steering wheel adjustment NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2612 of 3833

TF-2

SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP

GOES OUT) ........................................................ 56

HEAVY TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS

TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED ......................................... 56

4WD MODES CANNOT BE SWITCHED AFTER

ENGINE IS STARTED ......................................... 57

WHILE DRIVING, 4WD WARNING LAMP

FLASHES RAPIDLY. (WHEN IT FLASHERS FOR

APPROX. ONE MINUTE, THEN DOES NOT

ILLUMINATE.) ..................................................... 57

WHILE DRIVING, 4WD WARNING LAMP

FLASHES SLOWLY. (WHEN IT CONTINUES TO

ILLUMINATE UNTIL ENGINE TURNS OFF.) ...... 57

VEHICLE DOES NOT ENTER 4WD MODE EVEN THOUGH 4WD WARNING LAMP IS OFF. ... 58

TIGHT-CONER BRAKING SYMPTOM OCCURS

WHEN THE VEHICLE IS STARTED IN AUTO

WARNING LAMP REMAIN OFF). ....................... 58

4WD ACTUATOR RELAY (4WD SOLENOID

ACTUATOR RELAY) TURNS ON/OFF FRE-

QUENTLY ............................................................ 58

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 59

General Specifications ......................................... ... 59

Inspection and Adjustment ...................................... 59

PRELOAD TORQUE BEFORE DISASSEMBLY ... 59

PRELOAD TORQUE AFTER DISASSEMBLY

AND REASSEMBLY ............................................ 59

BACKLSH ............................................................ 59

COMPANION FLANGE RUNOUT ....................... 59

SELECTIVE PARTS ............................................ 59

PINION SLEEVE SHIM ........................................ 60

Page 2786 of 3833

BRC-2

4WD ACTUATOR RELAY (4WD SOLENOID

A C T U AT O R R E L AY ) T U R N S O N / O F F F R E -

QUENTLY ............................................................ 42

ABS Warning Lamp Does Not Illuminate. (ABS

Warning Lamp Does Not Come On When The Igni-

tion Switch Is Turned ON.) ...................................... 42

ABS Warning Lamp Illuminates With Ignition ON,

But Does Not Illuminates After A Few Seconds.

(ABS Warning Lamp Has Illuminated.) ................... 42

4WD Warning Lamp Does Not Illuminate With Igni-

tion ON. .................................................................. 43

4WD Warning Lamp Does Not Go Out Several Sec-

onds After Engine Is Started. (Drive Mode Indicator

Lamp Goes Out.) .................................................... 43

Heavy Tight-corner Braking Symptom Occurs

When The Vehicle Is Driven In Auto Mode And The

Steering Wheel Is Turned Fully To Either Side After

The Engine Is Started. ............................................ 44

Drive Modes Cannot Be Switched After Engine Is

Started. ................................................................... 45

Wheel Driving, 4WD Warning Lamp Flashes Rap-

idly. (When It Flashes For Approx. One Minute, Then

Does Not Illuminate.) .............................................. 45

Wheel Driving, 4WD Warning Lamp Flashes Slowly.

(When It Continues To Illuminate Until Engine Turns

OFF.) ....................................................................... 45

Vehicle Does Not Enter 4WD Mode Even Though

4WD Warning Lamp Is OFF. ................................... 46

Tight-corner Braking Symptom Occurs When The

Vehicle Is Started In Auto Mode (4WD Warning

Lamp Remain OFF). ............................................... 46

E-TS Actuator Relay (4WD Solenoid Actuator

Relay) Turns ON/OFF Frequently. .......................... 46

Inspection Of Drive Mode Change-over Switch Path ... 47

4WD/ABS CONTROL UNIT ...................................... 48

Removal and Installation ........................................ 48

REMOVAL ........................................................... 48

INSTALLATION .................................................... 48

WHEEL SENSORS ................................................... 49

Removal and Installation ........................................ 49

G-SENSOR (4WD MODEL ONLY) ............................ 50

Removal and Installation ........................................ 50

SENSOR ROTOR ................................................... ... 51

Removal and Installation ........................................ 51

REMOVAL ........................................................... 51

INSTALLATION .................................................... 51

ACTUATOR ............................................................... 52

Removal and Installation ........................................ 52

REMOVAL ........................................................... 53

INSTALLATION .................................................... 53

ESP/TCS/ABS

PRECAUTIONS ......................................................... 54

Precautions for Brake System ................................ 54

Precautions for Brake Control ................................ 54

Precautions for CAN System .................................. 54

FOR INSPECTION .............................................. 54

FOR HARNESS REPAIR .................................... 55PREPARATION ......................................................... 56

