crank OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 38 of 625

STARTING SYSTEMlB- 17

7. Seal area between solenoid and frame. See FigurelB-17.

8. With brushes and spring in housings held in place

with a 29 @llimeter socket, slide frame assembly in

position.

9. Install i+ulating sleeves in field frame.

10. Install knd frame and replace through bolts and

tighten bolts.

11. Install bolt holding field frame to solenoid.

SPEClFltjATlONS

Starter SpecificationsStarterNumber. . . .

.._.._..._...........................RatedVoltage

. . . . . . . . . . . . . . . . . . . . . . . . .No voad Test:

...............................................EF 12V0 .8 PS

.....................................................................12Volts

................................................................................................................................10.6Amperes

........................................................................................................................30-50RPM

......................................................................................................................7300-8500Cranking Amperes Test (InCar-Engine atOperating Temp.)

..................................175-205

Lock Test:

Volts

............................................................................................................................6 Min.

Amperes

....................................................................................................................280-320Volt$geRequiredtoCloseSolenoidContacts

....................................................................7.5MinimumDiameterof Commutatorin

Inches................................................................1.46Brush Spring Pressure in Ounces

....................................................................................40-46Minimum Length of Brushes in Inches...............................................................................2812. Check starter on bench before installing.

Starter Installation

1. Hold starter in position.

2. Install two bolts, one nut and lockwashers.

Tighten securely.

3. Install support bracket. To ensure a stress-freeintitallation, install bolt and two nuts only finger

tight. First tighten the bolt at the engine, then tighten

the two nuts at the starter end frame.

