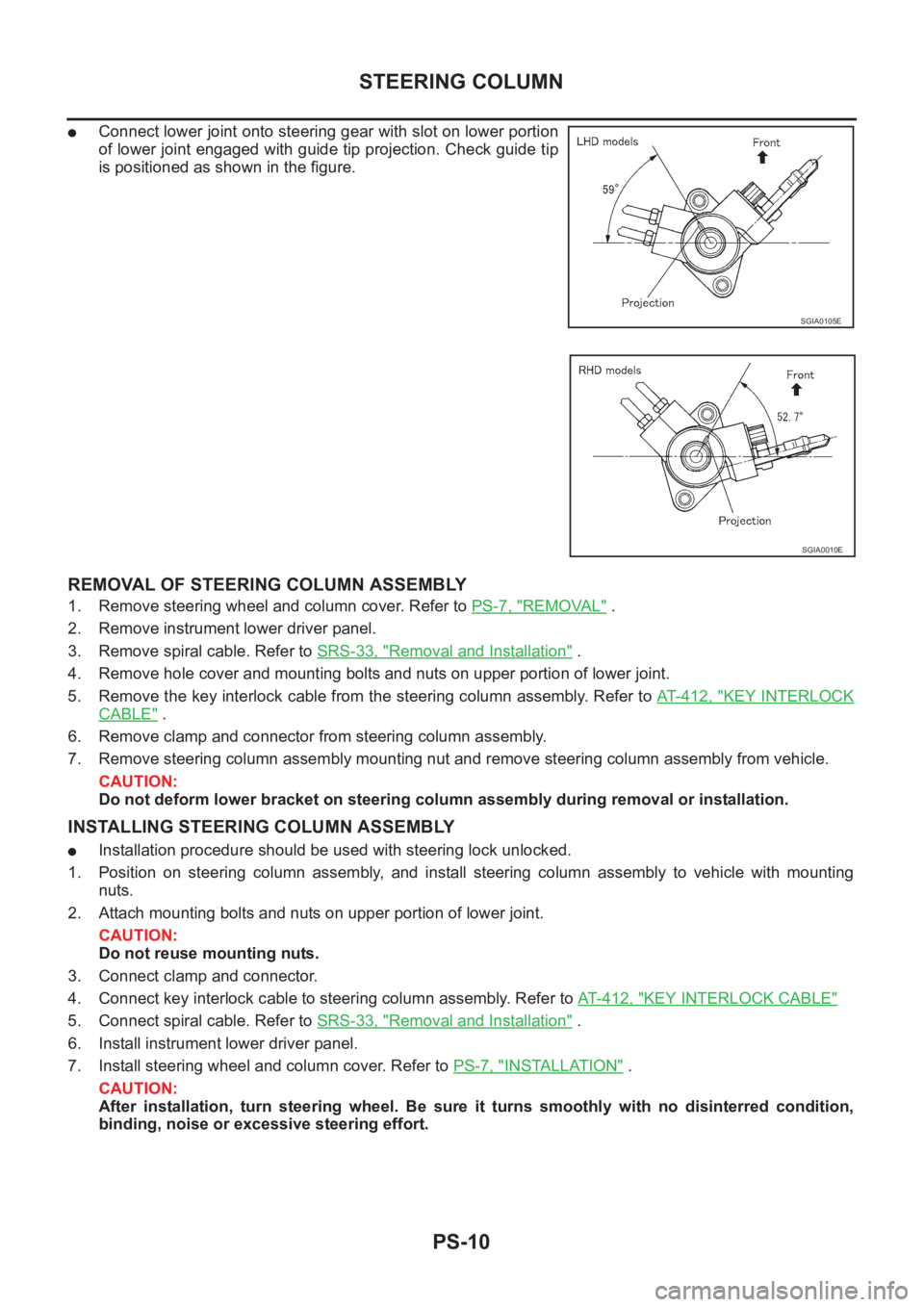

●Connect lower joint onto steering gear with slot on lower portion

of lower joint engaged with guide tip projection. Check guide tip

is positioned as shown in the figure.

REMOVAL OF STEERING COLUMN ASSEMBLY

1. Remove steering wheel and column cover. Refer to PS-7, "REMOVAL" .

2. Remove instrument lower driver panel.

3. Remove spiral cable. Refer to SRS-33, "

Removal and Installation" .

4. Remove hole cover and mounting bolts and nuts on upper portion of lower joint.

5. Remove the key interlock cable from the steering column assembly. Refer to AT- 4 1 2 , "

KEY INTERLOCK

CABLE" .

6. Remove clamp and connector from steering column assembly.

7. Remove steering column assembly mounting nut and remove steering column assembly from vehicle.

CAUTION:

Do not deform lower bracket on steering column assembly during removal or installation.

