Oldsmobile Aurora 1997 Owner's Manuals

Manufacturer: OLDSMOBILE, Model Year: 1997, Model line: Aurora, Model: Oldsmobile Aurora 1997Pages: 404, PDF Size: 20.75 MB

Page 281 of 404

There are only two reasons why the brake fluid level in the

reservoir might go down. The first

is that the brake fluid

goes down to

an acceptable level during normal brake

lining wear. When new linings are put in, the fluid level

goes back up. The other reason is that fluid is leaking out

of the brake system. If it is, you should have your brake

system fixed, since a leak means that sooner or later your

brakes won’t work well, or won’t work at all.

So, it isn’t a good idea to “top ofi?’ your brake fluid.

Adding brake fluid won’t correct a leak.

If you add fluid

when your linings are worn, then you’ll have too much

fluid when you get new brake linings. You should add

(or remove) brake fluid, as necessary, only when work is

done on

the brake hydraulic system. When

your brake fluid falls to a low level, your brake

warning light will come on.

A chime will sound if you

try

to drive with this warning light on. See “Brake

System Warning Light”

in the Index.

What to Add

When you do need brake fluid, use only DOT-3 brake

fluid

-- such as Delco Supreme 1 I @ (GM Part

No. 12377967). Use new brake fluid from a sealed

container only.

Always clean the brake fluid reservoir cap and the area

around the cap before removing

it. This will help keep

dirt from entering

the reservoir.

If you have too much brake fluid, it can spill on the

engine. The fluid will burn

if the engine is hot

enough.

You or others could be burned, and your

vehicle could be damaged. Add brake fluid only

when work is done on the brake hydraulic system. With the wronb -4nd

of fluid in your

brake

system, your brakes may not work well, or they

may not even work at all. This could cause

a

crash. Always use the proper brake fluid.

Page 282 of 404

NOTICE:

Using the wrong fluid can badly damage

brake system parts. For example, just

a few

drops

of mineral-based oil, such as engine

oil, in your brake system can damage brake

system parts

so badly that they’ll have to be

replaced. Don’t let someone put in the

wrong kind of fluid.

If you spill brake fluid on your vehicle’s

painted surfaces, the paint finish can be

damaged. Be careful not to spill brake fluid

on your vehicle.

If you do, wash it off

immediately. See “Appearance Care” in

the Index.

Brake Wear

Your Aurora has four-wheel disc brakes.

Disc brake pads have built-in wear indicators that make a

high-pitched warning sound when

the brake pads are worn

and new pads are needed. The sound may come and go or

be heard all the time your vehicle is moving (except when

you are pushing on the brake pedal fiily).

The brake wear warning sound means that soon

your brakes won’t work well. That could lead to

an accident. When you hear the brake wear

warning sound, have your vehicle serviced.

Page 283 of 404

Brake Ad-iustment

NOTICE:

Continuing to drive with worn-out brake pads

could result

in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect brake pads for wear and evenly torque wheel nuts in the

proper sequence to GM specifications.

Brake linings should always be replaced as complete

axle sets.

See “Brake System Inspection”

in Section 7 of this manual

under

Part C “Periodic Maintenance Inspections.”

Brake Pedal Travel

See your retailer if the brake pedal does not return to

normal height, or if there is a rapid increase in pedal

travel. This could be a sign

of brake trouble. Every

time you apply the brakes, with or without the

vehicle moving, your brakes adjust for wear.

Replacing Brake System Parts

The braking system on a modern vehicle is complex. Its

many parts have to be of top quality and work well

together if the vehicle is to have really good braking.

Your vehicle was designed and tested with top-quality

GM brake parts. When you replace parts

of your braking

system

-- for example, when your brake linings wear

down and

you have to have new ones put in -- be sure

you get new approved GM replacement parts. If you

don’t, your brakes may no longer work properly. For

example, if someone puts in brake linings that are wrong

for your vehicle, the balance between your front and

rear brakes can

change

-- for the worse. The braking performance

you’ve come to expect can change in many other ways

if

someone puts in the wrong replacement brake parts.

