tow NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 13 of 3066

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

lAfter performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DURE”.

The DTC should not be displayed in the “DTC CONFIRMA-

TION PROCEDURE” if the repair is completed.

lBefore proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

lDisassembly should be done in a clean work area.

lUse lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transaxle.

lPlace disassembled parts in order for easier and proper assembly.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lGaskets, seals and O-rings should be replaced any time the transaxle is disassembled.

lIt is very important to perform functional tests whenever they are indicated.

lThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

lProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

lBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

lExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

lAfter overhaul, refill the transaxle with new ATF.

lWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

to “Changing A/T Fluid”,AT-13, "

A/T FLUID".

Service Notice or PrecautionsECS004Q3

FAI L-S AFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

When the ignition key is turned “ON” following Fail-Safe operation, O/D OFF indicator lamp blinks for about 8

seconds. Refer to SELF-DIAGNOSTIC PROCEDURE(WITHOUT CONSULT-II)",AT- 2 7 3 , "

Diagnostic Proce-

dure Without CONSULT-II"(EXCEPT FOR EURO-OBD) or "TCM Self-diagnostic Procedure(NO TOOLS)",

AT- 5 1 , "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)"(EURO-OBD).

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW”, refer toAT-284, "

Work Flow"(EXCEPT FOR Euro-OBD) orAT-61, "Work

Flow"(Euro-OBD).

The SELF-DIAGNOSIS results will be as follows:

lThe first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

lDuring the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

lExternal leaks in the hub weld area.

lConverter hub is scored or damaged.

lConverter pilot is broken, damaged or fits poorly into crankshaft.

lSteel particles are found after flushing the cooler and cooler lines.

lPump is damaged or steel particles are found in the converter.

