engine oil NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 25 of 3066

OVERALL SYSTEM

AT-19

D

E

F

G

H

I

J

K

L

MA

B

AT

Shift MechanismECS004QD

CONSTRUCTION

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5Reverse clutch R/C To transmit input power to front sun gear7.

6High clutch H/C To transmit input power to front planetary carrier10.

15Forward clutch F/C To connect front planetary carrier10with forward one-way clutch16.

17Overrun clutch O/C To connect front planetary carrier10with rear internal gear13.

4Brake band B/B To lock front sun gear7.

16Forward one-way clutch F/O.C When forward clutch15is engaged, to stop rear internal gear13from rotating in

opposite direction against engine revolution.

18Low one-way clutch L/O.C To stop front planetary carrier10from rotating in opposite direction against

engine revolution.

19Low & reverse brake L & R/B To lock front planetary carrier10.

Shift positionRever

se

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e

brake

19Lock-

upRemarks

2nd

apply3rd

releas

e4th

apply

PPA R K

POSITION

RREVERSE

POSITION

Page 26 of 3066

AT-20

OVERALL SYSTEM

l*1: Operates when overdrive control switch is set in “OFF” position.

l*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not con-

tract because oil pressure area on the “release” side is greater than that on the “apply” side.

l*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

l*4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position.

l*5: Operates when overdrive control switch is “OFF”.

l:Operates.

lA: Operates when throttle opening is less than 3/16, activating engine brake.

lB: Operates during “progressive” acceleration.

lC: Operates but does not affect power transmission.

lD: Operates when throttle opening is less than 3/16, but does not affect engine brake.

