manual transmission NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

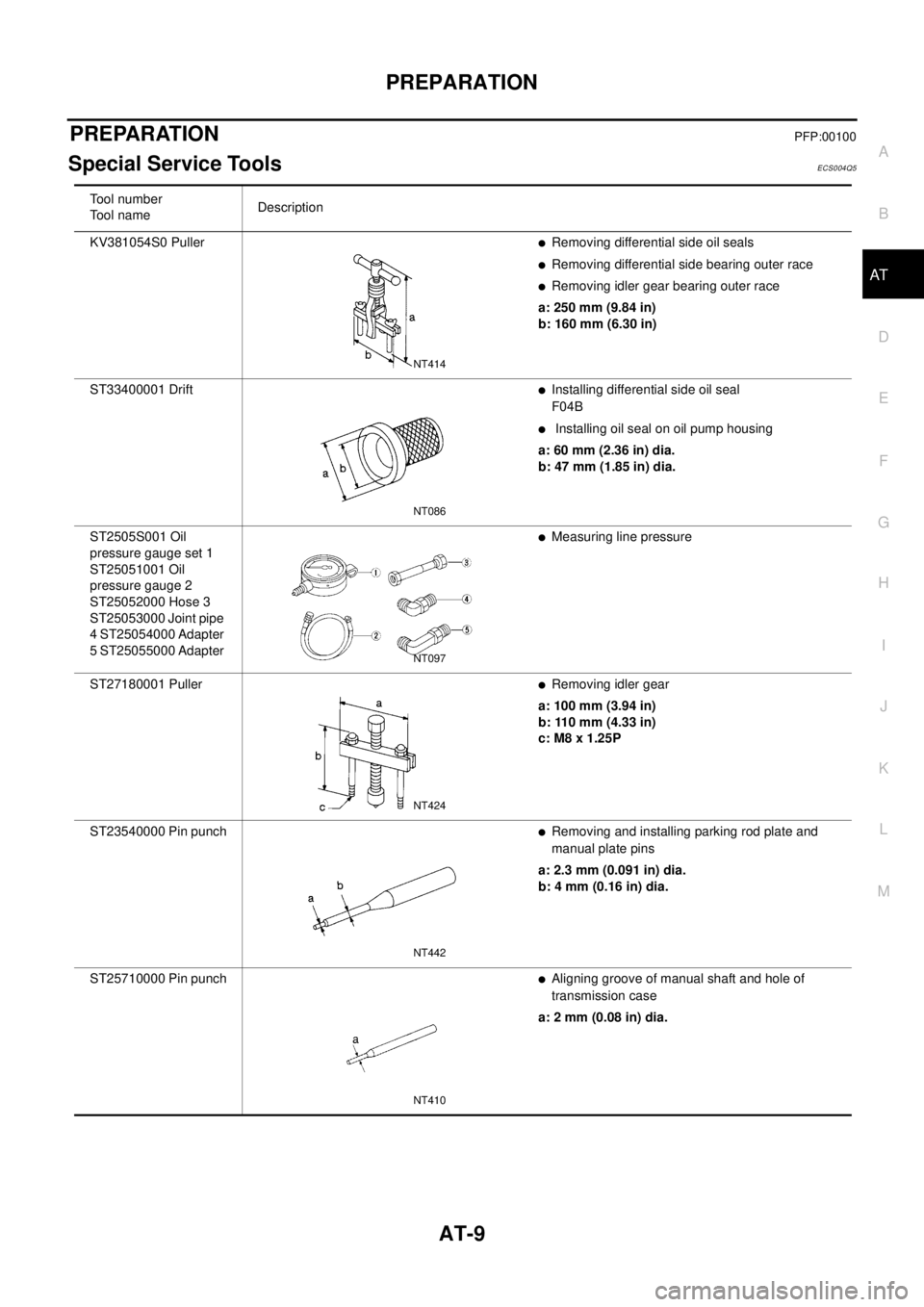

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 15 of 3066

PREPARATION

AT-9

D

E

F

G

H

I

J

K

L

MA

B

AT

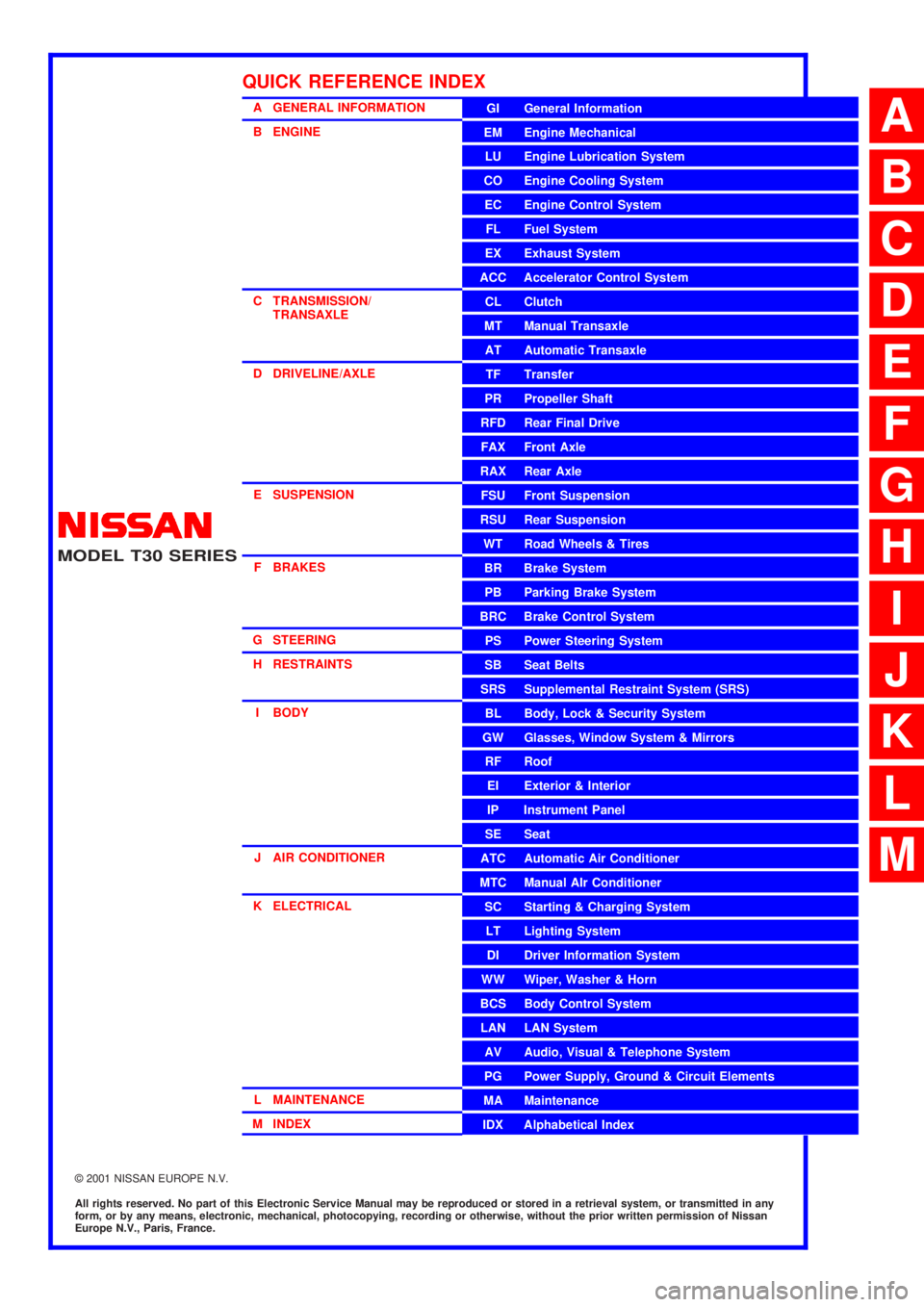

PREPARATIONPFP:00100

Special Service ToolsECS004Q5

Tool number

To o l n a m eDescription

KV381054S0 Puller

lRemoving differential side oil seals

lRemoving differential side bearing outer race

lRemoving idler gear bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33400001 Drift

lInstalling differential side oil seal

F04B

lInstalling oil seal on oil pump housing

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST2505S001 Oil

pressure gauge set 1

ST25051001 Oil

pressure gauge 2

ST25052000 Hose 3

ST25053000 Joint pipe

4 ST25054000 Adapter

5 ST25055000 Adapter

lMeasuring line pressure

ST27180001 Puller

lRemoving idler gear

a: 100 mm (3.94 in)

b: 110 mm (4.33 in)

c: M8 x 1.25P

ST23540000 Pin punch

lRemoving and installing parking rod plate and

manual plate pins

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

ST25710000 Pin punch

lAligning groove of manual shaft and hole of

transmission case

a: 2 mm (0.08 in) dia.