SAT652J

Page 687 of 3066

BLOWER UNIT

ATC-109

C

D

E

F

G

H

I

K

L

MA

B

AT C

BLOWER UNITPFP:27200

Removal and InstallationEJS000UL

REMOVAL

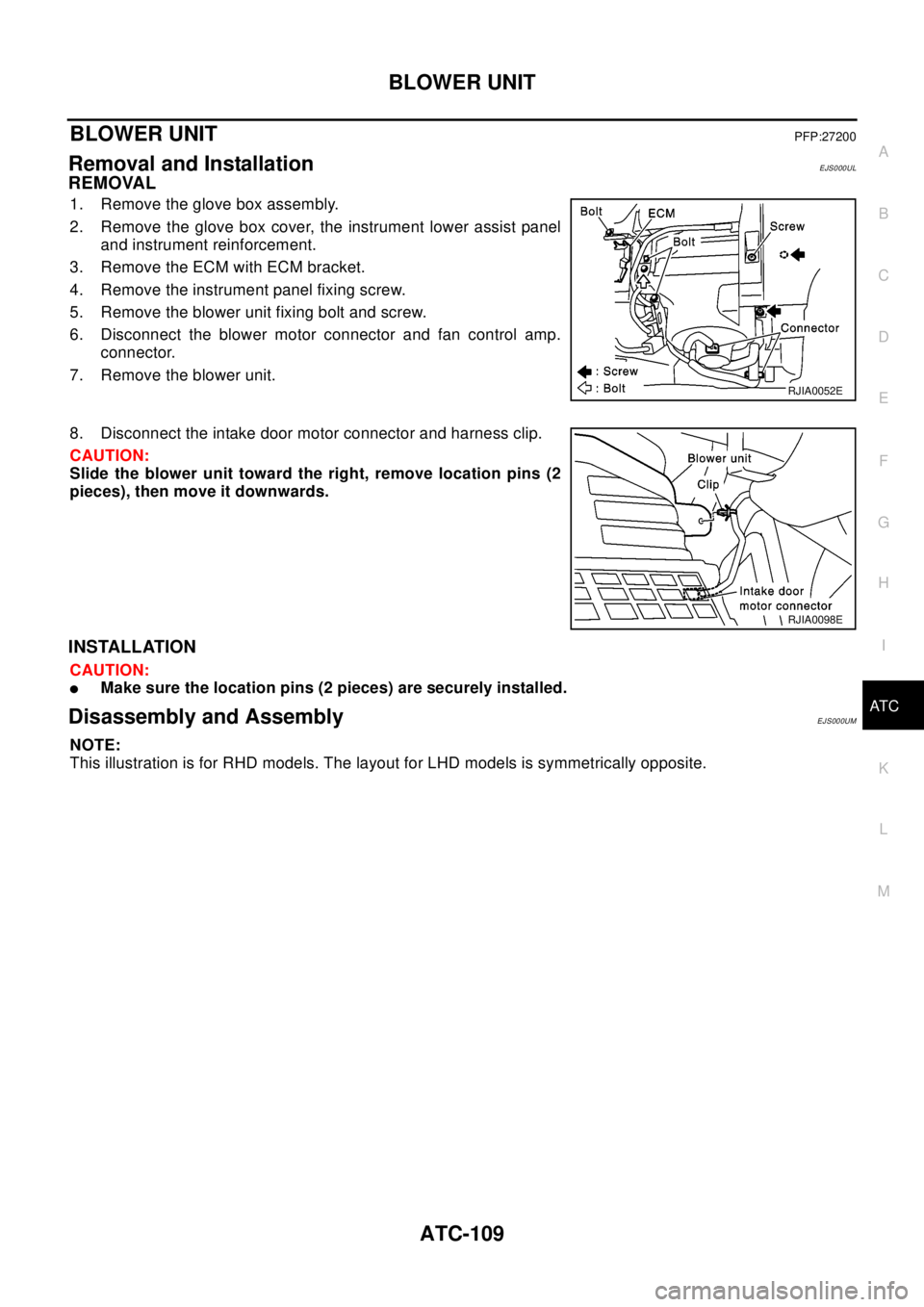

1. Remove the glove box assembly.

2. Remove the glove box cover, the instrument lower assist panel

and instrument reinforcement.

3. Remove the ECM with ECM bracket.

4. Remove the instrument panel fixing screw.

5. Remove the blower unit fixing bolt and screw.

6. Disconnect the blower motor connector and fan control amp.

connector.

7. Remove the blower unit.

8. Disconnect the intake door motor connector and harness clip.

CAUTION:

Slide the blower unit toward the right, remove location pins (2

pieces), then move it downwards.

INSTALLATION

CAUTION:

lMake sure the location pins (2 pieces) are securely installed.

Disassembly and AssemblyEJS000UM

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA0052E

RJIA0098E

Page 750 of 3066

BL-6

HOOD

Install in the reverse order of removal.

