jacking OPEL CALIBRA 1988 Service Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 144 of 525

14Front brake disc shield -

removal and refitting

3

Removal

1Where applicable, remove the wheel trim,

then loosen the relevant front roadwheel bolts

and apply the handbrake. Jack up the front of

the vehicle, and support on axle stands (see

“Jacking and Vehicle Support”) positioned

under the body side members. Remove the

roadwheel.

2Remove the brake disc, as described in

Section 10.

3Using a screwdriver inserted through the

holes in the hub flange, extract the three

screws securing the disc shield to the hub

carrier.

4Using plate shears or an alternative tool, cut

a section of metal from the rear edge of the

shield to enable the shield to be withdrawn

over the hub, then remove the shield (see

illustration).

Refitting

5If a new shield is to be fitted, cut out a

section of metal, as during removal of the old

shield, to enable the shield to be fitted.

Smooth the cut edges, and coat them with

anti-corrosion paint.

6Further refitting is a reversal of removal,

remembering the following points.

7Refit the brake disc, as described in

Section 10.

8Do not fully tighten the roadwheel bolts until

the vehicle is resting on its wheels.

15Master cylinder - removal and

refitting

4

Note: Refer to the note at the beginning of

Section 3 before proceeding

Removal

1Disconnect the battery negative lead.

2Depress the footbrake pedal several times

to dissipate the vacuum in the servo unit.3Disconnect the wiring plug from the brake

fluid level sensor in the reservoir filler cap.

4If possible, use a teat pipette or an old

hydrometer to remove the brake fluid from the

reservoir. This will reduce the loss of fluid later

in the procedure.

5Locate a container beneath the master

cylinder, to catch the brake fluid that will be

released.

6Identify the brake fluid pipes for position,

then unscrew the union nuts and disconnect

the pipes from the master cylinder.

7Unscrew the two securing nuts, and

withdraw the master cylinder from the studs

on the vacuum servo unit (see illustration).

8Clean the external surfaces of the cylinder,

then using a screwdriver carefully prise the

fluid reservoir and its seals from the top of the

cylinder.

9If desired, on models without ABS, the

master cylinder can be overhauled, as

described in Section 16.

10No overhaul of the master cylinder is

possible on models with ABS, see Section 17.

Refitting

11Refitting is a reversal of removal, but use

new seals when fitting the brake fluid

reservoir, and on completion, bleed the

complete brake hydraulic system, as

described in Section 3.

16Master cylinder (non-ABS) -

overhaul

4

Note: Before dismantling the master cylinder,

check that replacement parts can be obtained

and retain the old components to compare

them with the new ones

1With the master cylinder removed as

described in Section 15, continue as follows,

according to type.

GMF type master cylinder

2Clamp the master cylinder in a soft-jawed

vice.

3Where applicable, unscrew the pressure-

proportioning valves from the base of the

cylinder.4Carefully prise out the sealing ring from the

end of the cylinder bore.

5Depress the primary piston slightly using a

piece of wood or plastic. Then hold the piston

in the depressed position by inserting a

smooth pin or rod of 3.0 mm (0.12 in) diameter

through the primary fluid reservoir port in the

cylinder (see illustration).

6Extract the circlip from the end of the

cylinder bore using a screwdriver. Take care

not to damage the piston or cylinder bore.

7Withdraw the pin or rod retaining the piston.

8Withdraw the primary piston assembly from

the cylinder, if necessary tapping the cylinder

on a wooden block to free the piston from the

bore.

9Apply low air pressure - e.g. from a foot

pump - to the front fluid reservoir port in the

cylinder, to eject the secondary piston

assembly.

10Clean all the components, in clean brake

fluid or methylated spirit only, and examine

them for wear and damage. In particular,

check the surfaces of the pistons and cylinder

bore for scoring and corrosion. If the bore

shows signs of wear, renew the complete

master cylinder assembly (see illustration).

11If the cylinder bore is in good condition,

obtain a repair kit, which will contain all the

necessary renewable items. A Vauxhall dealer

will supply a pre-assembled kit of parts, which

should be fitted as follows.

