Oldsmobile Aurora 1998 Owner's Manuals

Manufacturer: OLDSMOBILE, Model Year: 1998, Model line: Aurora, Model: Oldsmobile Aurora 1998Pages: 380, PDF Size: 19.75 MB

Page 291 of 380

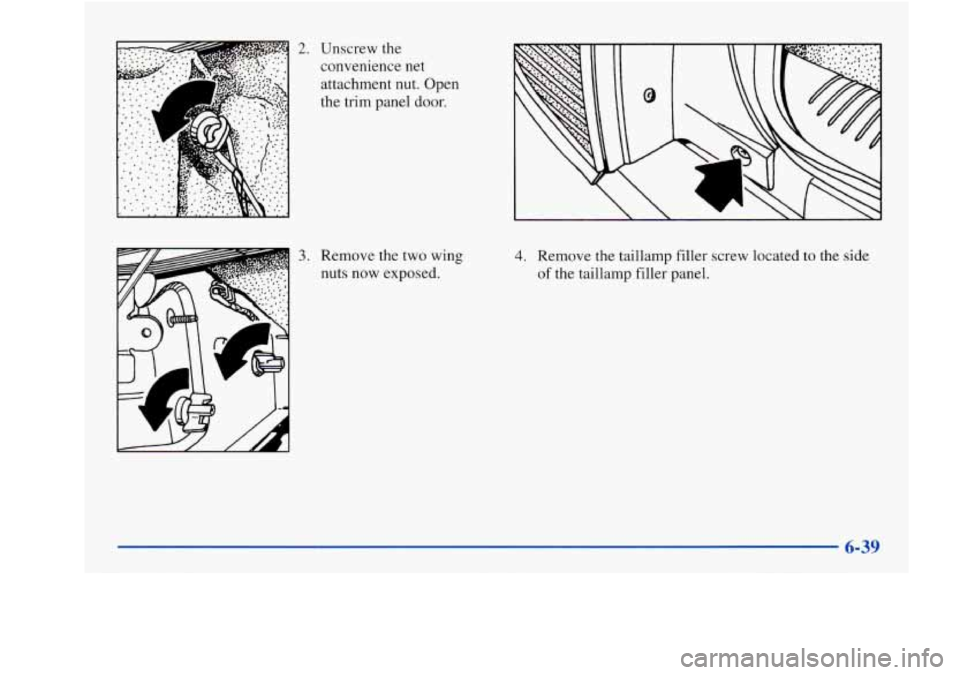

2.

3.

Unscrew the

convenience net

attachment nut. Open

the trim panel door.

Remove the two wing

nuts now exposed.

4. Remove the taillamp filler screw located to the side

of the taillamp filler panel.

