set clock NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 587 of 3066

PRECAUTIONS

ATC-9

C

D

E

F

G

H

I

K

L

MA

B

AT C

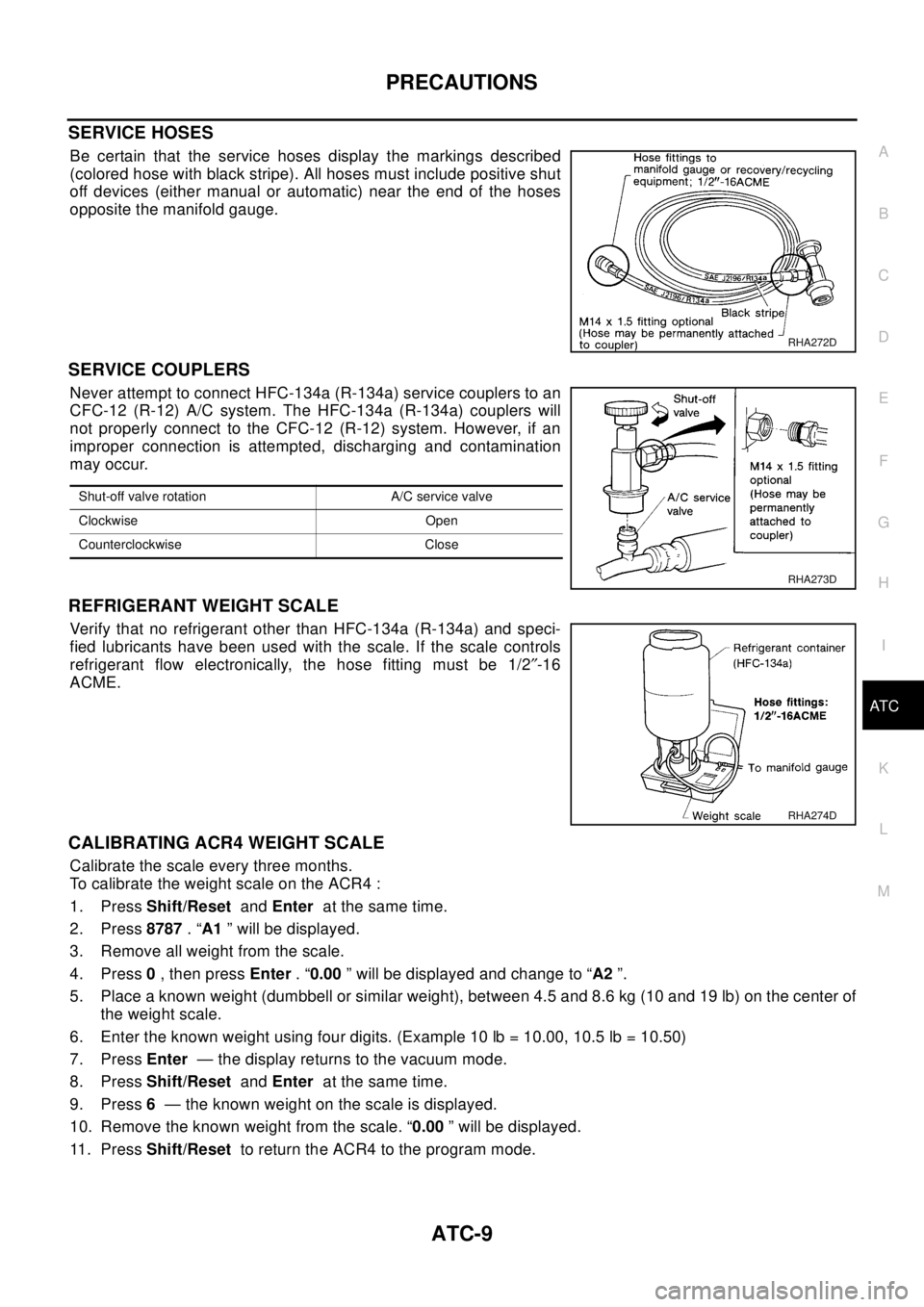

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to an

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. If the scale controls

refrigerant flow electronically, the hose fitting must be 1/2²-16

ACME.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale every three months.

