clock NISSAN X-TRAIL 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2024 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual EM-54

[QR20DE]

CYLINDER HEAD

5. Remove camshaft. Refer toEM-33, "Removal and Installation".

6. Securely support bottom of cylinder block with a jack or equivalent tool, and remove the hoist that was

s NISSAN X-TRAIL 2003 Electronic Owners Manual EM-54

[QR20DE]

CYLINDER HEAD

5. Remove camshaft. Refer toEM-33, "Removal and Installation".

6. Securely support bottom of cylinder block with a jack or equivalent tool, and remove the hoist that was

s](/img/5/57402/w960_57402-2023.png)

EM-54

[QR20DE]

CYLINDER HEAD

5. Remove camshaft. Refer toEM-33, "Removal and Installation".

6. Securely support bottom of cylinder block with a jack or equivalent tool, and remove the hoist that was

supporting it.

7. Remove cylinder head loosening bolts in reverse order shown in

the figure.

INSPECTION AFTER REMOVAL

OuterDiameterofCylinderHeadBolts

lCylinder head bolts are tightened by plastic zone tightening

method. Whenever the size difference between d1 and d2

exceeds the limit, replace them with new one.

lIf reduction of outer diameter appears in a position other than

d2, use it as d2 point.

INSTALLATION

1. Install cylinder head gasket.

2. Follow the steps below to tighten fixing bolts in the order shown

in figure to install cylinder head.

CAUTION:

lIf cylinder head bolts are re-used, check their outer diam-

eters before installation. Refer toEM-54, "

Outer Diameter

of Cylinder Head Bolts".

lIn step “c”, loosen bolts in the reverse order of that indi-

catedinfigure.

a. Apply new engine oil to threads and seating surface of mounting

bolts.

b. Tighten all bolts to 98.1 N·m (10 kg-m, 72 ft-lb).

c. Completely loosen to 0 N·m (0 kg-m, 0 ft-lb).

d. Tighten all bolts to 34.3 to 44.1 N·m (3.5 to 4.4 kg-m, 26 to 32 ft-lb).

e. Turn all bolts 75°to 80°(target: 75°) degrees clockwise.

f. Turn all bolts 75°to 80°(target: 75°) degrees clockwise again.

CAUTION:

Check and confirm the tightening angle by using angle

wrench or protractor. Avoid judgment by visual inspection

without the tool.

KBIA0058E

Limit (d1 - d2) : More than 0.23 mm (0.0091 in)

KBIA0189E

KBIA0058E

KBIA0059E

Page 2042 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual EM-72

[QR20DE]

CYLINDER BLOCK

12. Install the connecting rod bearings to the connecting rod and the

connecting rod cap.

lWhen installing the connecting rod bearings, apply engine oil

to the bearing su NISSAN X-TRAIL 2003 Electronic Owners Manual EM-72

[QR20DE]

CYLINDER BLOCK

12. Install the connecting rod bearings to the connecting rod and the

connecting rod cap.

lWhen installing the connecting rod bearings, apply engine oil

to the bearing su](/img/5/57402/w960_57402-2041.png)

EM-72

[QR20DE]

CYLINDER BLOCK

12. Install the connecting rod bearings to the connecting rod and the

connecting rod cap.

lWhen installing the connecting rod bearings, apply engine oil

to the bearing surface (inside). Do not apply oil to the back

surface, but thoroughly clean it.

lWhen installing, align the connecting rod bearing stopper pro-

trusion with the notch of the connecting rod to install.

lCheck the oil holes on the connecting rod and those on the

corresponding bearing are aligned.

13. Install the piston and connecting rod assembly to the crankshaft.

lPosition the crankshaft pin corresponding to the connecting

rod to be installed onto the bottom dead center.

lApply engine oil sufficiently to the cylinder bore, piston and

crankshaft pin.

lMatch the cylinder position with the cylinder No. on the con-

necting rod to install.

lUsing a piston ring compressor, install the piston with the front

mark on the piston crown facing the front of the engine.

CAUTION:

Be careful not to damage the crankshaft pin, resulting from

an interference of the connecting rod big end.

14. Install the connecting rod cap.

lMatch the stamped cylinder number marks on the connecting

rodwiththoseonthecaptoinstall.