12Lubricate the cylinder bore with clean

brake fluid or brake grease, then clamp the

cylinder in a soft-jawed vice, with the bore

horizontal.

13Remove the plug from the end of the

assembly tube, and insert the short part of the

tube into the cylinder bore as far as the

shoulder on the tube.

14Use a piece of wood or plastic to push the

components out of the tube and into the

cylinder bore. Then hold the primary piston in

the depressed position by inserting the pin or

rod used during dismantling through the

cylinder primary fluid reservoir port.

15Fit a new circlip to the end of the cylinder

bore, ensuring that it seats correctly, and that

the piston is free to move.

16Depress the primary piston, and withdraw

the pin or rod from the fluid reservoir port.

Braking system 9•13

16.5 Holding the primary piston depressed

while extracting the circlip from the

cylinder body - GMF type master cylinder15.7 Master cylinder securing nut

(arrowed)14.4 Cutting a section of metal from a new

front brake disc shield prior to fitting

9

Page 147 of 525

16If adjustment is necessary, slacken the

locknut, turn the fork to give the specified

dimension, then tighten the locknut.

17Where applicable, coat the contact faces

of the servo and the mounting bracket with

sealing compound, then refit the bracket to

the servo, and tighten the securing nuts to the

specified torque.

18Coat the threads of the servo securing

bolts with locking fluid, then fit the servo to

the bulkhead and tighten the securing bolts.

19Refit the securing bolt cover plugs to the

cowl panel.

20Refit the master cylinder to the servo, and

tighten the securing nuts to the specified

torque.

21Reconnect the vacuum pipe to the servo.

22Refit the coolant expansion tank, as

described in Chapter 3.

23Refit the windscreen wiper motor and

linkage as described in Chapter 12, then refit

the windscreen cowl panel.

24Further refitting is a reversal of removal.

On completion, test the operation of the

servo, as described in Section 18.

20ABS hydraulic modulator -

removal and refitting

4

Note: Refer to Section 2, and the note at the

beginning of Section 3, before proceeding

Removal

1Disconnect the battery negative lead.

2Remove the brake fluid reservoir cap, and

secure a piece of polythene over the filler

neck with a rubber band, or by refitting the

cap. This will reduce the loss of fluid during

the following procedure.

3Remove the securing screw, and withdraw

the plastic cover from the hydraulic

modulator.

4Remove the two clamp screws, and lift off

the modulator wiring harness clamp (see

illustration).

5Disconnect the modulator wiring plug,

levering it from the socket with a screwdriver if

necessary.6Unscrew the brake fluid pipe union nuts,

and disconnect the pipes from the modulator.

Be prepared for fluid spillage, and plug the

open ends to prevent dirt ingress and further

fluid loss. Move the pipes just clear of the

modulator, taking care not to strain them.

7Unscrew the three modulator securing nuts

(see illustration), then tilt the modulator

slightly, and withdraw it upwards from its

bracket, sufficiently to gain access to the

earth lead securing nut at the front lower edge

of the modulator.

8Unscrew the securing nut and disconnect

the earth lead, then withdraw the modulator

from the vehicle, taking care not to spill brake

fluid on the vehicle paintwork.

9If a new modulator is to be fitted, pull the

two relays from the top of the old modulator,

and transfer them to the new unit. No attempt

must be made to dismantle the modulator.

Refitting

10Before refitting the modulator, check that

the bolts securing the mounting bracket to the

body panel are tight, and that the modulator

rubber mountings are in good condition.

Renew the rubber mountings if necessary.

11Refitting is a reversal of removal,

remembering the following points.

12Make sure that the earth lead is

reconnected before fitting the modulator to its

mounting bracket.13On completion, remove the polythene

sheet from the brake fluid reservoir filler neck,

and bleed the complete brake hydraulic

system, as described in Section 3.

14Check that the ABS warning lamp

extinguishes when first starting the engine

after the modulator has been removed. At the

earliest opportunity, take the vehicle to a

Vauxhall dealer, and have the complete

system tested, using the dedicated ABS test

equipment.

21ABS wheel sensors - removal

and refitting

3

Note: Refer to Section 2 before proceeding

Front wheel sensor

Removal

1Disconnect the battery negative lead.