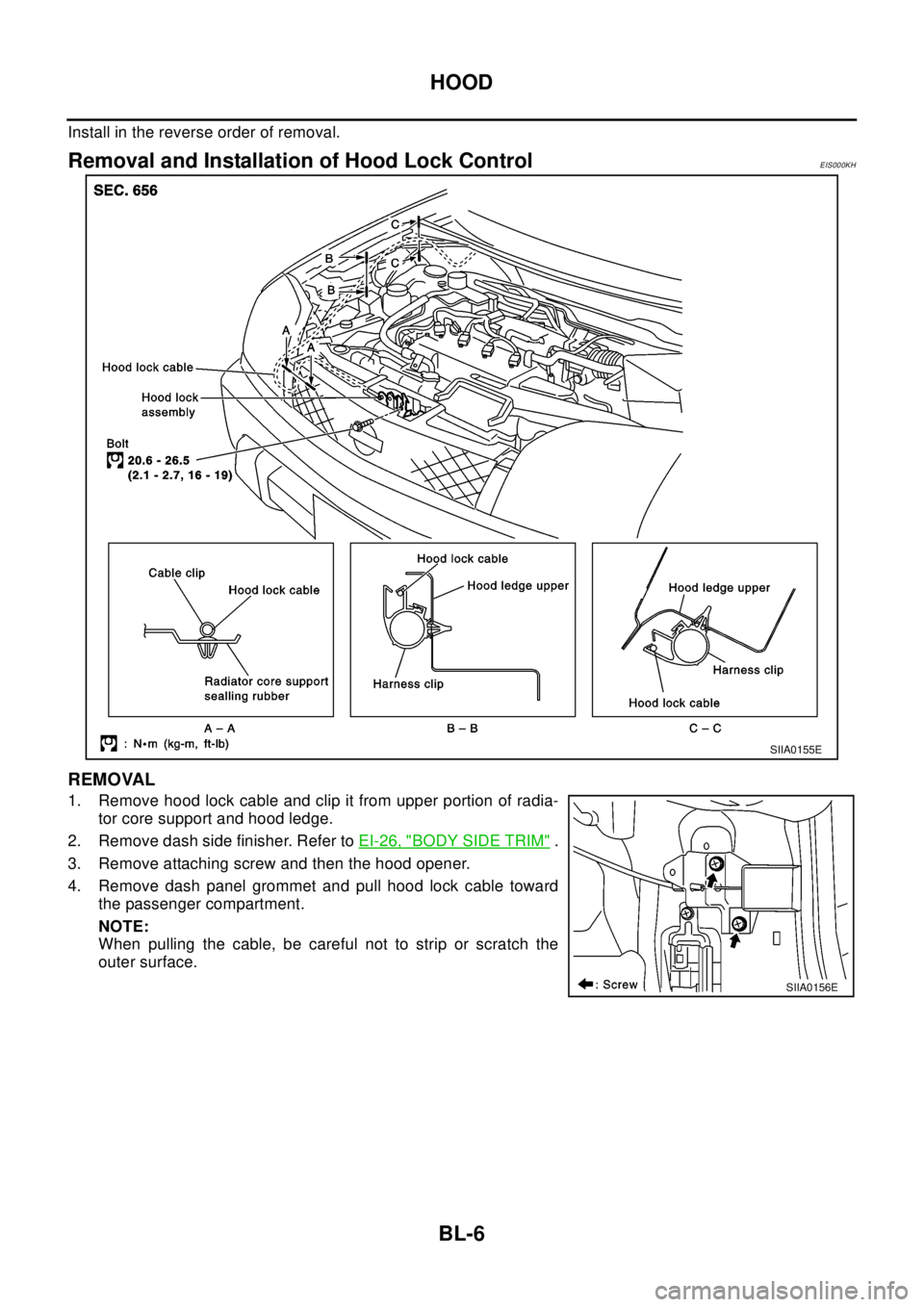

Removal and Installation of Hood Lock ControlEIS000KH

REMOVAL

1. Remove hood lock cable and clip it from upper portion of radia-

tor core support and hood ledge.

2. Remove dash side finisher. Refer toEI-26, "

BODY SIDE TRIM".

3. Remove attaching screw and then the hood opener.

4. Remove dash panel grommet and pull hood lock cable toward

the passenger compartment.

NOTE:

When pulling the cable, be careful not to strip or scratch the

outer surface.