To calibrate the weight scale on the ACR4 :

1. PressShift/ResetandEnterat the same time.

2. Press8787.“A1” will be displayed.

3. Remove all weight from the scale.

4. Press0,thenpressEnter.“0.00” will be displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb) on the center of

the weight scale.

6. Enter the known weight using four digits. (Example 10 lb = 10.00, 10.5 lb = 10.50)

7. PressEnter— the display returns to the vacuum mode.

8. PressShift/ResetandEnterat the same time.

9. Press6— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” will be displayed.

11 . P r e s sShift/Resetto return the ACR4 to the program mode.

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 841 of 3066

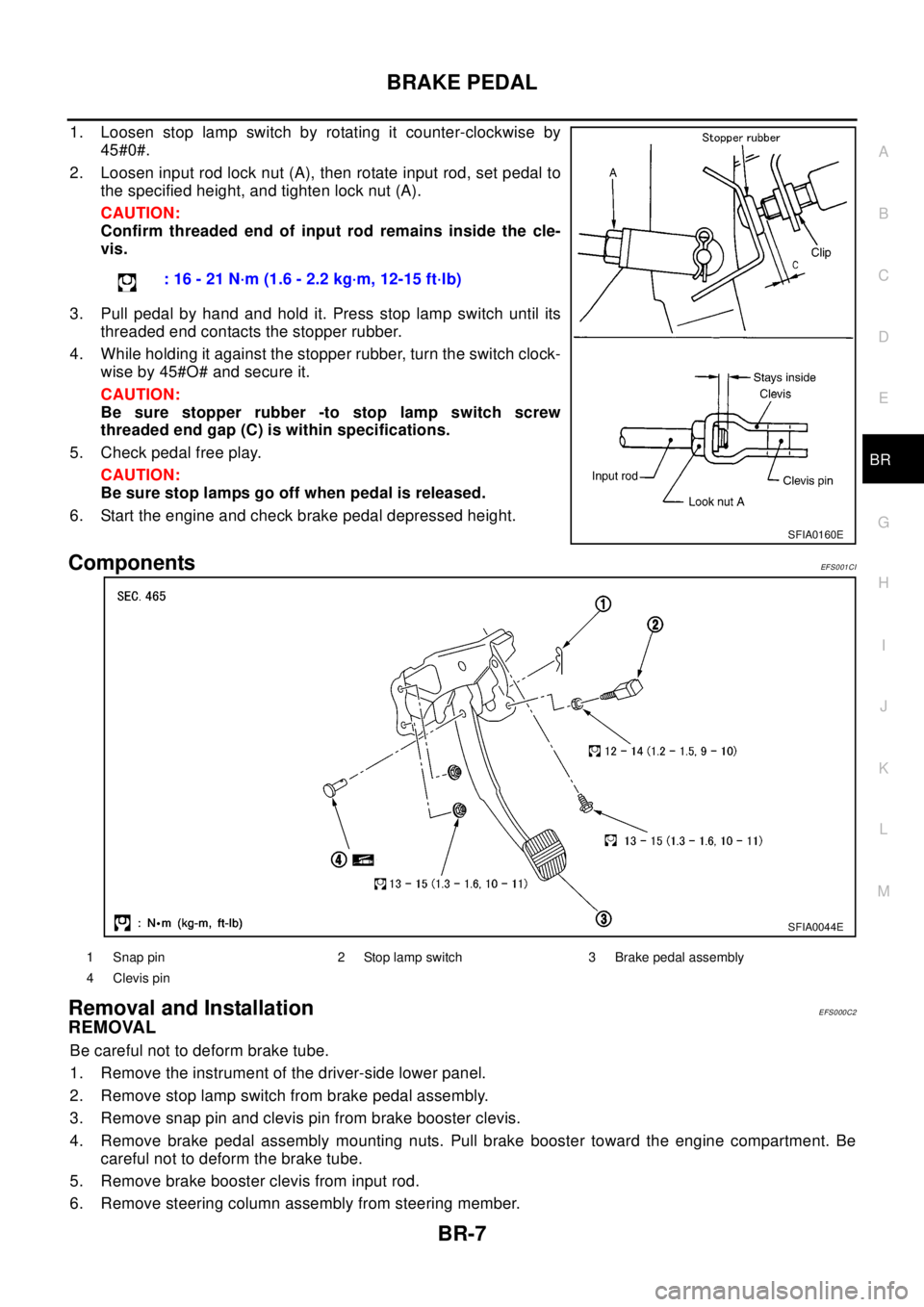

BRAKE PEDAL

BR-7

C

D

E

G

H

I

J

K

L

MA

B

BR

1. Loosen stop lamp switch by rotating it counter-clockwise by

45#0#.

2. Loosen input rod lock nut (A), then rotate input rod, set pedal to

the specified height, and tighten lock nut (A).

CAUTION:

Confirm threaded end of input rod remains inside the cle-

vis.

3. Pull pedal by hand and hold it. Press stop lamp switch until its

threaded end contacts the stopper rubber.

4. While holding it against the stopper rubber, turn the switch clock-

wise by 45#O# and secure it.

CAUTION:

Be sure stopper rubber -to stop lamp switch screw

threaded end gap (C) is within specifications.

5. Check pedal free play.

CAUTION:

Be sure stop lamps go off when pedal is released.

6. Start the engine and check brake pedal depressed height.

ComponentsEF S0 01 CI

Removal and InstallationEFS000C2

REMOVAL

Be careful not to deform brake tube.

1. Remove the instrument of the driver-side lower panel.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from brake booster clevis.

4. Remove brake pedal assembly mounting nuts. Pull brake booster toward the engine compartment. Be

careful not to deform the brake tube.

5. Remove brake booster clevis from input rod.

6. Remove steering column assembly from steering member.: 16 - 21 N·m (1.6 - 2.2 kg·m, 12-15 ft·lb)

SFIA0160E

SFIA0044E

1 Snap pin 2 Stop lamp switch 3 Brake pedal assembly

4 Clevis pin

Page 1163 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-49

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

MI Flashing without DTC

If the ECM is in Diagnostic Test Mode II, MI may flash when engine is running. In this cas NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-49

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

MI Flashing without DTC

If the ECM is in Diagnostic Test Mode II, MI may flash when engine is running. In this cas](/img/5/57402/w960_57402-1162.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-49