15. Tighten the connecting rod bolt as follows.

a. Apply engine oil to the threads and seats of the connecting rod

bolts.

b. Tighten bolts to 18.6 to 20.6 N·m (1.9 to 2.1 kg-m, 14 to 15 ft-lb).

c. Put mating (with paint) on each bolt and connecting rod cap, all

in the same direction (when using a protractor).

d. Then tighten all bolts 90 to 95 degrees clockwise (target: 90

degrees) (Angle tightening).

CAUTION:

Always use either an angle wrench or protractor. Avoid

tightening based on visual check alone.

lAfter tightening the bolt, make sure that the crankshaft rotates smoothly.

lCheck the connecting rod side clearance. Refer toEM-81, "CONNECTING ROD SIDE CLEARANCE".

PBIC0266E

PBIC0267E

KBIA0067E

KBIA0068E

Page 2109 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual FUEL SUPPLY PUMP

EM-139

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

5. Remove RH front wheel.

6. Remove RH splash cover (combined with under cover)

7. Remove fuel hose from fuel supply pump.

8. Remove the ha NISSAN X-TRAIL 2003 Electronic Owners Manual FUEL SUPPLY PUMP

EM-139

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

5. Remove RH front wheel.

6. Remove RH splash cover (combined with under cover)

7. Remove fuel hose from fuel supply pump.

8. Remove the ha](/img/5/57402/w960_57402-2108.png)

FUEL SUPPLY PUMP

EM-139

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

5. Remove RH front wheel.

6. Remove RH splash cover (combined with under cover)

7. Remove fuel hose from fuel supply pump.

8. Remove the harness connector from the fuel supply pump.

9. Remove the fuel supply pump rear bracket.

lLoosen the fuel bolts in the reverse order of that show in the

figure and remove them.

10. Remove fuel supply pump center spill tube.

11. Remove front chain case.

lLoosen fixing bolts in the reverse order of that shown in the

figure and remove them.

lRemove No. 6, 10 and 11 bolts with the rubber washer as

space is limited for pulling them out.

CAUTION:

lWhile front chain case is removed, cover openings to

prevent entry of foreign material into engine.

lDo not remove two mass dampers on the back of cover.

12. Set the No. 1 piston to TDC on its compression stroke.

lTurn crankshaft pulley clockwise so that the alignment mark

(punched mark) on each camshaft sprocket is positioned as

showninthefigure.

lNo position indicator is provided on the crankshaft pul-

ley.

lWhen installing, color coded links on the secondary tim-

ing chain can be used as alignment marks. Marking may

not be necessary for removal; however, make alignment

marks as required because the alignment mark on fuel

supply pump sprocket may not be easy to see.

SBIA0214E

JEM121G

SBIA0189E

SEM515G

Page 2124 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual EM-154

[YD22DDTi]

CAMSHAFT

Valve Clearance

EBS00BOJ

INSPECTION

lWhen the camshaft or parts in connection with valves are

removed or replaced, and a malfunction has occurred (poor

starting, idling, or NISSAN X-TRAIL 2003 Electronic Owners Manual EM-154

[YD22DDTi]

CAMSHAFT

Valve Clearance

EBS00BOJ

INSPECTION

lWhen the camshaft or parts in connection with valves are

removed or replaced, and a malfunction has occurred (poor

starting, idling, or](/img/5/57402/w960_57402-2123.png)

EM-154

[YD22DDTi]

CAMSHAFT

Valve Clearance

EBS00BOJ

INSPECTION

lWhen the camshaft or parts in connection with valves are

removed or replaced, and a malfunction has occurred (poor

starting, idling, or other malfunction) due to the mis adjustment

of the valve clearance, inspect as follows.

lInspect and adjust when the engine is cool (at normal tempera-

ture).

lBe careful of the intake and exhaust valve arrangement. The

valve arrangement is different from that in a normal engine.

NOTE:

The camshafts have, alternately, either an intake valve or an

exhaust valve.(Refer to illustration)

1. Drain engine coolant. Refer toCO-30, "

Changing Engine Coolant".

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove air duct and air inlet pipe. Refer toEM-112, "

Removal and Installation".

4. Remove rocker cover. Refer toEM-147, "

Removal and Installation".

5. Remove vacuum pump. Refer toEM-131, "

Removal and Installation".

6. Remove injection tube and fuel injector. Refer toEM-135, "

Removal and Installation".

7. Remove secondary timing chain. Refer toEM-158, "

Removal and Installation"

Check valve clearance while engine is cold and not running.