2Where applicable, remove the wheel trim,

then loosen the relevant front roadwheel bolts

and apply the handbrake. Jack up the front of

the vehicle, and support on axle stands (see

“Jacking and Vehicle Support”) positioned

under the body side members. Remove the

roadwheel.

3Unclip the sensor wiring connector from the

retaining clip under the wheel arch, then

separate the two halves of the wiring

connector, prising them apart with a

screwdriver if necessary (see illustration).

4Using a Allen key or hexagon bit, unscrew

the bolt securing the wheel sensor to its

mounting bracket, then carefully lever the

sensor from the bracket using a screwdriver

(see illustration). Recover the seal ring.

Refitting

5Examine the condition of the seal ring, and

renew if necessary.

6Refitting is a reversal of removal,

remembering the following points.

7Smear a little grease on the sensor casing

before fitting it to the bracket.

8Do not fully tighten the roadwheel bolts until

the vehicle is resting on its wheels.

9Check that the ABS warning lamp

extinguishes when first starting the engine

after a wheel sensor has been removed. At

9•16Braking system

20.4 ABS hydraulic modulator (cover

removed)

1 Wiring harness

clamp screws2 Earth lead

3 Relays

21.3 Front wheel sensor wiring under

wheelarch - DOHC model

1 ABS sensor connector

2 Disc pad wear sensor wiring connector

21.4 ABS front wheel sensor securing bolt

(arrowed) - DOHC model20.7 ABS hydraulic modulator securing

screws (arrowed)

Page 148 of 525

the earliest opportunity, take the vehicle to a

Vauxhall dealer, and have the complete

system tested, using the dedicated ABS test

equipment.

Rear wheel sensor

Removal

10Disconnect the battery negative lead.

11Where applicable, remove the wheel trim,

then loosen the relevant rear roadwheel bolts

and chock the front wheels. Jack up the rear

of the vehicle, and support on axle stands

(see “Jacking and Vehicle Support”)

positioned under the body side members.

Remove the roadwheel.

