transmission oil NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 7 of 3833

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

●Use approved bonding agent, sealants or their equivalents when required.

●Use tools and recommended special tools where specified for safe and efficient service repairs.

●When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

●Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for All Mode 4 × 4 SystemEAS000GQ

Even if the 2WD mode is selected, the All mode 4 × 4 system occasionally changes from 2WD to 4WD auto-

matically depending on the driving conditions.

When spinning the front wheels by running the engine with the front wheels jacked up or mounted on the free

rollers / or a chassis dynamometer, be careful because the vehicle may suddenly move due to the driving

force from the rear wheels.

To avoid personal injury and vehicle damage, use one of the following methods when working with the front

wheels drive force and spinning freely.

● Remove the propeller shaft.

● Use free rollers / chassis dynamometer designed for 4WD vehicles.

Precautions for Three Way CatalystEAS000FR

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

●Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

●When checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

●Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS000P9

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission control devices and systems, and could

also affect the warranty coverage validity.

DIESEL ENGINE

Diesel fuel of at least 50 cetane.

If two types of diesel fuel are available, use summer or winter fuel properly according to the following temper-

ature conditions.

●Above –7°C (20°F) ... Summer type diesel fuel.

●Below –7°C (20°F) ... Winter type diesel fuel.

SGI234

Page 77 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual OIL PAN AND OIL STRAINER

EM-27

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

4. Insert Tool (Seal cutter) between lower and upper oil pan slide

tool by tapping on the side of the tool with a hammer.

5. Rem NISSAN X-TRAIL 2001 Service Repair Manual OIL PAN AND OIL STRAINER

EM-27

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

4. Insert Tool (Seal cutter) between lower and upper oil pan slide

tool by tapping on the side of the tool with a hammer.

5. Rem](/img/5/57405/w960_57405-76.png)

OIL PAN AND OIL STRAINER

EM-27

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

4. Insert Tool (Seal cutter) between lower and upper oil pan slide

tool by tapping on the side of the tool with a hammer.

5. Remove lower oil pan.

6. Remove drive belts. Refer to EM-12, "

DRIVE BELTS" .

7. Remove A/C compressor with piping connected. And locate it

aside temporarily with ropes or equivalent not to disturb the fol-

lowing work

8. Remove front exhaust tube and its support. Refer to EX-2,

"EXHAUST SYSTEM" .

9. Set a suitable transmission jack under transaxle and hoist

engine with engine slinger.

10. Remove center member.

11. Remove rear plate cover, and four engine-to transaxle bolts.

12. Loosen bolts in reverse order of illustration to remove upper oil

pan.

●Disregard No. 1, 2 and 3 when loosening.

●Insert Tool (Seal cutter) between upper oil pan and cylinder

block. Slide tool by tapping on the side of the tool with a ham-

mer.

13. Remove oil strainer.

INSPECTION AFTER REMOVAL

Clean oil strainer if any object attached.

INSTALLATION

1. Install oil strainer.

2. Install upper oil pan in the order below.

SEM365EA

PBIC0257E

SBIA0233E

SEM365EA

Page 78 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-28

[QR]

OIL PAN AND OIL STRAINER

a. Apply liquid gasket thoroughly as in illustration.

Use Genuine Liquid Gasket or equivalent.

b. Install O-rings as front cover side.

c. Tighten bolts in numerical NISSAN X-TRAIL 2001 Service Repair Manual EM-28

[QR]

OIL PAN AND OIL STRAINER

a. Apply liquid gasket thoroughly as in illustration.

Use Genuine Liquid Gasket or equivalent.

b. Install O-rings as front cover side.

c. Tighten bolts in numerical](/img/5/57405/w960_57405-77.png)

EM-28

[QR]

OIL PAN AND OIL STRAINER

a. Apply liquid gasket thoroughly as in illustration.