Page 41 of 625

I

ilC- 201973 OPEL SERVICE MANUAL

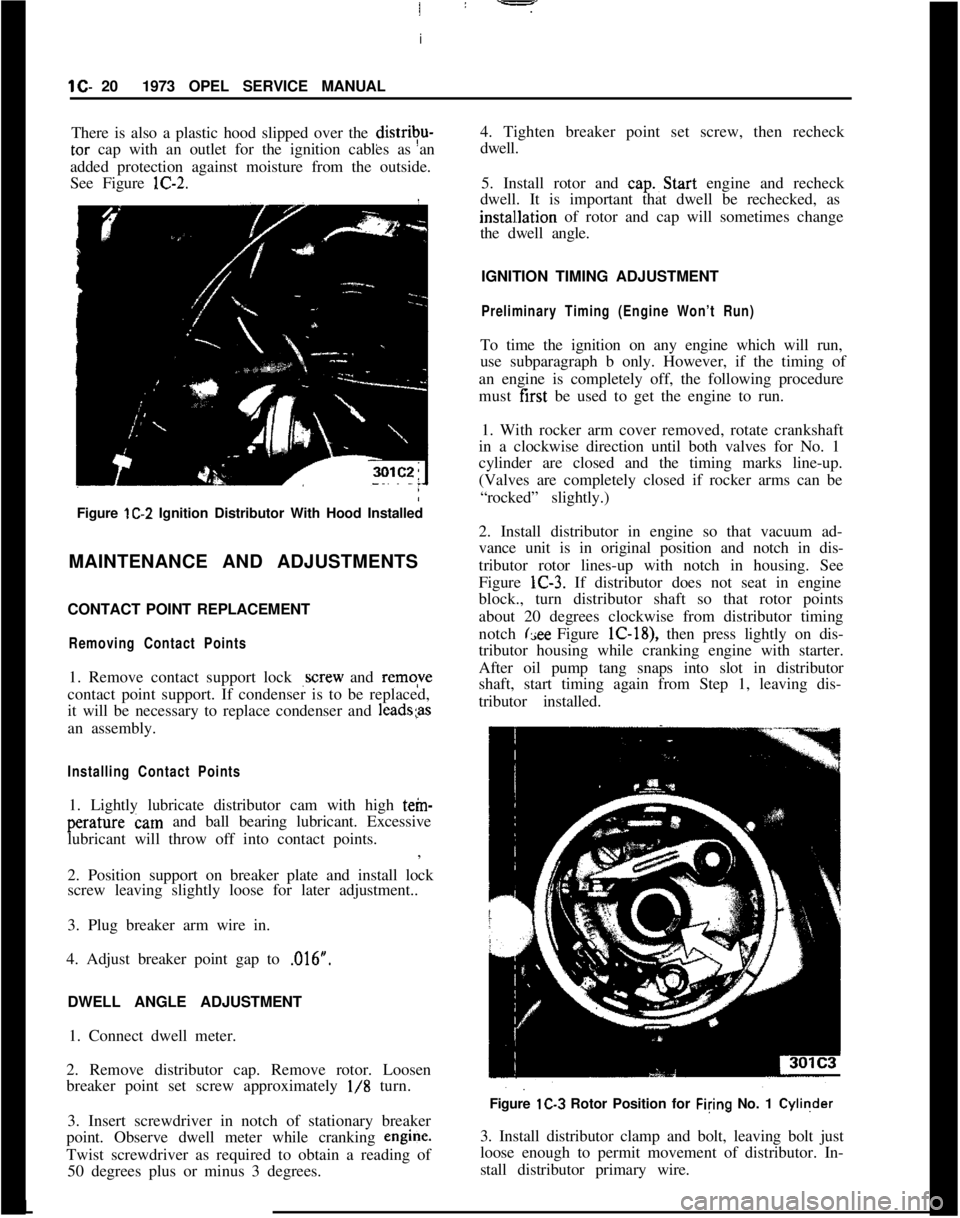

There is also a plastic hood slipped over the distrivu-tar cap with an outlet for the ignition cables as an

added protection against moisture from the outside.

See Figure lC-2.

Figure lC-2 Ignition Distributor With Hood Installed

MAINTENANCE AND ADJUSTMENTS

CONTACT POINT REPLACEMENT

Removing Contact Points1. Remove contact support lock

,screw and remqve

contact point support. If condenser is to be replaced,

it will be necessary to replace condenser and

1eads;asan assembly.

Installing Contact Points1. Lightly lubricate distributor cam with high tein-perature cam and ball bearing lubricant. Excessive

lubricant will throw off into contact points.

:

,

2. Position support on breaker plate and install lock

screw leaving slightly loose for later adjustment..

3. Plug breaker arm wire in.

4. Adjust breaker point gap to ,016”.

/

DWELL ANGLE ADJUSTMENT

1. Connect dwell meter.

2. Remove distributor cap. Remove rotor. Loosen

breaker point set screw approximately

l/8 turn.

3. Insert screwdriver in notch of stationary breaker

point. Observe dwell meter while cranking engine.

Twist screwdriver as required to obtain a reading of

50 degrees plus or minus 3 degrees.4. Tighten breaker point set screw, then recheck

dwell.

5. Install rotor and cap.~Start engine and recheck

dwell. It is important that dwell be rechecked, as

instal~lation of rotor and cap will sometimes change

the dwell angle.

IGNITION TIMING ADJUSTMENT

Preliminary Timing (Engine Won’t Run)To time the ignition on any engine which will run,

use subparagraph b only. However, if the timing of

an engine is completely off, the following procedure

must first be used to get the engine to run.

1. With rocker arm cover removed, rotate crankshaft

in a clockwise direction until both valves for No. 1

cylinder are closed and the timing marks line-up.

(Valves are completely closed if rocker arms can be

“rocked” slightly.)