6-39

Page 292 of 380

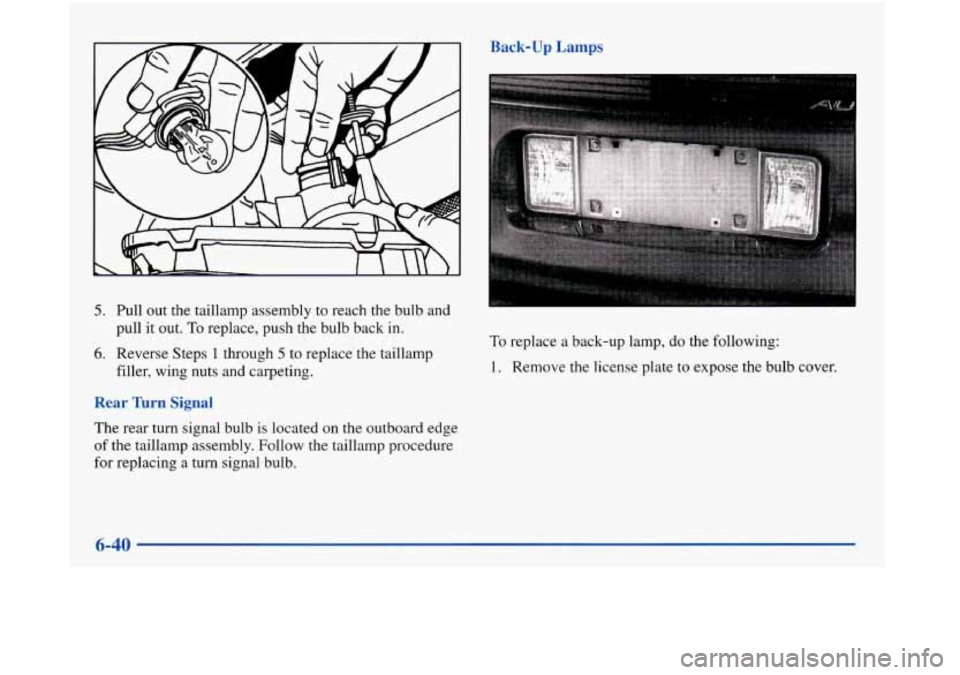

Back-up Lamps

5. Pull out the taillamp assembly to reach the bulb and

pull it out.

To replace, push the bulb back in.

6. Reverse Steps 1 through 5 to replace the taillamp

filler, wing nuts and carpeting.

Rear lhrn Signal

The rear turn signal bulb is located on the outboard edge

of the taillamp assembly. Follow the taillamp procedure

for replacing a turn signal bulb.

To replace a back-up lamp, do the following:

1. Remove the license plate to expose the bulb cover.

6-40

Page 293 of 380

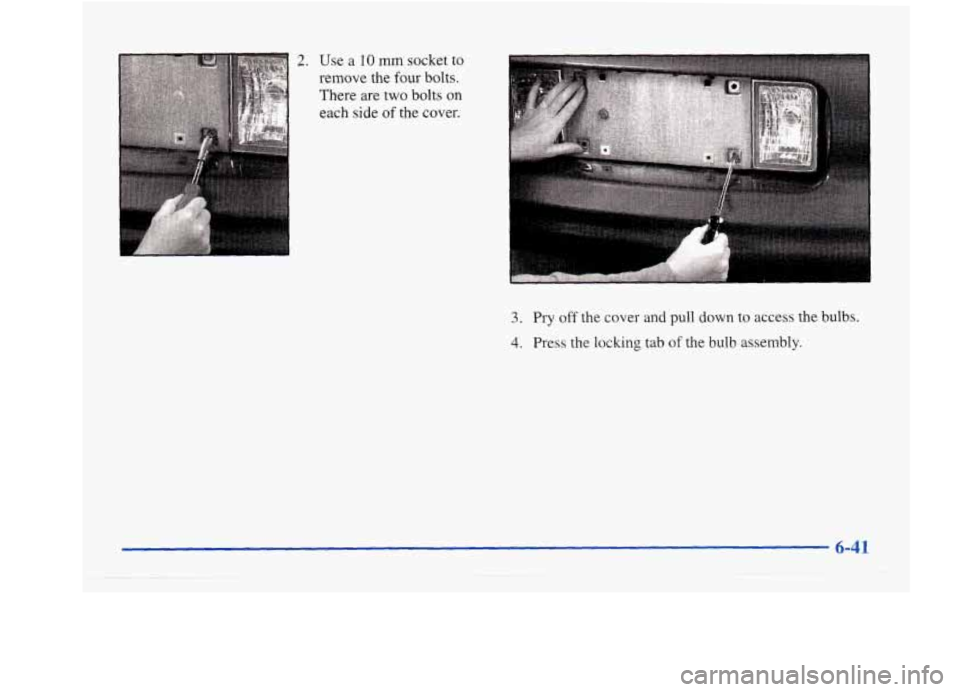

2. Use a 10 mm socket to

remove the four bolts.

There are two

bolts on

each side of the cover.

3. Pry off the cover and pull down to access the bulbs.

4. Press the locking tab of the bulb assembly.

6-41

Page 294 of 380

5. Twist the socket one-quarter of a turn to the left

(counterclockwise) and pull to remove.

6. Replace the bulb and reverse Steps 1 through 4 to

replace the assembly and tighten the bolts.