SIIA0155E

SIIA0156E

Page 800 of 3066

BL-56

FRONT DOOR LOCK

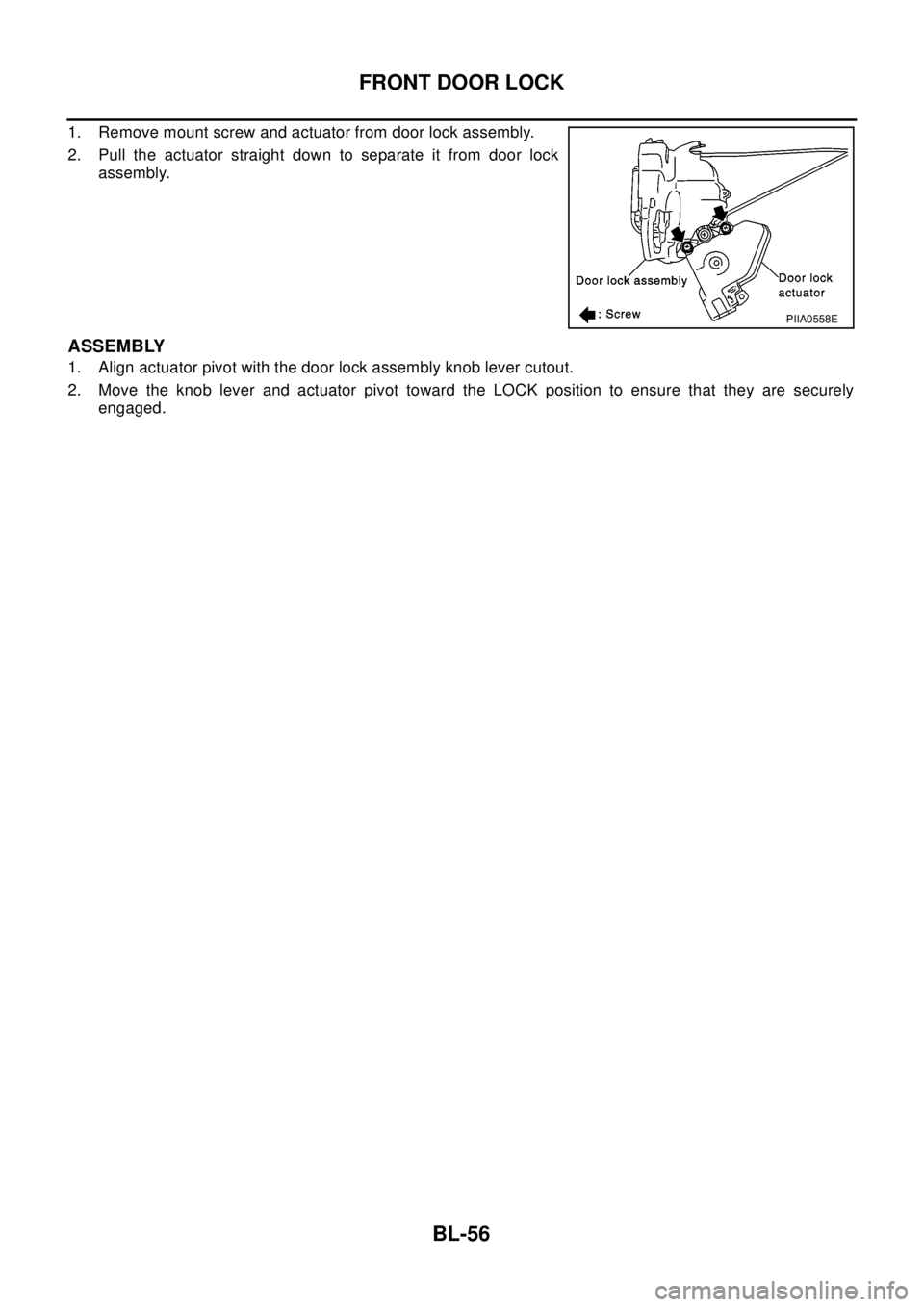

1. Remove mount screw and actuator from door lock assembly.

2. Pull the actuator straight down to separate it from door lock

assembly.

ASSEMBLY

1. Align actuator pivot with the door lock assembly knob lever cutout.

2. Move the knob lever and actuator pivot toward the LOCK position to ensure that they are securely

engaged.

