belt NISSAN X-TRAIL 2003 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1115 of 3066

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QR (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 12

Alphabetical Index .................................................. 12

DTC No. Index ....................................................... 14

PRECAUTIONS ........................................................ 16

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 16

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 16

Precaution .............................................................. 16

Wiring Diagrams and Trouble Diagnosis ................ 19

PREPARATION ......................................................... 20

Special Service Tools ............................................. 20

Commercial Service Tools ...................................... 20

ENGINE CONTROL SYSTEM .................................. 22

System Diagram ..................................................... 22

Vacuum Hose Drawing ........................................... 23

System Chart ......................................................... 24

Multiport Fuel Injection (MFI) System .................... 24

Electronic Ignition (EI) System ............................... 27

Air Conditioning Cut Control ................................... 27

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 28

CAN communication .............................................. 28

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Throttle Valve Closed Position Learning ................ 31

Accelerator Pedal Released Position Learning ...... 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 48

Malfunction Indicator (MI) ....................................... 48

OBD System Operation Chart ................................ 51

TROUBLE DIAGNOSIS ............................................ 57

Trouble Diagnosis Introduction ............................... 57DTC Inspection Priority Chart ................................. 61

Fail-safe Chart ........................................................ 62

Basic Inspection ..................................................... 64

Symptom Matrix Chart ............................................ 69

Engine Control Component Parts Location ............ 73

Circuit Diagram ....................................................... 77

ECM Harness Connector Terminal Layout ............. 79

ECM Terminals and Reference Value ..................... 79

CONSULT-II Function ............................................. 86

Generic Scan Tool (GST) Function ......................... 96

CONSULT-II Reference Value in Data Monitor ....... 97

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................100

TROUBLE DIAGNOSIS - SPECIFICATION VALUE. 103

Description ............................................................103

Testing Condition ..................................................103

Inspection Procedure ............................................103

Diagnostic Procedure ...........................................104

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................107

Description ............................................................107

Diagnostic Procedure ...........................................107

POWER SUPPLY CIRCUIT FOR ECM ...................108

Wiring Diagram .....................................................108

ECM Terminals and Reference Value ...................109

Diagnostic Procedure ...........................................109

Component Inspection ..........................................113

DTC U1000 CAN COMMUNICATION LINE ............114

Description ............................................................114

On Board Diagnosis Logic ....................................114

DTC Confirmation Procedure ...............................114

Wiring Diagram .....................................................115

Diagnostic Procedure ...........................................116

DTC P0011 IVT CONTROL .....................................117

Description ............................................................117

CONSULT-II Reference Value in Data Monitor Mode

.117

ECM Terminals and Reference Value ...................117

On Board Diagnosis Logic ....................................118

Page 1119 of 3066

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA DTC P1805 BRAKE SWITCH ................................ 329

