weight NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 21 of 3833

HOW TO USE THIS MANUAL

GI-19

C

D

E

F

G

H

I

J

K

L

MB

GI

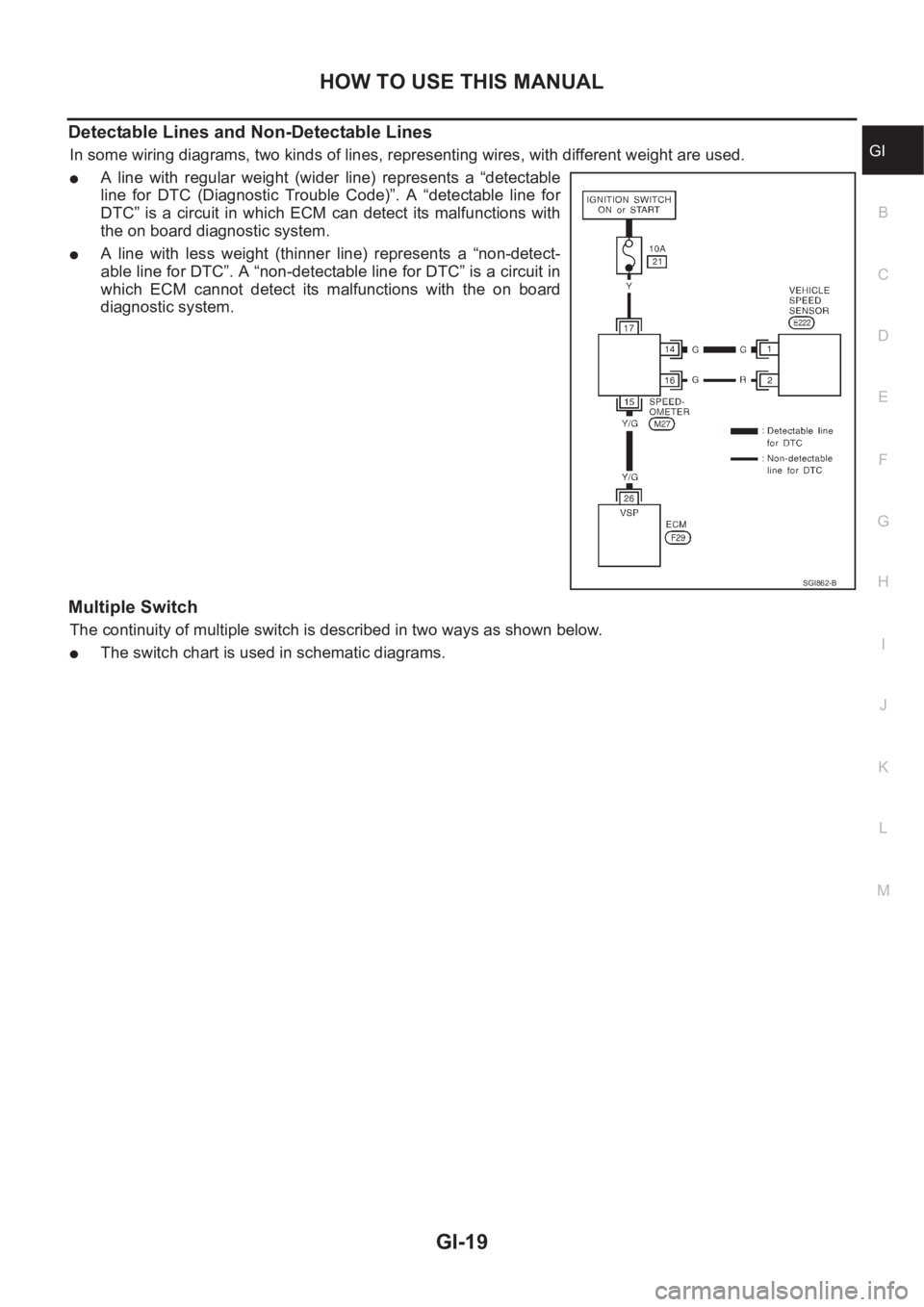

Detectable Lines and Non-Detectable Lines

In some wiring diagrams, two kinds of lines, representing wires, with different weight are used.

