width NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 46 of 3833

GI-44

IDENTIFICATION INFORMATION

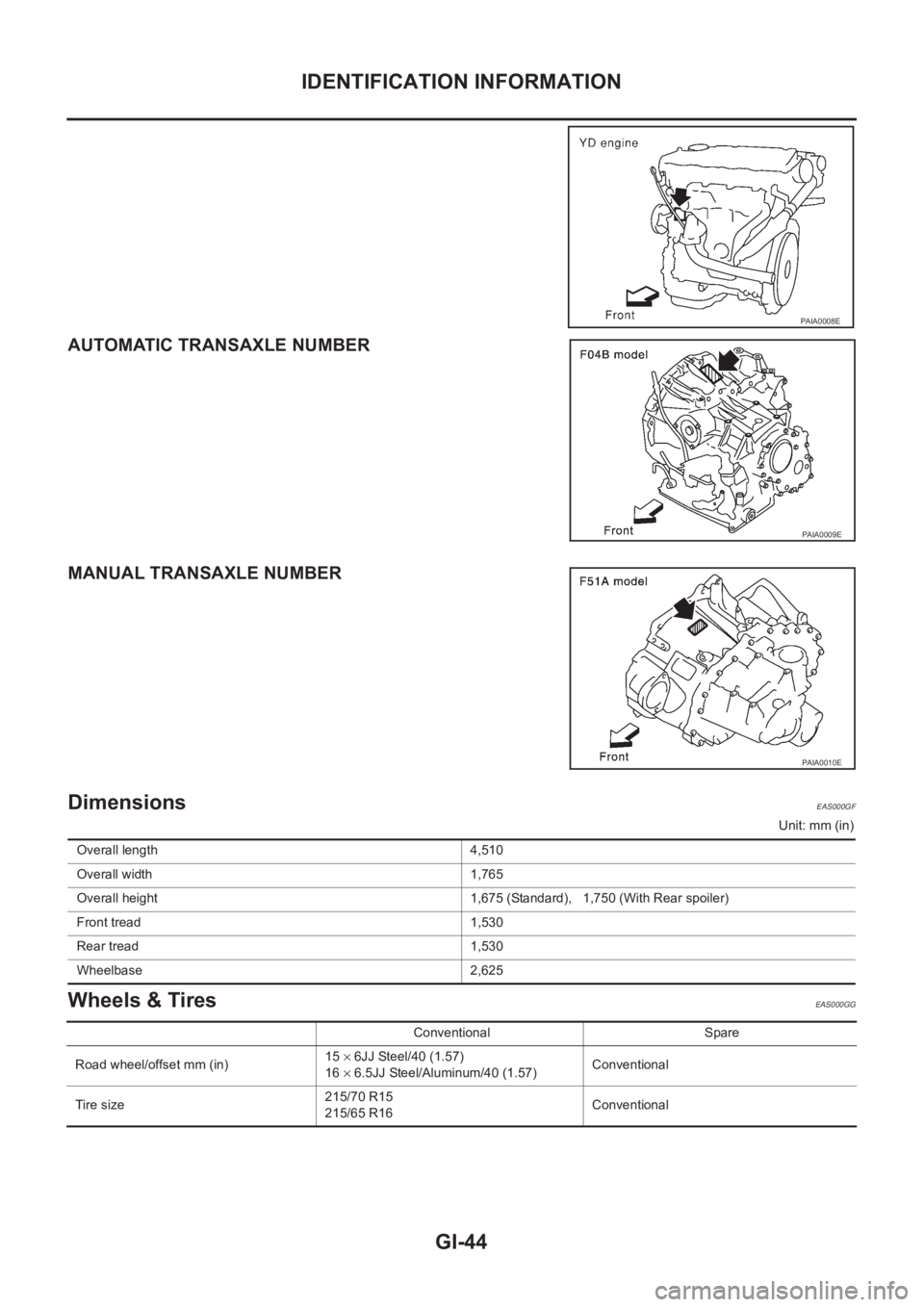

AUTOMATIC TRANSAXLE NUMBER

MANUAL TRANSAXLE NUMBER

Dimensions EAS000GF

Unit: mm (in)

Wheels & Tires EAS000GG

PAIA0008E

PAIA0009E

PAIA0010E

Overall length 4,510

Overall width 1,765

Overall height 1,675 (Standard), 1,750 (With Rear spoiler)

Front tread 1,530

Rear tread 1,530

Wheelbase 2,625

Conventional Spare

Road wheel/offset mm (in)15 × 6JJ Steel/40 (1.57)

16 × 6.5JJ Steel/Aluminum/40 (1.57)Conventional

Tir e s iz e215/70 R15

215/65 R16Conventional

Page 114 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-64

[QR]

CYLINDER HEAD

5. Install valve spring.

●Install smaller pitch (valve spring seat side) to cylinder head

side.