PIIA0558E

Page 803 of 3066

REAR DOOR LOCK

BL-59

C

D

E

F

G

H

J

K

L

MA

B

BL

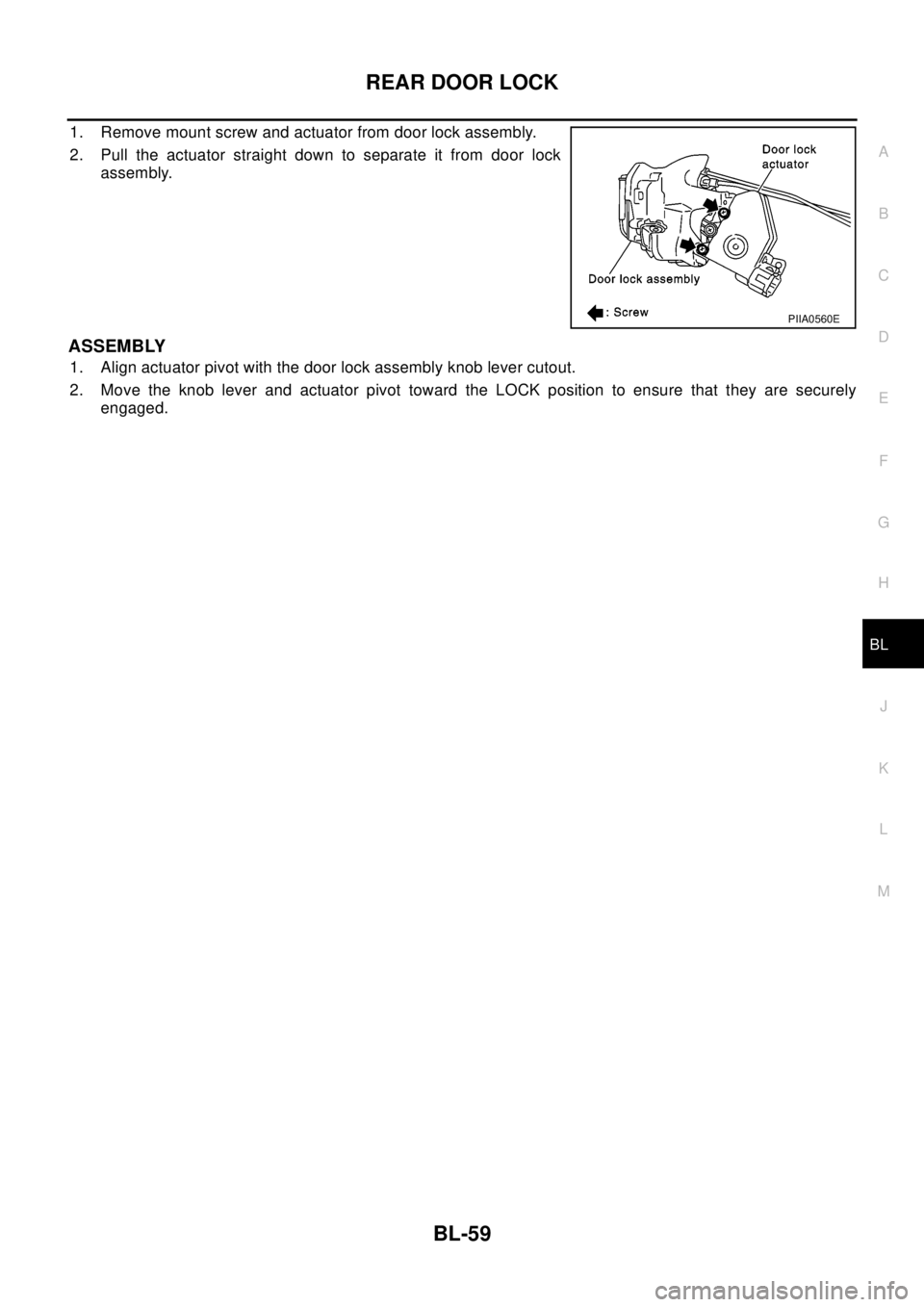

1. Remove mount screw and actuator from door lock assembly.

2. Pull the actuator straight down to separate it from door lock

assembly.

ASSEMBLY

1. Align actuator pivot with the door lock assembly knob lever cutout.

2. Move the knob lever and actuator pivot toward the LOCK position to ensure that they are securely

engaged.