8. Set the No. 1 piston to TDC on its compression stroke.

lTurn crankshaft pulley clockwise so that the knock pin on

camshaft LH faces straight above. (No position indicator, etc.

is provided on the crankshaft pulley.)

9. Put an alignment mark with paint, etc. on the crankshaft pulley

and on the oil pump as an angle indicator.

10. While referring to the figure, measure the valve clearance

marked in the table below.

lThe injection order is 1-3-4-2.

SBIA0178E

SBIA0179E

JEM177G

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDCXXX X

SBIA0180E

Page 2125 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual CAMSHAFT

EM-155

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

lMeasure the valve clearance using a fine feeler gauge when

the engine is cool (at normal temperature).

11. Set the No. 4 cylinder at TDC by rotati NISSAN X-TRAIL 2003 Electronic Owners Manual CAMSHAFT

EM-155

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

lMeasure the valve clearance using a fine feeler gauge when

the engine is cool (at normal temperature).

11. Set the No. 4 cylinder at TDC by rotati](/img/5/57402/w960_57402-2124.png)

CAMSHAFT

EM-155

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

lMeasure the valve clearance using a fine feeler gauge when

the engine is cool (at normal temperature).

11. Set the No. 4 cylinder at TDC by rotating the crankshaft clock-

wise once.

12. While referring to the figure, measure the valve clearance

marked in the table below.

13. If the valve clearance is outside the specification, adjust as fol-

lows.

ADJUSTMENTS

lRemove the adjusting shim for parts which are outside the spec-

ified valve clearance.

1. Remove the spill tube. Refer toEM-135, "

Removal and Installa-

tion".

2. Extract the engine oil on the upper side of the cylinder head (for

theairblowinginstep7).

3. Rotate the crankshaft to face the camshaft for adjusting shims

that are to be removed upward.

4. Grip the camshaft with camshaft pliers, them using the camshaft

as a support point, push the adjusting shim downward to com-

press the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head and the outer

circumference of the valve lifter.Valve clearance (Cold):

Standard:

Intake : 0.24 - 0.32 mm (0.0094 - 0.0126 in)

Exhaust : 0.26 - 0.34 mm (0.0102 - 0.0134 in)

SBIA0181E

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDCXX XX

SBIA0182E

SBIA0183E

SBIA0184E

Page 2129 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual SECONDARY TIMING CHAIN

EM-159

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

4. Remove front chain case.

lLoosen fixing bolts in the reverse order of that shown in the

figure and remove them.

lRemove No. 6, 10 NISSAN X-TRAIL 2003 Electronic Owners Manual SECONDARY TIMING CHAIN

EM-159

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

4. Remove front chain case.

lLoosen fixing bolts in the reverse order of that shown in the

figure and remove them.

lRemove No. 6, 10](/img/5/57402/w960_57402-2128.png)

SECONDARY TIMING CHAIN

EM-159

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

4. Remove front chain case.

lLoosen fixing bolts in the reverse order of that shown in the

figure and remove them.

lRemove No. 6, 10 and 11 bolts with the rubber washer as

space is limited for pulling them out.

CAUTION:

lWhile front chain case is removed, cover openings to

prevent entry of foreign material into engine.

lDo not remove two mass dampers on the back of cover.

5. Set the No. 1 piston to TDC on its compression stroke.

lTurn crankshaft pulley clockwise so that the alignment mark

(punched mark) on each camshaft sprocket is positioned as

showninthefigure.

lNo position indicator is provided on the crankshaft pul-

ley.

lWhen installing, color coded links on the secondary tim-

ing chain can be used as alignment marks. Marking may

not be necessary for removal; however, make alignment

marks as required because the alignment mark on fuel

supply pump sprocket may not be easy to see.

6. Remove chain tensioner.

a. Push the plunger of chain tensioner and keep it pressed with a

push pin.

b. Using a hexagon-head wrench [face to face: 5 mm, (0.20 in)

SST], remove bolts to remove chain tensioner.