Description ........................................................... 329

CONSULT-II Reference Value in Data Monitor Mode

. 329

ECM Terminals and Reference Value .................. 329

On Board Diagnosis Logic ................................... 329

DTC Confirmation Procedure ............................... 329

Wiring Diagram .................................................... 330

Diagnostic Procedure ........................................... 331

Component Inspection ......................................... 332

IGNITION SIGNAL .................................................. 334

Component Description ........................................ 334

ECM Terminals and Reference Value .................. 334

Wiring Diagram .................................................... 335

Diagnostic Procedure ........................................... 337

Component Inspection ......................................... 341

Removal and Installation ...................................... 342

INJECTOR CIRCUIT ............................................... 343

Component Description ........................................ 343

CONSULT-II Reference Value in Data Monitor Mode

. 343

ECM Terminals and Reference Value .................. 343

Wiring Diagram .................................................... 344

Diagnostic Procedure ........................................... 345

Component Inspection ......................................... 347

Removal and Installation ...................................... 347

START SIGNAL ...................................................... 348

CONSULT-II Reference Value in Data Monitor Mode

. 348

ECM Terminals and Reference Value .................. 348

Wiring Diagram .................................................... 349

Diagnostic Procedure ........................................... 350

FUEL PUMP CIRCUIT ............................................ 352

Description ........................................................... 352

CONSULT-II Reference Value in Data Monitor Mode

. 352

ECM Terminals and Reference Value .................. 352

Wiring Diagram .................................................... 354

Diagnostic Procedure ........................................... 355

Component Inspection ......................................... 357

Removal and Installation ...................................... 358

REFRIGERANT PRESSURE SENSOR ................. 359

Component Description ........................................ 359

ECM Terminals and Reference Value .................. 359

Wiring Diagram .................................................... 360

Diagnostic Procedure ........................................... 361

Removal and Installation ...................................... 362

ELECTRICAL LOAD SIGNAL ................................ 363

CONSULT-II Reference Value in Data Monitor Mode

. 363

ECM Terminals and Reference Value .................. 363

Wiring Diagram .................................................... 364

Diagnostic Procedure ........................................... 366

DATA LINK CONNECTOR ..................................... 371

Wiring Diagram .................................................... 371

EVAPORATIVE EMISSION SYSTEM ..................... 372

Description ........................................................... 372

Component Inspection ......................................... 374POSITIVE CRANKCASE VENTILATION ...............375

Description ............................................................375

Component Inspection ..........................................375

SERVICE DATA AND SPECIFICATIONS (SDS) ....377

Fuel Pressure .......................................................377

Idle Speed and Ignition Timing .............................377

Calculated Load Value ..........................................377

Mass Air Flow Sensor ...........................................377

Intake Air Temperature Sensor .............................377

Engine Coolant Temperature Sensor ...................377

Heated Oxygen Sensor 1 Heater .........................377

Heated Oxygen sensor 2 Heater ..........................377

Crankshaft Position Sensor (POS) .......................377

Camshaft Position Sensor (PHASE) ....................377

Throttle Control Motor ...........................................378

Injector ..................................................................378

Fuel Pump ............................................................378

QR (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................379

Alphabetical Index ................................................379

DTC No. Index ......................................................380

PRECAUTIONS ......................................................381

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................381

On Board Diagnostic (OBD) System of Engine and

A/T ........................................................................381

Precaution ............................................................381

Wiring Diagrams and Trouble Diagnosis ..............384

PREPARATION .......................................................385

Special Service Tools ...........................................385

Commercial Service Tools ....................................385

ENGINE CONTROL SYSTEM ................................387

System Diagram ...................................................387

Vacuum Hose Drawing .........................................388

System Chart ........................................................389

Multiport Fuel Injection (MFI) System ...................389

Electronic Ignition (EI) System .............................392

Air Conditioning Cut Control .................................392

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................393

CAN communication .............................................393

BASIC SERVICE PROCEDURE .............................395

Idle Speed and Ignition Timing Check ..................395

Throttle Valve Closed Position Learning ...............396

Accelerator Pedal Released Position Learning ....396

Idle Air Volume Learning ......................................396

Fuel Pressure Check ............................................399

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........401

Introduction ...........................................................401

Two Trip Detection Logic ......................................401

Emission-related Diagnostic Information ..............401

NATS (Nissan Anti-theft System) .........................403

Malfunction Indicator (MI) .....................................404

TROUBLE DIAGNOSIS ..........................................407

Trouble Diagnosis Introduction .............................407

Page 1122 of 3066

EC-8

Component Inspection ..........................................584

Removal and Installation ......................................586

HO2S2 .....................................................................587

Component Description ........................................587

CONSULT-II Reference Value in Data Monitor Mode

.587

ECM Terminals and Reference Value ...................587

Wiring Diagram .....................................................588

Diagnostic Procedure ...........................................589

Component Inspection ..........................................590

Removal and Installation ......................................591

IGNITION SIGNAL ..................................................592

Component Description ........................................592

ECM Terminals and Reference Value ...................592

Wiring Diagram .....................................................593

Diagnostic Procedure ...........................................595

Component Inspection ..........................................599

Removal and Installation ......................................600

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE .................................................601