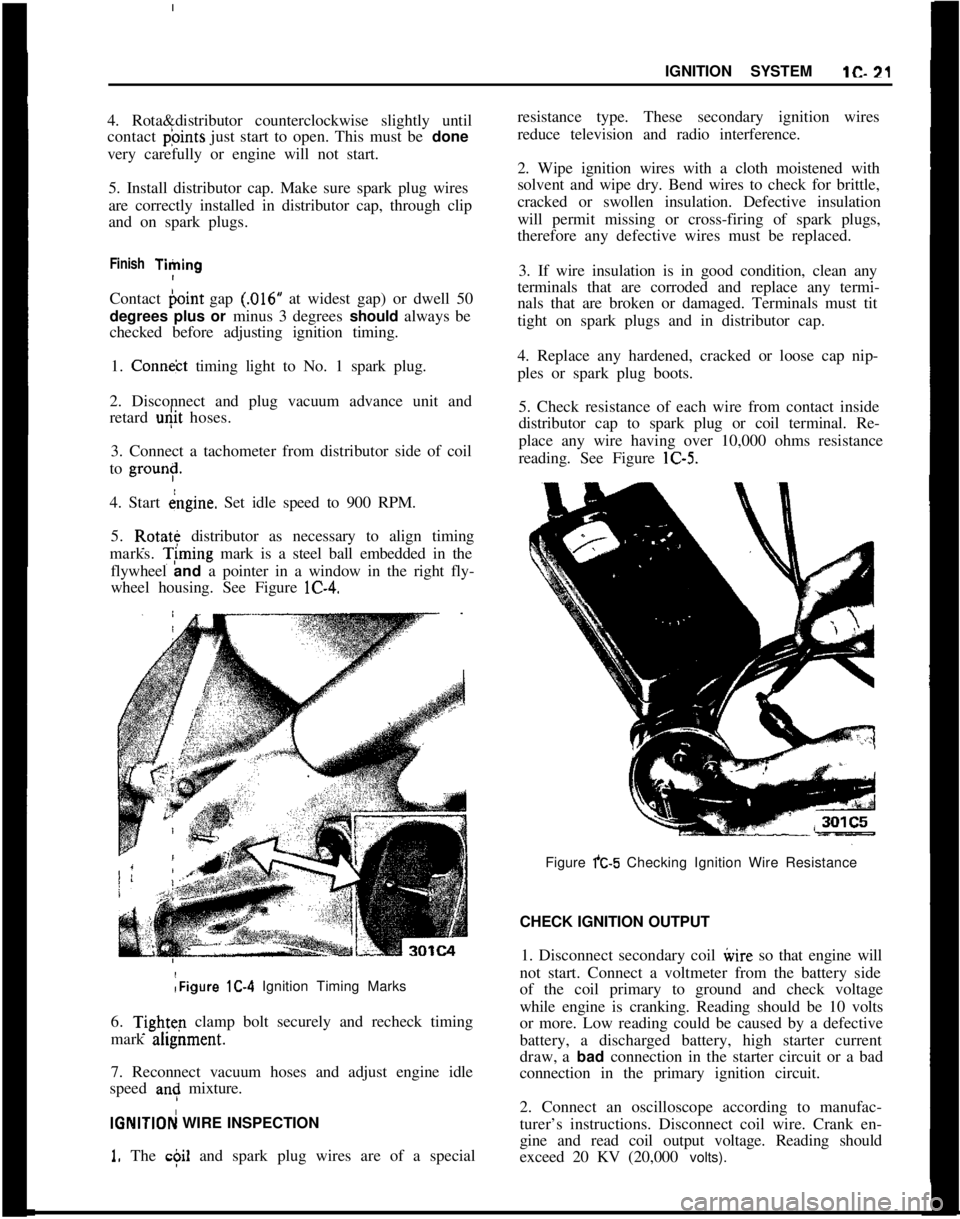

2. Install distributor in engine so that vacuum ad-

vance unit is in original position and notch in dis-

tributor rotor lines-up with notch in housing. See

Figure lC-3. If distributor does not seat in engine

block., turn distributor shaft so that rotor points

about 20 degrees clockwise from distributor timing

notch

(see Figure lC-18), then press lightly on dis-

tributor housing while cranking engine with starter.

After oil pump tang snaps into slot in distributor

shaft, start timing again from Step 1, leaving dis-

tributor installed.

Figure lC-3 Rotor Position for Filing No. 1 Cyliqder

3. Install distributor clamp and bolt, leaving bolt just

loose enough to permit movement of distributor. In-

stall distributor primary wire.L

Page 42 of 625

IGNITION SYSTEMlC-214. Rota&distributor counterclockwise slightly until

contact pbints just start to open. This must be done

very carefully or engine will not start.

5. Install distributor cap. Make sure spark plug wires

are correctly installed in distributor cap, through clip

and on spark plugs.

Finish TimingIContact boint gap

(.016” at widest gap) or dwell 50

degrees plus or minus 3 degrees should always be

checked before adjusting ignition timing.

1. Connekt timing light to No. 1 spark plug.

2. Disconnect and plug vacuum advance unit and

retard u$it hoses.

3. Connect a tachometer from distributor side of coil

to

groun$l.4. Start dngine. Set idle speed to 900 RPM.

5. Rotate distributor as necessary to align timing

marks. T;ming mark is a steel ball embedded in the

flywheel and a pointer in a window in the right fly-

wheel housing. See Figure lC-4.:Figure lC-4 Ignition Timing Marks

6.

Tightq clamp bolt securely and recheck timing

mark ahgnment.

7. Reconnect vacuum hoses and adjust engine idle

speed

an: mixture.

IGNlTlOFj WIRE INSPECTION

1. The c$il and spark plug wires are of a specialresistance type. These secondary ignition wires

reduce television and radio interference.

2. Wipe ignition wires with a cloth moistened with

solvent and wipe dry. Bend wires to check for brittle,

cracked or swollen insulation. Defective insulation

will permit missing or cross-firing of spark plugs,

therefore any defective wires must be replaced.

3. If wire insulation is in good condition, clean any

terminals that are corroded and replace any termi-

nals that are broken or damaged. Terminals must tit

tight on spark plugs and in distributor cap.

4. Replace any hardened, cracked or loose cap nip-

ples or spark plug boots.

5. Check resistance of each wire from contact inside

distributor cap to spark plug or coil terminal. Re-

place any wire having over 10,000 ohms resistance

reading. See Figure lC-5.