Use Genuine Liquid Gasket or equivalent.

b. Install O-rings as front cover side.

c. Tighten bolts in numerical order as shown.

●No. 10, 11and 18 indicate double tightening of bolts No. 1, 2

and 3.

NOTE:

Refer to the below for locating bolts.

M6 × 20 mm (0.79 in): No. 18, 19

M8 × 25 mm (0.98 in): No. 1, 2, 3, 11

M8 x 45 mm (1.77 in): No. 4, 10, 13, 14, 15, 16

M8 x100 mm (3.97 in): No. 5, 6, 7, 8, 9

d. Tighten transmission joint bolts.

e. Install rear plate cover.

3. Install lower oil pan.

Use Genuine Liquid Gasket or equivalent.

●Tighten bolts in numerical order as shown.

4. Install oil pan drain plug.

●Refer to illustration of components of former page for installation direction of washer.

5. Install in the reverse order of removal after this step.

●Pour engine oil at least 30 minutes after oil pan is installed.

INSPECTION AFTER INSTALLATION

●Check engine oil level. Refer to LU-7, "ENGINE OIL" .

●Check for leakage of engine oil when engine is warmed.

SBIA0253E

SBIA0233E

SBIA0254E

KBIA0096E

Page 125 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-75

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●A commercial engine stand can be used.

NOTE:

This example is an engine stand for holding at transaxle

mounting side with the flywheel or NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-75

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●A commercial engine stand can be used.

NOTE:

This example is an engine stand for holding at transaxle

mounting side with the flywheel or](/img/5/57405/w960_57405-124.png)

CYLINDER BLOCK

EM-75

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●A commercial engine stand can be used.

NOTE:

This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3. Drain engine oil and engine coolant from inside of engine.

4. Remove the following components and associated parts.

●Exhaust manifold and three way catalyst assembly; Refer to

EM-24, "

EXHAUST MANIFOLD AND THREE WAY CATA-

LYST" .

●Intake manifold collector; Refer to EM-16, "INTAKE MANI-

FOLD" .

●Intake manifold and fuel tube assembly; Refer to EM-16, "INTAKE MANIFOLD" .

●Ignition coil; Refer to EM-29, "IGNITION COIL" .

●Rocker cover; Refer to EM-35, "ROCKER COVER" .

●Oil pan and oil strainer; Refer to EM-26, "OIL PAN AND OIL STRAINER" .

●Front cover, timing chain and balancer unit; Refer to EM-37, "TIMING CHAIN" .

●Camshaft; Refer to EM-46, "CAMSHAFT" .

●Cylinder head; Refer to EM-59, "CYLINDER HEAD" .

5. Remove knock sensor.

CAUTION:

Carefully handle the sensor avoiding shocks.

6. Remove crankshaft position sensor (POS).

CAUTION:

●Avoid impacts such as a dropping.

●Do not disassemble.

●Keep it away from metal particles.

●Do not place sensor close to magnetic materials.

7. Remove flywheel (M/T model) or drive plate (A/T model). Fix crankshaft with a stopper plate, and remove

mounting bolts.

Torx bit (size T55): Flywheel (M/T model)

Torx socket (size T55): Drive plate (A/T model)

CAUTION:

Be careful not to damage contact surface for the clutch disc

of the flywheel.

NOTE:

The flywheels, two block construction, allows movement in

response to transmission side pressure, or when twisted in its

rotational direction. Therefore, some amount of noise is normal.

PBIC0085E

SBIA0273E

KBIA0062E

Page 158 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearance NISSAN X-TRAIL 2001 Service Repair Manual EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearance](/img/5/57405/w960_57405-157.png)

EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearanceStandard 0.028 - 0.045 (0.0011 - 0.0018)

Limit 0.10 (0.0039)

*1: Parts to be tightened in particular orders.

1)-: Order of tightening when tightening two or more times separately.