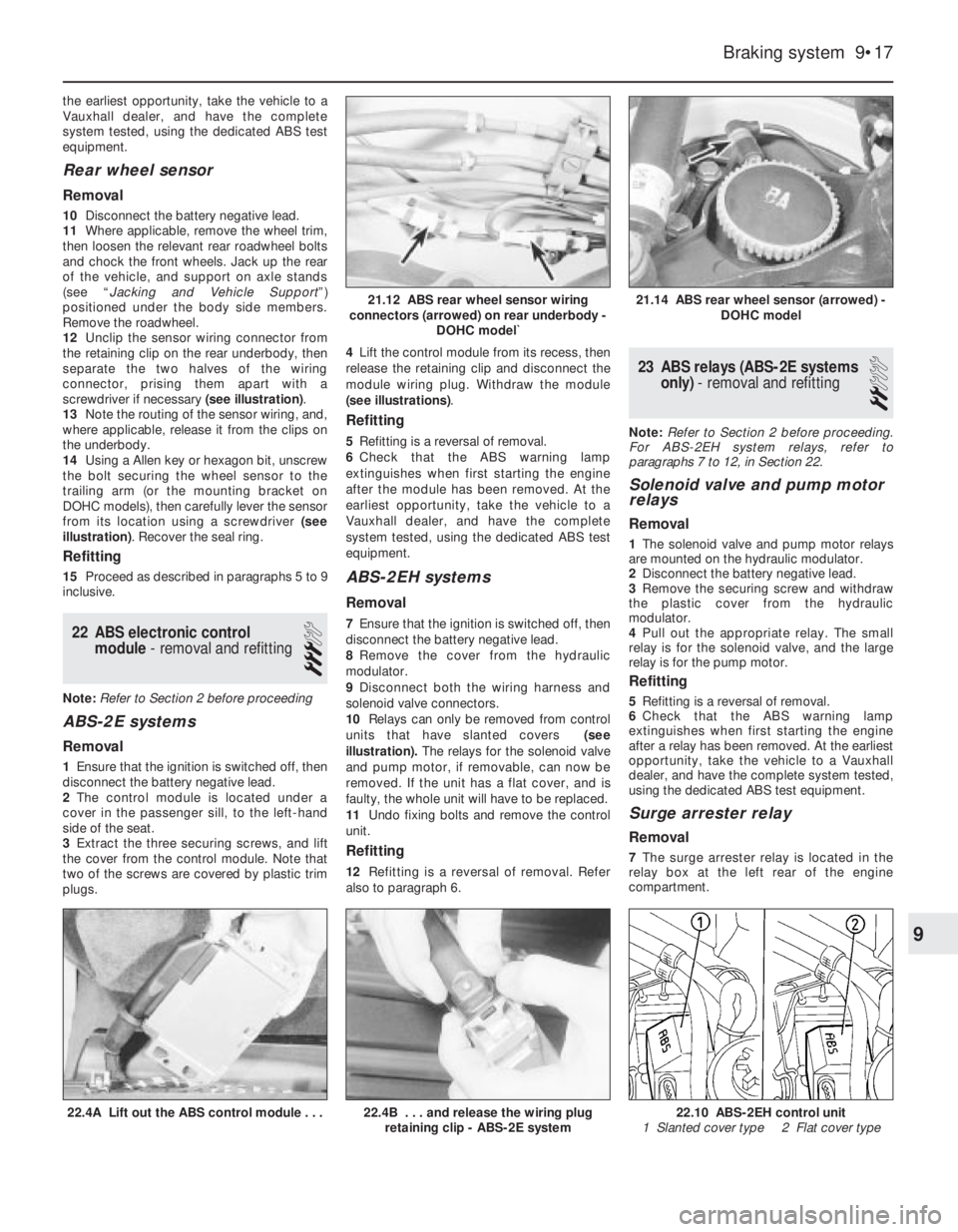

12Unclip the sensor wiring connector from

the retaining clip on the rear underbody, then

separate the two halves of the wiring

connector, prising them apart with a

screwdriver if necessary (see illustration).

13Note the routing of the sensor wiring, and,

where applicable, release it from the clips on

the underbody.

14Using a Allen key or hexagon bit, unscrew

the bolt securing the wheel sensor to the

trailing arm (or the mounting bracket on

DOHC models), then carefully lever the sensor

from its location using a screwdriver (see

illustration). Recover the seal ring.

Refitting

15Proceed as described in paragraphs 5 to 9

inclusive.

22ABS electronic control

module - removal and refitting

3

Note: Refer to Section 2 before proceeding

ABS-2E systems

Removal

1Ensure that the ignition is switched off, then

disconnect the battery negative lead.

2The control module is located under a

cover in the passenger sill, to the left-hand

side of the seat.

3Extract the three securing screws, and lift

the cover from the control module. Note that

two of the screws are covered by plastic trim

plugs. 4Lift the control module from its recess, then

release the retaining clip and disconnect the

module wiring plug. Withdraw the module

(see illustrations).

Refitting

5Refitting is a reversal of removal.

6Check that the ABS warning lamp

extinguishes when first starting the engine

after the module has been removed. At the

earliest opportunity, take the vehicle to a

Vauxhall dealer, and have the complete

system tested, using the dedicated ABS test

equipment.

ABS-2EH systems

Removal

7Ensure that the ignition is switched off, then

disconnect the battery negative lead.

8Remove the cover from the hydraulic

modulator.

9Disconnect both the wiring harness and

solenoid valve connectors.

10Relays can only be removed from control

units that have slanted covers (see

illustration). The relays for the solenoid valve

and pump motor, if removable, can now be

removed. If the unit has a flat cover, and is

faulty, the whole unit will have to be replaced.

11Undo fixing bolts and remove the control

unit.

Refitting

12Refitting is a reversal of removal. Refer

also to paragraph 6.

23ABS relays (ABS-2E systems

only) - removal and refitting

2

Note: Refer to Section 2 before proceeding.

For ABS-2EH system relays, refer to

paragraphs 7 to 12, in Section 22.

Solenoid valve and pump motor

relays

Removal

1The solenoid valve and pump motor relays

are mounted on the hydraulic modulator.