Figure fC-5 Checking Ignition Wire Resistance

CHECK IGNITION OUTPUT

1. Disconnect secondary coil ivire so that engine will

not start. Connect a voltmeter from the battery side

of the coil primary to ground and check voltage

while engine is cranking. Reading should be 10 volts

or more. Low reading could be caused by a defective

battery, a discharged battery, high starter current

draw, a bad connection in the starter circuit or a bad

connection in the primary ignition circuit.

2. Connect an oscilloscope according to manufac-

turer’s instructions. Disconnect coil wire. Crank en-

gine and read coil output voltage. Reading should

exceed 20 KV (20,000 volts).

Page 44 of 625

IGNITION SYSTEMlC- 23

9. Install:spark plugs using a 13/16 deep socket, an

extension and a torque wrench. Tighten to 22-29Ib.ft. 1

MAJOR REPAIRDlSTRlBtiTOR OVERHAULDistributbr Removal

1. Remove fuel pump. This is necessary because the

fuel

punp will block the distributor drive gear,

thereby preventing removal of the distributor. See

Figure lC-6.

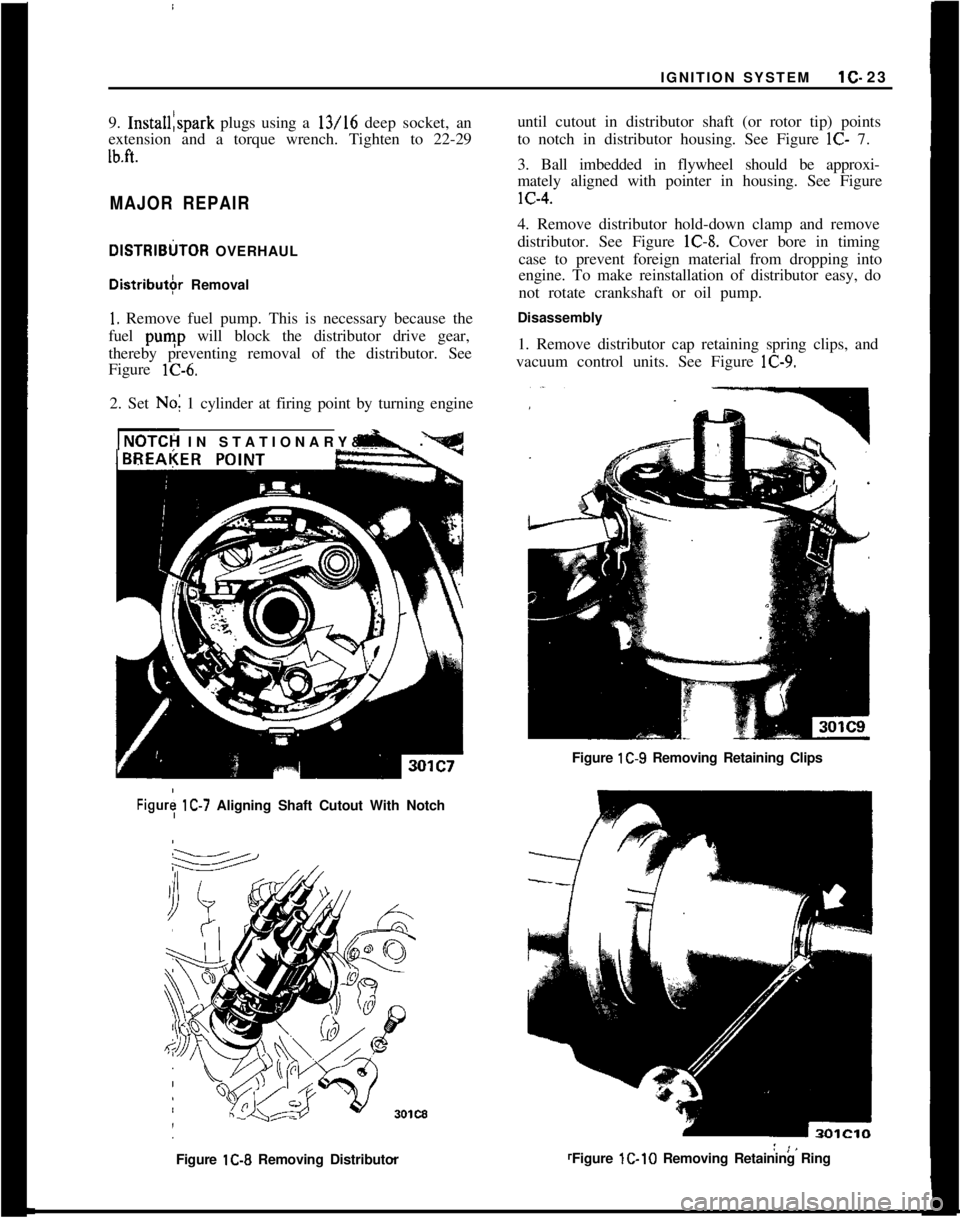

2. Set No; 1 cylinder at firing point by turning engine

INOTCH IN STATIONARY& -.until cutout in distributor shaft (or rotor tip) points

to notch in distributor housing. See Figure

lC- 7.