JEM121G

SBIA0189E

SEM515G

JEM124G

SBIA0227E

Page 2360 of 3066

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Brake fluid level and line check ...........................BR-9

Brake hydraulic line ...........................................BR-11

Brake inspection ................................................MA-39

Brake lines and cables inspection .....................MA-39

Brake master cylinder ........................................BR-13

Brake pedal .........................................................BR-6

Brake switch ........................EC-329,EC-562,EC-810

BRK/SW - Wiring diagram ...EC-330,EC-564,EC-811

Bulb specifications ..............................................LT-67

Bumper, front .........................................................EI-6

Bumper, rear ..........................................................EI-9

C

Camshaft inspection(QR20DE) .........................EM-38

Camshaft inspection(YD22DDTi) ....................EM-150

Camshaft position sensor (CMPS) ..................EC-739

Camshaft position sensor (PHASE) ..EC-223,EC-507

Camshaft(QR20DE) ..........................................EM-33

Camshaft(YD22DDTi) ......................................EM-149

CAN - Wiring diagramEC-115,EC-461,LAN-6,LAN-12

CAN (Controller Area Network) .........AT-129,AT-351,

LAN-3

,LAN-5,LAN-11

CAN Communication ..........................................TF-53

CAN communicationEC-28,EC-114,EC-393,EC-460,

AT-129

,AT-351,BRC-53,BRC-59,BRC-90,BRC-108,

LAN-3

,LAN-5,LAN-11

Canister-See EVAP canister .............EC-374,EC-649

CHARGE - Wiring diagram ................................SC-13

Charging system ................................................SC-12

Chassis and body maintenance ........................MA-35

CHIME - Wiring diagram .....................................DI-54

CIGAR - Wiring diagram ..................................WW-25

Cigarette lighter ...............................................WW-25

Circuit breaker ...................................................PG-12

CKPS - Wiring diagram ...................................EC-736

Clearance lamp ........................................LT-4,LT-40

Clock ...................................................................DI-60

CLOCK - Wiring diagram ....................................DI-60

Closed loop control ..............................EC-25,EC-390

Clutch cover .......................................................CL-15

Clutch disc .........................................................CL-15

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-5

Clutch release bearing .......................................CL-13

Clutch release mechanism ................................CL-13