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

MI Flashing without DTC

If the ECM is in Diagnostic Test Mode II, MI may flash when engine is running. In this case, check ECM diag-

nostic test mode.EC-49, "

HOW TO SWITCH DIAGNOSTIC TEST MODE".

How to switch the diagnostic test (function) modes, and details of the above functions are described later,EC-

49.

The following emission-related diagnostic information is cleared when the ECM memory is erased.

1. Diagnostic trouble codes

2. 1st trip diagnostic trouble codes

3. Freeze frame data

4. 1st trip freeze frame data

5. System readiness test (SRT) codes

6. Test values

7. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the time accurately with a clock.

lIt is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

lAlways ECM returns to Diagnostic Test Mode I after ignition switch is turned “OFF”.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch “ON” and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MI starts

blinking.

4. Fully release the accelerator pedal.

Mode II Ignition switch in

“ON” position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine running HEATED OXYGEN SENSOR 1

MONITORThis function allows the fuel mixture condition (lean or

rich), monitored by heated oxygen sensor 1, to be read. Diagnostic Test

ModeKEY and ENG.

Statu sFunction Explanation of Function

Page 1519 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-405

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

4. 1st trip freeze frame data

5. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the ti NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-405

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

4. 1st trip freeze frame data

5. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the ti](/img/5/57402/w960_57402-1518.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-405

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

4. 1st trip freeze frame data

5. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the time accurately with a clock.

lIt is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

lAlways ECM returns to Diagnostic Test Mode I after ignition switch is turned “OFF”.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch “ON” and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MI starts

blinking.

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

How to Set Diagnostic Test Mode II (Heated Oxygen Sensor 1 Monitor)

1. Set the ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer toEC-405, "How to Set Diagnostic

Test Mode II (Self-diagnostic Results)".