3. Ball imbedded in flywheel should be approxi-

mately aligned with pointer in housing. See FigurelC-4.

4. Remove distributor hold-down clamp and remove

distributor. See Figure lC-8. Cover bore in timing

case to prevent foreign material from dropping into

engine. To make reinstallation of distributor easy, do

not rotate crankshaft or oil pump.

Disassembly

1. Remove distributor cap retaining spring clips, and

vacuum control units. See Figure lC-9.

Figure lC-9 Removing Retaining Clips

Figury lC-7 Aligning Shaft Cutout With Notch

Figure lC-8 Removing DistributorFigure lC-10 Removing Retaining Ring

Page 58 of 625

WINDSHIELD WIPERSlE- 37WINDSHEILD WIPERS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Windshield Wiper Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Windshield Wiper

. . . . . . . . . . . . . . . . . . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Wiper Transmission

- 1900 and Manta. . . . . . . . . . . . . . . . . . . .W/per Transmission

- GT. . . . . a.* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and Inspection of Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Assembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

GeneralSpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Torque Specifications

. . . . . . . a.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTIOfV AND OPERATION

GENERAL;DESCRlPTlDNThe two-sbeed wiper consists of a round shaped per-

manent magnet type motor and speed reduction gear

box. IOPERATldN

=The wipei motor is controlled through a dash

mounted &itch on all cars. The Rallye and GT, in

addition tb the dash mounted switch, also have a

switch moimted in conjunction with the windshield

washer fodt pump. Depressing the washer pump will

allow the bipers to operate while the pump is de-

pressed. i

DIAGNO;SIS

PRELIMINj9RY INSPECTION

1. Make

c&in of firm wire connections at wiper

motor fuse block and wiper switch.

Page No.

1 E-37

1 E-37E-38

E-38

E-40

E-41

E-4 1E-42

1 E-43

1 E-432. Check to see that the fuse is not blown.

3. Be sure wiper motor is not loose on fire wall.

4. With the yellow wire disconnected from terminal

No. 53 on the

wi@er motor, turn the ignition switch

and wiper switch to the on position and check volt-

age available to the wiper motor. There should be 12

volts available at the durple wire with a properly

charged battery.

Checking Wiper Operation1. Turn ignition switch on and engage wiper switch

to see if wiper motor will operate.

2. If wiper action is slow or inoperative, turn swit-

ches off and detach wiper control

inn from crank

arm.3. Operate wiper manually checking for excessive

bind in linkage. Correct if necessary.

Page 59 of 625

1 E- 381973 OPEL SERVICE MANUAL

4. Turn switch on to see if wiper niotor will function

with wiper linkage’detached. If wiper motor will ndt

run, disconnect connector at wiper motor and co?-

nect hot lead from battery to terminal No. 53 onwiper motor. If wiper motor runs, the wiper switch

is faulty or there is an break in the lead wire. If wiper

motor still will not run, remove and bench test.

MAJOR REPAIRWIPER TRANSMISSIONS

Removal (1900 and Manta)1. Remove wiper blade (2).

2. Remove the wiper transmission retaining nut,

washer, and rubber seal ring. See .Figure lE-1.

Figure lE-1 Crank Arm Retaining Nut3. Remove instrument cluster housing.

If only left wiper transmission is to be serviced, it can

be done without removing any ‘other instrument

panel components. If the right side, or both, trans-

missions are to be serviced, then

it will be necessary

for complete instrument panel removal. On the Ral-

lye models, the gauge carrier must also be remove&Qn all

1900 and Manta Models the defroster ducts

are secured to the instrument panel cover, by two (‘2)

spring clips, and should not be removed from

dayhcover. Remove cover and duct as, a unit.

4. Remove retaining clips from transmission co;-netting rod pins. Pull connecting rods off pins. See

Item “A”, Figure lE-2.

5. Remove the screws securing the wiper transmis-

sion to the inner side of the cowl (Items “B”, Figuie

13), and remove the transmission assemblies.I

Figure lE-2 Connecting Rod Retaining Clips

Installation1. Place wiper transmissions into position at cowl

and install holding screws.