Special Service Tool ................................................ 56

Commercial Service Tool ........................................ 56

ON-VEHICLE SERVICE ............................................ 57

Adjustment of Neutral Position of Steering Wheel

Angle Sensor .......................................................... 57

GENERAL INFORMATION ....................................... 59

Fail-Safe .................................................................. 59

ABS SYSTEM ...................................................... 59

ESP/TCS SYSTEM .............................................. 59

Hydraulic Circuit ...................................................... 59

ABS Functions ........................................................ 59

TCS Functions ........................................................ 60

ESP Functions ........................................................ 60

System Diagram ..................................................... 61

CAN COMMUNICATION ........................................... 62

System Description ................................................. 62

FOR A/T MODELS ............................................... 62

FOR M/T MODELS .............................................. 62

TROUBLE DIAGNOSIS ............................................ 64

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ...................................................... 64

INTRODUCTION ................................................. 64

WORK FLOW ...................................................... 65

ASKING COMPLAINTS ....................................... 66

EXAMPLE OF DIAGNOSIS SHEET .................... 66

Component Parts and Harness Connector Location ... 67

Schematic ............................................................... 68

Wiring Diagram —ESP/TCS/ABS— ..................... 69

Control Unit Input/Output Signal Standard .............. 75

STANDARDS USING A CIRCUIT TESTER AND

OSCILLOSCOPE ................................................. 75

STANDARDS WITH CONSULT-II ........................ 78

Functions of CONSULT-II ....................................... 80

CONSULT-II MAINLY FUNCTION APPLICA-

TION TO ESP/TCS/ABS ...................................... 80

SELF-DIAGNOSIS ............................................... 81

DATA MONITOR .................................................. 83

ACTIVE TEST ...................................................... 87

For Correct and Quick Diagnosis ............................ 90

PRECAUTIONS FOR TROUBLE DIAGNOSIS ... 90

Basic Inspection ...................................................... 91

PRELIMINARY CHECK 1: (BRAKE FLUID

LEVEL AND LEAK INSPECTION) ....................... 91

PRELIMINARY CHECK 2: (INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL) ............... 92

PRELIMINARY CHECK 3: (INSPECTION FOR

ABS WARNING LAMP, ESP OFF INDICATOR

LAMP, AND SLIP INDICATOR LAMP) ................. 92

Inspection 1 Wheel Sensor and Circuit ................... 92

Inspection 2 Engine System ................................... 94

Inspection 3 ESP/TCS/ABS Control Unit System ... 94

Inspection 4 Pressure Sensor and the Circuit

between Pressure Sensor and ESP/TCS/ABS Con-

trol Unit. ................................................................... 95

Inspection 5 Steering wheel Angle Sensor and the

Circuit between Steering Wheel Angle Sensor and

ESP/TCS/ABS Control Unit. ................................... 96

Inspection 6 Yaw Rate Sensor and Side G sensor

Page 2841 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ON-VEHICLE SERVICE

BRC-57

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

ON-VEHICLE SERVICEPFP:00000

Adjustment of Neutral Position of Steering Wheel Angle SensorEFS0019R

●After removing/installing or r NISSAN X-TRAIL 2001 Service Repair Manual ON-VEHICLE SERVICE

BRC-57

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

ON-VEHICLE SERVICEPFP:00000

Adjustment of Neutral Position of Steering Wheel Angle SensorEFS0019R

●After removing/installing or r](/img/5/57405/w960_57405-2840.png)

ON-VEHICLE SERVICE

BRC-57

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

ON-VEHICLE SERVICEPFP:00000

Adjustment of Neutral Position of Steering Wheel Angle SensorEFS0019R

●After removing/installing or replacing the ESP/TCS/ABS control unit, steering wheel angle sensor, steer-

ing components, suspension components, and tires, or after adjusting the wheel alignment, make sure to

adjust the neutral position of the steering wheel angle sensor before running the vehicle.

