crank OPEL 1900 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 150 of 625

ROOF AND SUN ROOF2F-27

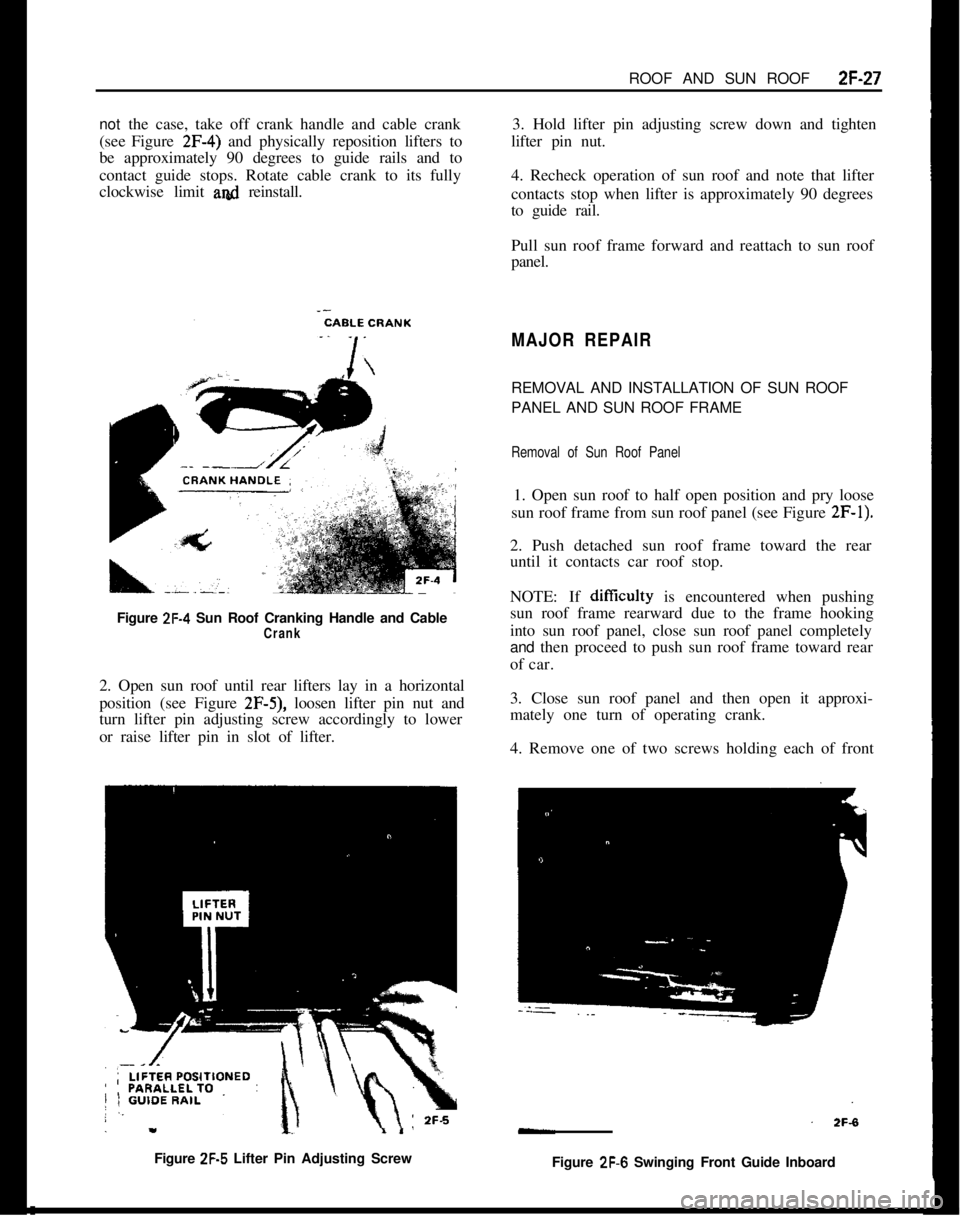

not the case, take off crank handle and cable crank

(see Figure 2F-4) and physically reposition lifters to

be approximately 90 degrees to guide rails and to

contact guide stops. Rotate cable crank to its fully

clockwise limit alad reinstall.