Clutch withdrawal lever ......................................CL-13

CMPS - Wiring diagram ...................................EC-741

Coil spring (rear) ...............................................RSU-8

Collision diagnosis ...........................................SRS-46

Combination meter .....................................DI-4,DI-22

Combination switch ................................LT-24,LT-44

Common rail fuel pressure sensor ...................EC-723

Component Location (auto A/C) .........ATC-31,MTC-4

Compression pressure(QR20DE) ......................EM-52

Compression pressure(YD22DDTi) .................EM-173

Compressor clutch removal and installation ..ATC-129

Compressor special service tool ......................ATC-11

Condenser .....................................................ATC-138

Connecting rod bearing clearance(QR20DE) ...EM-83

Connecting rod bearing clearance(YD22DDTi)EM-206

Connecting rod bushing clearance(QR20DE) ..EM-83

Connecting rod bushing clearance(YD22DDTi)EM-200

Connecting rod(QR20DE) .................................EM-82

Connecting rod(YD22DDTi) ..............EM-198,EM-202

Console box - See Instrument panel ..........IP-3,IP-10

CONSULT for engine ............EC-86,EC-434,EC-691

CONSUT for VDC ...........................................BRC-77

Control unit .....................................ATC-104,MTC-19

Control units (terminal arrangement) .................PG-73

Controller Area Network (CAN) ........AT-129,AT-351,

LAN-3

,LAN-5,LAN-11

Converter housing installation ...........AT-459,AT-556

COOL/F - Wiring diagram ...EC-315,EC-552,EC-763

Coolant mixture ratio .........................................MA-19

Coolant replacement(QR20DE) ........................MA-20

Coolant replacement(YD22DDTi) .....................MA-27

Cooling circuit (engine)(QR20DE) ......................CO-7

Cooling circuit (engine)(YD22DDTi) .................CO-28

Cooling fan control system(QR20DE) ...............CO-13

Cooling fan motor ..............................EC-324,EC-561

Cooling fan relay ................................EC-324,EC-561

Cooling fan(QR20DE) .......................................CO-13

Cooling fan(YD22DDTi) ....................................CO-34

Coupling sleeve (M/T) ...........................MT-19,MT-24

Cowl top ..............................................................EI-12

Cowl top cover ....................................................EI-12

Crankcase ventilation system ..........................EC-663

Crankcase ventilation system - See Positive crankcase

ventilation ...........................................EC-375

,EC-650

Crankshaft position sensor (POS) .....EC-217,EC-501