●Confirm identification color of valve spring.

6. Install valve sp NISSAN X-TRAIL 2001 Service Repair Manual EM-64

[QR]

CYLINDER HEAD

5. Install valve spring.

●Install smaller pitch (valve spring seat side) to cylinder head

side.

●Confirm identification color of valve spring.

6. Install valve sp](/img/5/57405/w960_57405-113.png)

EM-64

[QR]

CYLINDER HEAD

5. Install valve spring.

●Install smaller pitch (valve spring seat side) to cylinder head

side.

●Confirm identification color of valve spring.

6. Install valve spring retainer.

7. Install valve collet.

●Compress valve spring with valve spring compressor. Install

valve collet with magnet hand.

●Tap stem edge lightly with plastic hammer after installation to check its installed condition.

8. Install valve lifter.

9. Install spark plug tube.

●Press fit it into cylinder head as follows.

a. Remove old liquid gasket from cylinder head side mounting

hole.

b. Apply liquid gasket all round on spark plug tube with a 12 mm

(0.47 in) width from edge of spark plug tube on the press fit side.

Use Genuine Liquid gasket or equivalent.

c. Using a drift (commercial service tool), press fit spark plug tube

so that height is as same as H shown in figure.

CAUTION:

●When press fitting be careful not to deform spark plug tube.

●After press fitting, wipe off any protruding liquid gasket on top surface of cylinder head.

10. Install spark plug with spark plug wrench.

Inspection After DisassemblyEBS00KNS

CYLINDER HEAD DISTORTION

1. Wipe off engine oil and remove water scale (like deposit), gas-

ket, sealer, carbon, etc with scraper.

CAUTION:

Use utmost care not to allow gasket debris to enter pas-

sages for engine oil or water.

2. At each of several locations on bottom surface of cylinder head,

measure distortion in six directions.

VALVE DIMENSIONS

Check dimensions of each valve. For dimensions, refer to SDS, EM-

99, "Valve Dimensions" . Intake : Blue

Exhaust : Yellow

Press fit height “H” standard value:

38.55 - 38.65 mm (1.518 - 1.522 in)

PBIC0525E

SBIA0252E

Standard: 0.1mm (0.004 in)

PBIC0075E

SEM188A

Page 145 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-95

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CRANKSHAFT RUNOUT

●Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

●Place a dial gauge strai NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-95

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CRANKSHAFT RUNOUT

●Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

●Place a dial gauge strai](/img/5/57405/w960_57405-144.png)

CYLINDER BLOCK

EM-95

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CRANKSHAFT RUNOUT

●Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

●Place a dial gauge straight up on the No. 3 journal.

●While rotating the crankshaft, read the movement of the pointer

on the dial gauge. (Total indicator reading)

CONNECTING ROD BEARING OIL CLEARANCE

Method of Measurement

●Install the connecting rod bearings to the connecting rod and the

cap, and tighten the connecting rod bolts to the specified torque.

Using a inside micrometer measure the inner diameter of con-

necting rod bearing.

(Oil clearance) = (Inner diameter of connecting rod bearing) –

(Outer diameter of crankshaft pin)

●If out of specifications, check connecting rod big end inner diam-

eter and crankshaft pin outer diameter, and select appropriate

connecting rod bearing to adjust clearance to specifications.

Refer to EM-83, "

HOW TO SELECT CONNECTING ROD BEARING" .

Method of Using Plastigage

●Remove engine oil and dust on the crankshaft pin and the sur-

faces of each bearing completely.

●Cut a plastigage slightly shorter than the bearing width, and

place it in crankshaft axial direction, avoiding oil holes.

●Install the connecting rod bearings to the connecting rod cap,

and tighten the connecting rod bolts to the specified torque.

CAUTION:

Never rotate the crankshaft.