PIIA0560E

Page 841 of 3066

BRAKE PEDAL

BR-7

C

D

E

G

H

I

J

K

L

MA

B

BR

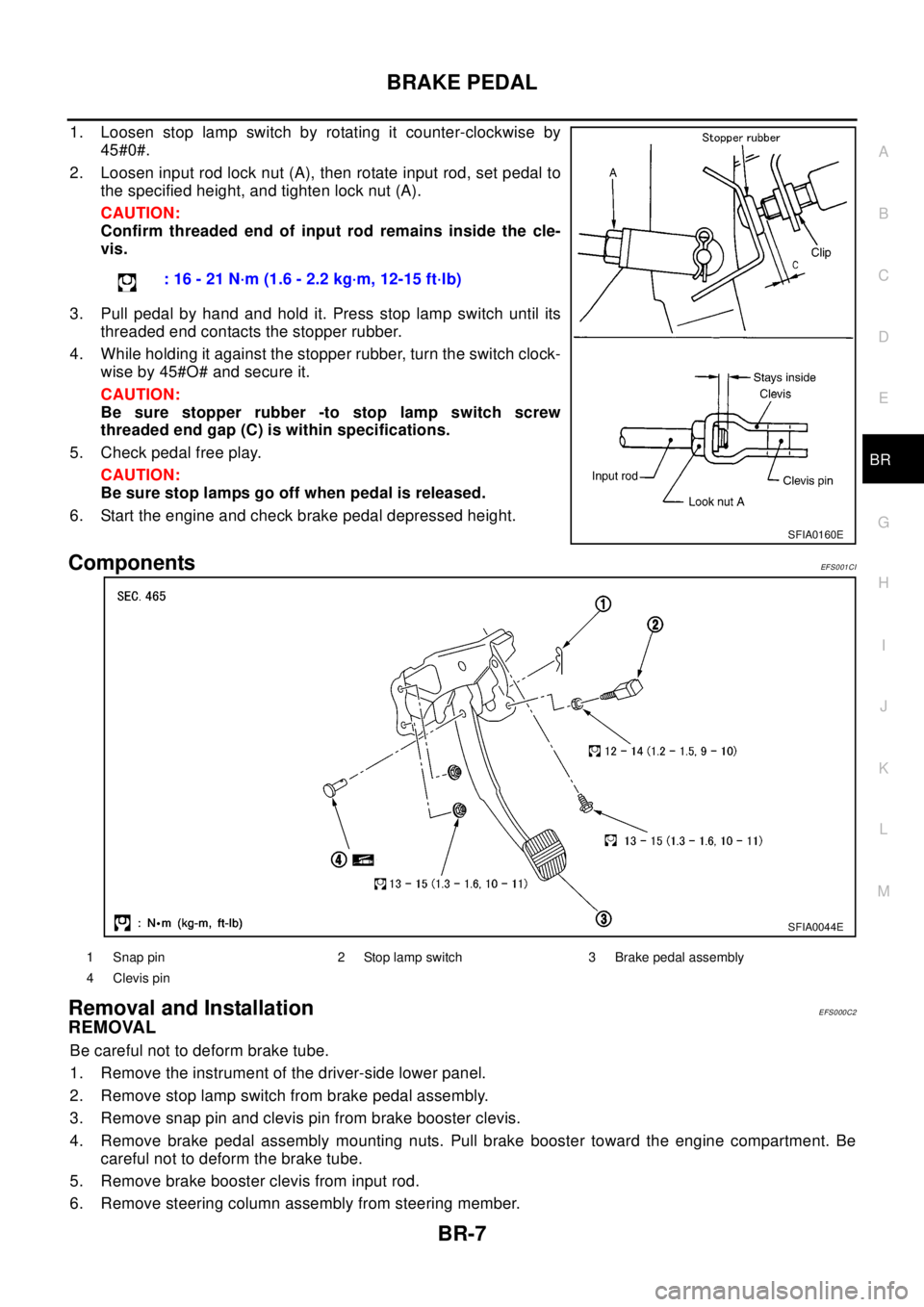

1. Loosen stop lamp switch by rotating it counter-clockwise by

45#0#.

2. Loosen input rod lock nut (A), then rotate input rod, set pedal to

the specified height, and tighten lock nut (A).

CAUTION:

Confirm threaded end of input rod remains inside the cle-

vis.

3. Pull pedal by hand and hold it. Press stop lamp switch until its

threaded end contacts the stopper rubber.

4. While holding it against the stopper rubber, turn the switch clock-

wise by 45#O# and secure it.

CAUTION:

Be sure stopper rubber -to stop lamp switch screw

threaded end gap (C) is within specifications.

5. Check pedal free play.

CAUTION:

Be sure stop lamps go off when pedal is released.

6. Start the engine and check brake pedal depressed height.

ComponentsEF S0 01 CI

Removal and InstallationEFS000C2

REMOVAL

Be careful not to deform brake tube.

1. Remove the instrument of the driver-side lower panel.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from brake booster clevis.

4. Remove brake pedal assembly mounting nuts. Pull brake booster toward the engine compartment. Be

careful not to deform the brake tube.