CAUTION:

To adjust the neutral position of the steering wheel angle sensor, make sure to use CONSULT-II.

(Adjustment cannot be done other than CONSULT-II.)

1. Stop the vehicle with the front wheels in the straight-ahead position.

2. Connect CONSULT-II to data link connector on the vehicle, and

turn the ignition switch to ON position (engine not running).

3. Touch “START”, “ABS”, “WORK SUPPORT” and “ST ANGLE

SENSOR ADJUSTMENT” on the CONSULT-II screen in this

order.

PBIB0196E

SFIA0364E

SFIA0365E

SFIA0370E

Page 2874 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual BRC-90

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

ABS Warning Lamp

Touch “ON” and “OFF”on the “ABS WARNING LAMP” screen to check that the ABS warning lamp operates as

follows.

NOTE:

During the active NISSAN X-TRAIL 2001 Service Repair Manual BRC-90

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

ABS Warning Lamp

Touch “ON” and “OFF”on the “ABS WARNING LAMP” screen to check that the ABS warning lamp operates as

follows.

NOTE:

During the active](/img/5/57405/w960_57405-2873.png)

BRC-90

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

ABS Warning Lamp

Touch “ON” and “OFF”on the “ABS WARNING LAMP” screen to check that the ABS warning lamp operates as

follows.

NOTE:

During the active test when “OFF” on the “ABS WARNING LAMP” screen is touched, all of the ESP OFF indi-

cator lamp, SLIP indicator lamp, and ABS warning lamp flash once. This is not abnormal.

For Correct and Quick DiagnosisEFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

●Before performing the trouble diagnosis, always read the GI-3, "PRECAUTIONS" to confirm the general

precautions.

●After replacement of ESP/TCS/ABS control unit, steering wheel angle sensor, steering parts, suspension

parts, or tires, and adjustment of alignment, always adjust the neutral position of steering wheel angle

sensor before driving.

●When the ESP/TCS/ABS control unit is replaced, check that the label on the computer unit is identical

color.

●After completing the trouble diagnosis, always erase the malfunctioning memory. Refer to BRC-81, "Pro-

cedure" .

●When inspection of the continuity or voltage between units is performed, check the connector terminals for

disconnection, looseness, bend, or collapse. If any malfunction is detected, repair or replace the applica-

ble part.

●Intermittent problems may be caused by a malfunction on harness, connector, or terminal. Move the har-

nesses, harness connectors, or terminals by hand to make sure that there is no contact malfunction.

●If a circuit tester is used for the check, be careful not to forcibly extend any connector terminal.

●For self-diagnosis, active test, and work support of ESP/TCS/ABS control unit with CONSULT-II, stop and

connect CONSULT-II and select “ABS”.

●CONSULT-II self-diagnosis results are displayed without regard to occurrence timing. In some case, the

later ones (timing value is small) appear on the next screen.

●While the self-diagnosis results of CONSULT-II shows a malfunction, if CONSULT-II active test is per-

formed, an engine system malfunction may be indicated. In this case, start the engine to resume the nor-

mal screen.

●ESP/TCS/ABS system electronically controls the brake operation and engine output. The following symp-

toms may be caused by the normal operations.

Operation ON OFF

ABS WARNING LAMP ON (Lamp ON) OFF (Lamp OFF)

Symptom Symptom description Result

Motor operation noiseDuring ESP, TCS, or ABS operation, sometimes a faint noise can be

heard. This is a motor operation noise in the ESP actuator.

Normal

Just after the engine starts, the motor operating noise may be heard.

This is a normal status of the system operation check.

System operation check

noiseWhen the engine starts, a“click” noise may be heard from the engine

compartment. This is a normal status of the system operation check.Normal

Page 2881 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

BRC-97

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.STEERING WHEEL ANGLE SENSOR CIRCUIT CHECK

1. Disconnect the ESP/TCS/ABS control unit connector and the steering wheel angle sensor c NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

BRC-97

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.STEERING WHEEL ANGLE SENSOR CIRCUIT CHECK

1. Disconnect the ESP/TCS/ABS control unit connector and the steering wheel angle sensor c](/img/5/57405/w960_57405-2880.png)

TROUBLE DIAGNOSIS

BRC-97

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.STEERING WHEEL ANGLE SENSOR CIRCUIT CHECK

1. Disconnect the ESP/TCS/ABS control unit connector and the steering wheel angle sensor connector.

2. Check for continuity between the ESP/TCS/ABS control unit

(vehicle-side connector B111) and the steering wheel angle sen-

sor (vehicle-side connector M81).