2. Push connecting rods onto transmission cranking

arm pins and install retaining clips. See Figure lE-2,

Item “A”.

3. Reinstall dash and instrument cluster parts.

4.

1nst:all the rubber seal ring, washer, and transmis-

sion retaining nut. See Figure IE-1.

5. Install wiper blades and check the position of the

blades in the park position. See Figure lE-3.

Figure lE-3 Wiper Blades in Park Position

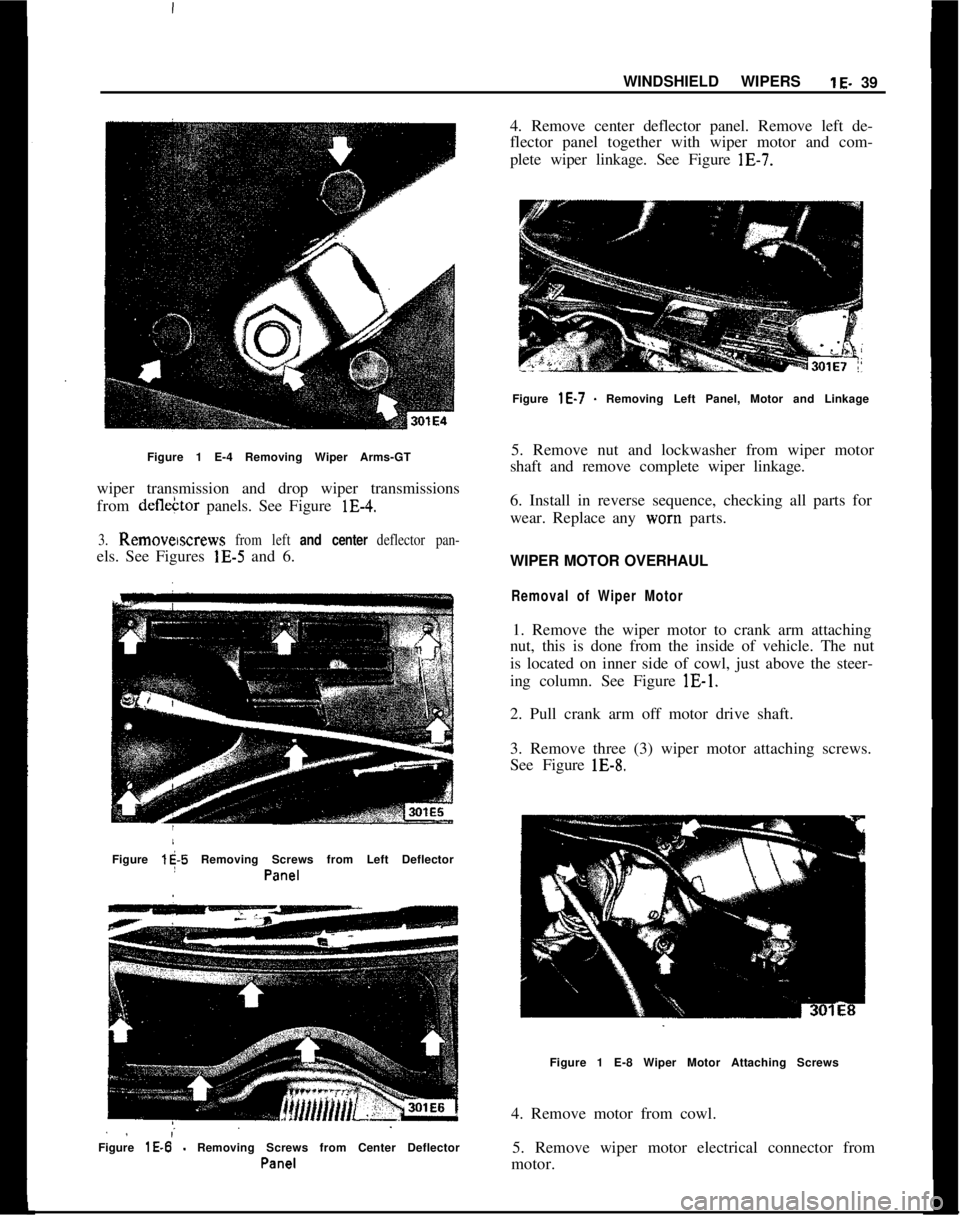

Removal and Installation of GT W/per Transmission1. Remove nuts and remove both wiper

arms. See

Figure lE-4.

2. Remove three (3) bolts from each windshield

Page 60 of 625

WINDSHIELD WIPERSlE- 39

Figure 1 E-4 Removing Wiper Arms-GT

wiper transmission and drop wiper transmissions

from defleCtor panels. See Figure lE-4.3. Remowscrews from left and center deflector pan-els. See Figures lE-5 and 6.