●Remove the connecting rod cap and bearings, and using the

scale on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is same as that described in “Method of Mea-

surement”.

MAIN BEARING OIL CLEARANCE

Method of Measurement

●Install the main bearings to the cylinder block and bearing cap. Measure the main bearing inner diameter

with the bearing cap bolt tightened to the specified torque.

(Oil clearance) = (Inner diameter of main bearing) – (Outer diameter of crankshaft journal)

●If out of specification, check main bearing housing inner diameter and crankshaft journal outer diameter,

and select appropriate main bearing to adjust clearance to specifications. Refer to EM-85, "

HOW TO

SELECT MAIN BEARING" . Limit: Less than 0.05 mm (0.002 in)

PBIC0271E

Standard : 0.028 - 0.045 mm (0.0011 - 0.0018 in)

Limit : 0.10 mm (0.0039 in)

PBIC0119E

EM142

Standard

No. 1, 3 and 5 journals : 0.012 - 0.022 mm (0.0005 - 0.0009 in)

No. 2 and 4 journals : 0.018 - 0.028 mm (0.0007 - 0.0011 in)

Limit : 0.1 mm (0.004 in)

Page 146 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-96

[QR]

CYLINDER BLOCK

Method of Using Plastigage

●Remove engine oil and dust on the crankshaft journal and the

surfaces of each bearing completely.

●Cut a plastigage slightly sh NISSAN X-TRAIL 2001 Service Repair Manual EM-96

[QR]

CYLINDER BLOCK

Method of Using Plastigage

●Remove engine oil and dust on the crankshaft journal and the

surfaces of each bearing completely.

●Cut a plastigage slightly sh](/img/5/57405/w960_57405-145.png)

EM-96

[QR]

CYLINDER BLOCK

Method of Using Plastigage

●Remove engine oil and dust on the crankshaft journal and the

surfaces of each bearing completely.

●Cut a plastigage slightly shorter than the bearing width, and

place it in crankshaft axial direction, avoiding oil holes.

●Tighten the main bearing bolts to the specified torque.

CAUTION:

Never rotate the crankshaft.

●Remove the bearing cap and bearings, and using the scale on

the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in “Method of Measurement”.

MAIN BEARING CRUSH HEIGHT

●When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of bear-

ing must protrude.

●If the standard is not met, replace main bearings.

OUTER DIAMETER OF LOWER CYLINDER BLOCK MOUNTING BOLT

●Perform only with M10 (0.39 in) bolts.

●Measure outer diameters (d1, d2) at two positions shown in the figure.

●Measure d2 at a point within block A.

●When the value of d1- d2 exceeds the limit (a large difference in

dimensions), replace the bolt with a new one.

OUTER DIAMETER OF CONNECTING ROD BOLT

●Measure outer diameter (d) at position shown in the figure.

●When “d ” exceeds the limit (when it becomes thinner), replace

the bolt with a new one.

EM142

Standard: There must be crush height.

SEM502G

Limit: 0.13 mm (0.0051 in) or more.

SBIA0285E

Limit: 7.75 mm (0.3051 in) or less.

SBIA0286E

Page 266 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-216

[YD22DDTi]

CYLINDER BLOCK

CRANKSHAFT RUNOUT

●Place V-block onto surface plate to support journals at both ends

of crankshaft.

●Position dial indicator vertically onto No. 3 journal.

●Rota NISSAN X-TRAIL 2001 Service Repair Manual EM-216

[YD22DDTi]

CYLINDER BLOCK

CRANKSHAFT RUNOUT

●Place V-block onto surface plate to support journals at both ends

of crankshaft.

●Position dial indicator vertically onto No. 3 journal.

●Rota](/img/5/57405/w960_57405-265.png)

EM-216

[YD22DDTi]

CYLINDER BLOCK

CRANKSHAFT RUNOUT

●Place V-block onto surface plate to support journals at both ends

of crankshaft.

●Position dial indicator vertically onto No. 3 journal.

●Rotate crankshaft to read needle movement on dial indicator.

(Total indicator reading)

CONNECTING ROD BEARING OIL CLEARANCE

Method by Measurement

●Install connecting rod bearings to connecting rod and cap, and

tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

(Bearing clearance) = (Connecting rod bearing inner diameter) −

(Crankshaft pin outer diameter)

●If out of specifications, check connecting rod big end inner diam-

eter and crankshaft pin outer diameter, and select appropriate

connecting rod bearing to adjust clearance to specifications.