3. Check for continuity between the steering wheel angle sensor

and ground.

Is inspection result OK?

YES >> GO TO 4.

NO >> Repair or replace the disconnected harness.

4.DATA MONITOR CHECK

Perform the “STR ANGLE SIG” value in “DATA MONITOR” and check that it is in normal condition.

Is inspection result OK?

YES >> Perform the ESP/TCS/ABS control unit self-diagnosis again.

NO >> Replace the spiral cable (with the steering wheel angle sensor) and adjust the neutral position of

steering wheel angle sensor. BRC-57, "

Adjustment of Neutral Position of Steering Wheel Angle

Sensor" .

SFIA0899E

ESP/TCS/ABS control unit

(Vehicle-side connector B111)Steering wheel angle sensor

(Vehicle-side connector M81)Continuity

2 (Y/R) 3 (Y/R) Yes

SFIA0898E

Steering wheel angle sensor

(Vehicle-side connector M81)ground Continuity

2 (B) — Yes

Steering condition STR ANGLE SIG (Data monitor)

Straight-ahead – 5 deg to + 5 deg

Tun the wheel to the right by 90°Approx. + 90 deg

Tun the wheel to the left by 90°Approx. – 90 deg

Page 2892 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual BRC-108

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

5. ESP/TCS/ABS CONTROL UNIT POWER SUPPLY CIRCUIT INSPECTION 2

1. Check the fuse 10A.

2. Check for continuity between the battery positive terminal and

t NISSAN X-TRAIL 2001 Service Repair Manual BRC-108

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

5. ESP/TCS/ABS CONTROL UNIT POWER SUPPLY CIRCUIT INSPECTION 2

1. Check the fuse 10A.

2. Check for continuity between the battery positive terminal and

t](/img/5/57405/w960_57405-2891.png)

BRC-108

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

5. ESP/TCS/ABS CONTROL UNIT POWER SUPPLY CIRCUIT INSPECTION 2

1. Check the fuse 10A.

2. Check for continuity between the battery positive terminal and

the ESP/TCS/ABS control unit (vehicle-side connector B111).

Is inspection result OK?

YES >> Check the battery for a loose terminal and low voltage or the alternator for abnormality.

NO >>

●Replace the fuse 10A.

●Harness disconnection

Inspection 12 When “EMERGENCY BRAKE” is indicated in the Self-Diagnosis

Results

EFS001AO

Inspection procedure

1. SELF-DIAGNOSIS RESULT CHECK

Check the self-diagnosis results.

When any items other than “EMERGENCY BRAKE” is displayed in the self-diagnosis results, follow the

instructions below.

CAUTION:

“EMERGENCY BRAKE” is indicated when the control unit itself is detected internal error. If this dis-

play item was indicated, replace the control unit.

Is

“EMERGENCY BRAKE” is indicated in the self-diagnosis results?

>> Replace the ESP/TCS/ABS control unit, and perform the self-diagnosis again.

Inspection 13 When “ST ANG SEN SIGNAL” is Indicated in the Self-Diagnosis

Results

EFS001AP

Inspection procedure

1. SELF-DIAGNOSIS RESULT CHECK 1

Check the self-diagnosis results.

When any items other than

“ST ANGLE SEN SIGNAL” is displayed in the self-diagnosis results:

YES >> Check and repair the applicable items. Perform the self-diagnosis again.

NO >> Perform the steering wheel angle sensor neutral position adjustment. GO TO 2.