Crankshaft position sensor (TDC) ...................EC-734

Crankshaft(QR20DE) ........................................EM-65

Crankshaft(YD22DDTi) ...................................EM-200

CRFPS - Wiring diagram .................................EC-724

Cylinder block boring(QR20DE) .......................EM-86

Cylinder block boring(YD22DDTi) ...................EM-204

Cylinder block(QR20DE) ..................................EM-64

Cylinder block(YD22DDTi) ..............................EM-188

Cylinder head bolt tightening(QR20DE) ...........EM-54

Cylinder head bolt tightening(YD22DDTi) .......EM-175

Cylinder head gasket selection(YD22DDTi) ...EM-175

Cylinder head(QR20DE) ...................................EM-52

Cylinder head(YD22DDTi) ..............................EM-173

D

Data link connector ............................EC-371

,EC-646

Data link connector for Consult ...........EC-88,EC-435,

EC-691

Daytime light system .............................................LT-9

Daytime running light - See Daytime light systemLT-9

DEF - Wiring diagram .......................................GW-10

Desiccant Assembly .......................ATC-27,ATC-140

Diagnosis sensor unit .....................................SRS-39

Page 2406 of 3066

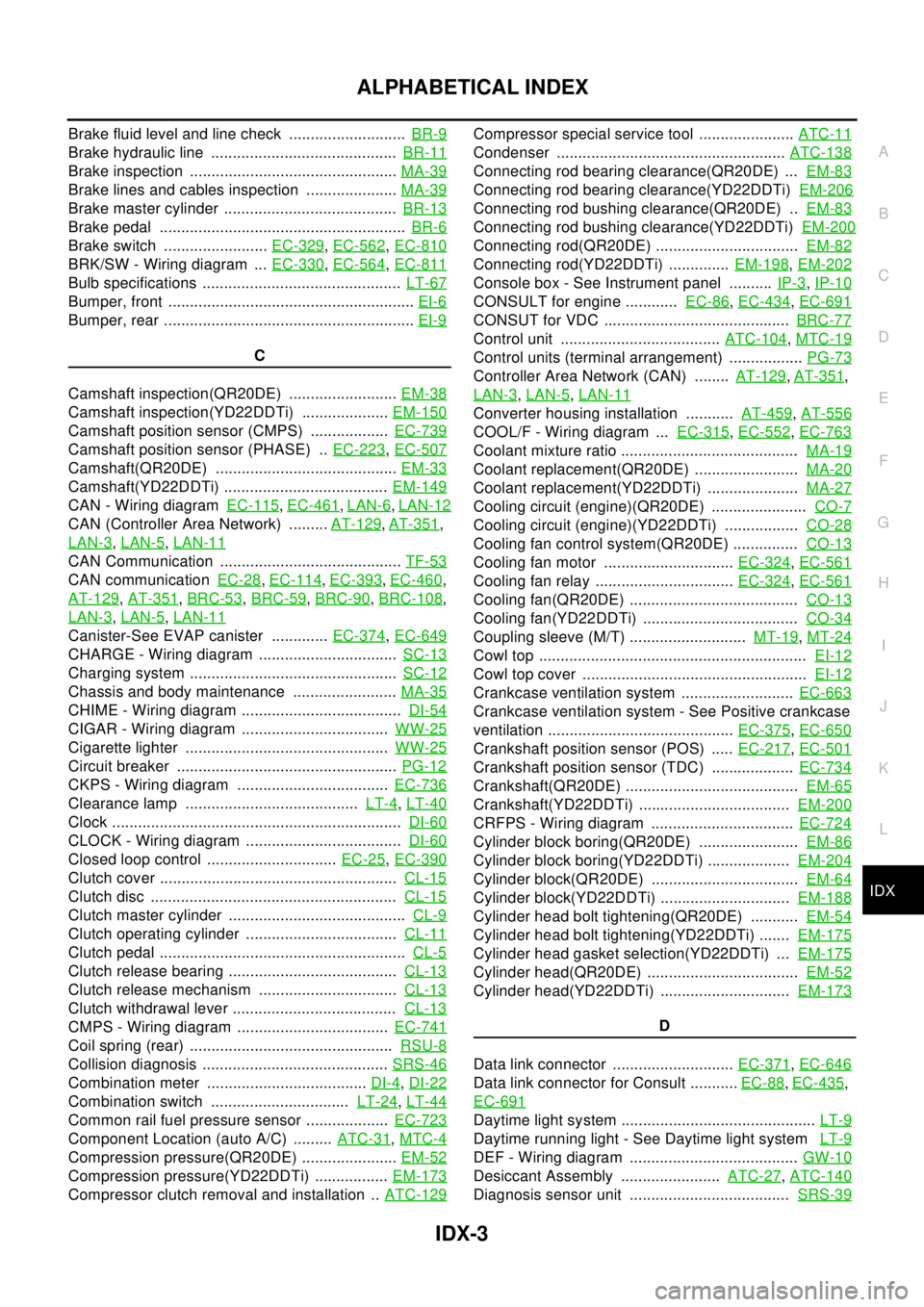

LT-8

HEADLAMP

Bulb Replacement

EKS003CH

HEAD LAMP

1. Disconnect connector of headlamp.

2. Remove rubber cap.

3. Unlock retaining spring, then remove bulb.

CLEARANCE LAMP

1. Turn the RH bulbsocket clockwise and unlock it.

Turn the LH bulbsocket counterclockwise and unlock it.

2. Remove the bulb from its socket.

CAUTION:

lDo not touch the glass of bulb directly by hand. Keep grease and other oily matters away from it.

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

lDo not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc.

may affect the performance of headlamp. When replacing bulb, be sure to replace it with new one.

lWhen bulb is installed, be sure to lock rubber cap to ensure watertightness.

Removal and InstallationEKS003CI

REMOVAL

1. Remove the front turn signal lamps. Refer toLT-22, "Removal

and Installation for Front Turn Signal Lamp"

2. Disconnect connector of headlamp and clearance lamp.

3. Remove the front grille. Refer toEI-11, "

FRONT GRILL"in

"EXTERIOR & INTERIOR (EI)" section.

4. Remove the headlamp mounting bolts.

5. Pull the headlamp toward the front of the vehicle.

INSTALLATION

lInstall in the reverse order of removal, taking care of the following points.

Headlamp mounting screws and nutHeadlamp (High/Low) : 12V 60/55 W(H4)

SKIA0073E

Clearance lamp : 12V 5W

SKIA0050E

Tightening torque : 4.5 - 6.4 N-m (0.45 - 0.65 kg-m, 39 - 56 in-lb)