2. Start Engine.

ECM has entered to Diagnostic Test Mode II (Heated oxygen sensor 1 monitor).

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer toEC-405, "How to Set Diagnostic

Test Mode II (Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer toDI-39,

"WA RN ING LA MPS"or seeEC-526.

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

lThese DTC numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MI as shown below.

PBIB0092E

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

Page 1984 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-14

[QR20DE]

DRIVE BELTS

2. Insert a rod approximately 6 mm (0.24in) in diameter through the rear of engine into holding boss to fix

tensioner pulley.

3. Hook auxiliary drive belt onto all pulleys e NISSAN X-TRAIL 2003 Electronic Repair Manual EM-14

[QR20DE]

DRIVE BELTS

2. Insert a rod approximately 6 mm (0.24in) in diameter through the rear of engine into holding boss to fix

tensioner pulley.

3. Hook auxiliary drive belt onto all pulleys e](/img/5/57402/w960_57402-1983.png)

EM-14

[QR20DE]

DRIVE BELTS

2. Insert a rod approximately 6 mm (0.24in) in diameter through the rear of engine into holding boss to fix

tensioner pulley.

3. Hook auxiliary drive belt onto all pulleys except for water pump. Hook belt onto water pump pulley at the

end.

CAUTION:

Confirm belts are completely set to pulleys.

4. Release tensioner, and apply tensions to belt.

5. Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

6. Confirm tensions of belt at indicator is within the allowable use range. Refer toEM-13, "

Checking Drive

Belts".

Removal and Installation of Auxiliary Drive Belt Auto- tensionerEBS009QR

REMOVAL

1. Remove front RH engine side cover.

2. Remove auxiliary drive belt.

lKeep tensioner pulley fixed with a tool such as a short-length screwdriver.

3. Remove alternator and then auxiliary drive belt auto-tensioner.

lRemove and install auxiliary drive belt auto-tensioner by fixing tension pulley.

INSTALLATION

lInstall in the reverse order of removal.

CAUTION:

Install auxiliary drive belt auto-tensioner carefully not to damage the water pump pulley.

KBIA0092E

Page 2004 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-34

[QR20DE]

CAMSHAFT

a. Loosen bolts in reverse order shown in the figure.

b. Remove the cover using Tool (Seal cutter).

5. Set No.1cylinder at TDC on its compression stroke with the

folowing proce NISSAN X-TRAIL 2003 Electronic Repair Manual EM-34

[QR20DE]

CAMSHAFT

a. Loosen bolts in reverse order shown in the figure.

b. Remove the cover using Tool (Seal cutter).

5. Set No.1cylinder at TDC on its compression stroke with the

folowing proce](/img/5/57402/w960_57402-2003.png)

EM-34

[QR20DE]

CAMSHAFT

a. Loosen bolts in reverse order shown in the figure.

b. Remove the cover using Tool (Seal cutter).

5. Set No.1cylinder at TDC on its compression stroke with the

folowing procedure.

a. Open splash cover on RH under cover.

b. Rotate crankshaft pulley clockwise, and align mating marks for

TDC with timing indicator on front cover.

c. At the same time, make sure that the mating marks on camshaft

sprockets are located as shown in the figure.

lIf not, rotate crankshaft pulley one more turn to line up the

mating marks to the positions in the figure.

6. Pull chain guide between camshaft sprockets out through front

cover.

7. Remove camshaft sprockets with the following procedure.

a. Line up the mating marks on camshaft sprockets, and paint an

indelible mating mark on timing chain link plate.

b. Push in tensioner plunger. Insert a stopper pin into hole on ten-

sioner body to fix chain tensioner and remove it.

lUse wire of 0.5mm (0.02in) in diameter as a stopper pin.