SFIA0924E

ESP/TCS/ABS control unit

(Vehicle-side connector B111)Battery terminal Continuity

1 (G/R) positive Yes

Self-diagnosis results

CONSUL-II indication item

EMERGENCY BRAKE

Self-diagnosis results

CONSUL-II indication item

ST ANGLE SEN SIGNAL

Page 2893 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

BRC-109

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

2.SELF-DIAGNOSIS RESULT CHECK 2

Turn the ignition switch OFF, and ON to erase the self-diagnosis results. And perform the ESP/TCS/ABS NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

BRC-109

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

2.SELF-DIAGNOSIS RESULT CHECK 2

Turn the ignition switch OFF, and ON to erase the self-diagnosis results. And perform the ESP/TCS/ABS](/img/5/57405/w960_57405-2892.png)

TROUBLE DIAGNOSIS

BRC-109

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

2.SELF-DIAGNOSIS RESULT CHECK 2

Turn the ignition switch OFF, and ON to erase the self-diagnosis results. And perform the ESP/TCS/ABS con-

trol unit self-diagnosis again.

Is the same self-diagnosis item indicated again?

YES >> After replacing the spiral cable (with the steering wheel angle sensor), perform the neutral position

adjustment. Then conduct the self-diagnosis again.

NO >> Inspection End

Inspection 14 Brake Fluid Level of Reservoir Tank, Communication Circuit

between ESP/TCS/ABS Control Unit and Brake Fluid Level Warning Switch

EFS001AQ

Inspection procedure

1.SELF-DIAGNOSIS RESULT CHECK 1

Check the self-diagnosis results.

Does the brake warning light turn on?

YES >> Check the pad for wear. Check the brake fluid for leakage.

NO >> GO TO 2.

2.SELF-DIAGNOSIS RESULT CHECK 2

1. Disconnect connectors for the brake fluid level warning switch and the ESP/TCS/ABS control unit.

2. Securely connect connectors. Perform the ESP/TCS/ABS control unit self-diagnosis again.

Is the same self-diagnosis item indicated again?

YES >> GO TO 3.

NO >> Poor connection of connector. Repair or replace the poorly connected connector.

3.CIRCUIT CHECK BETWEEN BRAKE FLUID LEVEL WARNING SWITCH AND ESP/TCS/ABS CON-

TROL UNIT

1. Disconnect connectors for the brake fluid level warning switch

and the ESP/TCS/ABS control unit.

2. Check for continuity between the brake fluid level warning switch (vehicle-side connector E19) and the

ESP/TCS/ABS control unit (vehicle-side connector B111).

Is inspection result OK?

YES >> Perform the ESP/TCS/ABS control unit self-diagnosis again.

NO >> Repair or replace the disconnected harness.