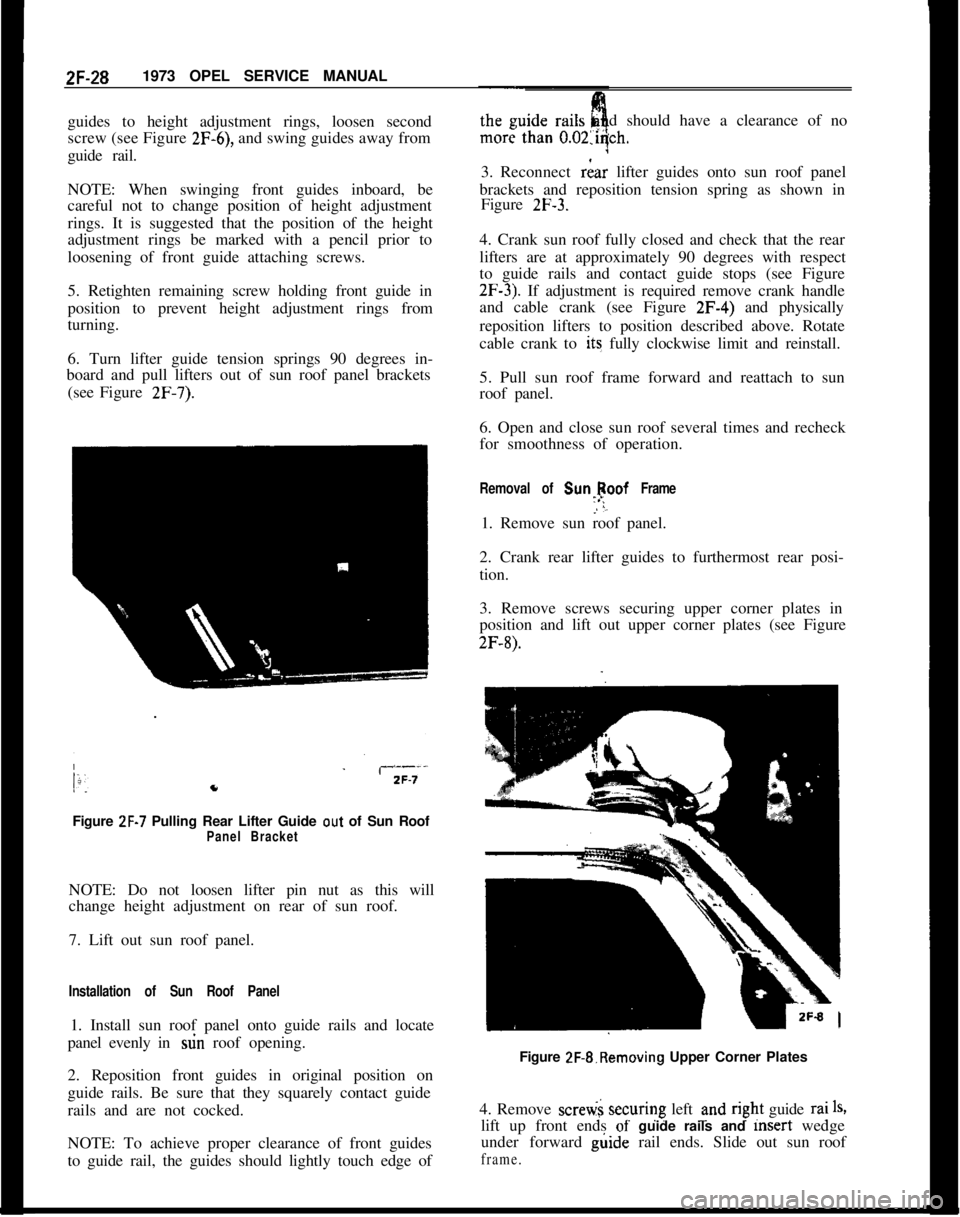

Figure 2F-4 Sun Roof Cranking Handle and CableCrank2. Open sun roof until rear lifters lay in a horizontal

position (see Figure

2F-5), loosen lifter pin nut and

turn lifter pin adjusting screw accordingly to lower

or raise lifter pin in slot of lifter.3. Hold lifter pin adjusting screw down and tighten

lifter pin nut.

4. Recheck operation of sun roof and note that lifter

contacts stop when lifter is approximately 90 degrees

to guide rail.

Pull sun roof frame forward and reattach to sun roof

panel.

MAJOR REPAIRREMOVAL AND INSTALLATION OF SUN ROOF

PANEL AND SUN ROOF FRAME

Removal of Sun Roof Panel1. Open sun roof to half open position and pry loose

sun roof frame from sun roof panel (see Figure

2F-1).2. Push detached sun roof frame toward the rear

until it contacts car roof stop.

NOTE: If difficulty is encountered when pushing

sun roof frame rearward due to the frame hooking

into sun roof panel, close sun roof panel completely

and then proceed to push sun roof frame toward rear

of car.

3. Close sun roof panel and then open it approxi-

mately one turn of operating crank.

4. Remove one of two screws holding each of front

Figure

2F-5 Lifter Pin Adjusting Screw

Figure ZF-6 Swinging Front Guide Inboard

Page 151 of 625

2F-281973 OPEL SERVICE MANUAL

guides to height adjustment rings, loosen second

screw (see Figure 2F-6), and swing guides away from

guide rail.

NOTE: When swinging front guides inboard, be

careful not to change position of height adjustment

rings. It is suggested that the position of the height

adjustment rings be marked with a pencil prior to

loosening of front guide attaching screws.

5. Retighten remaining screw holding front guide in

position to prevent height adjustment rings from

turning.

6. Turn lifter guide tension springs 90 degrees in-

board and pull lifters out of sun roof panel brackets

(see Figure

2F-7).Figure

ZF-7 Pulling Rear Lifter Guide out of Sun RoofPanel BracketNOTE: Do not loosen lifter pin nut as this will

change height adjustment on rear of sun roof.

7. Lift out sun roof panel.

Installation of Sun Roof Panel1. Install sun roof panel onto guide rails and locate

panel evenly in stin roof opening.

2. Reposition front guides in original position on

guide rails. Be sure that they squarely contact guide

rails and are not cocked.

NOTE: To achieve proper clearance of front guides

to guide rail, the guides should lightly touch edge ofdshould have a clearance of no

3. Reconnect

riar lifter guides onto sun roof panel

brackets and reposition tension spring as shown in

Figure

2F-3.4. Crank sun roof fully closed and check that the rear

lifters are at approximately 90 degrees with respect

to guide rails and contact guide stops (see Figure

2F-3). If adjustment is required remove crank handle

and cable crank (see Figure 2F-4) and physically

reposition lifters to position described above. Rotate

cable crank to its fully clockwise limit and reinstall.

5. Pull sun roof frame forward and reattach to sun

roof panel.

6. Open and close sun roof several times and recheck

for smoothness of operation.

Removal of Sunlpoof Frame1. Remove sun roof panel.

2. Crank rear lifter guides to furthermost rear posi-

tion.

3. Remove screws securing upper corner plates in

position and lift out upper corner plates (see Figure

2F-8).Figure 2F-&Removing Upper Corner Plates

4. Remove scretii securing left und

r@t guide rai1%lift up front ends

of- guide rails and msert wedge

under forward g&de rail ends. Slide out sun roof

frame.

Page 152 of 625

ROOF AND SUN ROOF2F-29Installation of Sun Roof Frame1. Slide sun roof frame into lower slot of guide rails,

position fully rearward and reattach guide rails to

roof.NOTE: Be sure guide rail retainers at rear of guide

rails are positioned with their dowels in bores of roof

frame.2. Install upper corner plates and secure in place..