KBIA0085E

KBIA0190E

KBIA0115E

KBIA0048E

Page 2014 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-44

[QR20DE]

TIMING CHAIN

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. Remove the parts listed below.

lEngine hood

lUndercover

lPCV hose

lIgnition co NISSAN X-TRAIL 2003 Electronic Repair Manual EM-44

[QR20DE]

TIMING CHAIN

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. Remove the parts listed below.

lEngine hood

lUndercover

lPCV hose

lIgnition co](/img/5/57402/w960_57402-2013.png)

EM-44

[QR20DE]

TIMING CHAIN

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. Remove the parts listed below.

lEngine hood

lUndercover

lPCV hose

lIgnition coil; Refer toEM-27, "Removal and Installation".

lRocker cover; Refer toEM-31, "Removal and Installation".

lEngine coolant reservoir tank

lAuxiliary drive belt; Refer toEM-13, "Removal and Installation".

lAlternator

lAuxiliary drive belt auto-tensioner; Refer toEM-14, "Removal and Installation of Auxiliary Drive Belt

Auto- tensioner".

lExhaust front tube; Refer toEX-2, "EXHAUST SYSTEM".

2. Remove A/C compressor from engine. Temporarily secure A/C compressor to vehicle side with a rope to

avoid putting a load on them.

3. Remove bracket mounting bolts for fixing A/C piping on right strut housing and exhaust manifold cover.

Doing so simplifies moving.

4. Move power steering pump with piping connected, and secure it to vehicle side temporarily.

5. Pull power steering reservoir tank out of brackets to move power steering piping.

CAUTION:

lTo avoid power steering fluid leakage, temporarily fix reservoir tank vertically.

6. Suspend engine with a hoist, and support the engine posture.

For installation of engine slingers, refer toEM-61, "

ENGINE ASSEMBLY"

7. Remove RH engine mount insulator.

8. Remove center member and rear engine mounting bracket.

9. Drain engine oil.

10. Remove oil pan upper and lower, and oil strainer. Refer toEM-24, "

Removal and Installation".

11. Remove Intake valve timing control cover.

a. Loosen bolts in reverse order shown in the figure.

b. Remove the cover using Tool (Seal cutter).

12. Pull chain guide between camshaft sprockets out through front

cover.

13. Set No.1 cylinder at TDC on its compression stroke with the fol-

lowing procedure.

a. Rotate crankshaft pulley clockwise and align mating marks to

timid indicator on front cover.

KBIA0085E

KBIA0190E

Page 2109 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual FUEL SUPPLY PUMP

EM-139

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

5. Remove RH front wheel.

6. Remove RH splash cover (combined with under cover)

7. Remove fuel hose from fuel supply pump.

8. Remove the ha NISSAN X-TRAIL 2003 Electronic Repair Manual FUEL SUPPLY PUMP

EM-139

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

5. Remove RH front wheel.

6. Remove RH splash cover (combined with under cover)

7. Remove fuel hose from fuel supply pump.

8. Remove the ha](/img/5/57402/w960_57402-2108.png)

FUEL SUPPLY PUMP

EM-139

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

5. Remove RH front wheel.

6. Remove RH splash cover (combined with under cover)

7. Remove fuel hose from fuel supply pump.

8. Remove the harness connector from the fuel supply pump.

9. Remove the fuel supply pump rear bracket.

lLoosen the fuel bolts in the reverse order of that show in the

figure and remove them.

10. Remove fuel supply pump center spill tube.

11. Remove front chain case.

lLoosen fixing bolts in the reverse order of that shown in the

figure and remove them.

lRemove No. 6, 10 and 11 bolts with the rubber washer as

space is limited for pulling them out.

CAUTION:

lWhile front chain case is removed, cover openings to

prevent entry of foreign material into engine.

lDo not remove two mass dampers on the back of cover.

12. Set the No. 1 piston to TDC on its compression stroke.

lTurn crankshaft pulley clockwise so that the alignment mark

(punched mark) on each camshaft sprocket is positioned as

showninthefigure.

lNo position indicator is provided on the crankshaft pul-

ley.

lWhen installing, color coded links on the secondary tim-

ing chain can be used as alignment marks. Marking may

not be necessary for removal; however, make alignment

marks as required because the alignment mark on fuel

supply pump sprocket may not be easy to see.