Description ............................................................601

CONSULT-II Reference Value in Data Monitor Mode

.601

ECM Terminals and Reference Value ...................601

Wiring Diagram .....................................................603

Diagnostic Procedure ...........................................604

Component Inspection ..........................................607

Removal and Installation ......................................607

IVT CONTROL SOLENOID VALVE ........................608

Description ............................................................608

CONSULT-II Reference Value in Data Monitor Mode

.608

ECM Terminals and Reference Value ...................609

Wiring Diagram .....................................................610

Diagnostic Procedure ...........................................611

Component Inspection ..........................................613

Removal and Installation ......................................613

PNP SWITCH ..........................................................614

Component Description ........................................614

CONSULT-II Reference Value in Data Monitor Mode

.614

ECM Terminals and Reference Value ...................614

Wiring Diagram .....................................................615

Diagnostic Procedure ...........................................616

INJECTOR CIRCUIT ...............................................618

Component Description ........................................618

CONSULT-II Reference Value in Data Monitor Mode

.618

ECM Terminals and Reference Value ...................618

Wiring Diagram .....................................................619

Diagnostic Procedure ...........................................620

Component Inspection ..........................................622

Removal and Installation ......................................622

START SIGNAL ......................................................623

CONSULT-II Reference Value in Data Monitor Mode

.623

ECM Terminals and Reference Value ...................623Wiring Diagram ..................................................... 624

Diagnostic Procedure ............................................ 625

FUEL PUMP CIRCUIT ............................................. 627

Description ............................................................ 627

CONSULT-II Reference Value in Data Monitor Mode

. 627

ECM Terminals and Reference Value ................... 627

Wiring Diagram ..................................................... 629

Diagnostic Procedure ............................................ 630

Component Inspection .......................................... 632

Removal and Installation ....................................... 633

REFRIGERANT PRESSURE SENSOR .................. 634

Component Description ........................................ 634

ECM Terminals and Reference Value ................... 634

Wiring Diagram ..................................................... 635

Diagnostic Procedure ............................................ 636

Removal and Installation ....................................... 637

ELECTRICAL LOAD SIGNAL ................................ 638

CONSULT-II Reference Value in Data Monitor Mode

. 638

ECM Terminals and Reference Value ................... 638

Wiring Diagram ..................................................... 639

Diagnostic Procedure ............................................ 641

DATA LINK CONNECTOR ...................................... 646

Wiring Diagram ..................................................... 646

EVAPORATIVE EMISSION SYSTEM ..................... 647

Description ............................................................ 647

Component Inspection .......................................... 649

POSITIVE CRANKCASE VENTILATION ................ 650

Description ............................................................ 650

Component Inspection .......................................... 650

SERVICE DATA AND SPECIFICATIONS (SDS) .... 652

Fuel Pressure ........................................................ 652

Idle Speed and Ignition Timing .............................. 652

Calculated Load Value .......................................... 652

Mass Air Flow Sensor ........................................... 652

Intake Air Temperature Sensor ............................. 652

Engine Coolant Temperature Sensor .................... 652

Heated Oxygen Sensor 1 Heater .......................... 652

Heated Oxygen sensor 2 Heater .......................... 652

Crankshaft Position Sensor (POS) ....................... 652

Camshaft Position Sensor (PHASE) ..................... 652

Throttle Control Motor ........................................... 653

Injector .................................................................. 653

Fuel Pump ............................................................. 653

YD

INDEX FOR DTC ..................................................... 654

Alphabetical Index ................................................. 654

DTC No. Index ...................................................... 654

PRECAUTIONS ....................................................... 656

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ............................................................... 656