Auto-tensioner 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Mass air flow sensor

3.8 - 4.5 (0.39 - 0.46, 34 - 39) *

2

Resonator

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*2

Air cleaner case lower

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*2

*1 Intake manifold17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Intake manifold collector 17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Intake manifold support 17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Electric throttle control actuator

7.2 - 9.6 (0.74 - 0.98, 64 - 84) *

2

EVAP canister purge volume control solenoid valve

4.3 - 5.8 (0.44 - 0.59, 38 - 51) *2

*1 Exhaust manifold 39.2 - 44.1 (4.0 - 4.5, 29 - 32)

Exhaust manifold cover

5.1 - 6.5 (0.52 - 0.66, 46 - 57) *

2

Heated oxygen sensor 40 - 50 (4.1 - 5.1, 30 - 36)

*1 Oil pan upper M6 bolt

8.1 - 9.5 (0.83 - 0.97, 72 - 84) *

2

M8 bolt 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Oil pan upper to transmission joint bolts 39.2 - 46.1 (4.0 - 4.7, 29 - 34)

*1 Oil pan lower

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Oil pan drain plug29.4 - 39.2 (3.0 - 4.0, 22 - 28)

Rear plate cover

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Oil strainer M6 bolt

8.1 - 9.5 (0.83 - 0.97, 72 - 84) *2

M8 bolt 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Oil level gauge guide 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Ignition coil

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *

2

Spark plug19.6 - 29.4 (2.0 - 3.0, 15 - 21)

*1 Fuel tube1)

2)9.3 - 10.8 (0.95 - 1.1, 0.7 - 0.8) *

2

20.6 - 26.5 (2.1 - 2.7, 16 - 19)

*1 Rocker cover1)

2)0.98 - 2.9 (0.1 - 0.3, 9 - 25) *

2

7.4 - 9.3 (0.75 - 0.95, 66 - 82) *2

PCV valve

1.96 - 2.94 (0.20 - 0.30, 18 - 26) *2

Intake valve timing control solenoid valve

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *2

*1 Intake valve timing control cover 11.8 - 13.7 (1.2 - 1.4, 9 - 10)

Camshaft position sensor (PHASE)

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *

2

Camshaft sprocket (Intake and Exhaust) 127- 157 (13.0 - 16.0, 94 - 115)

Chain tensioner

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Page 184 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-134

[YD22DDTi]

OIL PAN AND OIL STRAINER

4. Remove lower oil pan.

a. Insert Tool (seal cutter) between upper oil pan and lower oil pan.

●Be careful not to damage aluminum mating surface.

●Do no NISSAN X-TRAIL 2001 Service Repair Manual EM-134

[YD22DDTi]

OIL PAN AND OIL STRAINER

4. Remove lower oil pan.

a. Insert Tool (seal cutter) between upper oil pan and lower oil pan.

●Be careful not to damage aluminum mating surface.

●Do no](/img/5/57405/w960_57405-183.png)

EM-134

[YD22DDTi]

OIL PAN AND OIL STRAINER

4. Remove lower oil pan.

a. Insert Tool (seal cutter) between upper oil pan and lower oil pan.

●Be careful not to damage aluminum mating surface.

●Do not insert screwdriver, or oil pan flange will be

deformed.

b. Slide Tool by tapping on the side of the Tool with a hammer.

c. Remove lower oil pan.

5. Remove drive belts.

6. Remove A/C compressor and bracket.

7. Remove front exhaust tube and its support.

8. Set a suitable transmission jack under transaxle and hoist

engine with engine slinger. Refer to EM-193, "

Removal and

Installation" .

9. Remove center member.

10. Remove crankshaft position sensor (TDC) from transaxle.

CAUTION:

●Avoid impacts such as a dropping.

●Do not disassemble.

●Keep it away from metal particles.

●Do not place sensor close to magnetic materials.

11. Remove rear plate cover and four engine-to transaxle bolts.

12. Remove catalyst and rear diffuser. Refer to EM-126, "

Removal

and Installation" .