NT414

NT086

NT097

NT424

NT442

NT410

Page 461 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON-VEHICLE SERVICE

AT-455

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

6. Remove control valve assembly by removing fixing bolts.

Bolt length, number and location:

lBe careful not to drop manual valve and servo re NISSAN X-TRAIL 2003 Electronic Repair Manual ON-VEHICLE SERVICE

AT-455

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

6. Remove control valve assembly by removing fixing bolts.

Bolt length, number and location:

lBe careful not to drop manual valve and servo re](/img/5/57402/w960_57402-460.png)

ON-VEHICLE SERVICE

AT-455

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

6. Remove control valve assembly by removing fixing bolts.

Bolt length, number and location:

lBe careful not to drop manual valve and servo release accumulator return springs.

7. Disassemble and inspect control valve assembly if necessary. Refer toAT-454, "

Control Valve Assembly

and Accumulators".

8. Remove servo release and N-D accumulators by applying com-

pressed air if necessary.

lHold each piston with a rag.

INSTALLATION

lTighten fixing bolts to specification.

lSet manual shaft in Neutral position, then align manual

plate with groove in manual valve.

lAfter installing control valve assembly to transmission

case, make sure that selector lever can be moved to all

positions.

AAT260A

Bolt symbol A B C

Bolt length “ ” mm(in)40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

SAT935J

: 7 - 9 N-m (0.7 - 0.9 kg-m, 61 - 78 in-lb)

SAT497H

Page 474 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-468

[ALL]

DISASSEMBLY

c. Push terminal body into transmission case.

10. Remove manual valve from control valve assembly.

11. Remove return spring from servo release accumulator piston.

12. Remove s NISSAN X-TRAIL 2003 Electronic Repair Manual AT-468

[ALL]

DISASSEMBLY

c. Push terminal body into transmission case.

10. Remove manual valve from control valve assembly.

11. Remove return spring from servo release accumulator piston.

12. Remove s](/img/5/57402/w960_57402-473.png)

AT-468

[ALL]

DISASSEMBLY

c. Push terminal body into transmission case.

10. Remove manual valve from control valve assembly.

11. Remove return spring from servo release accumulator piston.

12. Remove servo release accumulator piston with compressed air.

13. Remove O-rings from servo release accumulator piston.

SCIA0801E

SAT005F

SAT018DA

SAT019DA

Page 488 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-482

[ALL]

REPAIR FOR COMPONENT PARTS

REPAIR FOR COMPONENT PARTS

PFP:00000

Manual ShaftECS004M0

COMPONENTS

REMOVAL

1. Remove detent spring from transmission case.

2. Drive out manual plate retaining NISSAN X-TRAIL 2003 Electronic Repair Manual AT-482

[ALL]

REPAIR FOR COMPONENT PARTS

REPAIR FOR COMPONENT PARTS

PFP:00000

Manual ShaftECS004M0

COMPONENTS

REMOVAL

1. Remove detent spring from transmission case.

2. Drive out manual plate retaining](/img/5/57402/w960_57402-487.png)

AT-482

[ALL]

REPAIR FOR COMPONENT PARTS

REPAIR FOR COMPONENT PARTS

PFP:00000

Manual ShaftECS004M0

COMPONENTS

REMOVAL

1. Remove detent spring from transmission case.

2. Drive out manual plate retaining pin.

SAT769J

SAT042F

SAT842DC

Page 489 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REPAIR FOR COMPONENT PARTS

AT-483

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

3. Drive and pull out parking rod plate retaining pin.

4. Remove parking rod plate from manual shaft.

5. Draw out parking rod from tra NISSAN X-TRAIL 2003 Electronic Repair Manual REPAIR FOR COMPONENT PARTS

AT-483

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

3. Drive and pull out parking rod plate retaining pin.

4. Remove parking rod plate from manual shaft.

5. Draw out parking rod from tra](/img/5/57402/w960_57402-488.png)

REPAIR FOR COMPONENT PARTS

AT-483

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

3. Drive and pull out parking rod plate retaining pin.

4. Remove parking rod plate from manual shaft.

5. Draw out parking rod from transmission case.

6. Pull out manual shaft retaining pin.

7. Remove manual shaft and manual plate from transmission case.

8. Remove manual shaft oil seal.

INSPECTION

lCheck component parts for wear or damage. Replace if necessary.

INSTALLATION

1. Install manual shaft oil seal.

lApply ATF to outer surface of oil seal.