Precautions ........................................................... 656

Wiring Diagrams and Trouble Diagnosis ............... 658

Page 1130 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EC-16

[QR (WITH EURO-OBD)]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00B0I

The Supplemental Restraint Sys NISSAN X-TRAIL 2003 Electronic Owners Guide EC-16

[QR (WITH EURO-OBD)]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00B0I

The Supplemental Restraint Sys](/img/5/57402/w960_57402-1129.png)

EC-16

[QR (WITH EURO-OBD)]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00B0I

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

On Board Diagnostic (OBD) System of Engine and A/TEBS00B0J

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch OFF and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MI to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lCertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer toPG-70, "

HAR-

NESS CONNECTOR".

lBe sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel injection system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionEBS00B0K

lAlways use a 12 volt battery as power source.

lDo not attempt to disconnect battery cables while engine is

running.

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative

battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lBefore removing parts, turn ignition switch OFF and then

disconnect battery ground cable.

SEF289H

Page 1495 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

EC-381

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00BEL

T NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

EC-381

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00BEL

T](/img/5/57402/w960_57402-1494.png)

PRECAUTIONS

EC-381

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00BEL

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WA RN ING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

On Board Diagnostic (OBD) System of Engine and A/TEBS00BEM

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch OFF and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MI to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lCertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer toPG-70, "

HAR-

NESS CONNECTOR".

lBe sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel injection system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionEBS00BEN

lAlways use a 12 volt battery as power source.

lDo not attempt to disconnect battery cables while engine is

running.

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative

battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lBefore removing parts, turn ignition switch OFF and then

disconnect battery ground cable.

SEF289H

Page 1770 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EC-656

[YD]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS008RR

The Supplemental Restraint System such as “ NISSAN X-TRAIL 2003 Electronic Owners Guide EC-656

[YD]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS008RR

The Supplemental Restraint System such as “](/img/5/57402/w960_57402-1769.png)

EC-656

[YD]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS008RR

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PrecautionsEBS00317

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative

battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lDo not disassemble ECM.

lWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

lSecurely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in coil and condenser, thus resulting in

damage to IC's.

lKeep engine control system harness at least 10cm (4 in)

away from adjacent harness, to prevent engine control sys-

tem malfunctions due to receiving external noise, degraded

operation of IC's, etc.

lKeep engine control system parts and harness dry.

SEF289H

PBIB0378E

SEF291H

Page 1941 of 3066

EI-1

EXTERIOR & INTERIOR

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION

A

B

EI

EXTERIOR & INTERIOR

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

CLIP AND FASTENER ............................................... 3

................................................................................. 3

FRONT BUMPER ....................................................... 6

Removal and Installation .......................................... 6

REMOVAL ............................................................. 8

INSTALLATION ..................................................... 8

REAR BUMPER ......................................................... 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ................................................... 10

FRONT GRILL ...........................................................11

Removal and Installation .........................................11

REMOVAL ............................................................11

INSTALLATION ....................................................11

COWL TOP ............................................................... 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

FENDER PROTECTOR ............................................ 13

Removal and Installation ........................................ 13

DOOR OUTSIDE MOLDING .................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 15

SIDE GUARD MOLDING .......................................... 16

Removal and Installation ........................................ 16

DOOR OUTSIDE LOWER MOLDING ...................... 17

Removal and Installation ........................................ 17

SIDE SILL PROTECTOR .......................................... 18

Removal and Installation ........................................ 18ROOF RAIL ............................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 20

ROOF SPOILER ....................................................... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSTALLATION ................................................... 21

LICENSE LAMP FINISHER ...................................... 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

