horn NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

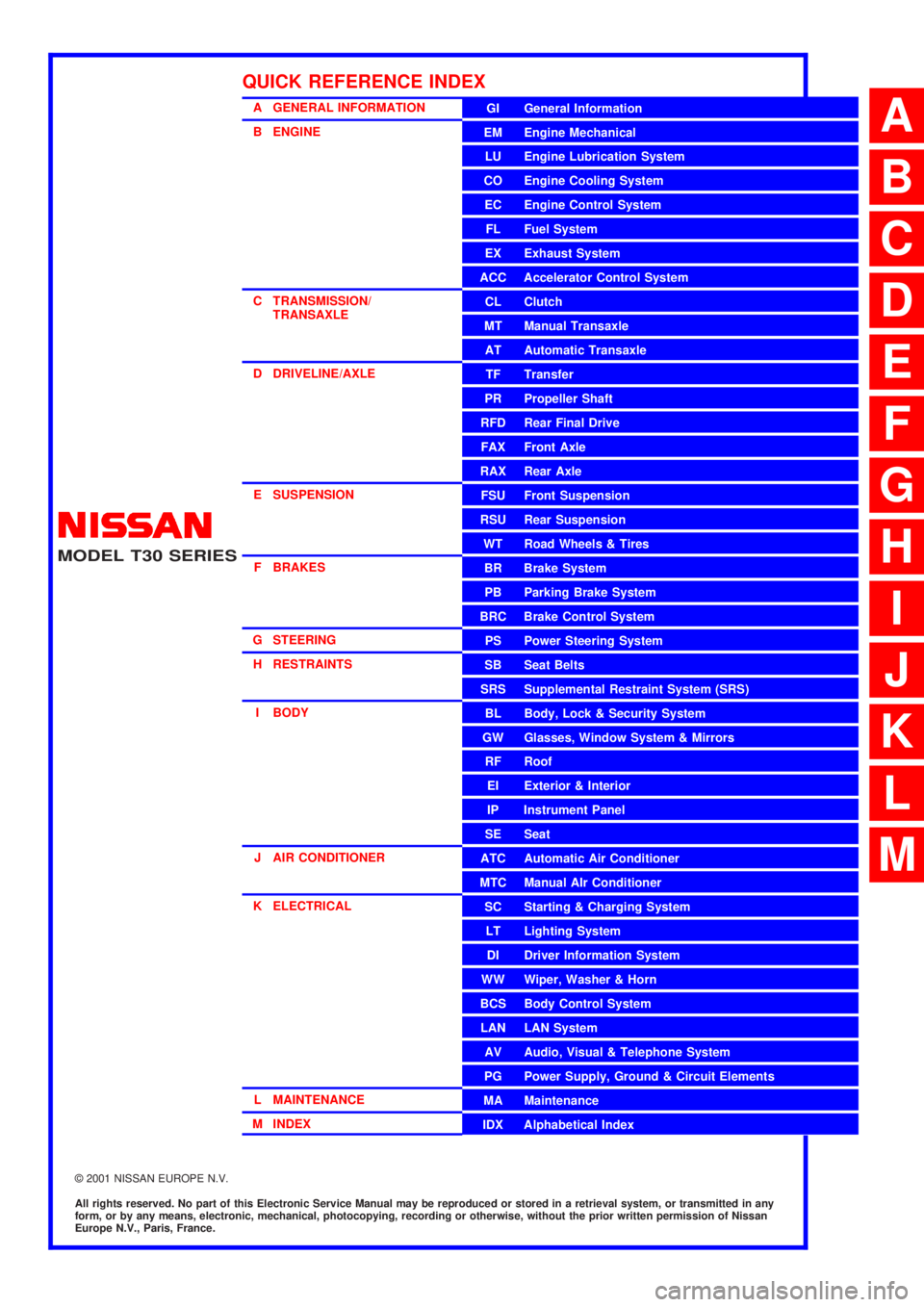

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 1024 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-14

[QR20DE]

RADIATOR

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualn NISSAN X-TRAIL 2003 Electronic Repair Manual CO-14

[QR20DE]

RADIATOR

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualn](/img/5/57402/w960_57402-1023.png)

CO-14

[QR20DE]

RADIATOR

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualness in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUsecompressedairlowerthan490kPa(5kg/cm2, 71psi) and keep distance more than 30 cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.Standard

: 78- 98 kPa (0.78-0.98bar, 0.8 - 1.0 kg/cm

2,

11 - 14 psi)

Limit

: 59kpa (0.59bar, 0.6kg/cm

2,9psi)

SLC135B

Page 1045 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual RADIATOR

CO-35

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator NISSAN X-TRAIL 2003 Electronic Repair Manual RADIATOR

CO-35

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator](/img/5/57402/w960_57402-1044.png)

RADIATOR

CO-35

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualness in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

Checking RadiatorEBS00BRH

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (4.9bar 5 kg/cm2, 71psi) and keep distance more than 30

cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.Standard

: 78 - 98 kpa (0.78 - 0.98bar, 0.8 - 1.0 kg/cm

2

,11-14psi)

Limit : 59kpa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC135B

Page 2174 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-204

[YD22DDTi]

CYLINDER BLOCK

MAIN BEARING HOUSING INNER DIAMETER

lWithout installing main bearings, install main bearing caps, and

tighten bolts to the specified torque.

lMeasure the inner diamete NISSAN X-TRAIL 2003 Electronic Repair Manual EM-204

[YD22DDTi]

CYLINDER BLOCK

MAIN BEARING HOUSING INNER DIAMETER

lWithout installing main bearings, install main bearing caps, and

tighten bolts to the specified torque.

lMeasure the inner diamete](/img/5/57402/w960_57402-2173.png)

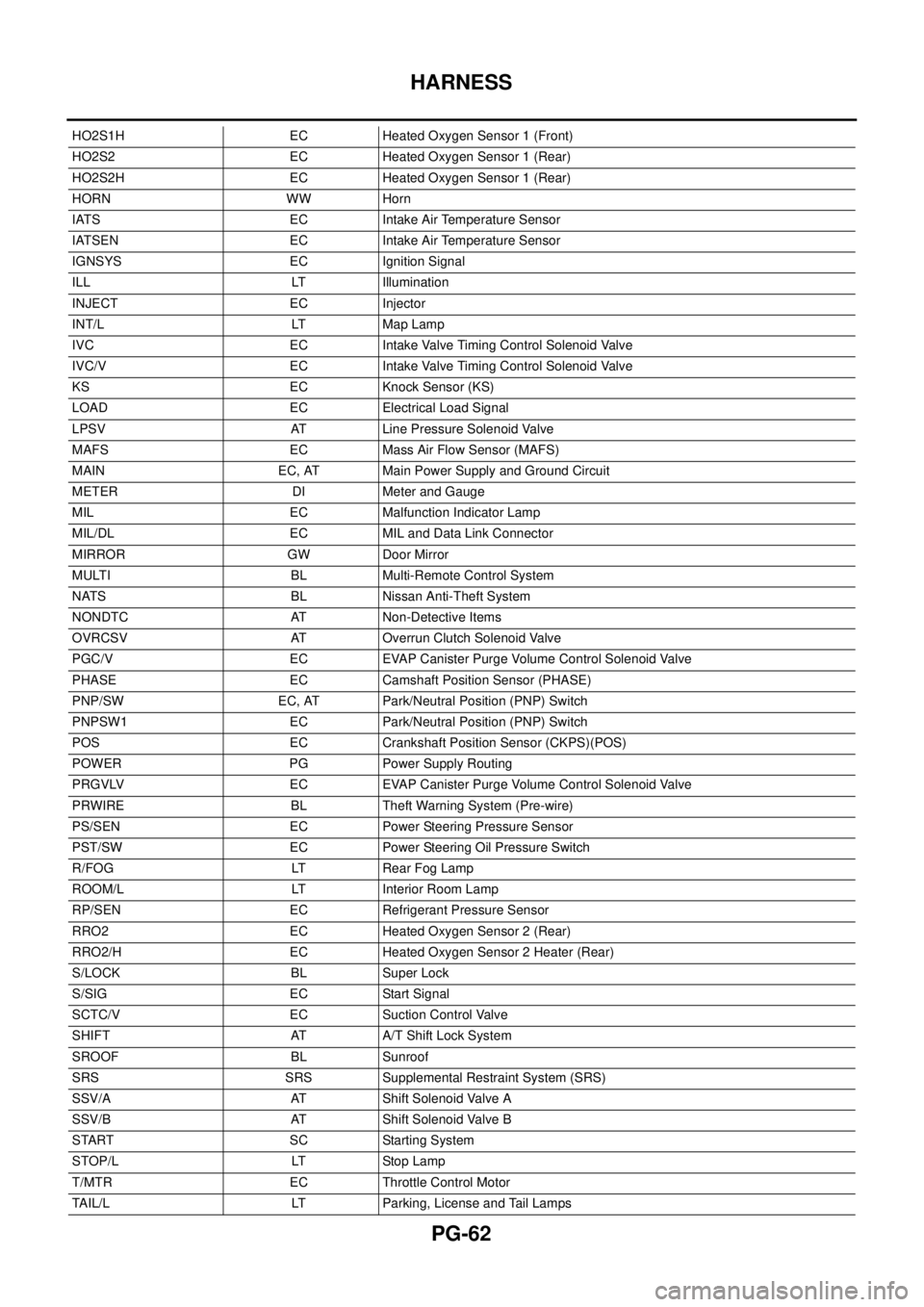

EM-204

[YD22DDTi]

CYLINDER BLOCK

MAIN BEARING HOUSING INNER DIAMETER

lWithout installing main bearings, install main bearing caps, and

tighten bolts to the specified torque.

lMeasure the inner diameter of main bearing housing with a bore

gauge.

lIf the measurement is out of the specified range, replace cylin-

der block and main bearing caps.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder Bore Inner Diameter

lUsing bore gauge, measure cylinder inner diameters at 6 posi-

tions; top, middle, and bottom (A, B, C) in 2 directions (X, Y).

lIf clearance exceeds the limit, or any flaws or seizures are found

on inner surface of cylinder, horn or bore the applicable cylinder

or redore all cylinder.

Piston Outer Diameter

Use micrometer to measure piston skirt outer diameter.

Calculation of Piston to Piston Bore Clearance

lCalculate using piston skirt outer diameter and cylinder inner diameter (direction X, position B).

(Clearance) = (Cylinder inner diameter)-(Piston skirt outer diameter) Standard : 66.654 - 66.681 mm (2.6242 - 2.6252 in) dia.

JEM214G

Cylinder inner diameter:

Standard : 86.000 - 86.030 mm

(3.3858 - 3.5870 in) dia.

Wear limit : 0.07 mm (0.0028 in)

Out-of-round limit (X - Y) : 0.015 mm (0.0006 in)

Taper limit (A - B - C) : 0.010 mm (0.0004 in)

JEM207G

FEM110

Piston skirt diameter:

Measurement position : 48.83 mm (1.9224 in)

Distance from the top

Standard : 85.925 - 85.955 mm

(3.3829 - 3.3841 in) dia.

0.25 (0.0098) O/S : 86.175 - 86.205 )

(3.3927 - 3.3939

0.50 (0.0197) O/S : 86.425 - 86.455

(3.4026 - 3.4036)

Specifications at room temperature [20°C(68°F)]:

0.065 - 0.085 mm (0.0026 - 0.0033 in)

PBIC0125E

Page 2362 of 3066

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FTS - Wiring diagram ......................................EC-752

Fuel check valve ..............................................EC-372

Fuel cut control (at no load high engine speed)EC-28,

EC-393

,EC-662

Fuel filler lid ........................................................BL-64

Fuel filter ..........................................................EC-664

Fuel filter replacement(QR20DE) .........................FL-4

Fuel filter replacement(YD22DDTi) .......FL-15,MA-30

Fuel gauge ..................................................DI-4,DI-22

Fuel injection control system ...........................EC-660

Fuel injection system .........................EC-194,EC-200

Fuel injector .....................................................EC-727

Fuel injector adjustment resistor ......................EC-777

Fuel injector and fuel tube(QR20DE) ................EM-29

Fuel injector and fuel tube(YD22DDTi) ............EM-135

Fuel leak ..........................................................EC-781

Fuel line inspection(QR20DE) .................FL-3,MA-23

Fuel line inspection(YD22DDTi) ............FL-14,MA-30

Fuel pressure check ............................EC-34,EC-399

Fuel pressure release ..........................EC-34,EC-399

Fuel pressure relief valve ................................EC-665

Fuel pump ..........................................EC-352,EC-627

Fuel pump and gauge(QR20DE) ..........................FL-4

Fuel system(QR20DE) .........................................FL-3

Fuel system(YD22DDTi) .....................................FL-14

Fuel tank(QR20DE) ..............................................FL-9

Fuel tank(YD22DDTi) .........................................FL-21

Fuel temperature sensor .................................EC-751

Fuse ...................................................................PG-12

Fuse and fusible link box ...................................PG-77

Fusible link .........................................................PG-12

G

Gear components (M/T) .......................MT-19

,MT-24

Generator ..........................................................SC-12

Generator - See Alternator ................................SC-12

Generic scan tool (GST) ....................................EC-96

Glass ..................................................GW-41,GW-43

GLOW - Wiring diagram ..................................EC-797

Glow plug .........................................................EC-796

Glow plug(YD22DDTi) .....................................EM-130

Glow relay ........................................................EC-796

Grease ...............................................................MA-17

Grille - See Exterior .............................................EI-11

Ground distribution ............................................PG-13

G-sensor .............................................................TF-50

H

H/AIM - Wiring diagram ......................................LT-15

H/LAMP - Wiring diagram ...........................LT-4,LT-5

H/MIRROR - Wiring diagram ............................GW-10

Harness connector ............................................PG-70

Harness layout ...................................................PG-29

Headlamp .............................................................LT-4

Headlamp aiming control ....................................LT-15

Headlamp leveler - See Headlamp aiming control .......

LT-15

Headlamp washer ............................................WW-19

Headlining - See Roof trim ..................................EI-29

Heated oxygen sensor 1 ....EC-160,EC-166,EC-174,

EC-284

,EC-290,EC-490,EC-581

Heated oxygen sensor 1 heater .........EC-120,EC-568

Heated oxygen sensor 2 ....EC-181,EC-187,EC-296,

EC-303

,EC-587

Heated oxygen sensor 2 heater .........EC-125,EC-573

Heated seat ...............................................SE-3,SE-5

HEATER - Wiring diagram ................................MTC-6

Heater and cooling unit (Heater core) ............ATC-115

Heater mirror .....................................................GW-10

Heater system - Wiring diagram .......................MTC-6

Heater unit (heater core) ..ATC-120,MTC-23,MTC-26

HFC134a (R134a) system precaution ...............ATC-4

HFC134a (R134a) system service procedureATC-123

HFC134a (R134a) system service tools ..........ATC-12

HFC134a system service equipment precautionATC-8

HO2S1 - Wiring diaram ......EC-122,EC-162,EC-169,

EC-177

,EC-492

HO2S2 - Wiring diagram ....EC-183,EC-190,EC-299,

EC-306

HO2S2H - Wiring diagram ...............................EC-127

Hood ....................................................................BL-4

Horn .................................................................WW-23

HORN - Wiring diagram ...................................WW-23

How to erase DTC ...........................................EC-666

HowtoeraseDTCforOBDsystem .....EC-46,EC-402

I

IATS - Wiring diagram .....................................EC-138

IATSEN - Wiring diagram ................................EC-578

Identification .....................................................ATC-10

Idle air volume learning ........................EC-31,EC-396

Idle speed .............................EC-64,EC-412,EC-672

IGN/SG - Wiring diagram .................................EC-335

Ignition coil .........................................EC-334,EC-592

Ignition coil(QR20DE) .......................................EM-27

Ignition control system .......................EC-334,EC-592

Ignition timing .......................................EC-64,EC-412

IGNSYS - Wiring diagram ................................EC-593

ILL - Wiring diagram ...........................................LT-45

Illumination ..........................................................LT-45

In vehicle sensor ...............ATC-95,ATC-97,ATC-106

INJECT - Wiring diagram ....EC-344,EC-619,EC-730

Injection nozzle(YD22DDTi) ...........................EM-135

Injector ...............................................EC-343,EC-618

Input shaft (FF M/T) ..............................MT-19,MT-24

Instrument panel ...................................................IP-3

INT/L - Wiring diagram ........................................LT-65

Intake air temparature sensor ............EC-136,EC-577

Intake door control linkage adjustment ............ATC-66

Intake door motorATC-64,ATC-112,MTC-10,MTC-22

Intake manifold(QR20DE) .................................EM-17

Page 2442 of 3066

LT-44

COMBINATION SWITCH

COMBINATION SWITCH

PFP:25567

Removal and InstallationEKS001V6

Refer toSRS-31, "SPIRAL CABLE"in "SUPPLEMENTAL RESTRAINT SYSTEM (SRS)" section for details.

Switch Circuit InspectionEKS001V7

Refer toLT- 2 4 , "Switch Circuit Inspection"in "LIGHTING AND TURN SIGNAL SWITCH" section, andWW-7,

"Terminal and Reference Values for Combination Switch",WW-15, "Terminal and Reference Values for Com-

bination Switch"in“ WW Wiper/Washer Horn” section for details.

Page 2496 of 3066

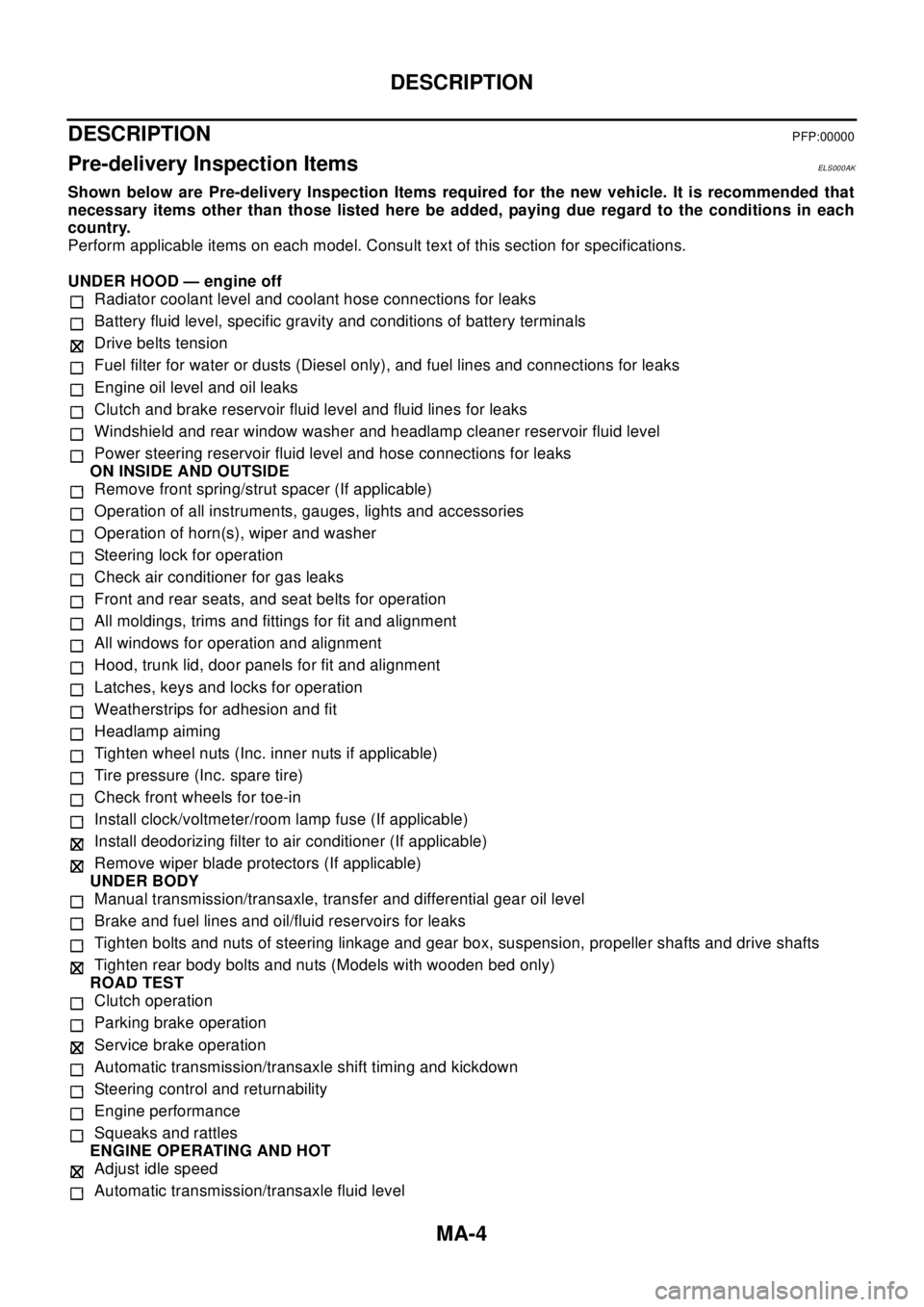

MA-4

DESCRIPTION

DESCRIPTION

PFP:00000

Pre-delivery Inspection ItemsELS000AK

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Page 2514 of 3066

MA-22

ENGINE MAINTENANCE (QR20DE)

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS000C1

WAR NIN G:

Never remove the radiator cap when the engine is hot; serious burns could be caused by high pres-

sure fluid escaping from the radiator.

Wrap a thick cloth around the cap and carefully remove it by turning it a quarter turn to allow built-up

pressure to escape and then turn the cap all the way off.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downward.

lUsecompressedairlowerthan490kPa(5kg/cm2, 71 psi) and keep distance more than 30 cm (11.8