●A line with regular weight (wider line) represents a “detectable

line for DTC (Diagnostic Trouble Code)”. A “detectable line for

DTC” is a circuit in which ECM can detect its malfunctions with

the on board diagnostic system.

●A line with less weight (thinner line) represents a “non-detect-

able line for DTC”. A “non-detectable line for DTC” is a circuit in

which ECM cannot detect its malfunctions with the on board

diagnostic system.

Multiple Switch

The continuity of multiple switch is described in two ways as shown below.

●The switch chart is used in schematic diagrams.

SGI862-B

Page 291 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual OIL PUMP

LU-11

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

●Measure clearance with feeler gauge and straightedge.

Side clearance between inner rotor and oil pump body (position

3).

Side clearance between outer r NISSAN X-TRAIL 2001 Service Repair Manual OIL PUMP

LU-11

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

●Measure clearance with feeler gauge and straightedge.

Side clearance between inner rotor and oil pump body (position

3).

Side clearance between outer r](/img/5/57405/w960_57405-290.png)

OIL PUMP

LU-11

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

●Measure clearance with feeler gauge and straightedge.

Side clearance between inner rotor and oil pump body (position

3).

Side clearance between outer rotor and oil pump body (position

4).

●Calculate the clearance between inner rotor and oil pump body

as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5).

2. Measure the inner diameter of oil pump body with inside

micrometer (Position 6).

(Clearance) = (Inner diameter of oil pump body) – (Outer diame-

ter of inner rotor)

Regulator Valve Clearance

(Clearance) = D1 (Valve hole diameter) – D2 (Outer diameter of

valve)

CAUTION:

●Coat regulator valve with engine oil.

●Check that it falls smoothly into the valve hole by its own

weight.Standard: 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Standard: 0.060 - 0.110 mm (0.0024 - 0.0043 in)

PBIC0252E

PBIC0253E

Standard: 0.035 - 0.070mm (0.0014 - 0.0028 in)

PBIC0254E

Standard: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

KBIA0043E

Page 304 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual LU-24

[YD22DDTi]

OIL PUMP

●Calculate the clearance between inner rotor and oil pump hous-

ing as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5)

2. M NISSAN X-TRAIL 2001 Service Repair Manual LU-24

[YD22DDTi]

OIL PUMP

●Calculate the clearance between inner rotor and oil pump hous-

ing as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5)

2. M](/img/5/57405/w960_57405-303.png)

LU-24

[YD22DDTi]

OIL PUMP

●Calculate the clearance between inner rotor and oil pump hous-

ing as follows.

1. Measure the outer diameter of protruded portion of inner rotor

(Position 5)

2. Measure the inner diameter of oil pump housing with inside

micrometer (Position 6)

(Clearance) = (Inner diameter of oil pump housing) – (Outer

diameter of inner rotor)

Regulator Valve

1. Visually inspect components for wear and damage.

2. Check oil pressure regulator valve sliding surface and valve spring.

3. Coat regulator valve with engine oil. Check that it falls smoothly into the valve hole by its own weight.

If damaged, replace regulator valve set or oil pump housing.

4. Check regulator valve to oil pump housing clearance.

CAUTION:

Coat regulator valve with engine oil.

ASSEMBLY

●Assemble in the reverse order of disassembly.

●Install the inner rotor and outer rotor with the punched marks on

the oil pump cover side.

●After warming up the engine, check for oil leakage and oil level.

Refer to LU-18, "

ENGINE OIL" .