3. Install sun roof panel.

REMOVAL AND INSTALLATION OF VELVET STRIP

ON SUN ROOF OPENING, AND VELVET STRIP AND

WEATHERSTRIP ON REAR OF SUN ROOF PANEL

Removal of Velvet Strip on Sun Roof Opening1. Fully open sun roof.

;2. Carefully pull off velvet strip using solvent to dis-

solve cement. Clean area thoroughly before installing

new velvet strip.

Installation of Velvet Strip On Sun Roof Opening1. Cut away for a distance of 1.5 inch the velvet

material on velvet strip that will be on the outside

when strip is cemented in positioAlso cut off to

this dimension the plastic cord i

not cut away velvet material on

1strip which is to be cemented

2. Using

nitrile vinyl trim adhesive (3M Vinyl Trim

Adhesive, Permalastic Viny1 Trim Adhesive or

equivalent) apply sparingly to both sun roof opening

and side of velvet strip to be cemented.

3. Immediately install new velvet strip and position

so that upper edge of velvet strip is flush with car

roof.4. Clean off excess cement being careful not to con-

tact velvet strip.

Removal of Velvet Strip and Wea’therstrip on Rear

of Sun Roof Panel1. Remove sun roof panel.

2. Carefully detach weatherstrip and velvet strip

from sun roof panel using solvent as required todisdolve cement. Thoroughly clean area before in-

stalling new velvet strip and weatherstrip.

Installing Velvet Strip and Weatherstrip On Rear

of Sun Roof Panel1. Using

nitrile vinyl trim adhesive (3M Vinyl Trim

Adhesive Permalastic Viny1 Trim Adhesive or

equivalent) apply sparingly to vertical and horizontal

contact areas at rear of sun roof panel (see Figure

2F-9) and also to side of velvet strip which will touch sun

roof panel.

REAR OF SUN ROOF PANEL

ICAR ROOF

VELVET STRIP

II

,/ WETRSTRIP 1APPLY CEMENT TO HORIZONTAL AND

VERTICAL SURFACES,TO BOTH SIDES

OF VELVET STRIP AND TO SIDE AND

BOTTOM OF WEATHERSTRIP2F-9

Figure

ZF-9 Installing Velvet Strip and Weatherstrip

on Rear of Sun Roof Panel

2. Immediately install new velvet strip and position

so that top edge of velvet strip is flush with sun roof

panel.

3. Apply cement to outboard edge of velvet strip and

to top and bottom contact surfaces of weatherstrip,

and install weatherstrip in position.

4. Clean off excess cement being careful not to con-

tact velvet strip.

5. Install sun roof panel.

REMOVAL AND INSTALLATION OF REAR GUIDES

AND CABLE

Removal of Rear Guides and Cable

1. Remove sun roof panel.

2. Crank rear lifter guides fully rearward and then

remove crank handle and cable crank.

Page 153 of 625

2F-301973 OPEL SERVICE MANUAL

3. Unscrew and remove upper and lower corner

plates (see Figure 2F-8).4. Unscrew and remove left and right upper cable

shields ans pull cable ends out of cable box.

5. Pull cable and rear lifter guides out of leftand

right guide rails.

Installation of Rear Guides and Cable1. Check both cables for wear or damage. If eigher

cable is defective, replace both cables.