SEM544G

SEM545G

JEM553G

PBIB0416E

Page 249 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-199

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

e. Hoist engine and install it to the engine stand.

NOTE:

It is possible to set engine sub-attachment and engine attach-

ment to eng NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-199

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

e. Hoist engine and install it to the engine stand.

NOTE:

It is possible to set engine sub-attachment and engine attach-

ment to eng](/img/5/57405/w960_57405-248.png)

CYLINDER BLOCK

EM-199

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

e. Hoist engine and install it to the engine stand.

NOTE:

It is possible to set engine sub-attachment and engine attach-

ment to engine stand at first, then install engine later.

●Commercial engine stand can be used.

NOTE:

The figure shows an example of general-purpose engine

stand that can hold mating surface of transmission with drive

plate and rear plate removed.

5. Drain engine oil and engine coolant from inside engine.

6. Remove the following parts and related parts. (Only major parts are listed.)

●Intake manifold (Refer to EM-123, "Removal and Installation" .)

●Exhaust manifold and Turbocharger (Refer to EM-127, "Removal and Installation" .)

●Rocker cover (Refer to EM-156, "Removal and Installation" .)

●Injection tube and fuel injector (Refer to EM-144, "Removal and Installation" .)

●Oil pan and oil strainer (Refer to EM-133, "Removal and Installation" .)

●Water pump (Refer to CO-39, "WATER PUMP" .)

●Thermostat and water piping (Refer to CO-41, "THERMOSTAT AND WATER PIPING" .)

●Vacuum pump and vacuum pipe (Refer to EM-139, "Removal and Installation" .)

●Secondary timing chain (Refer to EM-167, "Removal and Installation" .)

●Primary timing chain (Refer to EM-172, "Removal and Installation" .)

●Fuel supply pump (Refer to EM-147, "Removal and Installation" .)

●Camshaft (Refer to EM-158, "Removal and Installation" .)

●Cylinder head (Refer to EM-183, "Removal and Installation" .)

●Oil cooler (Refer to LU-25, "OIL COOLER" .)

●Accessory, accessory bracket and mount brackets

7. Remove fuel supply pump bracket.

8. Remove rear oil seal retainer.

JEM193G

PBIC0085E

Page 1752 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-1402

[YD]

ENGINE CONTROL SYSTEM

Crankcase Ventilation System

EBS0036K

DESCRIPTION

In this system, blow-by gas is sucked into the air duct after oil separation by oil separator in the rocker cover.

NISSAN X-TRAIL 2001 Service Repair Manual EC-1402

[YD]

ENGINE CONTROL SYSTEM

Crankcase Ventilation System

EBS0036K

DESCRIPTION

In this system, blow-by gas is sucked into the air duct after oil separation by oil separator in the rocker cover.](/img/5/57405/w960_57405-1751.png)

EC-1402

[YD]

ENGINE CONTROL SYSTEM

Crankcase Ventilation System

EBS0036K

DESCRIPTION

In this system, blow-by gas is sucked into the air duct after oil separation by oil separator in the rocker cover.

INSPECTION

Ventilation Hose

1. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any hose

cannot be freed of obstructions, replace.

CAN CommunicationEBS00NBH

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

PBIB0590E

SEC692

Page 1977 of 3833

MT-1

MANUAL TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

MT

MANUAL TRANSAXLE

PRECAUTIONS .......................................................... 3

Caution ..................................................................... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 6

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

MANUAL TRANSAXLE ......................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DOUBLE-CONE SYNCHRONIZER ...................... 9

REVERSE GEAR NOISE PREVENTION FUNC-

TION (SYNCHRONIZING METHOD) ................... 9

M/T OIL ..................................................................... 10

Changing M/T Oil ................................................... 10

DRAINING ........................................................... 10

FILLING ............................................................... 10

Checking M/T Oil .................................................... 10

OIL LEAKAGE AND OIL LEVEL ......................... 10

SIDE OIL SEAL .........................................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