DOOR FINISHER ...................................................... 23

Removal and Installation ........................................ 23

FRONT AND REAR ............................................ 23

BACK DOOR TRIM ................................................... 25

Removal and Installation ........................................ 25

BODY SIDE TRIM ..................................................... 26

Removal and Installation ........................................ 26

CENTER PILLAR LOWER GARNISH ................. 27

CENTER PILLAR UPPER GARNISH .................. 27

LUGGAGE SIDE LOWER FINISHER ................. 27

REAR PILLAR FINISHER ................................... 27

DASHBOARD SIDE FINISHER .......................... 27

BODY SIDE WELT .............................................. 27

FLOOR TRIM ............................................................ 28

Removal and Installation ........................................ 28

REMOVAL ........................................................... 28

INSTALLATION ................................................... 28

HEADLINING ............................................................ 29

Removal and Installation ........................................ 29

REMOVAL ........................................................... 29

INSTALLATION ................................................... 30

Page 1942 of 3066

EI-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS0 01 NW

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PrecautionsEIS001NX

lWhen removing or disassembling any part, be careful not to damage or deform it. Protect parts, which

may get in the way with cloth.

lWhen removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

lKeep removed parts protected with cloth.

lIf a clip is deformed or damaged, replace it.

lIf an unreusable part is removed, replace it with a new one.

lTighten bolts and nuts firmly to the specified torque.

lAfter re-assembly has been completed, make sure each part functions correctly.

lRemove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

lDo not use any organic solvent, such as thinner or benzine.