SAT043FC

SAT049F

SAT080D

SAT081D

Page 490 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-484

[ALL]

REPAIR FOR COMPONENT PARTS

2. Install manual shaft and manual plate.

3. Align groove of manual shaft and hole of transmission case.

4. Install manual shaft retaining pin up to bottom of h NISSAN X-TRAIL 2003 Electronic Repair Manual AT-484

[ALL]

REPAIR FOR COMPONENT PARTS

2. Install manual shaft and manual plate.

3. Align groove of manual shaft and hole of transmission case.

4. Install manual shaft retaining pin up to bottom of h](/img/5/57402/w960_57402-489.png)

AT-484

[ALL]

REPAIR FOR COMPONENT PARTS

2. Install manual shaft and manual plate.

3. Align groove of manual shaft and hole of transmission case.

4. Install manual shaft retaining pin up to bottom of hole.

5. Install parking rod to parking rod plate.

6. Set parking rod assembly onto manual shaft and drive retaining

pin.

lBoth ends of pin should protrude.

7. Drive manual plate retaining pin.

lBoth ends of pin should protrude.

8. Install detent spring. Tighten detent spring bolts to the specified

torque. Refer toAT-482, "

REPAIR FOR COMPONENT PARTS"

.

SAT044F

SAT045FC

SAT034JA

SAT047FC

SAT042F

Page 566 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-560

[ALL]

ASSEMBLY

15. Install lip seals for band servo oil holes on transmission case.

lApply petroleum jelly to lip seals.

16. Install L & R oil tube and oil sleeve. Tighten L & R oil tube bolts

NISSAN X-TRAIL 2003 Electronic Repair Manual AT-560

[ALL]

ASSEMBLY

15. Install lip seals for band servo oil holes on transmission case.

lApply petroleum jelly to lip seals.

16. Install L & R oil tube and oil sleeve. Tighten L & R oil tube bolts](/img/5/57402/w960_57402-565.png)

AT-560

[ALL]

ASSEMBLY

15. Install lip seals for band servo oil holes on transmission case.

lApply petroleum jelly to lip seals.

16. Install L & R oil tube and oil sleeve. Tighten L & R oil tube bolts

to the specified torque. Refer toAT- 4 6 1 , "

OVERHAUL".

17. Install control valve assembly.

a. Insert manual valve into control valve assembly.

lApply ATF to manual valve.

b. Set manual shaft in Neutral position.

c. Install control valve assembly on transmission case while align-

ing manual valve with manual plate.

d. Pass solenoid harness through transmission case and install

terminal body on transmission case by pushing it.

e. Install stopper ring to terminal body.

SAT006F

SAT862HA

SAT005F

SAT094J

SCIA0808E

Page 567 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ASSEMBLY

AT-561

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

f. Tighten boltsI,Xandl.

Bolt length, number and location:

18. Install oil pan.

a. Attach a magnet to oil pan.

b. Install new oil pan gasket on transmis NISSAN X-TRAIL 2003 Electronic Repair Manual ASSEMBLY

AT-561

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

f. Tighten boltsI,Xandl.

Bolt length, number and location:

18. Install oil pan.

a. Attach a magnet to oil pan.

b. Install new oil pan gasket on transmis](/img/5/57402/w960_57402-566.png)

ASSEMBLY

AT-561

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

f. Tighten boltsI,Xandl.

Bolt length, number and location:

18. Install oil pan.

a. Attach a magnet to oil pan.

b. Install new oil pan gasket on transmission case.

c. Install oil pan on transmission case.

lAlways replace oil pan bolts as they are self-sealing

bolts.

lTighten four bolts in a criss-cross pattern to prevent dis-

location of gasket.

d. Tighten oil pan bolts and drain plug to the specified torque.

Refer toAT- 4 6 1 , "

OVERHAUL".

19. Install park/neutral position (PNP) switch.

a. Set manual shaft in P position.

b. Temporarily install park/neutral position (PNP) switch on manual

shaft.

c. Move selector lever to N position.

BoltIXl

Bolt length “ ” mm (in)40 (1.57) 33 (1.30)43.5

(1.713)

Number of bolts 5 6 2

SAT004F

SAT003F

SAT033J

Page 1130 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-16

[QR (WITH EURO-OBD)]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00B0I

The Supplemental Restraint Sys NISSAN X-TRAIL 2003 Electronic Repair Manual EC-16

[QR (WITH EURO-OBD)]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00B0I

The Supplemental Restraint Sys](/img/5/57402/w960_57402-1129.png)

EC-16

[QR (WITH EURO-OBD)]

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00B0I

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

On Board Diagnostic (OBD) System of Engine and A/TEBS00B0J

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch OFF and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MI to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lCertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer toPG-70, "

HAR-

NESS CONNECTOR".

lBe sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel injection system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionEBS00B0K

lAlways use a 12 volt battery as power source.

lDo not attempt to disconnect battery cables while engine is

running.

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative

battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lBefore removing parts, turn ignition switch OFF and then

disconnect battery ground cable.

SEF289H