POSITION SWITCH .................................................. 12

Checking ................................................................ 12

BACK-UP LAMP SWITCH .................................. 12

PARK/NEUTRAL POSITION SWITCH ............... 12

CONTROL LINKAGE ............................................... 13

Removal and Installation of Control Device and

Cable ...................................................................... 13

AIR BREATHER HOSE ............................................ 14

Removal and Installation ........................................ 14

TRANSAXLE ASSEMBLY ........................................ 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

Component Parts (RS5F51A) ................................ 17CASE AND HOUSING COMPONENTS .............. 17

GEAR COMPONENTS ....................................... 18

SHIFT CONTROL COMPONENTS ..................... 20

FINAL DRIVE COMPONENTS ........................... 21

Component Parts (RS6F51A) ................................. 22

CASE AND HOUSING COMPONENTS .............. 22

GEAR COMPONENTS ....................................... 23

SHIFT CONTROL COMPONENTS ..................... 25

FINAL DRIVE COMPONENTS ........................... 26

Disassembly and Assembly (RS5F51A) ................. 26

DISASSEMBLY ................................................... 26

ASSEMBLY ......................................................... 30

Disassembly and Assembly (RS6F51A) ................. 35

DISASSEMBLY ................................................... 35

ASSEMBLY ......................................................... 39

Adjustment (RS5F51A) ........................................... 45

INPUT SHAFT END PLAY .................................. 45

MAINSHAFT END PLAY ..................................... 46

DIFFERENTIAL SIDE BEARING PRELOAD ...... 47

REVERSE IDLER GEAR END PLAY .................. 48

Adjustment (RS6F51A) ........................................... 49

INPUT SHAFT END PLAY .................................. 49