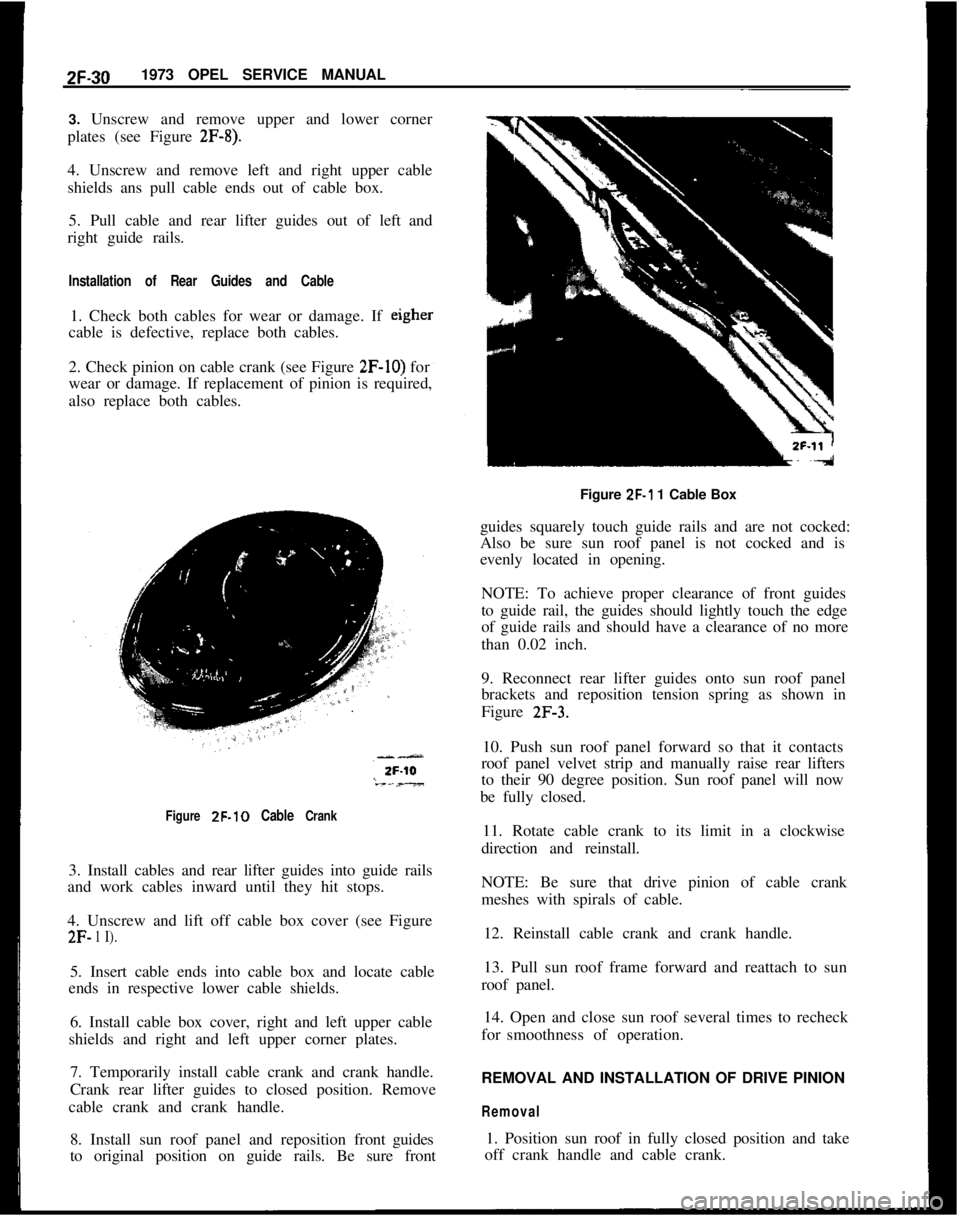

2. Check pinion on cable crank (see Figure

2F-IO) for

wear or damage. If replacement of pinion is required,

also replace both cables.

Figure ZF-10 Cable Crank3. Install cables and rear lifter guides into guide rails

and work cables inward until they hit stops.

4. Unscrew and lift off cable box cover (see Figure

2F- 1 I).5. Insert cable ends into cable box and locate cable

ends in respective lower cable shields.

6. Install cable box cover, right and left upper cable

shields and right and left upper corner plates.

7. Temporarily install cable crank and crank handle.

Crank rear lifter guides to closed position. Remove

cable crank and crank handle.

8. Install sun roof panel and reposition frontguides

to original position on guide rails. Be sure frontFigure

ZF-1 1 Cable Box

guides squarely touch guide rails and are not cocked:

Also be sure sun roof panel is not cocked and is

evenly located in opening.

NOTE: To achieve proper clearance of front guides

to guide rail, the guides should lightly touch the edge

of guide rails and should have a clearance of no more

than 0.02 inch.

9. Reconnect rear lifter guides onto sun roof panel

brackets and reposition tension spring as shown in

Figure

2F-3.10. Push sun roof panel forward so that it contacts

roof panel velvet strip and manually raise rear lifters

to their 90 degree position. Sun roof panel will now

be fully closed.

11. Rotate cable crank to its limit in a clockwise

direction and reinstall.

NOTE: Be sure that drive pinion of cable crank

meshes with spirals of cable.

12. Reinstall cable crank and crank handle.

13. Pull sun roof frame forward and reattach to sun

roof panel.

14. Open and close sun roof several times to recheck

forsmoothness of operation.

REMOVAL AND INSTALLATION OF DRIVE PINION

Removal1. Position sun roof in fully closed position and take

off crank handle and cable crank.

Page 154 of 625

2. Press off snap ring holding drive pinion in place

and remove drive pinion (see Figure 2F-10).

Installation1. Install drive pinion reverse of removal.

NOTE: If drive pinion is to be replaced, also replace

both cables to insure smooth operation of sun roof.

2. Rotate cable crank to its limit in a clockwise direc-

tion and install reverse of removal procedure.ROOF AND SUN ROOF2F-31

REMOVAL AND INSTALLATION OF FRONT AND

REAR WATER DRAINAGE HOSES

Removal of Front Water Drainage Hose

1, Remove sun visor from side of car which will have

drainage pipe taken out.

2. Partially detach pinchweld finishing strip from

door opening involved.

II2F-12L

Figure 2F-12 Sun Roof (Exploded View)

Page 293 of 625

6A- 21973 OPEL SERVICE MANUAL

ENGINE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

EngineConstruction..........................................................

LubricationSystem............................................................

DIAGNOSIS:

Excessive Oil Consumption............................................NoisyValvesandLifters..................................................

MAINTENANCE AND ADJUSTMENTS:

Valve

LifterAdjustment..................................................

MAJOR REPAIR:

Engine Removal and Installation..................................

Engine

OilPanRemoval

andInstallation..................

Manifold, Cylinder Head, Valve Train and

Lifters................................................................................

Connecting Rod Bearings................................................

Crankshaft Bearings and Seals....................................

Piston, Rings and Connecting Rods............................

TimingChainCoverandTimingChain......................

Camshaft..............................................................................

Oil Pump Cover and Gears............................................

SPECIFICATIONS:

BoltTorque.Specifications

..............................................General Specifications......................................................

Engine Dimension and Fits............................................Page No.

6A- 2

6A- 4

6A- 6

6A- 6

6A- 7

6A- 86A-106A-126A-156A-166A-196A-236A-256A-266A-276A-286A-29

DESCRIPTION AND OPERATION

ENGINE CONSTRUCTION

Engine UsageThe 1.9 liter engine is standard equipment on all 1973

Opel

1900, Manta and GT models. This engine has

a compression ratio of

7.6:1 and operates on“regular” low lead grade fuel.

Engine ConstructionThe

cyfinderhead is made of high-grade chromium

grey cast iron. The valve guides are cast intergal with

the head. The overhead camshaft is supported in four

bearings in the cylinder head.Location of the

vzllve seats in combustion chamber

is above the center of cylinder bore. The spark plug

is positioned in the center and near the highest point

of combustion chamber. This arrangement provides

for short flame travel, uniform combustion and good

cold start prop&ties. Exhaust valves have seat in-serts of highly heat and water resisting material. The

head surface is alumetized and so are the seats of the

inlet v&es Alumetizing makes the valve heads

non- scaling and promotes long life. All engines have“rota-caps”.