Interior Lamps

Front and Rear Reading Lamps

To change the bulbs in the front and rear reading lamps,

do the following:

1. Carefully insert a flat head screwdriver in the slot

2. Gently pry the lens cover away to expose the reading

3. Remove the bulb from its assembly and install a

between the lens

cover and molding.

lamp bulb. The lens cover should

pop off.

new bulb.

4. Snap the lens cover back in place.

6-42

Page 295 of 380

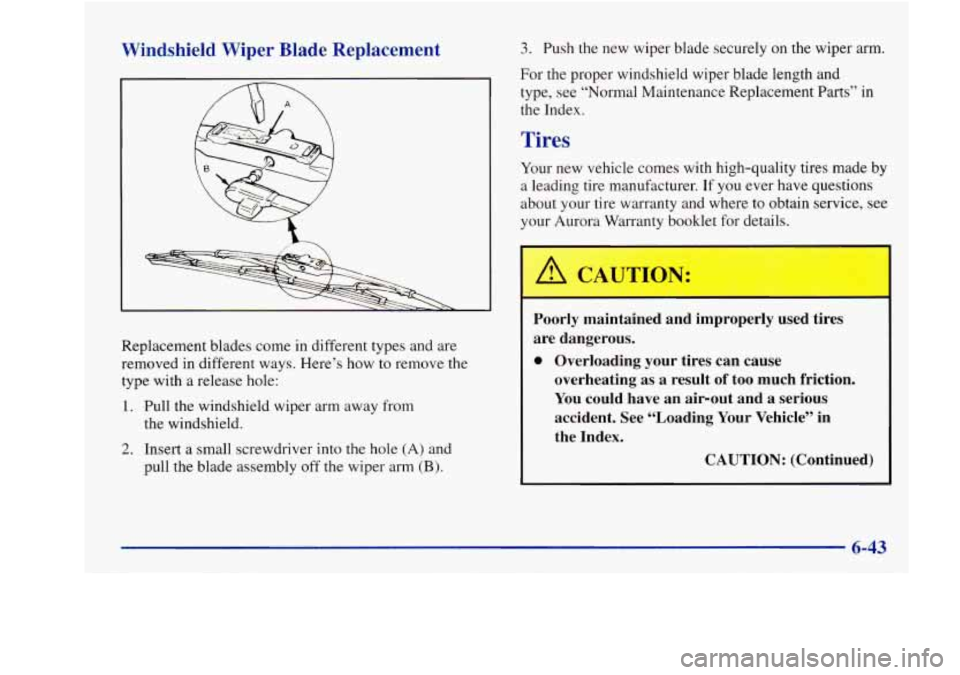

Windshield Wiper Blade Replacement

Replacement blades come in different types and are

removed in different ways. Here’s how

to remove the

type with a release hole:

1. Pull the windshield wiper arm away from

the windshield.

2. Insert a small screwdriver into the hole (A) and

pull the blade assembly

off the wiper arm (B).

3. Push the new wiper blade securely on the wiper arm.

For the proper windshield wiper blade length and

type, see “Normal Maintenance Replacement Parts” in

the Index.

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service, see

your Aurora Warranty booklet

for details.

Poorly maintained and improperly used tires

are dangerous.

0 Overloading your tires can cause

overheating as a result of

too much friction.

You could have an air-out and a serious

accident. See “Loading Your Vehicle” in

the Index.

CAUTION: (Continued)

Page 296 of 380

I

I

0

0

0

Underinflated tires pose the same danger as

overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

Overinflated tires are more likely to be

cut, punctured or broken by

a sudden

impact

-- such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents.

If your

tread is badly worn, or

if your tires have

been damaged, replace them.

I

Inflation -- Tire Pressure

The Tire-Loading Information label, which is on the

rear edge of the driver’s

door, shows the correct

inflation pressures for your tires when they’re cold.

“Cold”

means your vehicle has been sitting for at least

three hours

or driven no more than 1 mile (1.6 km).