MAINSHAFT END PLAY ..................................... 50

DIFFERENTIAL SIDE BEARING PRELOAD ...... 51

REVERSE IDLER GEAR END PLAY .................. 52

INPUT SHAFT AND GEARS .................................... 54

Assembly and Disassembly (RS5F51A) ................. 54

DISASSEMBLY ................................................... 54

INSPECTION AFTER DISASSEMBLY ................ 55

ASSEMBLY ......................................................... 57

Assembly and Disassembly (RS6F51A) ................. 61

DISASSEMBLY ................................................... 61

INSPECTION AFTER DISASSEMBLY ................ 62

ASSEMBLY ......................................................... 64

MAINSHAFT AND GEARS ....................................... 68

Assembly and Disassembly (RS5F51A) ................. 68

DISASSEMBLY ................................................... 68

INSPECTION AFTER DISASSEMBLY ................ 69

Page 2087 of 3833

PREPARATION

AT-9

D

E

F

G

H

I

J

K

L

MA

B

AT

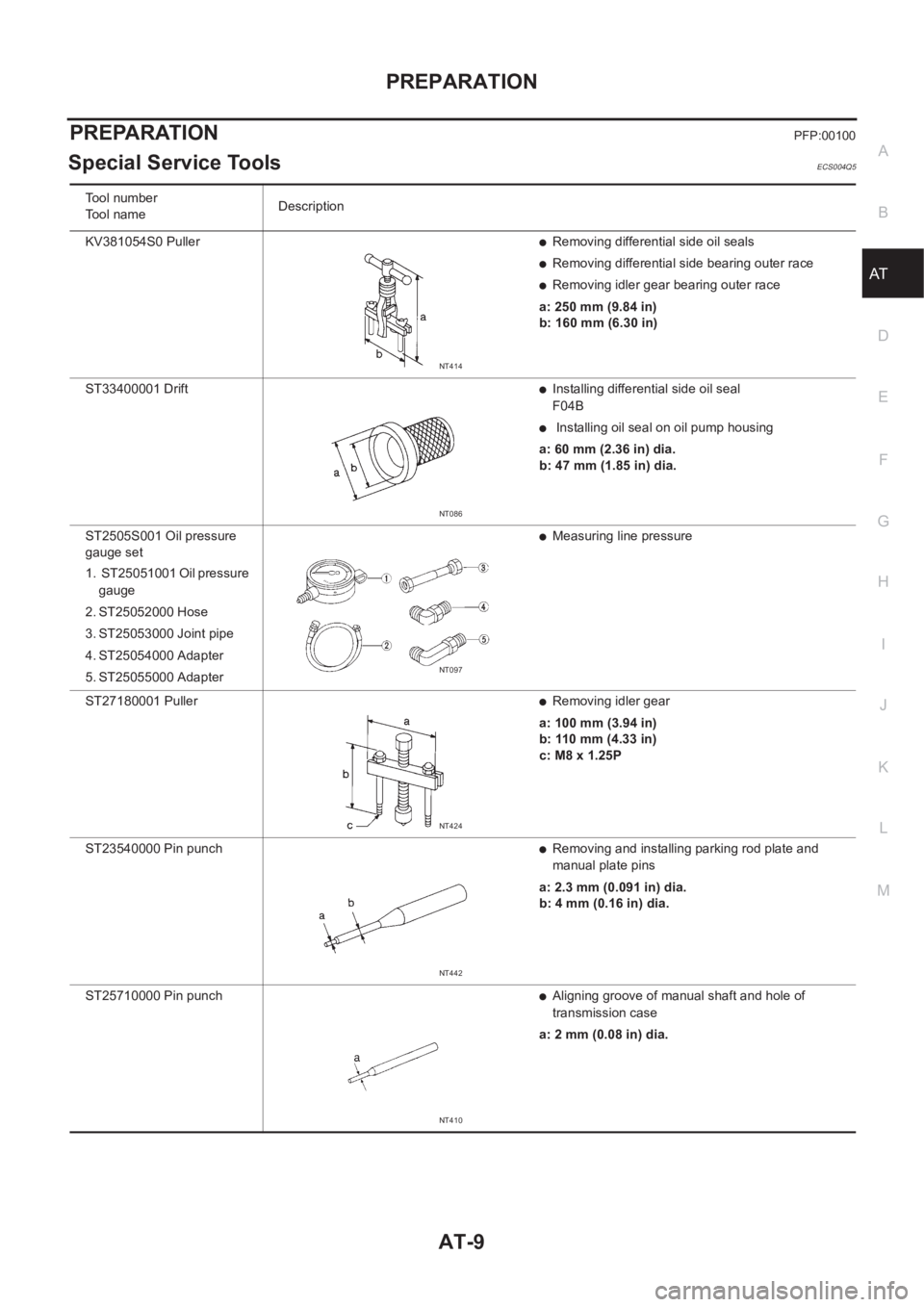

PREPARATIONPFP:00100

Special Service ToolsECS004Q5

Tool number

Tool nameDescription

KV381054S0 Puller

●Removing differential side oil seals

●Removing differential side bearing outer race

●Removing idler gear bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33400001 Drift

●Installing differential side oil seal

F04B

● Installing oil seal on oil pump housing

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST2505S001 Oil pressure

gauge set

1. ST25051001 Oil pressure

gauge

2. ST25052000 Hose

3. ST25053000 Joint pipe

4. ST25054000 Adapter

5. ST25055000 Adapter

●Measuring line pressure

ST27180001 Puller

●Removing idler gear

a: 100 mm (3.94 in)

b: 110 mm (4.33 in)

c: M8 x 1.25P

ST23540000 Pin punch

●Removing and installing parking rod plate and

manual plate pins

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

ST25710000 Pin punch

●Aligning groove of manual shaft and hole of

transmission case

a: 2 mm (0.08 in) dia.

NT414

NT086

NT097

NT424

NT442

NT410