POWER TRANSMISSION

“N” and “P” Positions

l“N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

l“P” position

NNEUTRAL

POSITION

D*41st *1D B B

Automatic

shift

1Û2Û3Û

4 2nd *1A B

3rd *1A *2C C B

*5

4th C *3C C

21st D B BAutomatic

shift

1Û2 2nd A B

11stBLocks (held

stationary) in

1st speed

1Ü2 2ndB Shift positionRever

se

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e

brake

19Lock-

upRemarks

2nd

apply3rd

releas

e4th

apply

Page 39 of 3066

OVERALL SYSTEM

AT-33

D

E

F

G

H

I

J

K

L

MA

B

AT

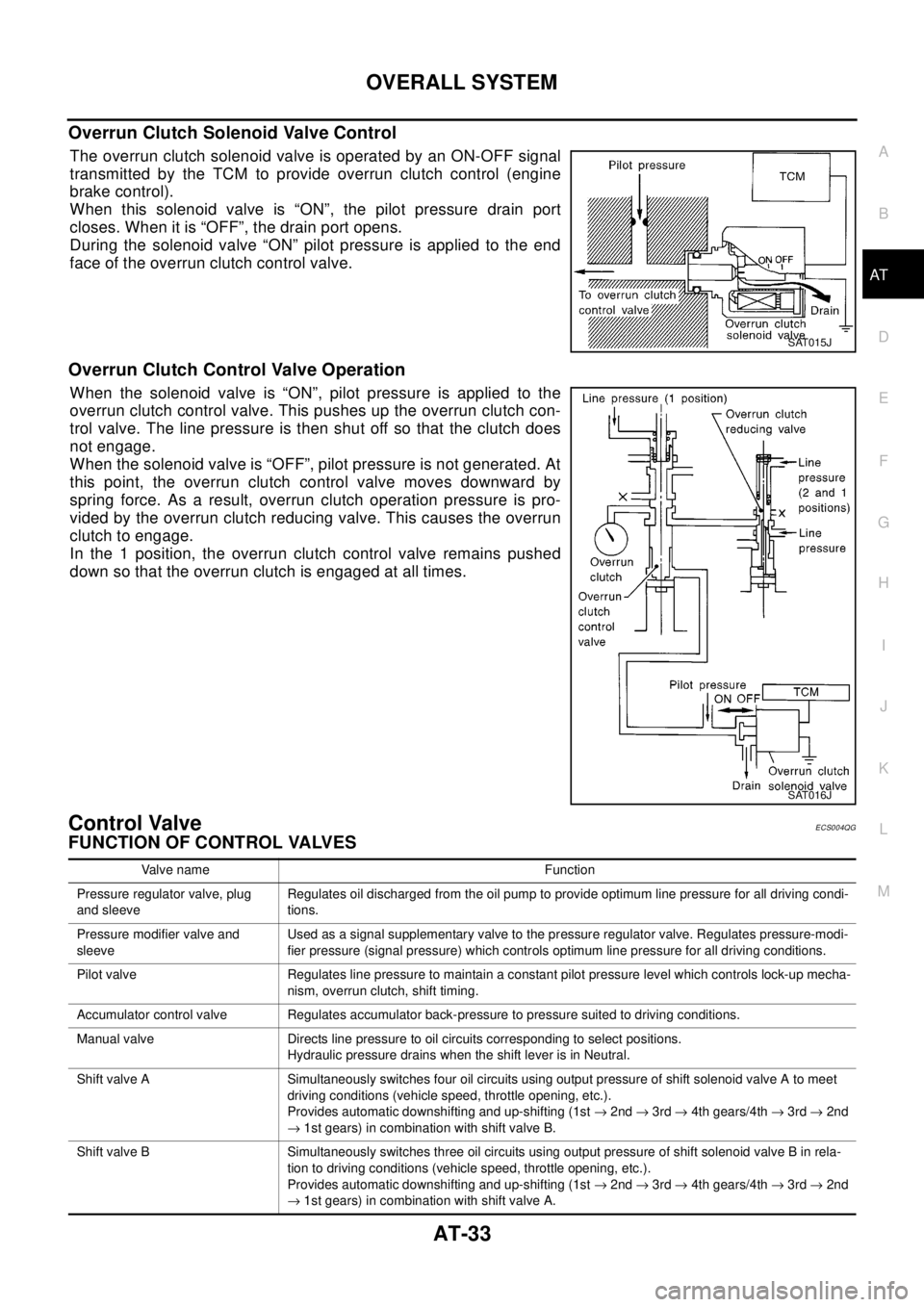

Overrun Clutch Solenoid Valve Control

TheoverrunclutchsolenoidvalveisoperatedbyanON-OFFsignal

transmitted by the TCM to provide overrun clutch control (engine

brake control).

When this solenoid valve is “ON”, the pilot pressure drain port

closes. When it is “OFF”, the drain port opens.

During the solenoid valve “ON” pilot pressure is applied to the end

face of the overrun clutch control valve.

Overrun Clutch Control Valve Operation

When the solenoid valve is “ON”, pilot pressure is applied to the

overrun clutch control valve. This pushes up the overrun clutch con-

trol valve. The line pressure is then shut off so that the clutch does

not engage.

When the solenoid valve is “OFF”, pilot pressure is not generated. At

this point, the overrun clutch control valve moves downward by

spring force. As a result, overrun clutch operation pressure is pro-

vided by the overrun clutch reducing valve. This causes the overrun

clutch to engage.

In the 1 position, the overrun clutch control valve remains pushed

down so that the overrun clutch is engaged at all times.

Control ValveECS004QG

FUNCTION OF CONTROL VALVES

SAT015J

SAT016J

Valve name Function

Pressure regulator valve, plug

and sleeveRegulates oil discharged from the oil pump to provide optimum line pressure for all driving condi-

tions.

Pressure modifier valve and

sleeveUsed as a signal supplementary valve to the pressure regulator valve. Regulates pressure-modi-

fier pressure (signal pressure) which controls optimum line pressure for all driving conditions.

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls lock-up mecha-

nism, overrun clutch, shift timing.

Accumulator control valve Regulates accumulator back-pressure to pressure suited to driving conditions.

Manual valve Directs line pressure to oil circuits corresponding to select positions.

Hydraulic pressure drains when the shift lever is in Neutral.

Shift valve A Simultaneously switches four oil circuits using output pressure of shift solenoid valve A to meet

driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st®2nd®3rd®4th gears/4th®3rd®2nd

®1st gears) in combination with shift valve B.

Shift valve B Simultaneously switches three oil circuits using output pressure of shift solenoid valve B in rela-

tion to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st®2nd®3rd®4th gears/4th®3rd®2nd

®1st gears) in combination with shift valve A.

Page 40 of 3066

AT-34

OVERALL SYSTEM

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simultaneously with appli-

cation of the brake band in D

4. (Interlocking occurs if the overrun clutch engages during D4.)

1st reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when down-shifting from

the “1” position 1

2to 11.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In “1” and “2” positions, line pressure acts on the overrun clutch reducing valve to increase the

pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control

valve, plug and sleeveActivates or inactivates the lock-up function.