Page 1967 of 3066

BODY SIDE TRIM

EI-27

C

D

E

F

G

H

J

K

L

MA

B

EI

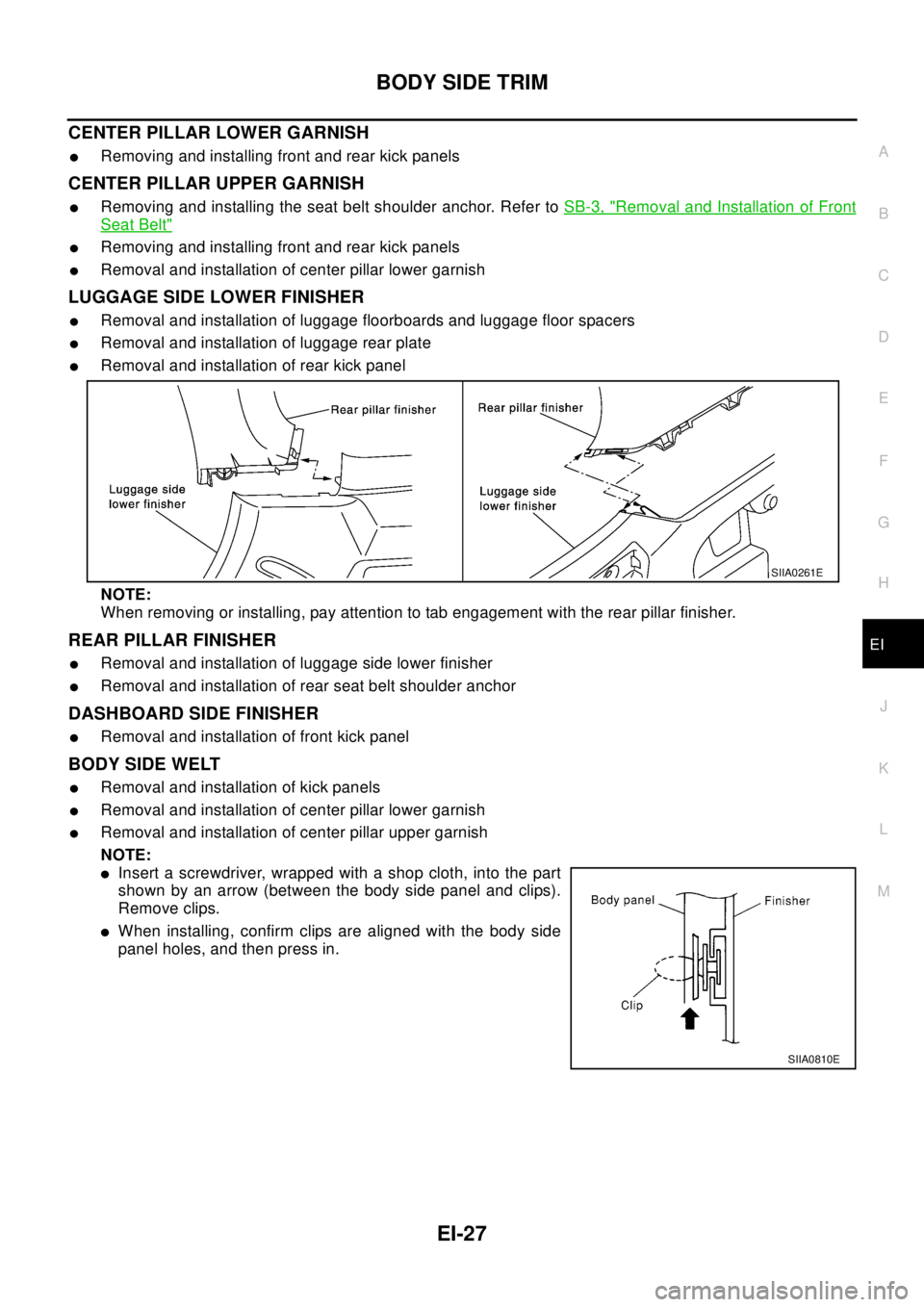

CENTER PILLAR LOWER GARNISH

lRemoving and installing front and rear kick panels

CENTER PILLAR UPPER GARNISH

lRemoving and installing the seat belt shoulder anchor. Refer toSB-3, "Removal and Installation of Front

Seat Belt"

lRemoving and installing front and rear kick panels

lRemoval and installation of center pillar lower garnish

LUGGAGE SIDE LOWER FINISHER

lRemoval and installation of luggage floorboards and luggage floor spacers

lRemoval and installation of luggage rear plate

lRemoval and installation of rear kick panel

NOTE:

When removing or installing, pay attention to tab engagement with the rear pillar finisher.

REAR PILLAR FINISHER

lRemoval and installation of luggage side lower finisher

lRemoval and installation of rear seat belt shoulder anchor

DASHBOARD SIDE FINISHER

lRemoval and installation of front kick panel

BODY SIDE WELT

lRemoval and installation of kick panels

lRemoval and installation of center pillar lower garnish

lRemoval and installation of center pillar upper garnish

NOTE:

lInsert a screwdriver, wrapped with a shop cloth, into the part

shown by an arrow (between the body side panel and clips).

Remove clips.

lWhen installing, confirm clips are aligned with the body side

panel holes, and then press in.