The forged, five main bearing crankshaft has large-

diameter main and connecting rod bearing journals

with considerable overlap for vibration-free operat-

ion. T&metal bearing shells are used for main and

connecting rod bearings. The crankshaft end play is

controlled by the rear main bearing.

Page 294 of 625

ENGINE MECHANICAL AND MOUNTS6A- 3

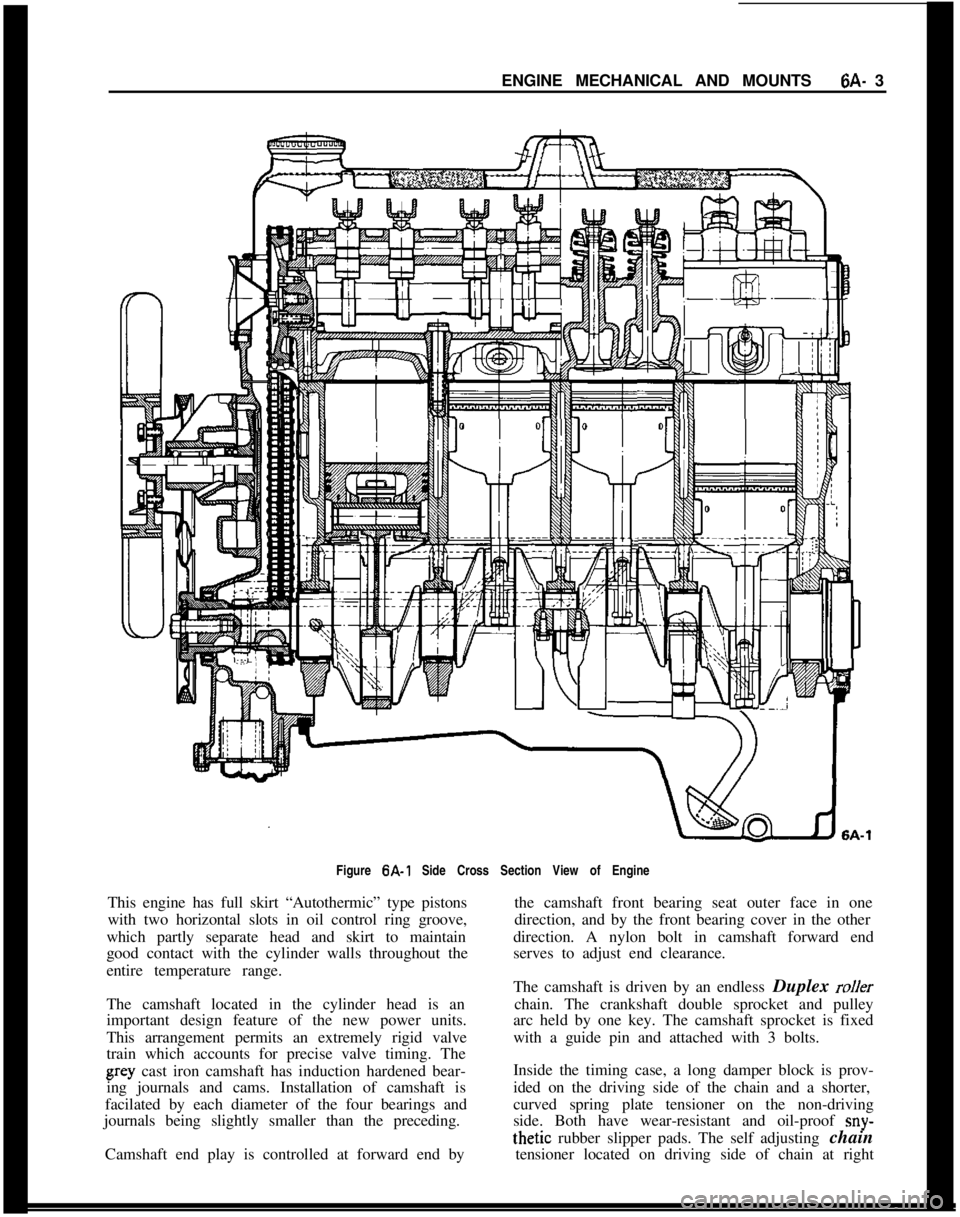

Figure 6A-1 Side Cross Section View of Engine

This engine has full skirt “Autothermic” type pistons

with two horizontal slots in oil control ring groove,

which partly separate head and skirt to maintain

good contact with the cylinder walls throughout the

entire temperature range.

The camshaft located in the cylinder head is an

important design feature of the new power units.

This arrangement permits an extremely rigid valve

train which accounts for precise valve timing. Thegray cast iron camshaft has induction hardened bear-

ing journals and cams. Installation of camshaft is

facilated by each diameter of the four bearings and

journals being slightly smaller than the preceding.

Camshaft end play is controlled at forward end bythe camshaft front bearing seat outer face in one

direction, and by the front bearing cover in the other

direction. A nylon bolt in camshaft forward end

serves to adjust end clearance.

The camshaft is driven by an endless Duplex

rollerchain. The crankshaft double sprocket and pulley

arc held by one key. The camshaft sprocket is fixed

with a guide pin and attached with 3 bolts.