Also provides smooth lock-up through transient application and release of the lock-up system.

1-2 accumulator valve and piston Dampens the shock encountered when 2nd gear band servo contracts, and provides smooth

shifting.

3-2 timing valve Switches oil pressure with 3-2 timing valve according to throttle opening.

Shuttle control valve Reduces shock when down-shifting from 3rd to 2nd and regulates overrun clutch.

Cooler check valve Regulates oil pressure which causes lock-up when driving at low speeds.Valve name Function

Page 71 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-65

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Stall TestECS004QR

STALL TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-65

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Stall TestECS004QR

STALL TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle](/img/5/57402/w960_57402-70.png)

TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-65

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Stall TestECS004QR

STALL TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

lIt is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in D

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately release

throttle.

lDuring test, never hold throttle wide open for less than 5

seconds.

Stall revolution:

8. Move selector lever to “N” position.

9. Cool off ATF.

lRun engine at idle for at least one minute.

10. Repeat steps 5 through 9 with selector lever in “2”, “1” and “R”

positions.ATF operating temperature:

50 - 80°C (122 - 176°F)

SAT647B

SAT513G

SAT514G

QR20DE 2,450 - 2,950 rpm

SAT771B

Page 74 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-68

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Line Pressure Test

ECS004QS

LINE PRESSURE TEST PORTS

Location of line pressure test ports are shown in the illustration.

lAlways replace pressur NISSAN X-TRAIL 2003 Electronic Repair Manual AT-68

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Line Pressure Test

ECS004QS

LINE PRESSURE TEST PORTS

Location of line pressure test ports are shown in the illustration.

lAlways replace pressur](/img/5/57402/w960_57402-73.png)

AT-68

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Line Pressure Test

ECS004QS

LINE PRESSURE TEST PORTS

Location of line pressure test ports are shown in the illustration.

lAlways replace pressure plugs as they are self-sealing

bolts.

LINE PRESSURE TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add fluid or

oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

3. Install pressure gauge to corresponding line pressure port.

4. Set parking brake and block wheels.

lContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

SCIA0709E

ATF operating temperature: 50 - 80°C (122 -176°F)

SAT647B

UAT008

UAT008

Page 75 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-69

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Start engine and measure line pressure at idle and stall speed.

lWhen measuring line pressure at stall speed, follo NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-69

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Start engine and measure line pressure at idle and stall speed.

lWhen measuring line pressure at stall speed, follo](/img/5/57402/w960_57402-74.png)

TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-69

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Start engine and measure line pressure at idle and stall speed.

lWhen measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer toAT-563, "

SERVICE DATA AND SPECIFI-

CATIONS (SDS)".

JUDGEMENT OF LINE PRESSURE TEST

Road TestECS004QT

DESCRIPTION

lThe purpose of the test is to determine overall performance of A/

T and analyze causes of problems.

lThe road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

SAT493G

Judgement Suspected parts

At idleLine pressure is low in all positions.

lOil pump wear

lControl piston damage

lPressure regulator valve or plug sticking

lSpring for pressure regulator valve damaged

lFluid pressure leakage between oil strainer and pressure regulator valve

lClogged strainer

Line pressure is low in particular posi-

tion.

lFluid pressure leakage between manual valve and particular clutch

lFor example, line pressure is:

-Low in “R” and “1” positions, but

-Normal in “D” and “2” positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to “CLUTCH AND BAND CHART”,AT-19, "

CLUTCH AND BAND

CHART".

Line pressure is high.

lMaladjustment of throttle position sensor

lA/T fluid temperature sensor damaged

lLine pressure solenoid valve sticking

lShort circuit of line pressure solenoid valve circuit

lPressure modifier valve sticking

lPressure regulator valve or plug sticking

lOpen in dropping resistor circuit

At stall

speedLine pressure is low.

lMaladjustment of throttle position sensor

lLine pressure solenoid valve sticking

lShort circuit of line pressure solenoid valve circuit

lPressure regulator valve or plug sticking

lPressure modifier valve sticking

lPilot valve sticking

SAT786A

Page 84 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-78

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Cruise Test — Part 1

1.CHECKSTARTINGGEAR(D1) POSITION

1. Drive vehicle for approx. 10 minutes to warm engine oil and ATF up to operating

tempe NISSAN X-TRAIL 2003 Electronic Repair Manual AT-78

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Cruise Test — Part 1

1.CHECKSTARTINGGEAR(D1) POSITION

1. Drive vehicle for approx. 10 minutes to warm engine oil and ATF up to operating

tempe](/img/5/57402/w960_57402-83.png)

AT-78

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Cruise Test — Part 1

1.CHECKSTARTINGGEAR(D1) POSITION

1. Drive vehicle for approx. 10 minutes to warm engine oil and ATF up to operating

temperature.