Figure

l$-5 Removing Screws from Left Deflector

I

Pa%?1

. .;Figure

lE-6 - Removing Screws from Center Deflector

Pall-Z!14. Remove center deflector panel. Remove left de-

flector panel together with wiper motor and com-

plete wiper linkage. See Figure lE-7.

Figure

lE-7 - Removing Left Panel, Motor and Linkage

5. Remove nut and lockwasher from wiper motor

shaft and remove complete wiper linkage.

6. Install in reverse sequence, checking all parts for

wear. Replace any worn parts.

WIPER MOTOR OVERHAUL

Removal of Wiper Motor1. Remove the wiper motor to crank arm attaching

nut, this is done from the inside of vehicle. The nut

is located on inner side of cowl, just above the steer-

ing column. See Figure lE-1.

2. Pull crank arm off motor drive shaft.

3. Remove three (3) wiper motor attaching screws.

See Figure lE-8.

Figure 1 E-8 Wiper Motor Attaching Screws

4. Remove motor from cowl.

5. Remove wiper motor electrical connector from

motor.

Page 63 of 625

1 E- 421973 OPEL SERVICE MANUAL

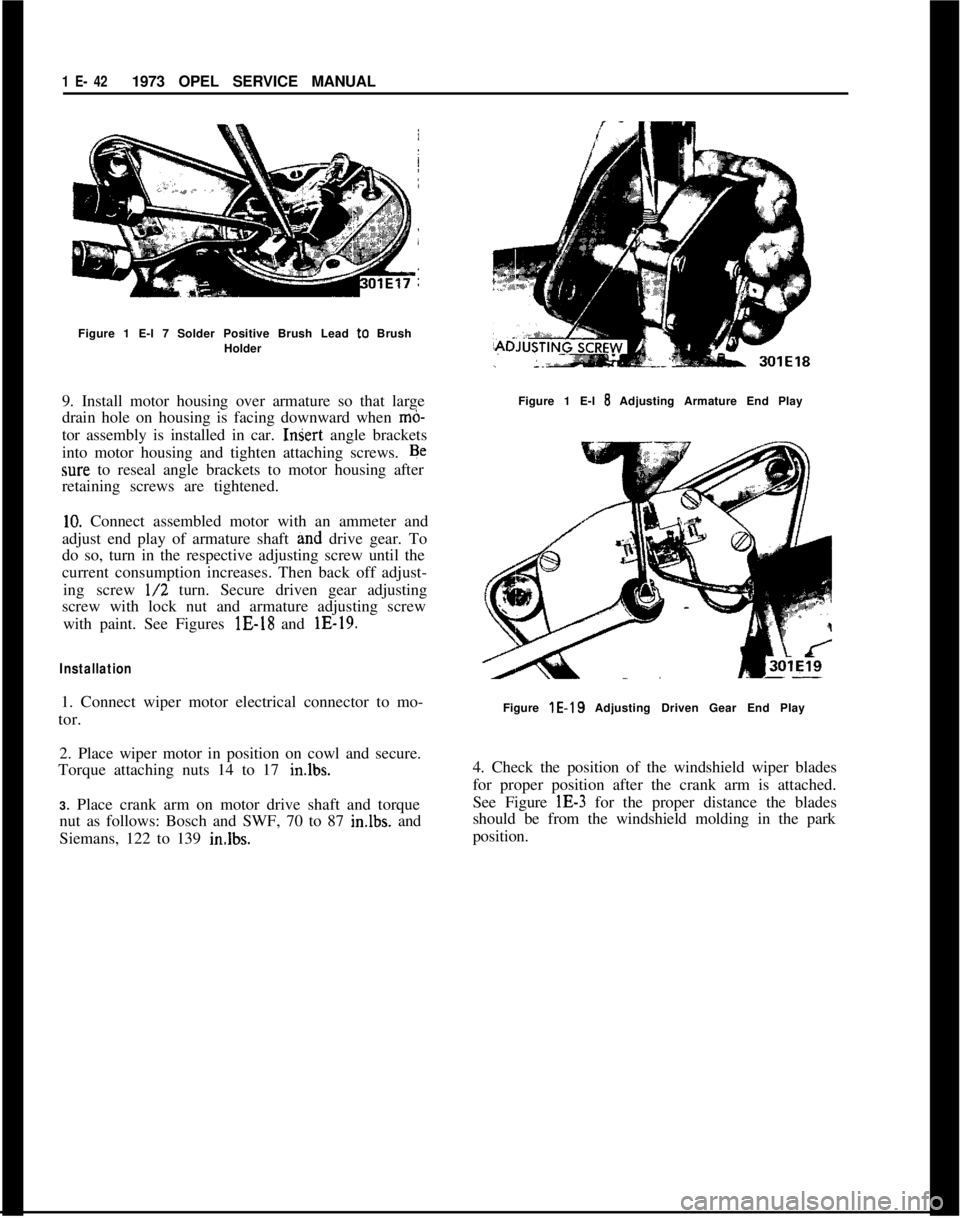

Figure 1 E-l 7 Solder Positive Brush Lead to Brush

Holder

9. Install motor housing over armature so that large

drain hole on housing is facing downward when

mb-tor assembly is installed in car.