Inside the timing case, a long damper block is prov-

ided on the driving side of the chain and a shorter,

curved spring plate tensioner on the non-driving

side. Both have wear-resistant and oil-proof

sny-thetic rubber slipper pads. The self adjusting chain

tensioner located on driving side of chain at right

Page 295 of 625

6A. 41973 OPEL SERVICE MANUAL

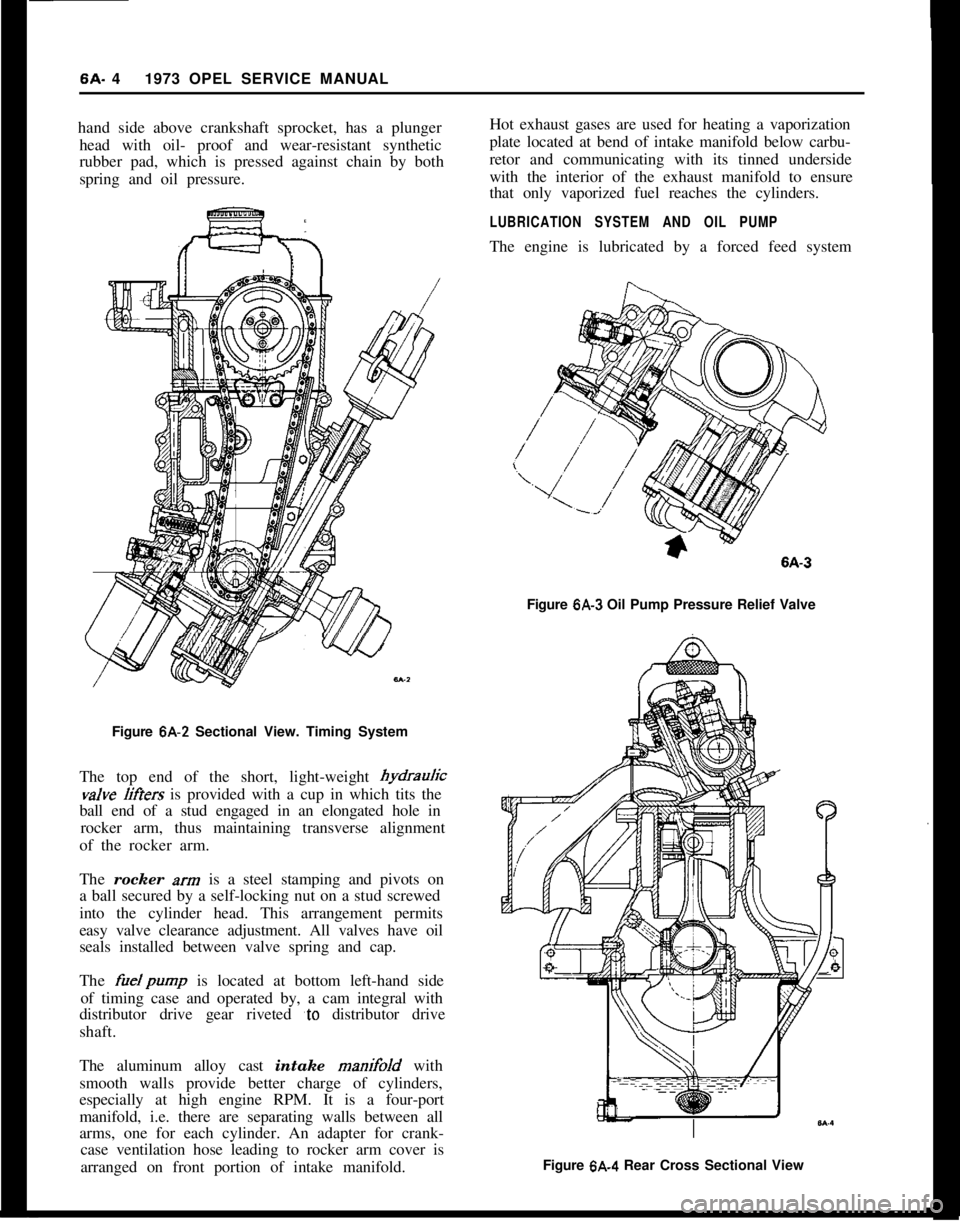

hand side above crankshaft sprocket, has a plunger

head with oil- proof and wear-resistant synthetic

rubber pad, which is pressed against chain by both

spring and oil pressure.

Figure 6A-2 Sectional View. Timing System

The top end of the short, light-weight hydrauricvalve

liffers is provided with a cup in which tits the

ball end of a stud engaged in an elongated hole in

rocker arm, thus maintaining transverse alignment

of the rocker arm.

The rocker

xrn is a steel stamping and pivots on

a ball secured by a self-locking nut on a stud screwed

into the cylinder head. This arrangement permits

easy valve clearance adjustment. All valves have oil

seals installed between valve spring and cap.

The

fuelpump is located at bottom left-hand side

of timing case and operated by, a cam integral with

distributor drive gear riveted

‘to distributor drive

shaft.

The aluminum alloy cast intake manifold with

smooth walls provide better charge of cylinders,

especially at high engine RPM. It is a four-port

manifold, i.e. there are separating walls between all

arms, one for each cylinder. An adapter for crank-

case ventilation hose leading to rocker arm cover is

arranged on front portion of intake manifold.Hot exhaust gases are used for heating a vaporization

plate located at bend of intake manifold below carbu-

retor and communicating with its tinned underside

with the interior of the exhaust manifold to ensure

that only vaporized fuel reaches the cylinders.