Page 284 of 404

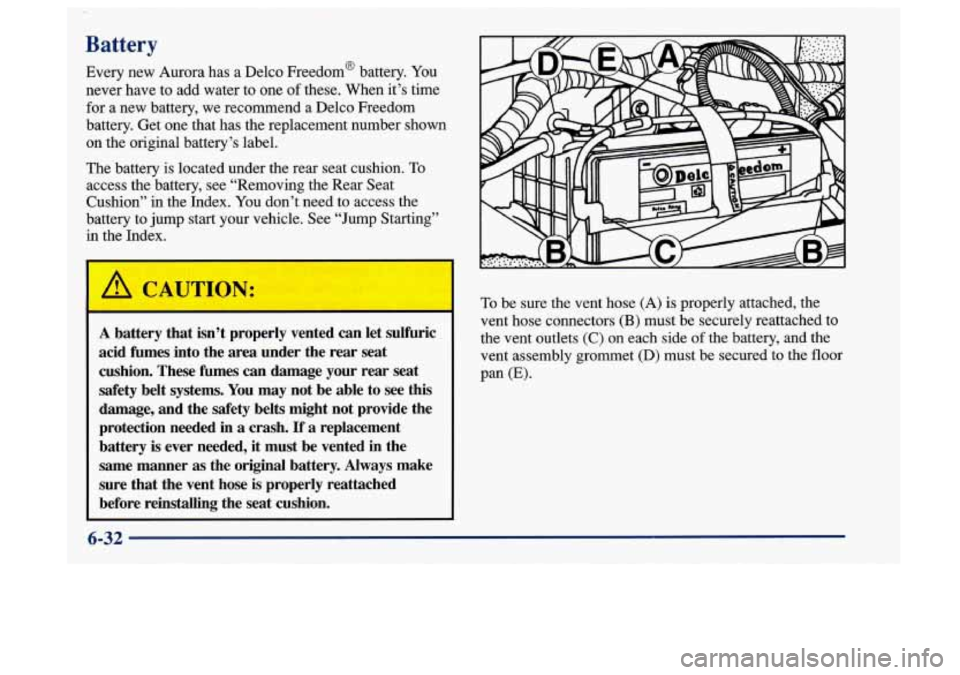

Battery

Every new Aurora has a Delco Freedom@ battery. You

never have to add water to one

of these. When it’s time

for a new battery, we recommend a Delco Freedom

battery. Get one that has the replacement number shown

on the original battery’s label.

The battery

is located under the rear seat cushion. To

access the battery,’ see “Removing the Rear Seat

Cushion”

in the Index. You don’t need to access the

battery to jump start your vehicle. See “Jump Starting”

in the Index.

A battery that isn’t properly vented can let sulfuric

acid fumes into the

area under the rear seat

cushion. These fumes can damage your rear seat

safety belt systems. You may not be able to see

this

damage, and the safety belts might not provide the

protection needed in

a crash. If a replacement

battery

is ever needed, it must be vented in the

same manner

as the original battery. Always make

sure that the vent hose

is properly reattached

before reinstalling the seat cushion.

To be sure the vent hose (A) is properly attached, the

vent hose connectors

(B) must be securely reattached to

the vent outlets

(C) on each side of the battery, and the

vent assembly grommet

(D) must be secured to the floor

pan

(E).

6-32

Page 285 of 404

Vehicle Storage

If you’re not going to drive your vehicle for 25 days or

more, take off the black, negative

(-) cable from

the battery. This will help keep your battery from

r ning down.

A CAUTION:

Batteries have acid that can burn you and gas

that can explode.

You can be badly hurt if you

aren’t careful. See

“Jump Starting” in the Index

for tips on working around

a battery without

getting hurt.

Contact your retailer to learn how to prepare your

vehicle for longer storage periods.

Also, for your audio system, see “Theft-Deterrent

Feature”

in the Index.