2. Park vehicle on flat surface.

3. Set overdrive control switch to “ON” position.

4. Move selector lever to “P” position.

5. Start engine.

6. Move selector lever to “D” position.

7. Accelerate vehicle by constantly depressing accelerator pedal

halfway.

8. Does vehicle start from D

1?

Read gear position.

Ye s o r N o

Yes >>GOTO2

No >> Go To "8. Vehicle Cannot Be Started From D

1”,AT-242,

"8. Vehicle Cannot Be Started From D1". Continue

ROAD TEST. ATF operating temperature : 50 - 80°C (122 - 176°F)

SAT774B

SAT775B

SAT495G

Page 93 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-87

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Transaxle noise in “P” and “N” posi-

tions.ON vehicle1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

2. Line pr NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-87

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Transaxle noise in “P” and “N” posi-

tions.ON vehicle1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

2. Line pr](/img/5/57402/w960_57402-92.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-87

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Transaxle noise in “P” and “N” posi-

tions.ON vehicle1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

2. Line pressure testAT-68, "

Line

Pressure

Te s t"

¬

3. Throttle position sensor (Accelerator

pedal position (App) sensor) AjustmentEC-154, "

DTC P0121 APP

SENSOR"

4. Vehicle speed sensor·A/T (Revolution

sensor) and vehicle speed sensor·MTRAT-392,

"VEHICLE

SPEED

SENSOR·A/

T(REVO-

LUTION

SENSOR)",

AT-397,

"DTC VEHI-

CLE

SPEED

SENSOR

MTR"

AT-142,

"DTC P0720

VEHICLE

SPEED

SENSOR·A/

T(REVO-

LUTION

SENSOR)",

AT-222,

"DTC VEHI-

CLE SPEED

SENSOR

MTR"

5. Engine speed signalAT-432,"ENGINE

SPEED

SIGNAL"

AT-147,

"DTC P0725

ENGINE

SPEED

SIGNAL"

OFF vehicle6. Oil pumpAT-485, "

Oil

Pump"¬

7. Torque converterAT-465,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬

Vehicle moves when changing into

“P” position, or parking gear does

not disengage when shifted out of

“P” position.

AT- 2 3 4 , "

3. In“P”Position, Vehicle

Moves Forward Or Backward When

Pushed"

ON vehicle 1. Control cable adjustmentAT-456,"Control

Cable

Adjustment"

¬

OFF vehicle 2. Parking componentsAT-461,

"Compo-

nents",AT-

482,

"REPAIR

FOR COM-

PONENT

PA R T S"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 100 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-94

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Excessive creep. ON vehicle 1. Engine idling rpm"EC-XX",

“Idle Speed

and Ignition

Timing”¬

No creep at all.

AT-237, "

6. Vehicle Does No NISSAN X-TRAIL 2003 Electronic Repair Manual AT-94

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Excessive creep. ON vehicle 1. Engine idling rpm"EC-XX",

“Idle Speed

and Ignition

Timing”¬

No creep at all.

AT-237, "

6. Vehicle Does No](/img/5/57402/w960_57402-99.png)

AT-94

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Excessive creep. ON vehicle 1. Engine idling rpm"EC-XX",

“Idle Speed

and Ignition

Timing”¬

No creep at all.

AT-237, "

6. Vehicle Does Not Creep

Backward In“R”Position"andAT-

240, "7. Vehicle Does Not Creep

Forward In“D”,“2”Or“1”Position"

ON vehicle1. Fluid levelAT- 6 4 ,

"FLUID

LEVEL

CHECK"

¬

2. Line pressure testAT- 4 3 6 ,

"LINE

PRES-

SURE

SOLENOID

VA LV E"

¬

3. Control valve assemblyAT- 4 5 4 ,

"Control

Va l v e

Assembly

and Accu-

mulators"

¬

OFF vehicle4. Forward clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

5. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

6. Torque converterAT- 4 6 5 ,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD