overheating NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 14 of 3066

AT-8

PRECAUTIONS

lVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

lConverter is contaminated with engine coolant containing antifreeze.

lInternal failure of stator roller clutch.

lHeavy clutch debris due to overheating (blue converter).

lSteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

lThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

lThe threads in one or more of the converter bolt holes are damaged.

lTransaxle failure did not display evidence of damaged or worn internal parts, steel particles or clutch plate

lining material in unit and inside the fluid filter.

lVehicle has been exposed to high mileage (only). The exception may be where the torque converter

clutch dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic,

such as taxi, delivery or police use.

EURO-OBD SELF-DIAGNOSIS — EURO-OBD —

lA/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the

table onAT-42, "

SELF-DIAGNOSTIC RESULT TEST MODE"for the indicator used to display each self-

diagnostic result.

lThe self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM mem-

ories.

Always perform the procedure “HOW TO ERASE DTC” onAT-39, "

HOW TO ERASE DTC"to com-

plete the repair and avoid unnecessary blinking of the MIL.

lThe following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

–PNP switch

–A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of EURO-OBD, refer toAT - 3 7 , "

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION".

lCertain systems and components, especially those related to EURO-OBD, may use a new style

slide-locking type harness connector.

For description and how to disconnect, refer toPG-70, "

HARNESS CONNECTOR".

Wiring Diagrams and Trouble DiagnosisECS004Q4

When you read wiring diagrams, refer to the following:

lGI-14, "How to Read Wiring Diagrams".

lPG-2, "POWER SUPPLY ROUTING".

When you perform trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

l"", “HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT”

Page 70 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS0 04 QQ

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for examp NISSAN X-TRAIL 2003 Electronic Repair Manual AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS0 04 QQ

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for examp](/img/5/57402/w960_57402-69.png)

AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS0 04 QQ

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to “Checking A/T Fluid”,AT-13, "A/T FLUID".

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 292 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for NISSAN X-TRAIL 2003 Electronic Repair Manual AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for](/img/5/57402/w960_57402-291.png)

AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to “Checking A/T Fluid”,AT-13, "A/T FLUID".

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 899 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-31

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Continuity exists, resistance value

Insulation inspection

lCheck resistance value between each pair of ABS solenoid E70 and E71 terminals NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-31

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Continuity exists, resistance value

Insulation inspection

lCheck resistance value between each pair of ABS solenoid E70 and E71 terminals](/img/5/57402/w960_57402-898.png)

TROUBLE DIAGNOSIS

BRC-31

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Continuity exists, resistance value

Insulation inspection

lCheck resistance value between each pair of ABS solenoid E70 and E71 terminals (No.1 (L), 2 ((R/B) 3

(L/W), 12 (Y/G), 25 (L/Y), 26 (B/Y), 27 (L/R), 28 (W/G).

ABS motor operation inspection

1. Connect 2-pin connector on ABS actuator E69 terminals No. 9

(R/B) and No. 10 (Y).

2. Apply voltage of Approx. 12V voltage between terminals E70

No. 5 (G/R) and terminals E71 No. 7 (W/G) on ABS relay unit.

Measure motor voltage (terminal E70 No. 4 (R/Y) - Body

ground) using an oscilloscope and check motor counter electro-

motive force duration when operation stops.

CAUTION:

lBefore measuring time, check each part of ABS relay unit

and confirm motor relay is normal.

lTo prevent overheating, ABS motor should be driven no

longer than 4 seconds.

lMotor counter electromotive force duration is based on the

time at 20°C, in ambient temperatures, with 12V battery volt-

age. If battery voltage is low, time will be slightly shorter.

SFIA0353E

Standard : 5.8 - 21.2 (W)

Motor counter electromotive force duration:

0.1 second or longer

SFIA0354E

Page 1011 of 3066

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

LEAK CHECK ....................................................... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR ................................................................ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly Radiator Fan ............. 13

DISASSEMBLY ................................................... 13

ASSEMBLY ......................................................... 13

INSPECTION ......................................................... 13

CHECKING RADIATOR CAP .............................. 13

CHECKING RADIATOR ...................................... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18WATER PUMP .......................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 20

INSPECTION AFTER INSTALLATION ................ 20

THERMOSTAT AND WATER CONTROL VALVE .... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Capacity .................................................................. 23

Thermostat ............................................................. 23

Water Control Valve ................................................ 23

Radiator .................................................................. 23

Tightening Torque ................................................... 23

YD22DDTi

PRECAUTIONS ........................................................ 24

Precautions For Liquid Gasket ............................... 24

REMOVAL AND LIQUID GASKET ...................... 24

LIQUID GASKET APPLICATION PROCEDURE... 24

PREPARATION ......................................................... 25

Special Service Tools ............................................. 25

OVERHEATING CAUSE ANALYSIS ........................ 26

Troubleshooting Chart ............................................ 26

COOLING SYSTEM .................................................. 28

Cooling Circuit ........................................................ 28

ENGINE COOLANT .................................................. 30

Inspection ............................................................... 30

LEVEL CHECK .................................................... 30

LEAK CHECK ...................................................... 30

Changing Engine Coolant ....................................... 30

DRAINING ENGINE COOLANT .......................... 30

REFILLING ENGINE COOLANT ......................... 31

FLUSHING COOLING SYSTEM ......................... 32

RADIATOR ................................................................ 33

Removal and Installation ........................................ 33

Page 1015 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartEBS009SB

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat tra NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartEBS009SB

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat tra](/img/5/57402/w960_57402-1014.png)

OVERHEATING CAUSE ANALYSIS

CO-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartEBS009SB

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

—— High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper coolant mixture

ratio———

Poor coolant quality — — —

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 1016 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at ex NISSAN X-TRAIL 2003 Electronic Repair Manual CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at ex](/img/5/57402/w960_57402-1015.png)

CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items

Page 1036 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-26

[YD22DDTi]

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS00BAW

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfun NISSAN X-TRAIL 2003 Electronic Repair Manual CO-26

[YD22DDTi]

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS00BAW

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfun](/img/5/57402/w960_57402-1035.png)

CO-26

[YD22DDTi]

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS00BAW

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

—— High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper coolant mixture

ratio———

Poor coolant quality — — —

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 1037 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear](/img/5/57402/w960_57402-1036.png)

OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items

Page 1118 of 3066

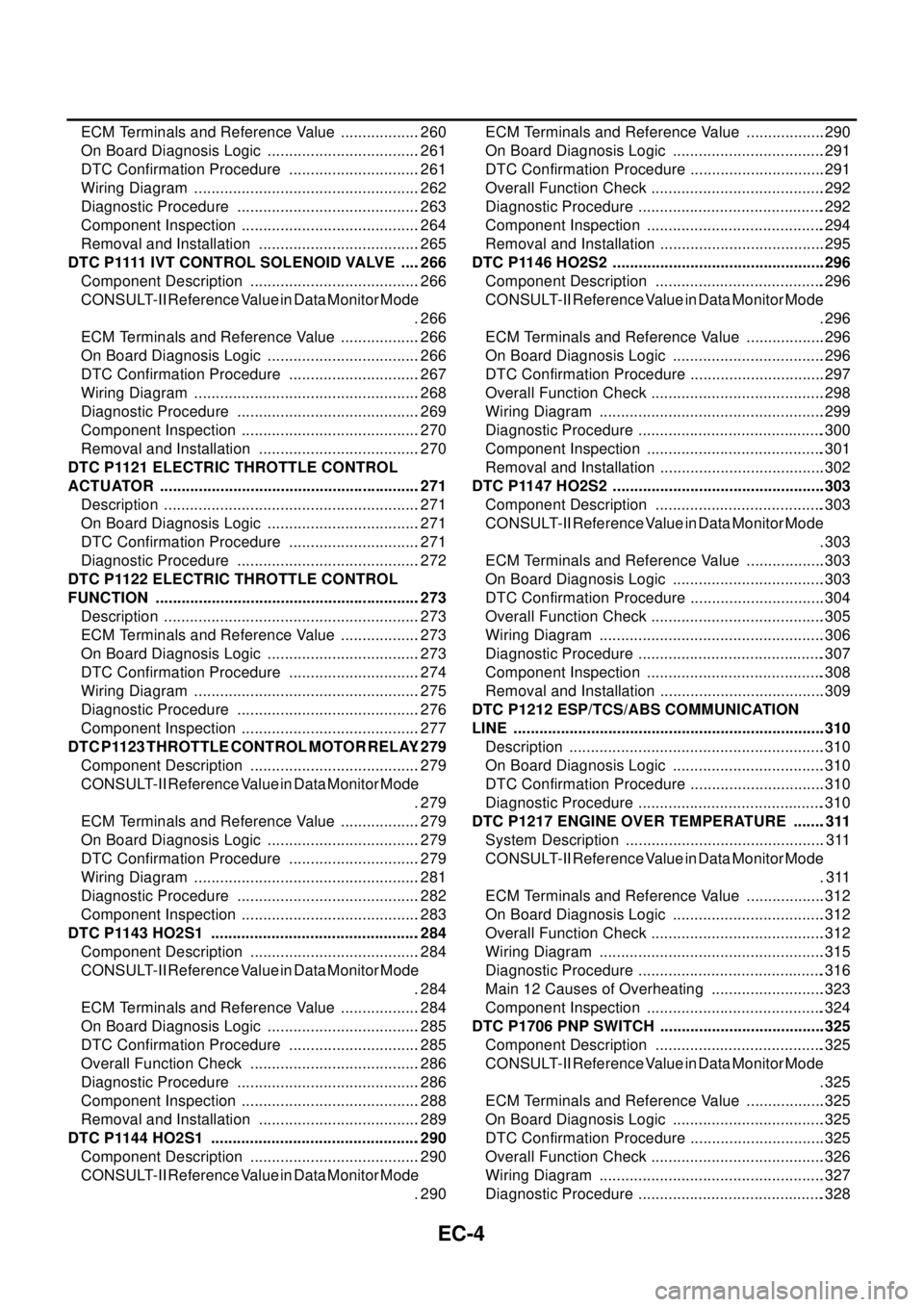

EC-4

ECM Terminals and Reference Value ...................260

On Board Diagnosis Logic ....................................261

DTC Confirmation Procedure ...............................261

Wiring Diagram .....................................................262

Diagnostic Procedure ...........................................263

Component Inspection ..........................................264

Removal and Installation ......................................265

D T C P 1111 I V T C ON T R OL S OL E N OI D VA LV E . .. ..266

Component Description ........................................266

CONSULT-II Reference Value in Data Monitor Mode

.266

ECM Terminals and Reference Value ...................266

On Board Diagnosis Logic ....................................266

DTC Confirmation Procedure ...............................267

Wiring Diagram .....................................................268

Diagnostic Procedure ...........................................269

Component Inspection ..........................................270

Removal and Installation ......................................270

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR .............................................................271

Description ............................................................271

On Board Diagnosis Logic ....................................271

DTC Confirmation Procedure ...............................271

Diagnostic Procedure ...........................................272

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION ..............................................................273

Description ............................................................273

ECM Terminals and Reference Value ...................273

On Board Diagnosis Logic ....................................273

DTC Confirmation Procedure ...............................274

Wiring Diagram .....................................................275

Diagnostic Procedure ...........................................276

Component Inspection ..........................................277

DTC P1123 THROTTLE CONTROL MOTOR RELAY.279

Component Description ........................................279

CONSULT-II Reference Value in Data Monitor Mode

.279

ECM Terminals and Reference Value ...................279

On Board Diagnosis Logic ....................................279

DTC Confirmation Procedure ...............................279

Wiring Diagram .....................................................281

Diagnostic Procedure ...........................................282

Component Inspection ..........................................283

DTC P1143 HO2S1 .................................................284