INSTALLING STEERING COLUMN ASSEMBLY

●Installation procedure should be used with steering lock unlocked.

1. Position on steering column assembly, and install steering column assembly to vehicle with mounting

nuts.

2. Attach mounting bolts and nuts on upper portion of lower joint.

CAUTION:

Do not reuse mounting nuts.

3. Connect clamp and connector.

4. Connect key interlock cable to steering column assembly. Refer to AT- 4 1 2 , "

KEY INTERLOCK CABLE"

5. Connect spiral cable. Refer to SRS-33, "Removal and Installation" .

6. Install instrument lower driver panel.

7. Install steering wheel and column cover. Refer to PS-7, "

INSTALLATION" .

CAUTION:

After installation, turn steering wheel. Be sure it turns smoothly with no disinterred condition,

binding, noise or excessive steering effort.

SGIA0105E

SGIA0010E

Page 3016 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual SRS-14

TROUBLE DIAGNOSIS

CONSULT-II Function

EHS000O6

DIAGNOSIS MODE FOR CONSULT-II

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result (also indicated by the number of warning lam NISSAN X-TRAIL 2001 Service Service Manual SRS-14

TROUBLE DIAGNOSIS

CONSULT-II Function

EHS000O6

DIAGNOSIS MODE FOR CONSULT-II

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result (also indicated by the number of warning lam](/img/5/57405/w960_57405-3015.png)

SRS-14

TROUBLE DIAGNOSIS

CONSULT-II Function

EHS000O6

DIAGNOSIS MODE FOR CONSULT-II

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-II screen in real time. This refers to a malfunctioning part requiring

repairs.

●“SELF-DIAG [PAST]”

Diagnosis results previously stored in the memory are displayed on the CONSULT-II screen. The stored

results are not erased until memory erasing is executed.

●“TROUBLE DIAG RECORD”

With TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-II screen.

●“ECU DISCRIMINATED NO.”

The diagnosis sensor unit for each vehicle model is assigned with its own, individual classification num-

ber. Refer to SRS-40, "

ECU DISCRIMINATED NO." This number will be displayed on the CONSULT-II

screen. When replacing the diagnosis sensor unit, refer to the part number for the compatibility. After

installation, replacement with a correct unit can be checked by confirming this classification number on the

CONSULT-II screen.

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

SRS803

SRS804

Page 3017 of 3833

![NISSAN X-TRAIL 2001 Service Service Manual TROUBLE DIAGNOSIS

SRS-15

C

D

E

F

G

I

J

K

L

MA

B

SRS

HOW TO ERASE SELF-DIAGNOSIS RESULTS

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result is displayed on the CONSULT-II screen in real time NISSAN X-TRAIL 2001 Service Service Manual TROUBLE DIAGNOSIS

SRS-15

C

D

E

F

G

I

J

K

L

MA

B

SRS

HOW TO ERASE SELF-DIAGNOSIS RESULTS

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result is displayed on the CONSULT-II screen in real time](/img/5/57405/w960_57405-3016.png)

TROUBLE DIAGNOSIS

SRS-15

C

D

E

F

G

I

J

K

L

MA

B

SRS

HOW TO ERASE SELF-DIAGNOSIS RESULTS

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result is displayed on the CONSULT-II screen in real time.

After the malfunction is repaired completely, no malfunction is detected on “SELF-DIAG [CURRENT]”.

●“SELF-DIAG [PAST]”

Return to the “SELF-DIAG [CURRENT]” CONSULT-II screen by touching “BACK” key of CONSULT-II and

select “SELF-DIAG [CURRENT]” in SELECT DIAG MODE. Touch “ERASE” in “SELF-DIAG [CURRENT]”

mode.

NOTE:

If the memory of the malfunction in “SELF-DIAG [PAST]” is not erased, the User mode shows the

system malfunction by the operation of the warning lamp even if the malfunction is repaired com-

pletely.

●“TROUBLE DIAG RECORD”

The memory of “TROUBLE DIAG RECORD” cannot be erased

Self-Diagnosis Function (Without CONSULT-II) EHS000O7

●The reading of these results is accomplished using one of two modes — “User mode” and “Diagnosis

mode”.

●After a malfunction is repaired, turn the ignition switch "OFF" for at least one second, the back "ON". Diag-

nosis mode returns to the User mode. At that time, the self-diagnostic result is cleared.

HOW TO CHANGE SELF-DIAGNOSIS MODE

HOW TO ERASE SELF-DIAGNOSIS RESULTS

After a malfunction is repaired, turn the ignition switch “OFF” for at least one second, then back “ON”. Diagno-

sis mode returns to the User mode. At that time, the self-diagnostic result is cleared.

SRS701

SHIA0183E