2Disconnect the battery negative lead.

3Remove the securing screw and withdraw

the plastic cover from the hydraulic

modulator.

4Pull out the appropriate relay. The small

relay is for the solenoid valve, and the large

relay is for the pump motor.

Refitting

5Refitting is a reversal of removal.

6Check that the ABS warning lamp

extinguishes when first starting the engine

after a relay has been removed. At the earliest

opportunity, take the vehicle to a Vauxhall

dealer, and have the complete system tested,

using the dedicated ABS test equipment.

Surge arrester relay

Removal

7The surge arrester relay is located in the

relay box at the left rear of the engine

compartment.

Braking system 9•17

22.4A Lift out the ABS control module . . .22.10 ABS-2EH control unit

1 Slanted cover type 2 Flat cover type22.4B . . . and release the wiring plug

retaining clip - ABS-2E system

21.14 ABS rear wheel sensor (arrowed) -

DOHC model21.12 ABS rear wheel sensor wiring

connectors (arrowed) on rear underbody -

DOHC model`

9

Page 149 of 525

8Disconnect the battery negative lead.

9Unclip the lid and open the relay box, then

pull out the relay (see illustration).

Refitting

10Refitting is a reversal of removal, with

reference to paragraph 6.

24Rear brake pressure-

proportioning valves -

removal and refitting

4

Note: Refer to the note at the beginning of

Section 3 before proceeding. Note also that

the valve must only be renewed in pairs, and

both valves must be of the same calibration.

Ensure that correct type of valves are fitted.

The bodies have been stamped for easier

identification.

Master cylinder-mounted valves

Removal

1Remove the brake fluid reservoir cap, and

secure a piece of polythene over the filler

neck with a rubber band, or by refitting the

cap. This will reduce the loss of fluid during

the following procedure.

2Locate a container beneath the master

cylinder, to catch the brake fluid that will be

released.

3Identify the two lower brake pipes for

position, then unscrew the union nuts and

disconnect the pipes from the proportioning

valves in the base of the master cylinder. Plug

the open ends of the pipes to prevent dirt

ingress.

4Unscrew the proportioning valves from the

master cylinder, and plug the open ends of

the cylinder to prevent dirt ingress.

Refitting

5Refitting is a reversal of removal, but on

completion, remove the polythene from the

brake fluid reservoir filler neck, and bleed the

complete hydraulic system, as described in

Section 3.

Rear underbody-mounted valves

Removal

6Proceed as described in paragraph 1.

7Chock the front wheels, then jack up the

rear of the vehicle, and support securely on

axle stands (see “Jacking and Vehicle

Support”) positioned under the body side

members.

8Working under the rear of the vehicle,

unscrew the union nut and disconnect the

brake pipe from one of the valves. Be

prepared for fluid spillage, and plug the open

end of the pipe to prevent dirt ingress and

further fluid spillage.

9Similarly, disconnect the flexible hose from

the valve.

10Pull the valve retaining clip from the

bracket on the underbody, noting that on

certain models, the retaining clip also secures

the ABS sensor wiring, and withdraw the valve

(see illustration).

11Repeat the procedure for the other valve.

Refitting

12Proceed as described in paragraph 5.

25Brake fluid pipes and hoses

- general, removal and refitting

4

Note: Refer to the note at the beginning of

Section 3, before proceeding.

General

1When checking the condition of the

system’s pipes and/or hoses, carefully check

that they do not foul other components such

as the power steering gear pipes (where

applicable), so that there is no risk of the

pipes chafing. If necessary use clips or ties to

secure braking system pipes and hoses well

clear of other components.

Rigid pipes

Removal

2Some of the commonly used brake pipes

can be obtained from Vauxhall parts dealers,

ready-formed and complete with unions, but

other brake pipes must be prepared using

4.75 mm (0.19 in) diameter brake pipe. Kits for

making the brake pipes can be obtained from

certain motor accessory shops.

3Before removing a brake pipe, remove the

brake fluid reservoir cap, and secure a piece

of polythene over the filler neck with a rubber

band, or by refitting the cap. This will reduce

the loss of fluid when the pipe is

disconnected.4Jack up the vehicle, and support securely

on axle stands (see “Jacking and Vehicle

Support”) positioned under the body side

members.