in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

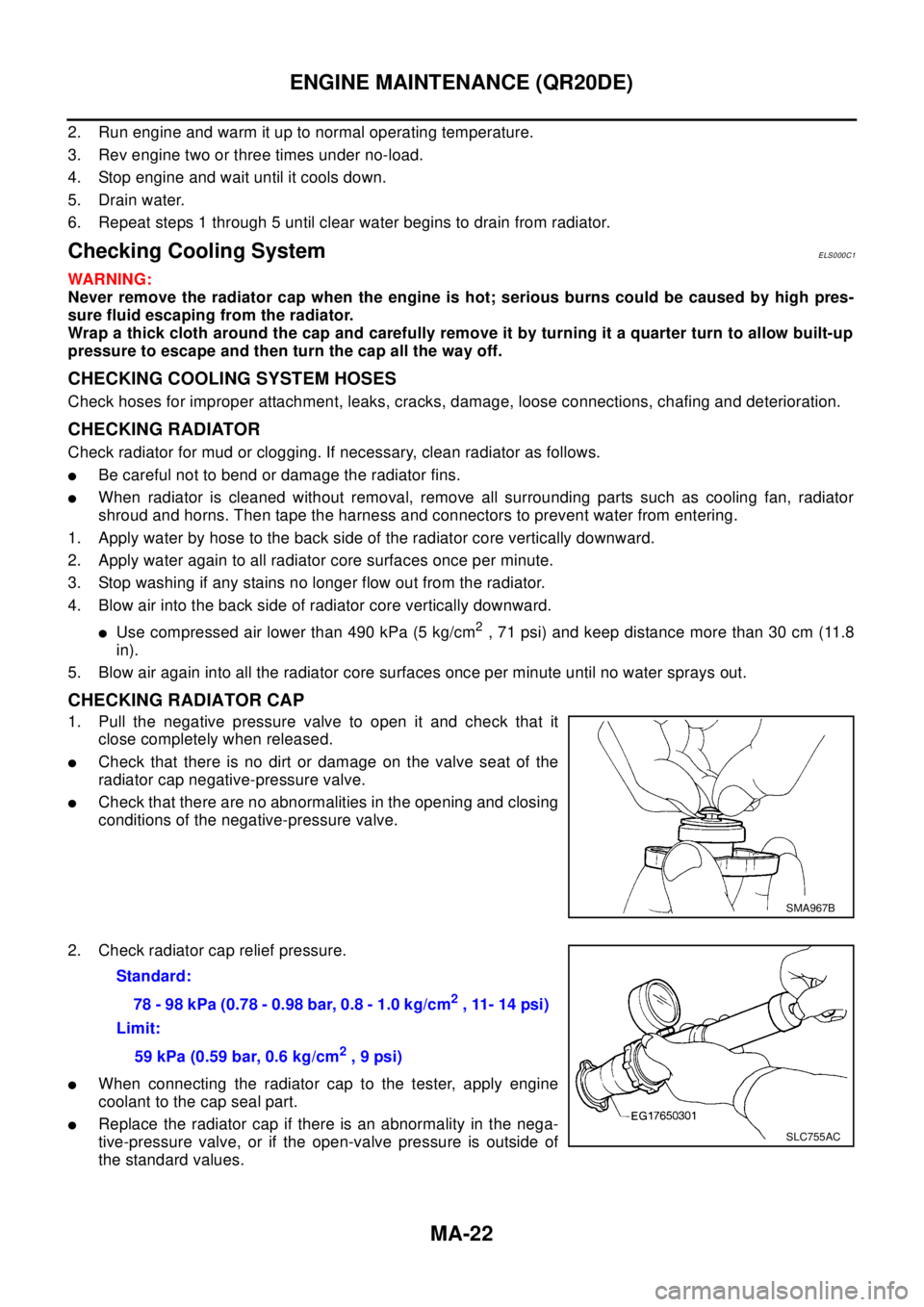

CHECKING RADIATOR CAP

1. Pull the negative pressure valve to open it and check that it

close completely when released.

lCheck that there is no dirt or damage on the valve seat of the

radiator cap negative-pressure valve.

lCheck that there are no abnormalities in the opening and closing

conditions of the negative-pressure valve.

2. Check radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply engine

coolant to the cap seal part.

lReplace the radiator cap if there is an abnormality in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

SMA967B

Standard:

78-98kPa(0.78-0.98bar,0.8-1.0kg/cm

2, 11- 14 psi)

Limit:

59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Page 2521 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-29

C

D

E

F

G

H

I

J

K

MA

B

MA

10. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief flag. Fill radiator and

reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS000C4

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (5 kg/cm2, 71psi) and keep distance more than 30 cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