InSert angle brackets

into motor housing and tighten attaching screws. Be

sure to reseal angle brackets to motor housing after

retaining screws are tightened.

10. Connect assembled motor with an ammeter and

adjust end play of armature shaft grid drive gear. To

do so, turn in the respective adjusting screw until the

current consumption increases. Then back off adjust-

ing screw

l/2 turn. Secure driven gear adjusting

screw with lock nut and armature adjusting screw

with paint. See Figures lE-18 and lE-19.

Installation1. Connect wiper motor electrical connector to mo-

tor.

2. Place wiper motor in position on cowl and secure.

Torque attaching nuts 14 to 17 in.lbs.

3. Place crank arm on motor drive shaft and torque

nut as follows: Bosch and SWF, 70 to 87 imlbs. and

Siemans, 122 to 139 in.lbs.Figure 1 E-l

8 Adjusting Armature End Play

Figure

lE-19 Adjusting Driven Gear End Play

4. Check the position of the windshield wiper blades

for proper position after the crank arm is attached.

See Figure lE-3 for the proper distance the blades

should be from the windshield molding in the park

position.

Page 64 of 625

WINDSHIELD WIPERSlE-43SPEhFlCATlONS

IGENEPAL SPECIFICATIONSiRated Voltage .

..__.,,,.,,,......................................,.,,... ~ __..__...__...._..................................... 12 VDC

,Test Voltage ___..................................................,...................,..,..................................... 13 VDC

Current Draw (Amps)

;No Load_, Low Speed

..__...__..__..,_,,..,,,.,,,,..,....................,,.................................................................. 1.5

I Hieh

SDeed .___,,...,,..,,._.._..............,...............................,,,..,,,.............................................. 2.2lLock:d

’

:Low Speed ___.,._,,,..,,,....................................,,.........,,..,,,.,,,,..................,,,........................... 16

,

High Speed . . . . . . . ..___.._........................................................................................................... 17

~Minimum Commutator Diameter __.................,,,,........................................................... .86 in.

‘Brush Spring Pressure

:New Brush

. . . . . . .._...__...................................................................................... 6.35 to 8.47 oz.Used Brush

..__,,,...,,.,,..................,...............................,,.,,,,.,,....................... 3.5 oz. minimum‘MinimumBrushLength

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24in.The windshield wiper motor instead of field coils has a permanent magnet

(oxide magnet). This motor design is sturdier and consumes less current.TORQirE SPECIFICATIONS

‘CrankArmtoMotorDriveShaft. . . . . . . . . . . . . . . . . . . . . . . . . .70to87in.lbs.iper Motor to Cowl

,

,.,,,.,,,,..,,............,..,,.,,.........................................14 to 17 in.lbs.

Page 147 of 625

2F-241973 OPEL SERVICE MANUAL

ROOF AND SUN ROOF

CONTENTS

,.,Subject

DESC,RIF?TION AND OPERATION: (Not Applicable)

DIAGNOSIS: Sun Roof Diagnosis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND ADJUSTMENTS:Sun Roof Height Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .

MAJOR REPAIR:

Removal and Installation

Sun Roof Panel andFrame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .

Velvet Strip and Weather Strip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RearGuides andCables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . .

Drive Pinion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water DrainHoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . .

Luggage Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS: (Not Applicable) Page No.

2F-24

2F-26

iF-27

2F-29

2F-29

2F-30

2F-31

2F-3i

DIAGNOSIS

SUN ROOF DIAGNOSIS

_ -

CONhTlONPAUSEI~C~RRECTI~X~

Sun roof does not operate

Transporter cable lengths

parallel. equal.Close sun roof, slide sun roof

frame to rear, remove.crank

handle

and cable crank. Check

that sun roof bears against sun

roof opening velvet strip and

that lifter’ portion of rear lifter

guides is positioned approximately

90 degrees to guide rails.

Turn

cable crank fully clockwise and

reinstall into cable box.

Transporter cables damaged

or worn. Replace cables. Both cables

must be replaced if either one

is damaged or worn.