Bulb Replacement

For any bulb changing procedure not listed in this

section, contact your Aurora retailer’s service

department.

For the type of bulb to

use, see “Replacement Bulbs” in

the Index.

Halogen Bulbs

I A CAUTION:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb.

You or

others could be injured. Be sure to read and

follow the instructions on the bulb package.

Page 286 of 404

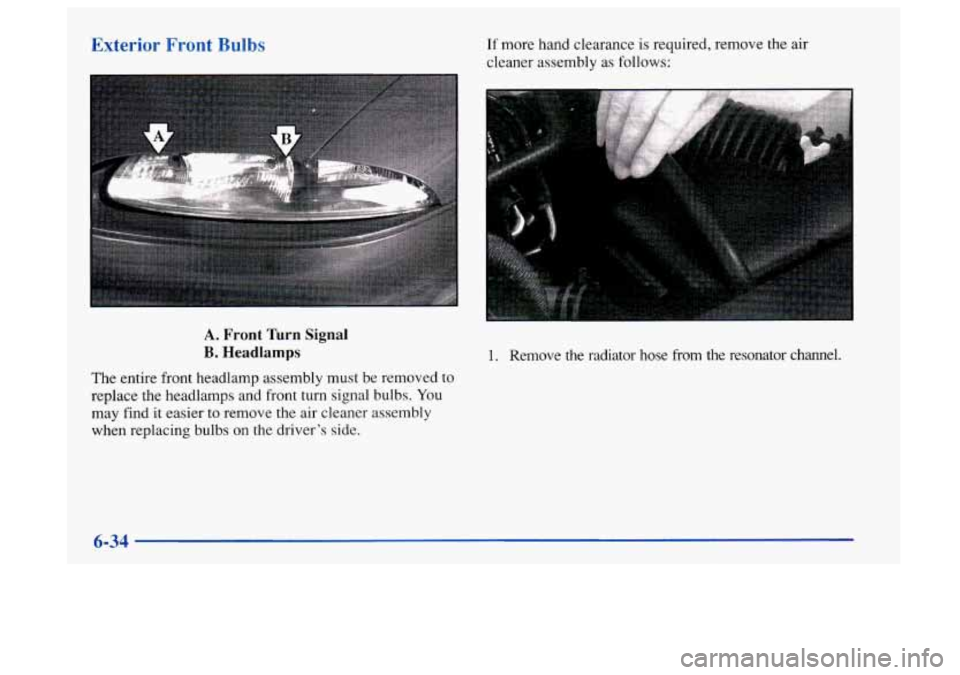

Exterior Front Bulbs If more hand clearance is required, remove the air

cleaner assembly as follows:

A. Front Wrn Signal

B. Headlamps

The entire front headlamp assembly must be removed to

replace the headlamps and front turn signal bulbs.

You

may find it easier to remove the air cleaner assembly

when replacing bulbs on the driver’s side.