5To remove a brake pipe, unscrew the

unions at each end, and release the pipe from

the retaining clips.

Refitting

6Refitting is a reversal of removal, taking

care not to overtighten the unions.

7On completion, remove the polythene from

the brake fluid reservoir filler neck, and bleed

the relevant hydraulic circuit(s), as described

in Section 3.

Flexible hoses

Removal

8Proceed as described previously for the

rigid pipes, but note that a flexible pipe must

never be installed twisted, although a slight

“set” is permissible to give it clearance from

adjacent components.

Refitting

9When reconnecting a flexible hose to a

front brake caliper, note that the sealing rings

on the union bolt must be renewed.

26Handbrake - adjustment

2

Models with rear drum brakes

1The handbrake will normally be kept in

correct adjustment by the self-adjusting

action of the rear brake shoes. However, due

to cable stretch over a period of time, the

travel of the handbrake lever may become

excessive, in which case the following

operations should be carried out.

2Chock the front wheels, jack up the rear of

the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.

3Fully release the handbrake.

4Turn the knurled nut on the cable adjuster

(mounted on the torsion beam), until the brake

shoes can just be heard to rub when the rear

wheels are turned by hand in the normal

direction of rotation (see illustration).

9•18Braking system

23.9 ABS surge arrester relay (arrowed)

26.4 Handbrake cable adjuster. Knurled

nut arrowed - all SOHC models24.10 Brake pressure-proportioning valve

on rear underbody - DOHC model

1 Valve 2 Retaining clip

Page 150 of 525

5Loosen the adjuster nut until the wheels are

just free to turn.

6The handbrake must start to operate with

the lever on the second notch of the ratchet.

7On completion of adjustment, check the

handbrake cables for free movement, and

apply a little grease to the adjuster threads to

prevent corrosion.

8Lower the vehicle to the ground.

Models with rear disc brakes

9Where applicable, remove the wheel trims,

then loosen the rear roadwheel bolts and

chock the front wheels. Jack up the rear of the

vehicle, and support securely on axle stands

(see “Jacking and Vehicle Support”)

positioned under the body side members.

Remove the roadwheels.

10Pull the handbrake lever as far as the

second notch on the ratchet.

11On DOHC models fitted with a catalytic

converter, unscrew the four securing nuts and

withdraw the exhaust centre box heat shield

by carefully sliding it round the centre box.

12On all SOHC models, loosen the knurled

nut on the cable adjuster (mounted on the

torsion beam).

13On DOHC models, loosen the nut

securing the cable equaliser yoke to the

handbrake lever operating rod.