NOTICE:

Don’t let anyone tell you that underinflation or

overinflation

is all right. It’s not. If your tires

don’t have enough

air (underinflation), you can

get the following:

Too much flexing

Too much heat

0 Tire overloading

Bad wear

0 Bad handling

Bad fuel economy.

If your tires have too much air (overinflation),

you can get the following:

Unusual wear

Bad handling

Rough ride

Needless damage from road hazards.

6-44

!

Page 297 of 380

When to Check

Check your tires once a month or more.

Don’t forget your compact spare tire. It should be at

60 psi (420 Wa).

How to Check

Use a good quality pocket-type gage to check tire

pressure. You can’t tell if your tires are properly inflated

simply by looking at them. Radial tires may look

properly inflated even when they’re underinflated.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out dirt and moisture.

Tire Inspection and Rotation

Tires should be rotated every 6,000 to 8,000 miles

(10 000 to 13 000 km). Any time you notice unusual

wear, rotate your tires as soon as possible and check

wheel alignment. Also check for damaged tires or wheels.

See “When It’s Time for New Tires” and

“Wheel

Replacement” later in this section for more information.

The purpose

of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first

rotation is the most important. See “Scheduled

Maintenance Services” in the Index for scheduled

rotation intervals. When

rotating your tires, always use the correct

rotation pattern shown here.

Don’t include the compact spare tire in your

tire rotation.

After the tires have been rotated, adjust the front and

rear inflation pressures as shown

on the Tire-Loading

Information label. Make certain that all wheel nuts

are properly tightened. See “Wheel Nut Torque” in

the Index.

Page 298 of 380

When It’s Time for New Tires

-

Rust or dirt on a wheel, or on the parts to which

it is fastened, can make wheel nuts become loose

after

a time. The wheel could come off and cause

an accident. When you change a wheel, remove

any rust or

dirt from places where the wheel

attaches to the vehicle. In an emergency, you can

use a cloth or a paper towel to

do this; but be

sure to use a scraper or wire brush later,

if you

need to, to get all the rust or dirt

off. (See

“Changing a

Flat Tire” in the Index.)

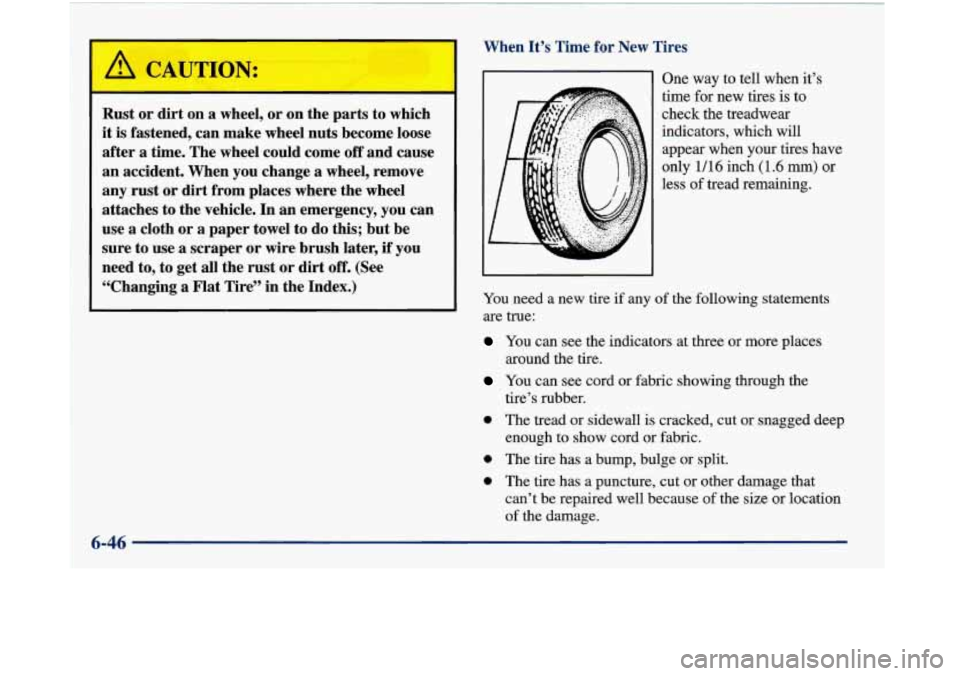

One way to tell when it’s

time for new tires is to

check the treadwear

indicators, which will

appear when your tires have

only

1/16 inch (1.6 mm) or

less of tread remaining.