1. Remove the radiator hose fi-om the resonator channel.

6-34

Page 287 of 404

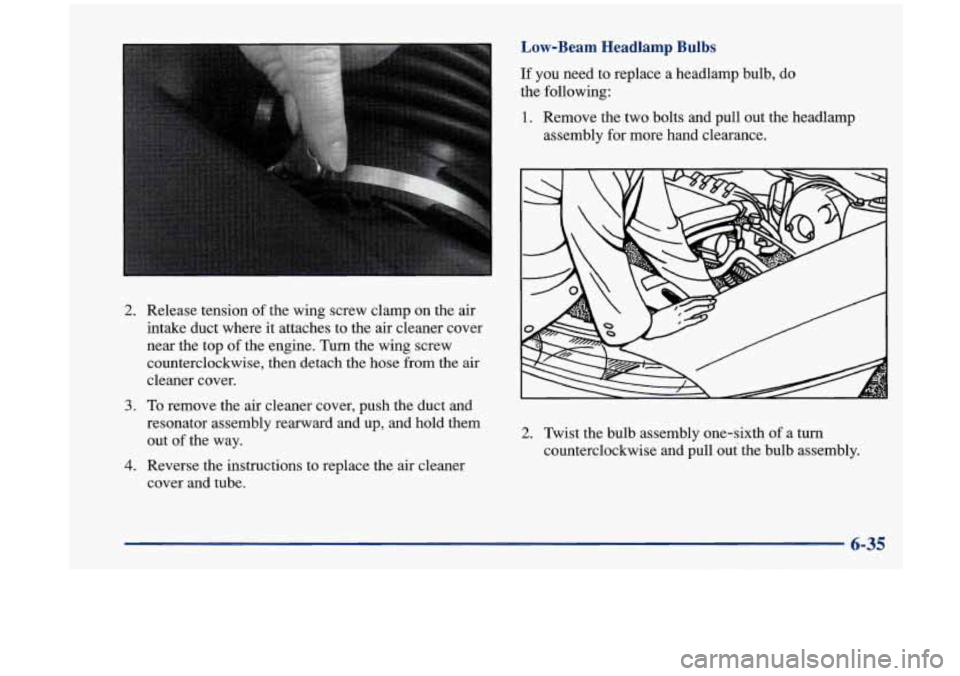

2. Release tension of the wing screw clamp on the air

intake duct where it attaches to the air cleaner cover

near the top of the engine.

Turn the wing screw

counterclockwise, then detach the hose

from the air

cleaner cover.

3. To remove the air cleaner cover, push the duct and

resonator assembly rearward and up, and hold them

out

of the way.

cover and tube.

4. Reverse the instructions to replace the air cleaner

Low-Beam Headlamp Bulbs

If you need to replace a headlamp bulb, do

the following:

1. Remove the two bolts and pull out the headlamp

assembly for more hand clearance.

2. Twist the bulb assembly one-sixth of a turn

counterclockwise and pull out the bulb assembly.

6-35

Page 288 of 404

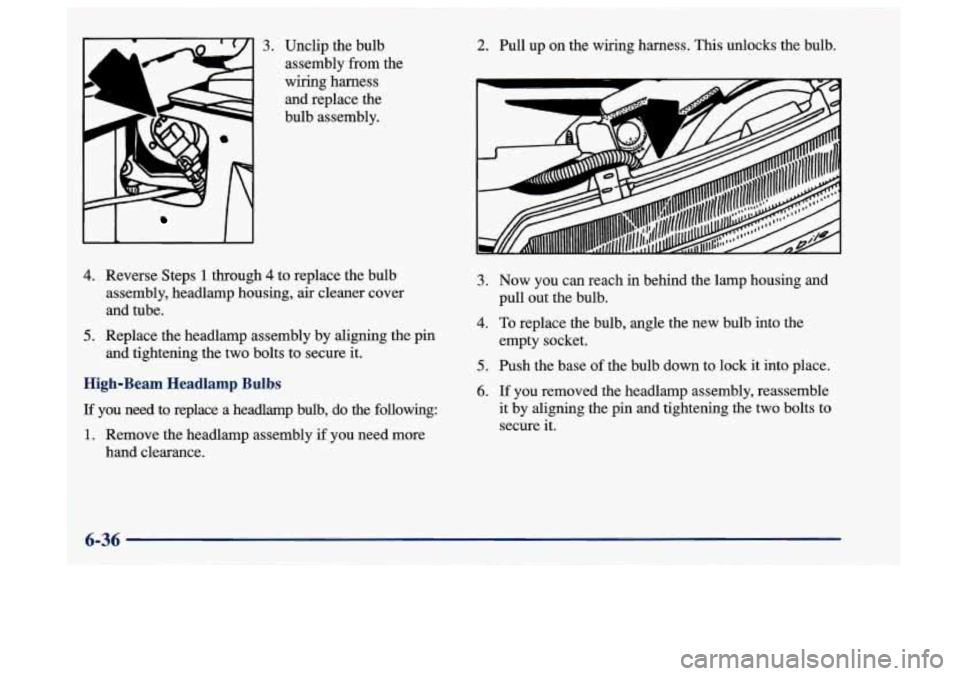

3.