Self-diagnosis results

CONSUL-II indication item

BR FLUID LEVER LOW

SFIA0925E

ESP/TCS/ABS control unit

(Vehicle-side connector B111)Brake fluid level warning switch

(Vehicle-side connector E19)Continuity

40 (Y/B) 1 (Y/B) Yes

Page 2917 of 3833

STEERING WHEEL

PS-7

C

D

E

F

H

I

J

K

L

MA

B

PS

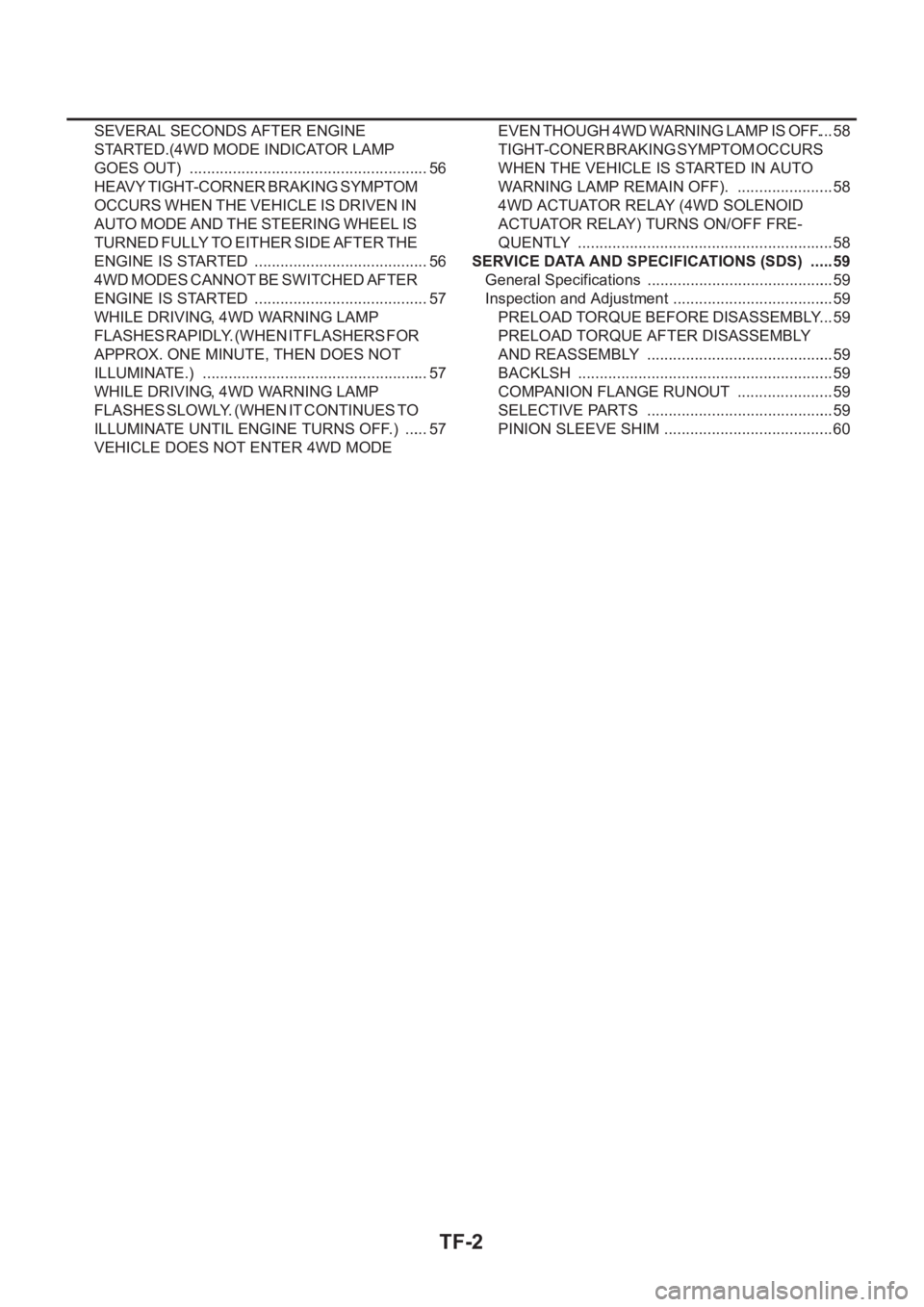

●Start engine. With engine at idle, turn steering wheel from stop

to stop and measure steering angles.

●If angles are outside specification, measure rack stroke.

●If rack stroke is outside of specification, disassemble steering

gear to check rack stroke.

●Steering angles are not adjustable. If any of steering angles is different from specified value, check steer-

ing gear, the column and the front suspension components for wear or damage. If any abnormality exists,

replace the malfunctioning parts.

Removal and InstallationEGS0004F

REMOVAL

1. Remove air bag module. Refer to SRS-29, "DRIVER AIR BAG MODULE" .

2. Remove horn connector.

3. Remove steering wheel mounting nut and paint mating marks on steering wheel body and top of column

shaft.