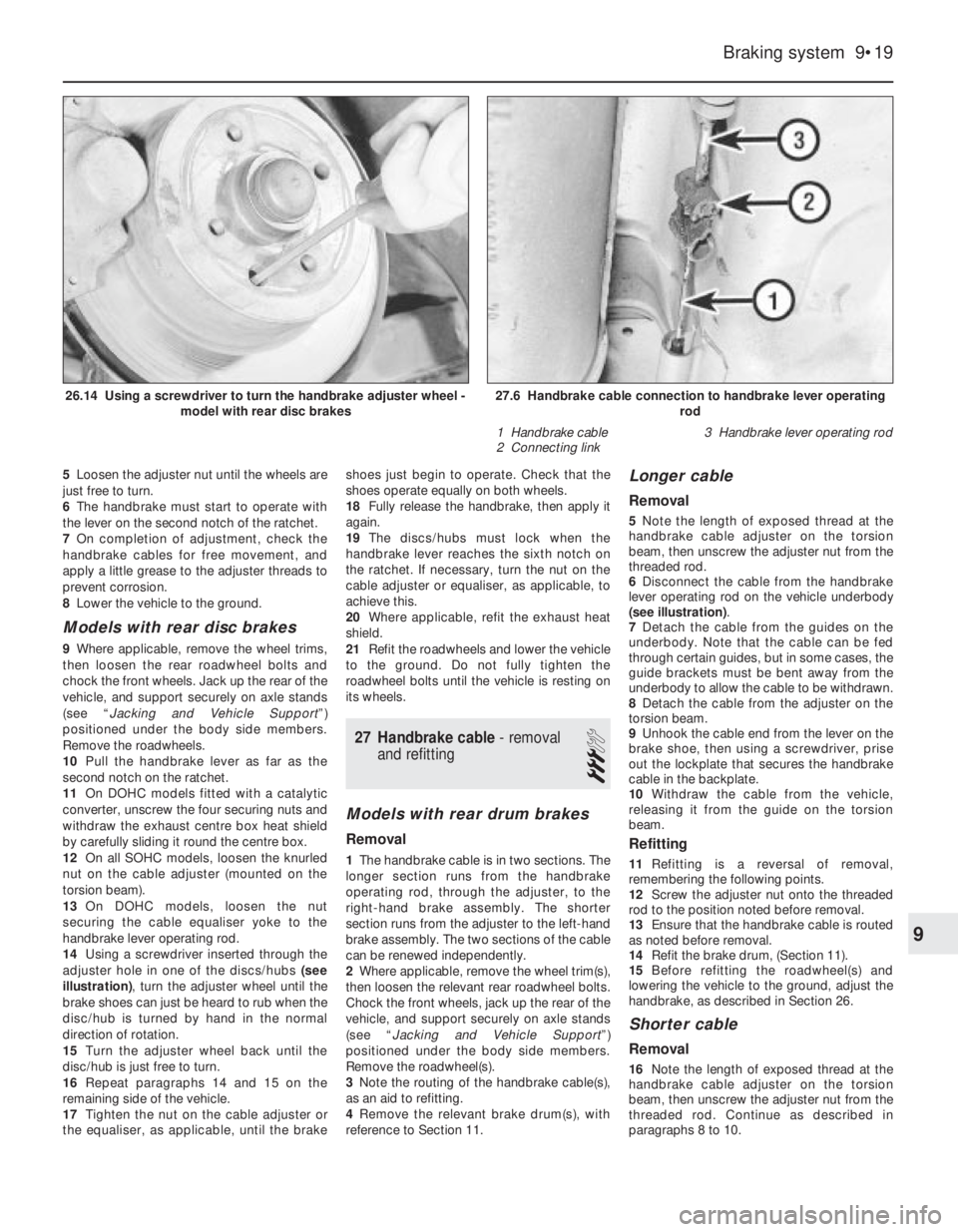

14Using a screwdriver inserted through the

adjuster hole in one of the discs/hubs (see

illustration), turn the adjuster wheel until the

brake shoes can just be heard to rub when the

disc/hub is turned by hand in the normal

direction of rotation.

15Turn the adjuster wheel back until the

disc/hub is just free to turn.

16Repeat paragraphs 14 and 15 on the

remaining side of the vehicle.

17Tighten the nut on the cable adjuster or

the equaliser, as applicable, until the brakeshoes just begin to operate. Check that the

shoes operate equally on both wheels.

18Fully release the handbrake, then apply it

again.

19The discs/hubs must lock when the

handbrake lever reaches the sixth notch on

the ratchet. If necessary, turn the nut on the

cable adjuster or equaliser, as applicable, to

achieve this.

20Where applicable, refit the exhaust heat

shield.

21Refit the roadwheels and lower the vehicle

to the ground. Do not fully tighten the

roadwheel bolts until the vehicle is resting on

its wheels.

27Handbrake cable - removal

and refitting

3

Models with rear drum brakes

Removal

1The handbrake cable is in two sections. The

longer section runs from the handbrake

operating rod, through the adjuster, to the

right-hand brake assembly. The shorter

section runs from the adjuster to the left-hand

brake assembly. The two sections of the cable

can be renewed independently.

2Where applicable, remove the wheel trim(s),

then loosen the relevant rear roadwheel bolts.

Chock the front wheels, jack up the rear of the

vehicle, and support securely on axle stands

(see “Jacking and Vehicle Support”)

positioned under the body side members.

Remove the roadwheel(s).

3Note the routing of the handbrake cable(s),

as an aid to refitting.