PBIC0253E

Standard : 0.045 - 0.091mm (0.0018 - 0.0036 in)

SBIA0124E

Clearance "6":

0.040 - 0.097 mm (0.0016 - 0.0038 in)

JLC358B

JLC286B

Page 429 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-79

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE ST NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-79

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE ST](/img/5/57405/w960_57405-428.png)

TROUBLE DIAGNOSIS

EC-79

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FL-9

Fuel piping 5 5 5 5 5 5FL-3,EM-

32

Vapor lock—

Valve deposit

555555 5—

Poor fuel (Heavy weight gaso-

line, Low octane)—

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throttle control actuatorEM-16

Air leakage from intake manifold/

Collector/GasketEM-16

Cranking Battery

111111 11SC-3

Alternator circuitSC-12

Starter circuit 3SC-20

Signal plate 6EM-73

PNP switch

4MT-12 or

AT- 11 5

Engine Cylinder head

55555 55 5EM-59

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-73

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Page 821 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-471

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGIN NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-471

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGIN](/img/5/57405/w960_57405-820.png)

TROUBLE DIAGNOSIS

EC-471

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FL-9

Fuel piping 5 5 5 5 5 5FL-3,EM-

32

Vapor lock—

Valve deposit

555555 5—

Poor fuel (Heavy weight gaso-

line, Low octane)—

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throttle control actuatorEM-16

Air leakage from intake manifold/

Collector/GasketEM-16

Cranking Battery

111111 11SC-3

Alternator circuitSC-12

Starter circuit 3SC-20

Signal plate 6EM-73

PNP switch

4MT-12 or

AT-349

Engine Cylinder head

55555 55 5EM-59

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-73

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nismTiming chain

55555 55 5EM-37

CamshaftEM-46

Intake valve

3EM-59

Exhaust valve

Page 1161 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-811

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/F NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-811

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/F](/img/5/57405/w960_57405-1160.png)

TROUBLE DIAGNOSIS

EC-811

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FL-9

Fuel piping 5 5 5 5 5 5FL-3,EM-

32

Vapor lock—

Valve deposit

555555 5—

Poor fuel (Heavy weight gaso-

line, Low octane)—

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throttle control actuatorEM-16

Air leakage from intake manifold/

Collector/GasketEM-16

Cranking Battery

111111 11SC-3

Alternator circuitSC-12

Starter circuit 3SC-20

Signal plate 6EM-73

PNP switch

4MT-12 or

AT- 11 5

Engine Cylinder head

55555 55 5EM-59

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-73

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nismTiming chain

55555 55 5EM-37

CamshaftEM-46

Intake valve

3EM-59

Exhaust valve

Page 1508 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-1158

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/D NISSAN X-TRAIL 2001 Service Repair Manual EC-1158

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/D](/img/5/57405/w960_57405-1507.png)

EC-1158

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FL-9

Fuel piping 555 55 5FL-3,EM-

32

Vapor lock—

Valve deposit

555555 5—

Poor fuel (Heavy weight gaso-

line, Low octane)—

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throttle control actuatorEM-16

Air leakage from intake manifold/

Collector/GasketEM-16

Cranking Battery

111111 11SC-3

Alternator circuitSC-12

Starter circuit 3SC-20

Signal plate 6EM-73

PNP switch

4MT-12 or

AT- 3 4 9

Engine Cylinder head

55555 55 5EM-59

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-73

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nismTimin g c hain

55555 55 5EM-37

CamshaftEM-46

Intake valve

3EM-59

Exhaust valve

Page 1933 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual FUEL TANK

FL-9

[QR]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL TANKPFP:17202

Removal and InstallationEBS00KOW

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-3, NISSAN X-TRAIL 2001 Service Repair Manual FUEL TANK

FL-9

[QR]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL TANKPFP:17202

Removal and InstallationEBS00KOW

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-3,](/img/5/57405/w960_57405-1932.png)

FUEL TANK

FL-9

[QR]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL TANKPFP:17202

Removal and InstallationEBS00KOW

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-3, "

General Precau-

tions" .

1. Release fuel pressure from fuel line. Refer to EC-775, "

FUEL

PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)], EC-

11 3 9 , "FUEL PRESSURE RELEASE" [QR20DE (WITHOUT

EURO-OBD)], EC-42, "

FUEL PRESSURE RELEASE"

[QR25DE (WITH EURO-OBD)] or EC-452, "FUEL PRESSURE

RELEASE" [QR25DE (WITHOUT EURO-OBD)].