SBIA0214E

JEM121G

SBIA0189E

SEM515G

Page 2124 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-154

[YD22DDTi]

CAMSHAFT

Valve Clearance

EBS00BOJ

INSPECTION

lWhen the camshaft or parts in connection with valves are

removed or replaced, and a malfunction has occurred (poor

starting, idling, or NISSAN X-TRAIL 2003 Electronic Repair Manual EM-154

[YD22DDTi]

CAMSHAFT

Valve Clearance

EBS00BOJ

INSPECTION

lWhen the camshaft or parts in connection with valves are

removed or replaced, and a malfunction has occurred (poor

starting, idling, or](/img/5/57402/w960_57402-2123.png)

EM-154

[YD22DDTi]

CAMSHAFT

Valve Clearance

EBS00BOJ

INSPECTION

lWhen the camshaft or parts in connection with valves are

removed or replaced, and a malfunction has occurred (poor

starting, idling, or other malfunction) due to the mis adjustment

of the valve clearance, inspect as follows.

lInspect and adjust when the engine is cool (at normal tempera-

ture).

lBe careful of the intake and exhaust valve arrangement. The

valve arrangement is different from that in a normal engine.

NOTE:

The camshafts have, alternately, either an intake valve or an

exhaust valve.(Refer to illustration)

1. Drain engine coolant. Refer toCO-30, "

Changing Engine Coolant".

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove air duct and air inlet pipe. Refer toEM-112, "

Removal and Installation".

4. Remove rocker cover. Refer toEM-147, "

Removal and Installation".

5. Remove vacuum pump. Refer toEM-131, "

Removal and Installation".

6. Remove injection tube and fuel injector. Refer toEM-135, "

Removal and Installation".

7. Remove secondary timing chain. Refer toEM-158, "

Removal and Installation"

Check valve clearance while engine is cold and not running.

8. Set the No. 1 piston to TDC on its compression stroke.

lTurn crankshaft pulley clockwise so that the knock pin on

camshaft LH faces straight above. (No position indicator, etc.

is provided on the crankshaft pulley.)

9. Put an alignment mark with paint, etc. on the crankshaft pulley

and on the oil pump as an angle indicator.

10. While referring to the figure, measure the valve clearance

marked in the table below.

lThe injection order is 1-3-4-2.

SBIA0178E

SBIA0179E

JEM177G

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDCXXX X

SBIA0180E

Page 2125 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAMSHAFT

EM-155

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

lMeasure the valve clearance using a fine feeler gauge when

the engine is cool (at normal temperature).

11. Set the No. 4 cylinder at TDC by rotati NISSAN X-TRAIL 2003 Electronic Repair Manual CAMSHAFT

EM-155

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

lMeasure the valve clearance using a fine feeler gauge when

the engine is cool (at normal temperature).

11. Set the No. 4 cylinder at TDC by rotati](/img/5/57402/w960_57402-2124.png)

CAMSHAFT

EM-155

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

lMeasure the valve clearance using a fine feeler gauge when

the engine is cool (at normal temperature).

11. Set the No. 4 cylinder at TDC by rotating the crankshaft clock-

wise once.

12. While referring to the figure, measure the valve clearance

marked in the table below.

13. If the valve clearance is outside the specification, adjust as fol-

lows.

ADJUSTMENTS

lRemove the adjusting shim for parts which are outside the spec-

ified valve clearance.

1. Remove the spill tube. Refer toEM-135, "

Removal and Installa-

tion".

2. Extract the engine oil on the upper side of the cylinder head (for

theairblowinginstep7).

3. Rotate the crankshaft to face the camshaft for adjusting shims

that are to be removed upward.

4. Grip the camshaft with camshaft pliers, them using the camshaft

as a support point, push the adjusting shim downward to com-

press the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head and the outer

circumference of the valve lifter.Valve clearance (Cold):

Standard:

Intake : 0.24 - 0.32 mm (0.0094 - 0.0126 in)

Exhaust : 0.26 - 0.34 mm (0.0102 - 0.0134 in)

SBIA0181E

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDCXX XX

SBIA0182E

SBIA0183E

SBIA0184E