Component Description ........................................284

CONSULT-II Reference Value in Data Monitor Mode

.284

ECM Terminals and Reference Value ...................284

On Board Diagnosis Logic ....................................285

DTC Confirmation Procedure ...............................285

Overall Function Check ........................................286

Diagnostic Procedure ...........................................286

Component Inspection ..........................................288

Removal and Installation ......................................289

DTC P1144 HO2S1 .................................................290

Component Description ........................................290

CONSULT-II Reference Value in Data Monitor Mode

.290ECM Terminals and Reference Value ................... 290

On Board Diagnosis Logic .................................... 291

DTC Confirmation Procedure ................................ 291

Overall Function Check ......................................... 292

Diagnostic Procedure ............................................ 292

Component Inspection .......................................... 294

Removal and Installation ....................................... 295

DTC P1146 HO2S2 .................................................. 296

Component Description ........................................ 296

CONSULT-II Reference Value in Data Monitor Mode

. 296

ECM Terminals and Reference Value ................... 296

On Board Diagnosis Logic .................................... 296

DTC Confirmation Procedure ................................ 297

Overall Function Check ......................................... 298

Wiring Diagram ..................................................... 299

Diagnostic Procedure ............................................ 300

Component Inspection .......................................... 301

Removal and Installation ....................................... 302

DTC P1147 HO2S2 .................................................. 303

Component Description ........................................ 303

CONSULT-II Reference Value in Data Monitor Mode

. 303

ECM Terminals and Reference Value ................... 303

On Board Diagnosis Logic .................................... 303

DTC Confirmation Procedure ................................ 304

Overall Function Check ......................................... 305

Wiring Diagram ..................................................... 306

Diagnostic Procedure ............................................ 307

Component Inspection .......................................... 308

Removal and Installation ....................................... 309

DTC P1212 ESP/TCS/ABS COMMUNICATION

LINE ......................................................................... 310

Description ............................................................ 310

On Board Diagnosis Logic .................................... 310

DTC Confirmation Procedure ................................ 310

Diagnostic Procedure ............................................ 310

DTC P1217 ENGINE OVER TEMPERATURE ........311

System Description ...............................................311

CONSULT-II Reference Value in Data Monitor Mode

.311

ECM Terminals and Reference Value ................... 312

On Board Diagnosis Logic .................................... 312

Overall Function Check ......................................... 312

Wiring Diagram ..................................................... 315

Diagnostic Procedure ............................................ 316

Main 12 Causes of Overheating ........................... 323

Component Inspection .......................................... 324

DTC P1706 PNP SWITCH ....................................... 325

Component Description ........................................ 325

CONSULT-II Reference Value in Data Monitor Mode

. 325

ECM Terminals and Reference Value ................... 325

On Board Diagnosis Logic .................................... 325

DTC Confirmation Procedure ................................ 325

Overall Function Check ......................................... 326

Wiring Diagram ..................................................... 327

Diagnostic Procedure ............................................ 328