2. Open the fuel filler cap and release the pressure inside the fuel

tank.

3. Remove rear seat bottom.

4. Remove inspection hole cover, harness connector and fuel feed

hose.

5. Drain fuel from fuel tank if necessary. For the draining procedure, refer to Step 4 in removal of FL-4,

"FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY" .

CAUTION:

For the safety work and to maintain fuel tank gravity at center, drain fuel to the level where fuel

tank weight at left and right becomes equal.

6. Disconnect the quick connector.

●Put mating marks on hoses for correct installation.

PBIC0246E

1. Fuel filler cap 2. Grommet 3. Fuel filler tube

4. Vent hose 5. Vent tube 6. Fuel tank

7. Fuel filler hose 8. Fuel tank band 9. Fuel tank protector

KBIA0280E

Page 1945 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual FUEL TANK

FL-21

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL TANKPFP:17202

Removal and InstallationEBS00BL3

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer t NISSAN X-TRAIL 2001 Service Repair Manual FUEL TANK

FL-21

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL TANKPFP:17202

Removal and InstallationEBS00BL3

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer t](/img/5/57405/w960_57405-1944.png)

FUEL TANK

FL-21

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL TANKPFP:17202

Removal and InstallationEBS00BL3

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-14, "

General Precau-

tions" .

1. Disconnect battery ground cable.

2. Open the fuel filler cap and release the pressure inside the fuel

tank.

3. Remove rear seat bottom.

4. Peel off floor carpet, then remove inspection hole cover.

5. Disconnect the harness connector, fuel feed tube and fuel return

tube.

6. Drain fuel from fuel tank if necessary. For the draining proce-

dure, refer to step 4 in removal of FL-17, "

FUEL LEVEL SEN-

SOR UNIT" .

CAUTION:

For the safety work and to maintain fuel tank gravity at center, drain fuel to the level where fuel

tank weight at left and right becomes equal.

7. Disconnect the quick connector.

●Put mating marks on hoses for correct installation.

8. Remove exhaust center tube and insulator. Refer to EX-2, "

EXHAUST SYSTEM" .

9. Remove propeller shaft, Refer to PR-2, "

REAR PROPELLER SHAFT" .

SBIA0145E

1. Fuel filler cap 2. Grommet 3. Fuel filler tube

4. Vent hose 5. Vent tube 6. Fuel tank

7. Fuel filler hose 8. Fuel tank band 9. Fuel tank protector

SBIA0140E

Page 2085 of 3833

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

●After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DURE”.

The DTC should not be displayed in the “DTC CONFIRMA-

TION PROCEDURE” if the repair is completed.

●Before proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

●Disassembly should be done in a clean work area.

●Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transaxle.

●Place disassembled parts in order for easier and proper assembly.

●All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

●Gaskets, seals and O-rings should be replaced any time the transaxle is disassembled.

●It is very important to perform functional tests whenever they are indicated.

●The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

●Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

●Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

●Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

●After overhaul, refill the transaxle with new ATF.

●When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

to “Changing A/T Fluid”, AT-13, "

A/T FLUID" .

Service Notice or PrecautionsECS004Q3

FA I L - S A F E

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

When the ignition key is turned “ON” following Fail-Safe operation, O/D OFF indicator lamp blinks for about 8

seconds. Refer to AT- 2 5 3 , "

SELF-DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-II)" (EXCEPT FOR

EURO-OBD) or AT-51, "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)" (EURO-OBD).

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW”, refer to AT-262, "

Work Flow" (EXCEPT FOR Euro-OBD) or AT- 6 0 , "Work

Flow" (Euro-OBD).

The SELF-DIAGNOSIS results will be as follows:

●The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

●During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

●External leaks in the hub weld area.

●Converter hub is scored or damaged.

●Converter pilot is broken, damaged or fits poorly into crankshaft.

●Steel particles are found after flushing the cooler and cooler lines.

●Pump is damaged or steel particles are found in the converter.

●Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

SAT652J