5. Remove brake booster clevis from input rod.

6. Remove steering column assembly from steering member.: 16 - 21 N·m (1.6 - 2.2 kg·m, 12-15 ft·lb)

SFIA0160E

SFIA0044E

1 Snap pin 2 Stop lamp switch 3 Brake pedal assembly

4 Clevis pin

Page 842 of 3066

BR-8

BRAKE PEDAL

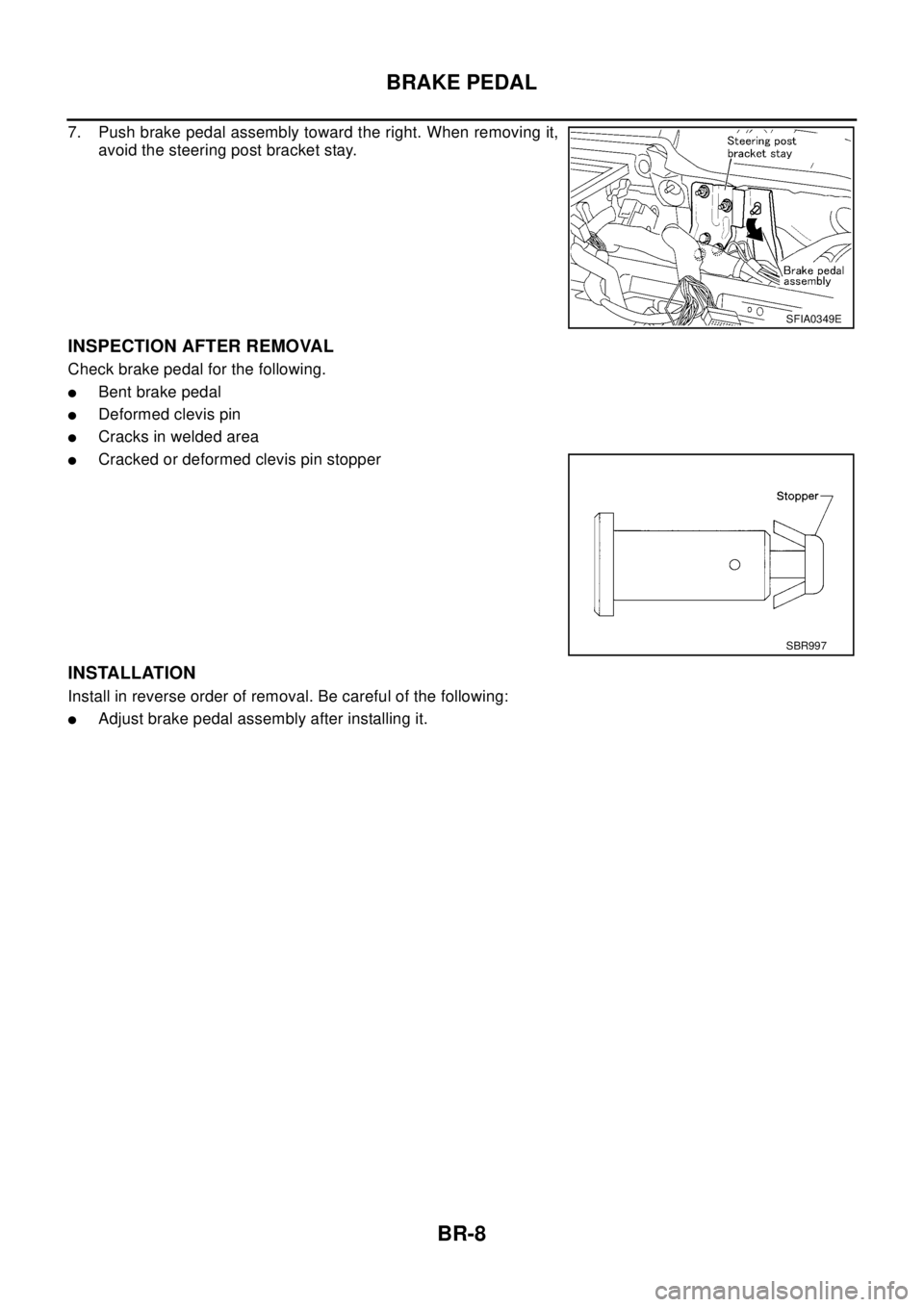

7. Push brake pedal assembly toward the right. When removing it,

avoid the steering post bracket stay.

INSPECTION AFTER REMOVAL

Check brake pedal for the following.

lBent brake pedal

lDeformed clevis pin

lCracks in welded area

lCracked or deformed clevis pin stopper

INSTALLATION

Install in reverse order of removal. Be careful of the following:

lAdjust brake pedal assembly after installing it.

SFIA0349E

SBR997

Page 1072 of 3066

DI-18

COMBINATION METERS (LHD MODELS)

The Fuel Gauge Does Not Move to F-position.

EKS002ZK

1.QUESTIONNAIRE 1

Does it take a long time for the pointer to move to F-position?

YES?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTIONNAIRE 2

Was the vehicle fueled with the ignition switch ON?

YES?

YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise it will take a long time to move

to F-position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTIONNAIRE 3

Is the floor or the vehicle inclined?

YES?

YES >> It may not be filled fully.

NO >> GO TO 4.

4.QUESTIONNAIRE 4

During driving, does the fuel gauge pointer move gradually toward E-position?

YES?

YES >> Check the components. Refer toDI-19, "Electrical Components Inspection".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

The Fuel Gauge Does Not Work.EKS002ZL

1.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit, sub fuel level sensor unit and terminals (meter-side,

module-side, and harness-side) for poor connection and bend.

OK or NG

OK >> GO TO 2.

NG >> Repair connector.

2.CHECK INSTALLATION CONDITION

Check fuel level sensor unit or sub fuel level sensor unit installation (refer toFL-4, "

FUEL LEVEL SENSOR

UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for QR engine models orFL-17, "FUEL LEVEL SEN-

SOR UNIT"for YD engine models, and check whether the float arm interferes or binds with any components

inside the arm.

OK or NG

OK >> Fuel level sensor unit is OK.

NG >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-19, "

Electrical Components

Inspection".

Page 1090 of 3066

DI-36

COMBINATION METERS (RHD MODELS)

The Fuel Gauge Does Not Move to F-position.