Page 2420 of 3066

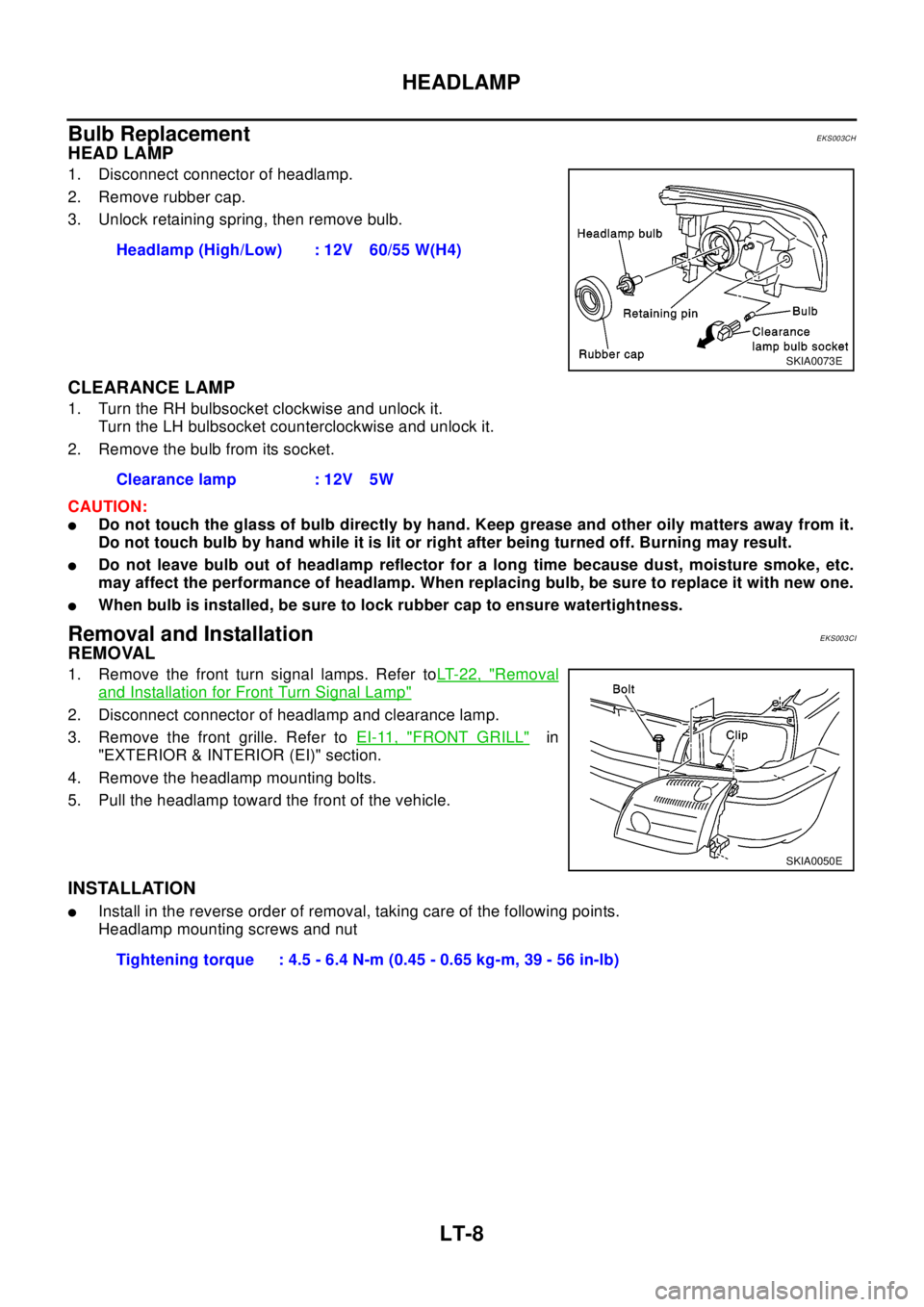

LT-22

TURN SIGNAL AND HAZARD WARNING LAMPS

Bulb Replacement

EKS0034D

FRONT TURN SIGNAL LAMP

1. Remove the front turn signal lamp. Refer toLT- 2 2 , "Removal and

Installation for Front Turn Signal Lamp"

2. Turn the bulb socket counterclockwise and unlock it.

3. Remove the bulb from its socket.

SIDE TURN SIGNAL LAMP

1. Remove side turn signal lamp. Refer toLT- 2 3 , "Removal and

Installation for Side Turn Signal Lamp"

2. Turn the bulb socket counterclockwise and unlock it.

3. Remove the bulb from its socket.

REAR TURN SIGNAL LAMP

Refer toLT- 4 2 , "REAR COMBINATION LAMP"

Removal and Installation for Front Turn Signal LampEKS003BH

REMOVAL

1. Press the upper pawl to remove front turn signal lamp toward

the front of the vehicle.

2. Disconnect front turn signal lamp connector.

INSTALLATION

1. Connect front turn signal lamp connector.

2. Insert the pawl into head lamp hole, and install front turn signal lamp.

SKIA0053E

Front turn signal lamp : 12V 21W (amber)

PKIA0468E

Side turn signal lamp : 12V 5W

SKIA0054E

Page 2425 of 3066

STOP LAMP

LT-27

C

D

E

F

G

H

I

J

L

MA

B

LT

Bulb ReplacementEKS0034K

STOP LAMP

Refer toLT- 4 2 , "REAR COMBINATION LAMP"

HIGH-MOUNTED STOP LAMP

1. Remove the high-mounted stop lamp cover. Refer toLT- 2 7 ,

"HIGH-MOUNTED STOP LAMP"in “Removal and Installation”.

2. Turn the high-mounted stop lamp bulb socket counterclockwise

and unlock it.

3. Remove the bulb.

Removal and InstallationEKS0034L

STOP LAMP

Refer toLT- 4 2 , "REAR COMBINATION LAMP"

HIGH-MOUNTED STOP LAMP

1. Open the backdoor. Then, pull the edge of the cover (A in the

figure below) to each side in turn downward until the pawls

inside the cover are released.

2. Pull down the cover toward under the vehicle.

3. Remove the high-mounted stop lamp mounting bolts.

4. Disconnect the high-mounted stop lamp connector and remove

from the vehicle.High-mounted Stop Lamp : 12V 5W

PKIA0496E

PKIA0497E

PKIA0498E