SIIA0261E

SIIA0810E

Page 1968 of 3066

EI-28

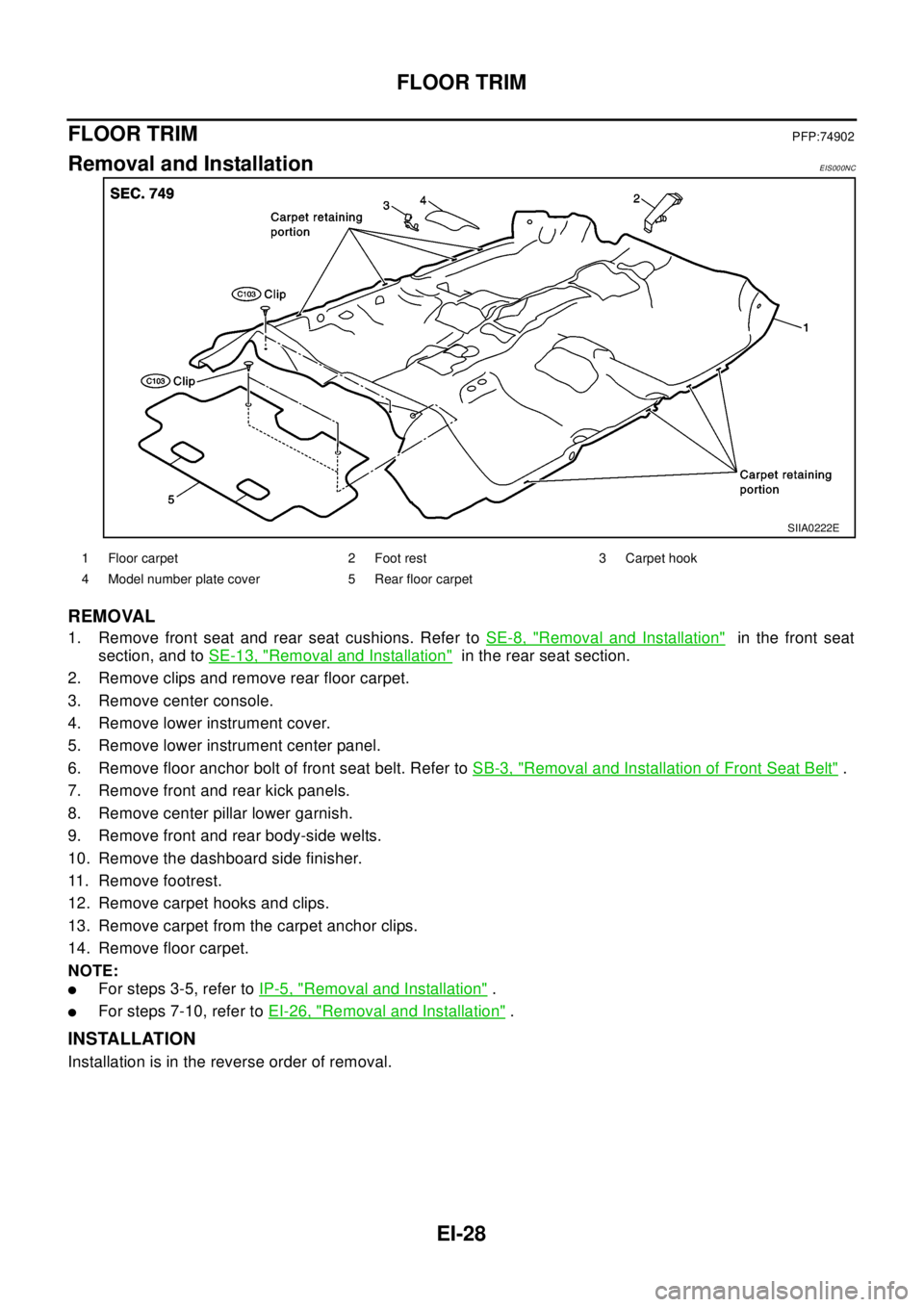

FLOOR TRIM

FLOOR TRIM

PFP:74902

Removal and InstallationEIS000NC

REMOVAL

1. Remove front seat and rear seat cushions. Refer toSE-8, "Removal and Installation"in the front seat

section, and toSE-13, "

Removal and Installation"in the rear seat section.

2. Remove clips and remove rear floor carpet.

3. Remove center console.

4. Remove lower instrument cover.

5. Remove lower instrument center panel.

6. Remove floor anchor bolt of front seat belt. Refer toSB-3, "

Removal and Installation of Front Seat Belt".

7. Remove front and rear kick panels.

8. Remove center pillar lower garnish.

9. Remove front and rear body-side welts.

10. Remove the dashboard side finisher.

11. Remove footrest.

12. Remove carpet hooks and clips.

13. Remove carpet from the carpet anchor clips.

14. Remove floor carpet.

NOTE:

lFor steps 3-5, refer toIP-5, "Removal and Installation".

lFor steps 7-10, refer toEI-26, "Removal and Installation".

INSTALLATION

Installation is in the reverse order of removal.

SIIA0222E

1 Floor carpet 2 Foot rest 3 Carpet hook

4 Model number plate cover 5 Rear floor carpet