Refer to EM-207, "

HOW TO SELECT CONNECTING ROD

BEARING" .

Method Using Plastigage

●Remove contamination such as engine oil, dust completely from

crankshaft pins and each bearing surface.

●Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

●Install connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

●Remove connecting rod caps and bearings, and measure plasti-

gage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in “Method by Measurement”.

MAIN BEARING OIL CLEARANCE

Method by Measurement

●Install main bearings to the cylinder block and bearing cap, and tighten the bolts to the specified torque.

Then, measure the inner diameter of the main bearings.

(Bearing clearance) = (Bearing inner diameter) − (Crankshaft journal outer diameter)

●If out of specification, check main bearing housing inner diameter and crankshaft journal outer diameter,

and select appropriate main bearing to adjust clearance to specifications. Refer to EM-208, "

HOW TO

SELECT MAIN BEARING" . Standard : 0.05 mm (0.0020 in)

Limit : 0.10 mm (0.0039 in)

FEM116

Standard : 0.031 - 0.061 mm (0.0012 - 0.0024 in)

PBIC0119E

EM142

Standard : 0.039 - 0.066 mm (0.0015 - 0.0026 in)

Page 267 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-217

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Method Using Plastigage

●Remove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surf NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-217

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Method Using Plastigage

●Remove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surf](/img/5/57405/w960_57405-266.png)

CYLINDER BLOCK

EM-217

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Method Using Plastigage

●Remove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surface.

●Cut plastigage slightly shorter than bearing width. Place it in

crankshaft turning direction, avoiding oil holes.

●Install main bearings and bearing cap and tighten to the speci-

fied torque.

CAUTION:

Never rotate crankshaft.

●Remove main bearings and bearing caps, and measure plasti-

gage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in “Method by Measurement”.

MAIN BEARING CRUSH HEIGHT

●When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of bear-

ing must protrude.

●If out of specification, replace main bearings.

MAIN BEARING CAP BOLT DEFORMATION

●Measure the outer diameter of threaded area, d1 and d2, at the

points specified in the figure.

●When the necked point is identified at a point other than where

specified, measure at the point as d2.

●Calculate the difference between d1 and d2.

CONNECTING ROD BOLT DEFORMATION

●Install nuts to connecting rod bolts. Check that the nut can be

screwed smoothly on bolt threads by hand to the last thread on

the bolt.

●If the nut does not screw in smoothly, measure the outer diame-

ter of the bolt thread at the point specified in the figure.

●If a necked point is identified, measure at that point.

●If the measurement exceeds the limit, replace connecting rod

bolts and nuts.

EM142

Standard : Crush height must exist.

SEM502G

Limit : 0.13 mm (0.0051 in)

JEM219G

Standard : 8.90 - 9.00 mm (0.3504 - 0.3543 in) dia.

Limit : 8.75 mm (0. 3445 in) dia.

JEM220G

Page 278 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-228

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

AVAILABLE MAIN BEARING

Main bearing

Unit: mm (in)

Under size

Unit: mm (in)

AVAILABLE CONNECTING ROD BEARING

Connecting Rod Bearing

Unit: mm (in NISSAN X-TRAIL 2001 Service Repair Manual EM-228

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

AVAILABLE MAIN BEARING

Main bearing

Unit: mm (in)

Under size

Unit: mm (in)

AVAILABLE CONNECTING ROD BEARING

Connecting Rod Bearing

Unit: mm (in](/img/5/57405/w960_57405-277.png)

EM-228

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

AVAILABLE MAIN BEARING

Main bearing

Unit: mm (in)

Under size

Unit: mm (in)

AVAILABLE CONNECTING ROD BEARING

Connecting Rod Bearing

Unit: mm (in)

Under size

Unit: mm (in)

MISCELLANEOUS COMPONENTS

Flywheel

Unit: mm (in)

*: Total indicator reading Grade number Thickness “T” Width “W” Identification color

0 1.816 - 1.820 (0.0715 - 0.0717)

19.9 - 20.1 (0.783 - 0.791)Black

1 1.820 - 1.824 (0.0717 - 0.0718) Brown

2 1.824 - 1.828 (0.0718 - 0.0720) Green

3 1.828 - 1.832 (0.0720 - 0.0721) Yellow

4 1.832 - 1.836 (0.0721 - 0.0723) Blue

SEM255G

Size Thickness Main journal diameter “Dm”

0.25 (0.0098) 1.949 - 1.953 (0.0767 - 0.0769)Grind so that bearing clearance is the

specified value.