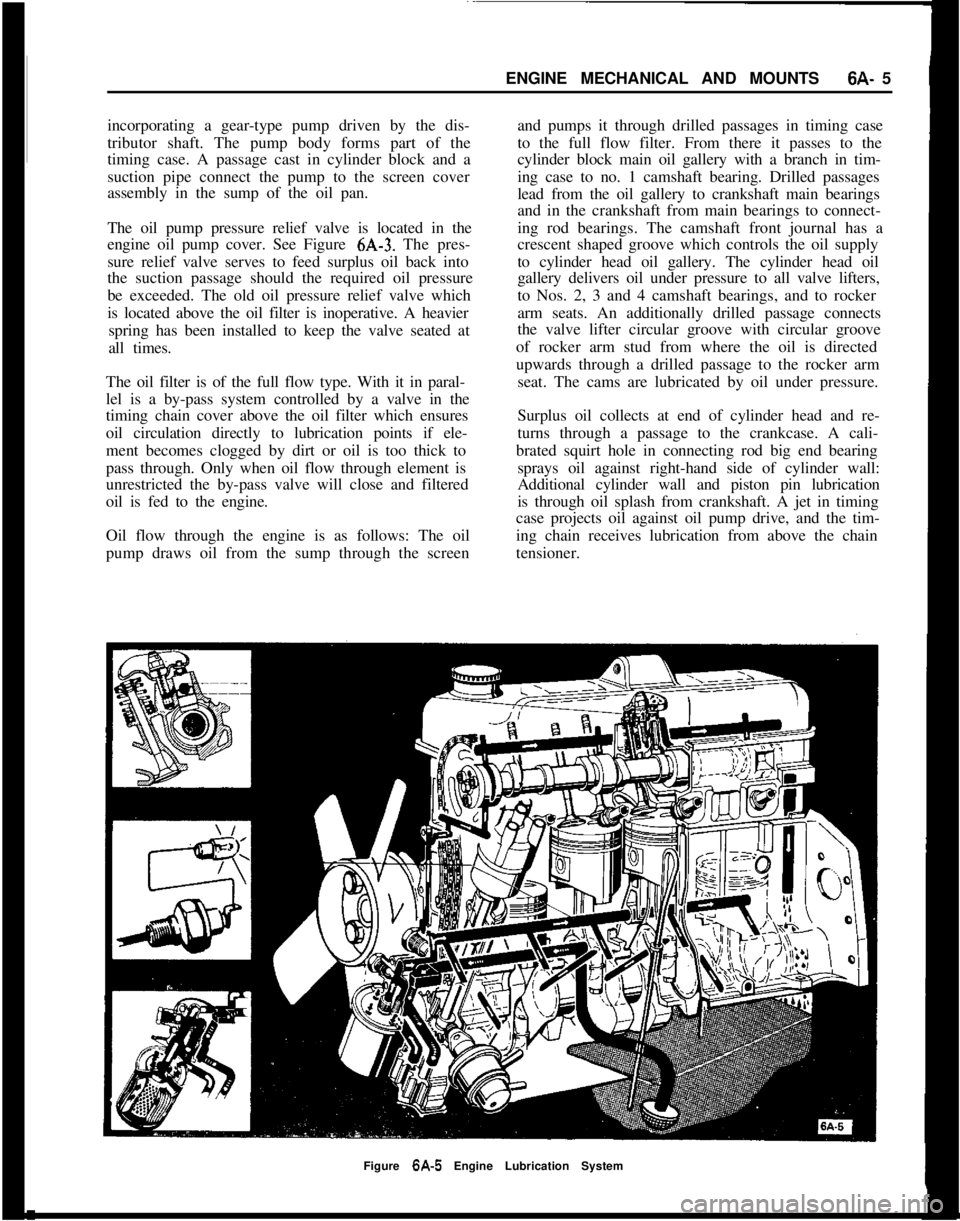

LUBRICATION SYSTEM AND OIL PUMPThe engine is lubricated by a forced feed system

Figure

6A-3 Oil Pump Pressure Relief Valve

Figure 6A.4 Rear Cross Sectional View

Page 296 of 625

ENGINE MECHANICAL AND MOUNTS6A- 5

incorporating a gear-type pump driven by the dis-

tributor shaft. The pump body forms part of the

timing case. A passage cast in cylinder block and a

suction pipe connect the pump to the screen cover

assembly in the sump of the oil pan.

The oil pump pressure relief valve is located in the

engine oil pump cover. See Figure 6A-3. The pres-

sure relief valve serves to feed surplus oil back into

the suction passage should the required oil pressure

be exceeded. The old oil pressure relief valve which

is located above the oil filter is inoperative. A heavier

spring has been installed to keep the valve seated at

all times.

The oil filter is of the full flow type. With it in paral-

lel is a by-pass system controlled by a valve in the

timing chain cover above the oil filter which ensures

oil circulation directly to lubrication points if ele-

ment becomes clogged by dirt or oil is too thick to

pass through. Only when oil flow through element is

unrestricted the by-pass valve will close and filtered

oil is fed to the engine.

Oil flow through the engine is as follows: The oil

pump draws oil from the sump through the screenand pumps it through drilled passages in timing case

to the full flow filter. From there it passes to the

cylinder block main oil gallery with a branch in tim-

ing case to no. 1 camshaft bearing. Drilled passages

lead from the oil gallery to crankshaft main bearings

and in the crankshaft from main bearings to connect-

ing rod bearings. The camshaft front journal has a

crescent shaped groove which controls the oil supply

to cylinder head oil gallery. The cylinder head oil

gallery delivers oil under pressure to all valve lifters,

to Nos. 2, 3 and 4 camshaft bearings, and to rocker

arm seats. An additionally drilled passage connects

the valve lifter circular groove with circular groove

of rocker arm stud from where the oil is directed

upwards through a drilled passage to the rocker arm

seat. The cams are lubricated by oil under pressure.

Surplus oil collects at end of cylinder head and re-

turns through a passage to the crankcase. A cali-

brated squirt hole in connecting rod big end bearing

sprays oil against right-hand side of cylinder wall:

Additional cylinder wall and piston pin lubrication

is through oil splash from crankshaft. A jet in timing

case projects oil against oil pump drive, and the tim-

ing chain receives lubrication from above the chain

tensioner.