II II

Unclip the bulb

assembly from the

wiring harness and replace the

bulb assembly.

4. Reverse Steps 1 through 4 to replace the bulb

assembly, headlamp housing, air cleaner cover

and tube.

5. Replace the headlamp assembly by aligning the pin

and tightening the two bolts to secure it.

High-Beam Headlamp Bulbs

If you need to replace a headlamp bulb, do the following:

1. Remove the headlap assembly if you need more

hand clearance.

2. Pull up on the wiring harness. This unlocks the bulb.

- v-

3. Now you can reach in behind the lamp housing and

4. To replace the bulb, angle the new bulb into the

pull out

the bulb.

empty socket.

5. Push the base of the bulb down to lock it into place.

6. If you removed the headlamp assembly, reassemble

it by aligning the pin and tightening the two bolts to

secure it.

Page 289 of 404

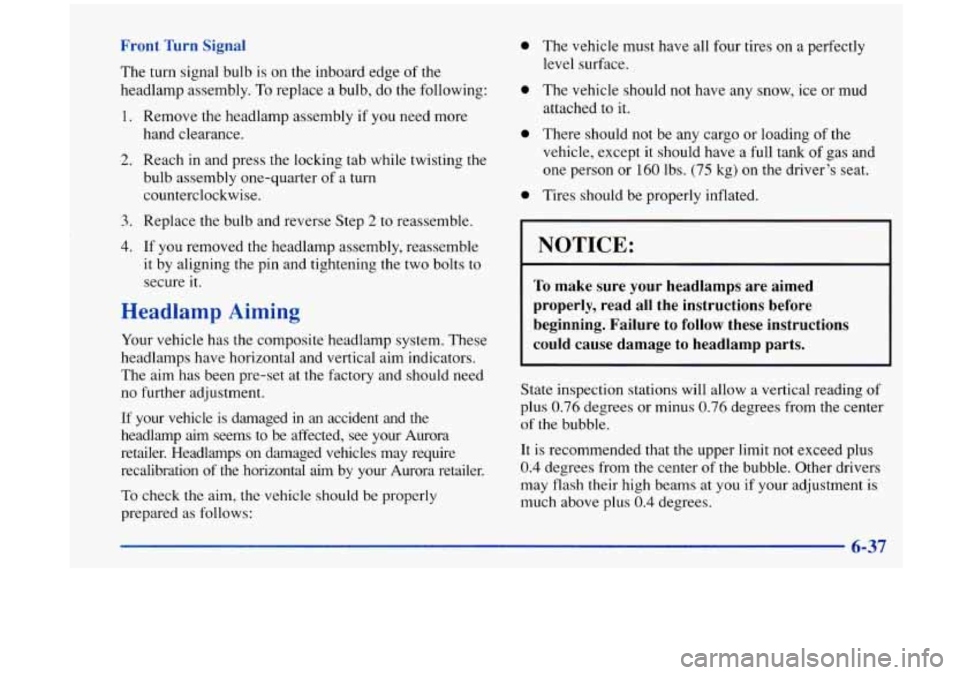

Front Turn Signal

The turn signal bulb is on the inboard edge of the

headlamp assembly.

To replace a bulb, do the following:

1.

2.

3.

4.

Remove the headlamp assembly if you need more

hand clearance.

Reach in and press the locking tab while twisting the

bulb assembly one-quarter of a turn

counterclockwise.

Replace the bulb and reverse Step

2 to reassemble.

If you removed the headlamp assembly, reassemble

it by aligning the pin and tightening the two bolts to

secure

it.

Headlamp Aiming

Your vehicle has the composite headlamp system. These

headlamps have horizontal and vertical aim indicators.

The aim has been pre-set at the factory and should need

no further adjustment.