EKS0030V

1.QUESTIONNAIRE 1

Does it take a long time for the pointer to move to F-position?

YES?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTIONNAIRE 2

Was the vehicle fueled with the ignition switch ON?

YES ?

YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise it will take a long time to move

to F-position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTIONNAIRE 3

Is the floor or the vehicle inclined?

YES?

YES >> It may not be filled fully.

NO >> GO TO 4.

4.QUESTIONNAIRE 4

During driving, does the fuel gauge pointer move gradually toward E-position?

YES ?

YES >> Check the components. Refer toDI-37, "Electrical Components Inspection".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

The Fuel Gauge Does Not Work.EKS0030W

1.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit, sub fuel level sensor unit and terminals (meter-side,

module-side, and harness-side) for poor connection and bend.

OK or NG

OK >> GO TO 2.

NG >> Repair connector.

2.CHECK INSTALLATION CONDITION

Check fuel level sensor unit or sub fuel level sensor unit installation (refer toFL-4, "

FUEL LEVEL SENSOR

UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for QR engine models orFL-17, "FUEL LEVEL SEN-

SOR UNIT"for YD engine models, and check whether the float arm interferes or binds with any components

inside the arm.

OK or NG

OK >> Fuel level sensor unit is OK.

NG >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-37, "

Electrical Components

Inspection".

Page 1204 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-90

[QR (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

DATA MONITOR MODE

Monitored Item

´: Applicable

Monitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSCAN

DIAG

SUP-

PORT

MNTRDescription Remarks

ENG SPEED NISSAN X-TRAIL 2003 Electronic Repair Manual EC-90

[QR (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

DATA MONITOR MODE

Monitored Item

´: Applicable

Monitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSCAN

DIAG

SUP-

PORT

MNTRDescription Remarks

ENG SPEED](/img/5/57402/w960_57402-1203.png)

EC-90

[QR (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

DATA MONITOR MODE

Monitored Item

´: Applicable

Monitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSCAN

DIAG

SUP-

PORT

MNTRDescription Remarks

ENG SPEED [rpm]´´

lIndicates the engine speed computed

from the signal of the crankshaft position

sensor (POS).

lAccuracy becomes poor if engine

speed drops below the idle rpm.

lIf the signal is interrupted while the

engine is running, an abnormal

value may be indicated.

MAS A/F SE-B1 [V]´´

lThe signal voltage of the mass air flow

sensor is displayed.lWhen the engine is stopped, a

certain value is indicated.

COOLAN TEMP/S

[°C] or [°F]´´

lThe engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.

lWhen the engine coolant tempera-

ture sensor is open or short-cir-

cuited, ECM enters fail-safe mode.

The engine coolant temperature

determined by the ECM is dis-

played.

HO2S1 (B1) [V]´´

lThe signal voltage of the heated oxygen

sensor 1 is displayed.

HO2S2 (B1) [V]´´

lThe signal voltage of the heated oxygen

sensor 2 is displayed.

HO2S1 MNTR (B1)

[RICH/LEAN]´´

lDisplay of heated oxygen sensor 1 sig-

nal during air-fuel ratio feedback control:

RICH ... means the mixture became

“rich”, and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

“lean”, and control is being affected

toward a rich mixture.lAfter turning ON the ignition

switch, “RICH” is displayed until

air-fuel mixture ratio feedback

control begins.

lWhen the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continu-

ously.

HO2S2 MNTR (B1)

[RICH/LEAN]´

lDisplay of heated oxygen sensor 2 sig-

nal:

RICH ... means the amount of oxygen

after three way catalyst is relatively

small.

LEAN ... means the amount of oxygen

after three way catalyst is relatively

large.

lWhen the engine is stopped, a

certain value is indicated.

VHCL SPEED SE

[km/h] or [mph]´´

lThe vehicle speed computed from the

vehicle speed signal is displayed.

BATTERY VOLT

[V]´´

lThe power supply voltage of ECM is dis-

played.

ACCEL SEN 1 [V]´´

lThe accelerator pedal position sensor

signal voltage is displayed.

ACCEL SEN 2 [V]´

THRTL SEN 1 [V]´´

lThe throttle position sensor signal volt-

age is displayed.

THRTL SEN 2 [V]´

INT/ATEMPSE

[°C] or [°F]´´

lThe intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

START SIGNAL

[ON/OFF]´´

lIndicates [ON/OFF] condition from the

starter signal.lAfter starting the engine, [OFF] is

displayed regardless of the starter

signal.