4. Using a steering wheel puller, remove steering wheel.

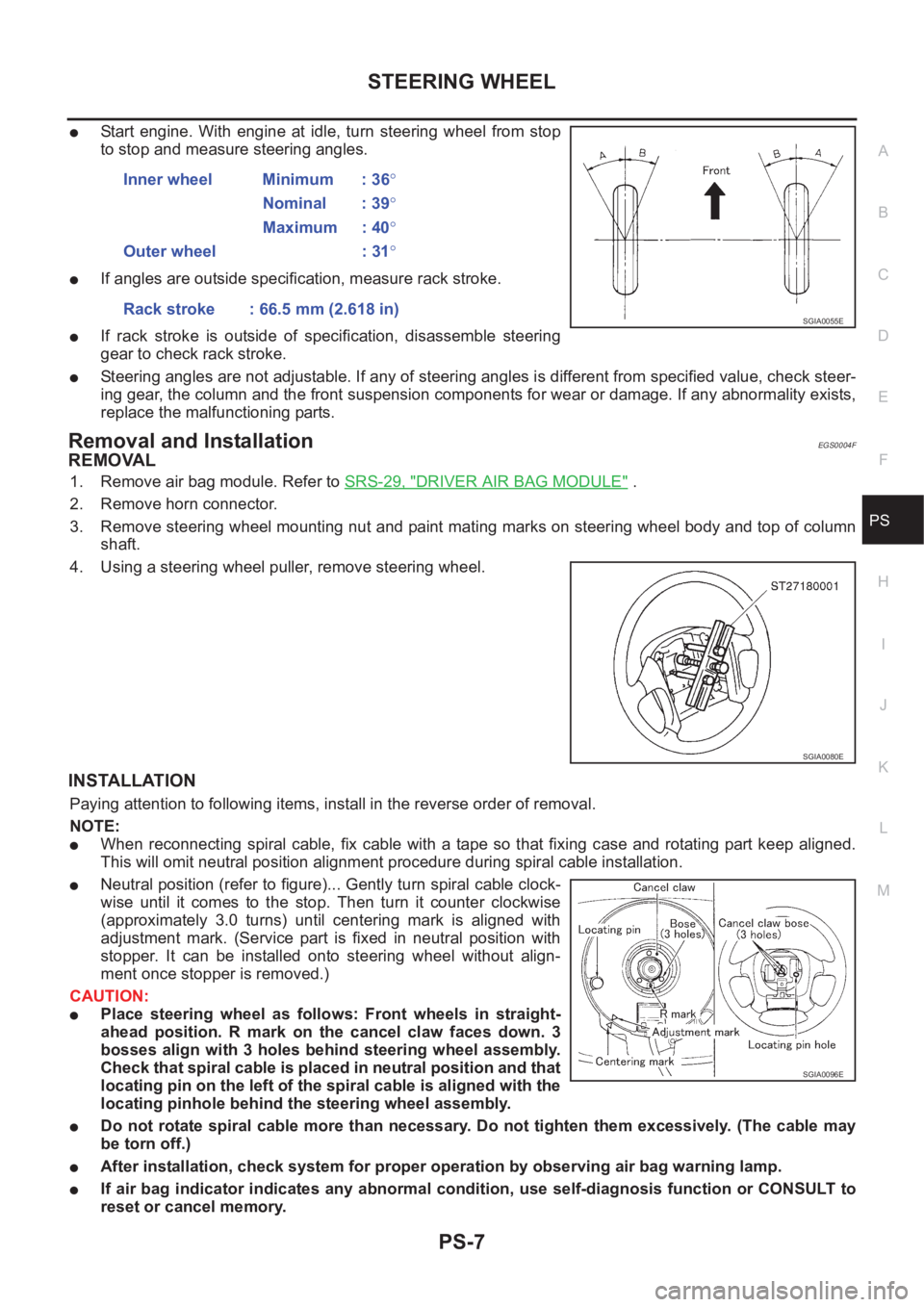

INSTALLATION

Paying attention to following items, install in the reverse order of removal.

NOTE:

●When reconnecting spiral cable, fix cable with a tape so that fixing case and rotating part keep aligned.

This will omit neutral position alignment procedure during spiral cable installation.

●Neutral position (refer to figure)... Gently turn spiral cable clock-

wise until it comes to the stop. Then turn it counter clockwise

(approximately 3.0 turns) until centering mark is aligned with

adjustment mark. (Service part is fixed in neutral position with

stopper. It can be installed onto steering wheel without align-

ment once stopper is removed.)

CAUTION:

●Place steering wheel as follows: Front wheels in straight-

ahead position. R mark on the cancel claw faces down. 3

bosses align with 3 holes behind steering wheel assembly.

Check that spiral cable is placed in neutral position and that

locating pin on the left of the spiral cable is aligned with the

locating pinhole behind the steering wheel assembly.

●Do not rotate spiral cable more than necessary. Do not tighten them excessively. (The cable may

be torn off.)

●After installation, check system for proper operation by observing air bag warning lamp.

●If air bag indicator indicates any abnormal condition, use self-diagnosis function or CONSULT to

reset or cancel memory.Inner wheel Minimum : 36°

Nominal : 39°

Maximum : 40°

Outer wheel : 31°

Rack stroke : 66.5 mm (2.618 in)

SGIA0055E

SGIA0080E

SGIA0096E