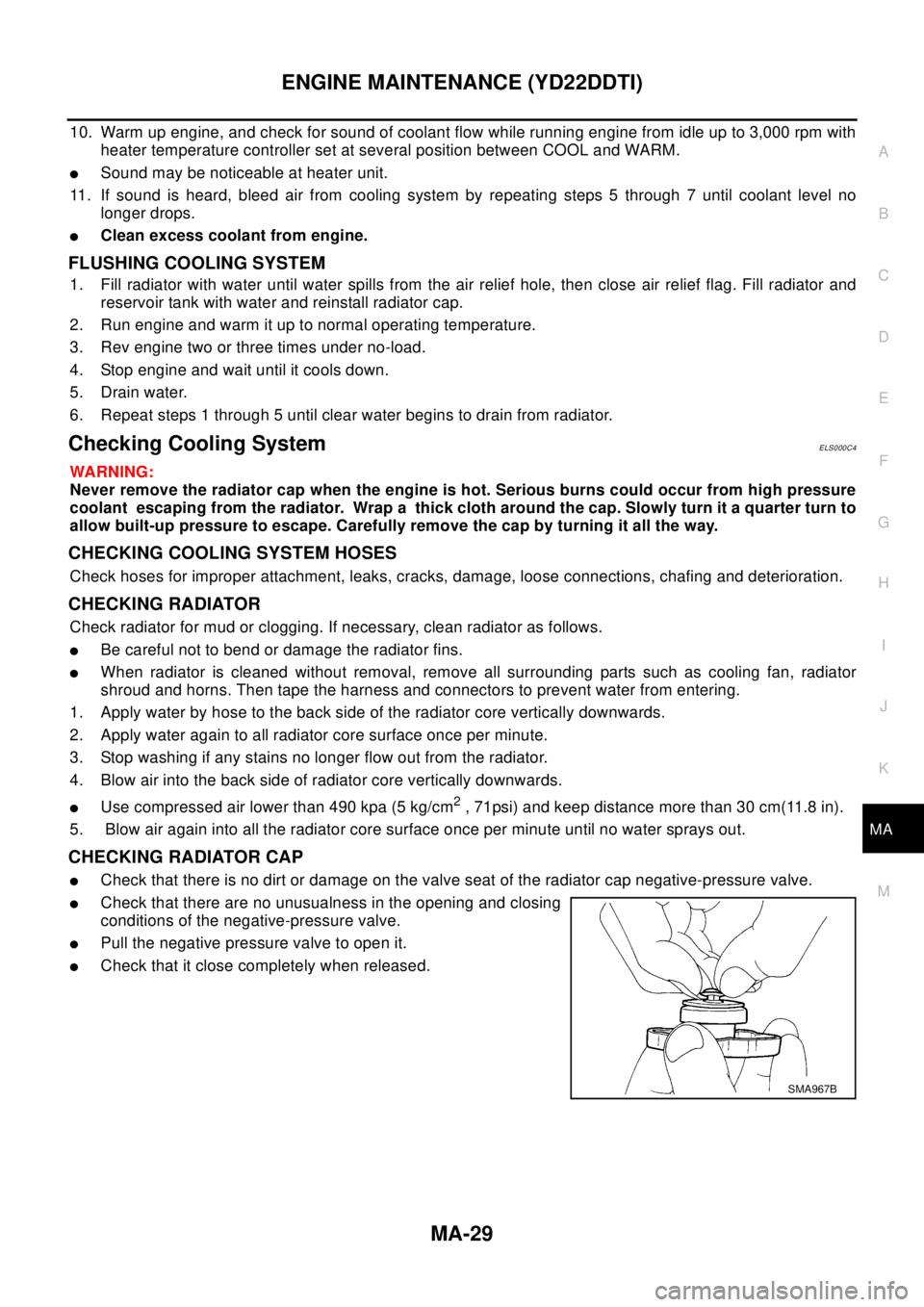

CHECKING RADIATOR CAP

lCheck that there is no dirt or damage on the valve seat of the radiator cap negative-pressure valve.

lCheck that there are no unusualness in the opening and closing

conditions of the negative-pressure valve.

lPull the negative pressure valve to open it.

lCheck that it close completely when released.

SMA967B

Page 2738 of 3066

PG-62

HARNESS

HO2S1H EC Heated Oxygen Sensor 1 (Front)

HO2S2 EC Heated Oxygen Sensor 1 (Rear)

HO2S2H EC Heated Oxygen Sensor 1 (Rear)

HORN WW Horn

IATS EC Intake Air Temperature Sensor

IATSEN EC Intake Air Temperature Sensor

IGNSYS EC Ignition Signal

ILL LT Illumination

INJECT EC Injector

INT/L LT Map Lamp

IVC EC Intake Valve Timing Control Solenoid Valve

IVC/V EC Intake Valve Timing Control Solenoid Valve

KS EC Knock Sensor (KS)

LOAD EC Electrical Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC MassAirFlowSensor(MAFS)

MAIN EC, AT Main Power Supply and Ground Circuit

METER DI Meter and Gauge

MIL EC Malfunction Indicator Lamp

MIL/DL EC MIL and Data Link Connector