You need a new tire if any of the following statements

are true:

You can see the indicators at three or more places

You can see cord or fabric showing through the

around

the tire.

tire’s rubber.

e The tread or sidewall is cracked, cut or snagged deep

enough to show cord or fabric.

e The tire has a bump, bulge or split.

e The tire has a puncture, cut or other damage that

can’t be repaired well because of the size or location

of the damage.

6-46

Page 299 of 380

Buying New Tires

To find out what kind and size of tires you need, look at

the Tire-Loading Information label.

The tires installed on your vehicle when it was new had

a Tire Performance Criteria Specification (TPC Spec)

number on each tire’s sidewall. When you get new tires,

get ones with that same TPC Spec number. That way

your vehicle will continue to have tires that are designed

to give proper endurance, handling, speed rating,

traction, ride and other things during normal service

on

your vehicle. If your tires have an all-season tread

design, the

TPC number will be followed by an “MS”

(for mud and snow).

If you ever replace your tires with those not having a

TPC Spec number, make sure they are the same size,

load range, speed rating and construction type (bias,

bias-belted or radial) as your original tires. Mixing tires could cause

you to

lose control while

driving.

If you mix tires of different sizes or types

(radial and bias-belted tires), the vehicle may not

handle properly, and you could have

a crash.

Using tires of different sizes may also cause

damage to your vehicle. Be sure to use the same

size and type tires on all wheels.

It’s all right to drive with your compact spare,

though. It was developed for use on your vehicle.

If you use bias-ply tires on your vehicle, the

wheel rim flanges could develop cracks after

many miles of driving.

A tire and/or wheel could

fail suddenly, causing a crash. Use only radial-ply

tires with the wheels on your vehicle.

6-47

Page 300 of 380

Uniform Tire Quality Grading

The following information relates to the system

developed

by the United States National Highway

Traffic Safety Administration, which grades tires by

treadwear, traction and temperature performance. (This applies only to vehicles sold in the United States.) The

grades are molded on the sidewalls of most passenger

car tires. The Uniform Tire Quality Grading system does

not apply to deep tread, winter-type snow tires,

space-saver or temporary use spare tires, tires with

nominal rim diameters of 10 to 12 inches (25 to

30 cm),

or to some limited-production tires.

While the tires available on General Motors passenger

cars and light trucks may vary with respect to these

grades, they must also conform to Federal safety

requirements and additional General Motors Tire

Performance Criteria (TPC) standards.

Treadwear

The treadwear grade is a comparative rating based on

the wear rate

of the tire when tested under controlled

conditions on a specified government test course.

For example, a tire graded

150 would wear one and a

half (1 1/2) times as well on the government course

as a tire graded 100. The relative performance of tires depends upon

the actual conditions of their use,

however, and may depart significantly from the norm

due to variations in driving habits, service practices and

differences in road characteristics and climate.

Traction -- A, B, C

The traction grades, from highest to lowest, are A, B,

and C, and they represent the tire’s ability to stop on

wet pavement as measured under controlled conditions

on specified government test surfaces

of asphalt

and concrete.

A tire marked C may have poor

traction performance.

Warning: The traction grade assigned to this tire is based

on braking (straight ahead) traction tests and does not

include cornering (turning) traction.

Temperature -- A, B, C

The temperature grades are A (the highest), B, and C,

representing the tire’s resistance to the generation of

heat and its ability

to dissipate heat when tested under

controlled conditions on a specified indoor laboratory

test wheel. Sustained high temperature can cause the

material of the tire to degenerate and reduce tire life, and

excessive temperature can lead to sudden tire failure.

6-48