If your vehicle is damaged in an accident and the

headlamp aim seems

to be affected, see your Aurora

retailer. Headlamps on damaged vehicles may require

recalibration

of the horizontal aim by your Aurora retailer.

To check the aim, the vehicle should be properly

prepared as

follows:

e

0

e

The vehicle must have all four tires on a perfectly

level surface.

The vehicle should not have

any snow, ice or mud

attached to it.

There should not be any cargo or loading of the

vehicle, except it should have a full tank

of gas and

one person or

160 lbs. (75 kg) on the driver’s seat.

Tires should be properly inflated.

I NOTICE:

To make sure your headlamps are aimed

properly, read all the instructions before

beginning. Failure to

follow these instructions

could cause damage to headlamp parts.

State inspection stations will allow a vertical reading of

plus

0.76 degrees or minus 0.76 degrees from the center

of the bubble.

It is recommended that the upper limit not exceed plus

0.4 degrees from the center of the bubble. Other drivers

may flash their high beams at

you if your adjustment is

much above plus

0.4 degrees.

6-37

Page 290 of 404

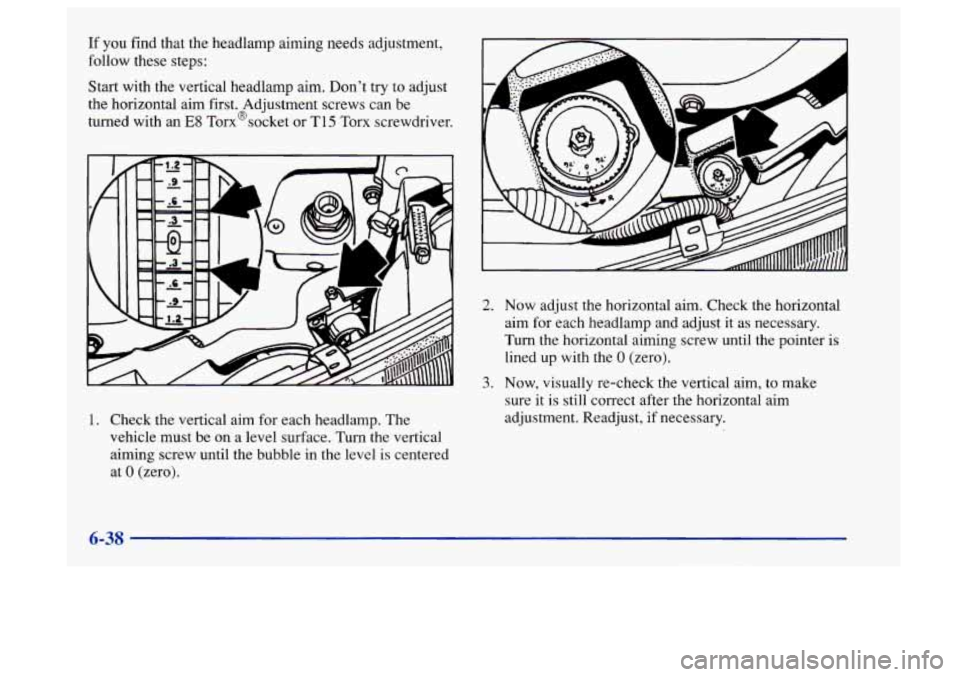

If you find that the headlamp aiming needs adjustment,

follow these steps:

Start with the vertical headlamp aim. Don't try

to adjust

the horizontal aim first. Adjustment screws can be

turned with an

E8 Torx@socket or T15 Torx screwdriver.

1. Check the vertical aim for each headlamp. The

vehicle must be on a level surface.

Turn the vertical

aiming screw until the bubble in

the level is centered

at

0 (zero).

2. Now adjust the horizontal aim. Check the horizontal

aim for each headlamp and adjust it as necessary.

Turn the horizontal aiming screw until the pointer is

lined up with the

0 (zero).

3. Now, visually re-check the vertical aim, to make

sure it is still correct after the horizontal aim

adjustment. Readjust,

if necessary.

6-38