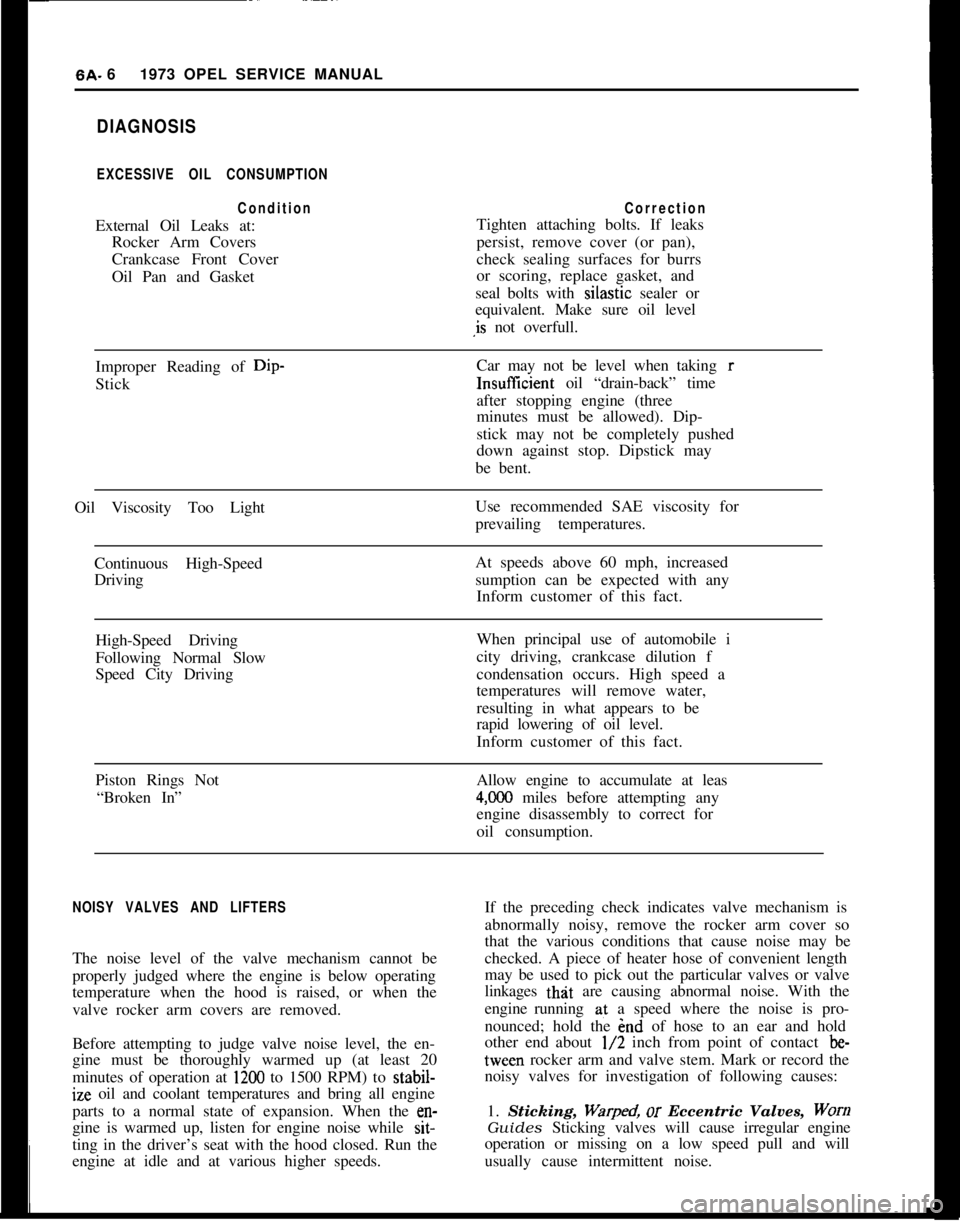

Figure 6A-5 Engine Lubrication System

Page 297 of 625

6A. 61973 OPEL SERVICE MANUALDIAGNOSIS

EXCESSIVE OIL CONSUMPTION

ConditionCorrectionExternal Oil Leaks at:Tighten attaching bolts. If leaks

Rocker Arm Coverspersist, remove cover (or pan),

Crankcase Front Covercheck sealing surfaces for burrs

Oil Pan and Gasketor scoring, replace gasket, and

seal bolts with silastic sealer or

equivalent. Make sure oil level

,is not overfull.

Improper Reading of Dip-Car may not be level when taking r

StickInsuffIcient oil “drain-back” time

after stopping engine (three

minutes must be allowed). Dip-

stick may not be completely pushed

down against stop. Dipstick may

be bent.

Oil Viscosity Too LightUse recommended SAE viscosity for

prevailing temperatures.

Continuous High-SpeedAt speeds above 60 mph, increased

Drivingsumption can be expected with any

Inform customer of this fact.

High-Speed DrivingWhen principal use of automobile i

Following Normal Slowcity driving, crankcase dilution f

Speed City Drivingcondensation occurs. High speed a

temperatures will remove water,

resulting in what appears to be

rapid lowering of oil level.

Inform customer of this fact.

Piston Rings NotAllow engine to accumulate at leas

“Broken In”

4,OCO miles before attempting any

engine disassembly to correct for

oil consumption.

NOISY VALVES AND LIFTERSIf the preceding check indicates valve mechanism is

abnormally noisy, remove the rocker arm cover so

that the various conditions that cause noise may be

The noise level of the valve mechanism cannot bechecked. A piece of heater hose of convenient length

properly judged where the engine is below operatingmay be used to pick out the particular valves or valve

temperature when the hood is raised, or when thelinkages

thit are causing abnormal noise. With the

valve rocker arm covers are removed.engine running at a speed where the noise is pro-

nounced; hold the end of hose to an ear and hold

Before attempting to judge valve noise level, the en-other end about

l/2 inch from point of contact be-

gine must be thoroughly warmed up (at least 20tween rocker arm and valve stem. Mark or record the

minutes of operation at

1200 to 1500 RPM) to stabil-noisy valves for investigation of following causes:ize oil and coolant temperatures and bring all engine

parts to a normal state of expansion. When the

en-1. Sticking, Warped, or Eccentric Valves, Worngine is warmed up, listen for engine noise while

sit-Guides Sticking valves will cause irregular engine

ting in the driver’s seat with the hood closed. Run theoperation or missing on a low speed pull and will

engine at idle and at various higher speeds.usually cause intermittent noise.