MIRROR GW Door Mirror

MULTI BL Multi-Remote Control System

NATS BL Nissan Anti-Theft System

NONDTC AT Non-Detective Items

OVRCSV AT Overrun Clutch Solenoid Valve

PGC/V EC EVAP Canister Purge Volume Control Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW EC, AT Park/Neutral Position (PNP) Switch

PNPSW1 EC Park/Neutral Position (PNP) Switch

POS EC Crankshaft Position Sensor (CKPS)(POS)

POWER PG Power Supply Routing

PRGVLV EC EVAP Canister Purge Volume Control Solenoid Valve

PRWIRE BL Theft Warning System (Pre-wire)

PS/SEN EC Power Steering Pressure Sensor

PST/SW EC Power Steering Oil Pressure Switch

R/FOG LT Rear Fog Lamp

ROOM/L LT Interior Room Lamp

RP/SEN EC Refrigerant Pressure Sensor

RRO2 EC Heated Oxygen Sensor 2 (Rear)

RRO2/H EC Heated Oxygen Sensor 2 Heater (Rear)

S/LOCK BL Super Lock

S/SIG EC Start Signal

SCTC/V EC Suction Control Valve

SHIFT AT A/T Shift Lock System

SROOF BL Sunroof

SRS SRS Supplemental Restraint System (SRS)

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L LT Stop Lamp

T/MTR EC Throttle Control Motor

TAIL/L LT Parking, License and Tail Lamps