Grade number Thickness “T” Width “W” Identification color (mark)

0 1.492 - 1.496 (0.0587 - 0.0589)

22.9 - 23.1

(0.902 - 0.909)Black

1 1.496 - 1.500 (0.0589 - 0.0591) Brown

2 1.500 - 1.504 (0.0591 - 0.0592) Green

Size Thickness Crank pin journal diameter “Dp”

0.08 (0.0031) 1.536 - 1.540 (0.0605 - 0.0606)

Grind so that bearing clearance is the

specified value. 0.12 (0.0047) 1.556 - 1.560 (0.0613 - 0.0614)

0.25 (0.0098) 1.621 - 1.625 (0.0638 - 0.0640)

Flywheel runout [TIR]*Standard 0.45 (0.0177) or less

Limit 1.3 (0.051) or less

Page 300 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual LU-20

[YD22DDTi]

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS00B05

REMOVAL

CAUTION:

●Be careful not to get burned when the engine and engine oil

are hot.

●When removing, prepare a s NISSAN X-TRAIL 2001 Service Repair Manual LU-20

[YD22DDTi]

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS00B05

REMOVAL

CAUTION:

●Be careful not to get burned when the engine and engine oil

are hot.

●When removing, prepare a s](/img/5/57405/w960_57405-299.png)

LU-20

[YD22DDTi]

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS00B05

REMOVAL

CAUTION:

●Be careful not to get burned when the engine and engine oil

are hot.

●When removing, prepare a shop cloth to absorb any engine

oil leakage or spillage.

●Do not allow engine oil to adhere to the drive belts.

●Completely wipe off any engine oil that adhere to the engine

and the vehicle.

1. Using a socket wrench [plane-to-plane width: 17 mm (0.67 in)],

loosen the filter body approximately four turns.

2. Drain the engine oil after matching the "DRAIN" arrow mark at

the bottom of the filter body to the protrusion on the oil filter

bracket.

●Catch the engine oil with a pan or cloth.

CAUTION:

●The drained engine oil flows over the right surface of

the filter body.

●Completely wipe clean any engine oil remaining on the

filter body or vehicle.

3. Remove the filter body, then remove the oil filter.

PBIC1248E

JLC290B

JLC291B

Page 384 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-34

[QR25(WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJ NISSAN X-TRAIL 2001 Service Repair Manual EC-34

[QR25(WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJ](/img/5/57405/w960_57405-383.png)

EC-34

[QR25(WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

●During warm-up

●When starting the engine

●During acceleration

●Hot-engine operation

●When selector lever is changed from “N” to “D”

●High-load, high-speed operation

●During deceleration

●During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses

heated oxygen sensor 1 in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about heated

oxygen sensor 1, refer to EC-163

. This maintains the mixture ratio within the range of stoichiometric (ideal air-

fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of heated oxygen sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

●Deceleration and acceleration

●High-load, high-speed operation

●Malfunction of heated oxygen sensor 1 or its circuit

●Insufficient activation of heated oxygen sensor 1 at low engine coolant temperature

●High engine coolant temperature

●During warm-up

●After shifting from “N” to “D”

●When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from heated oxygen

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as orig-

PBIB0121E

Page 385 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ENGINE CONTROL SYSTEM

EC-35

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during oper NISSAN X-TRAIL 2001 Service Repair Manual ENGINE CONTROL SYSTEM

EC-35

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during oper](/img/5/57405/w960_57405-384.png)

ENGINE CONTROL SYSTEM

EC-35

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from heated oxygen sensor 1 indicates whether the mixture ratio is RICH or LEAN compared

to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an

increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Electronic Ignition (EI) SystemEBS00M0D

INPUT/OUTPUT SIGNAL CHART

SEF337W

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS)

Engine speed

Piston position

Ignition

timing con-

trolPower transistor Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Ignition switch Start signal

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Battery Battery voltage

Wheel sensor Vehicle speed