4Remove the relevant brake drum(s), with

reference to Section 11.

Longer cable

Removal

5Note the length of exposed thread at the

handbrake cable adjuster on the torsion

beam, then unscrew the adjuster nut from the

threaded rod.

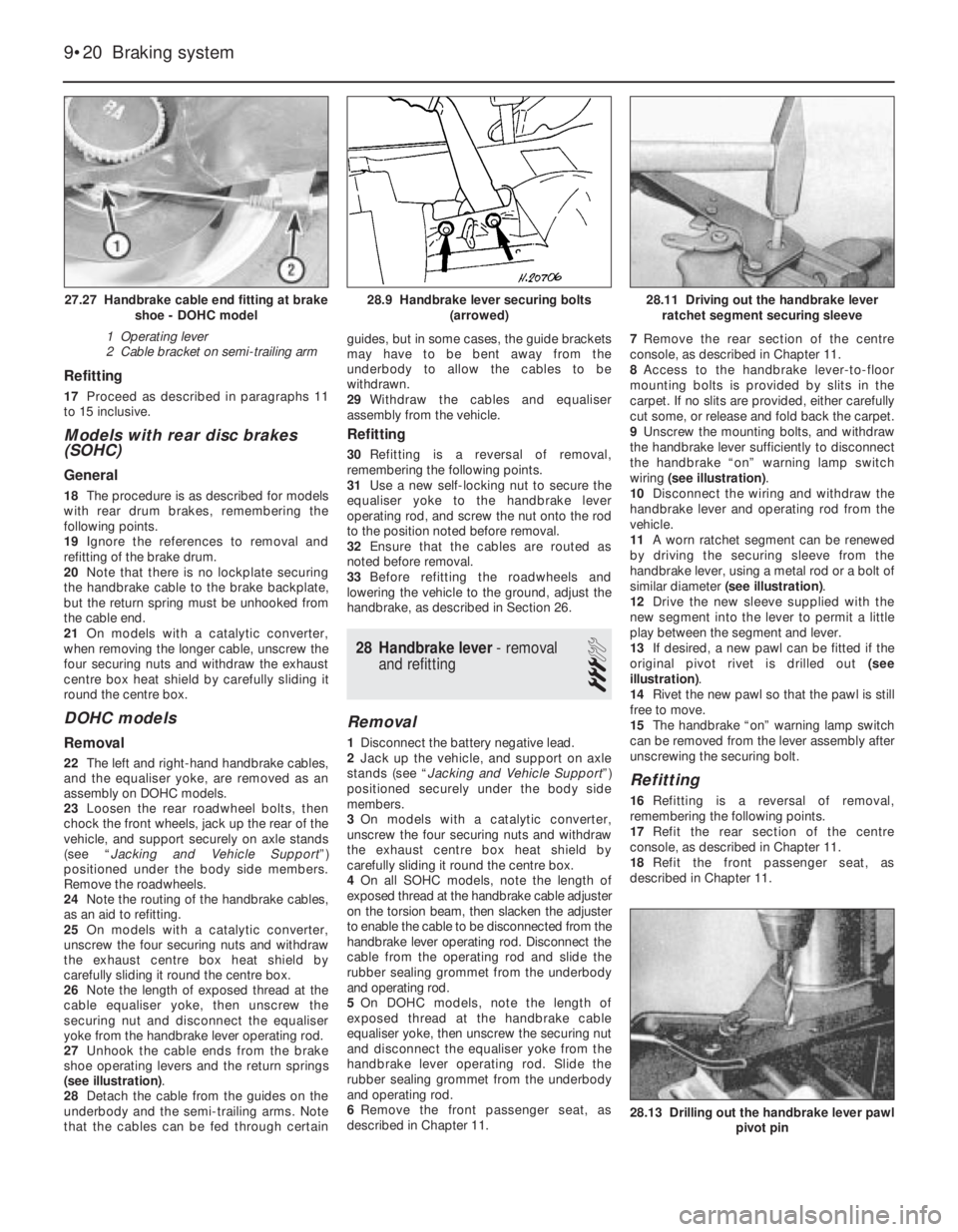

6Disconnect the cable from the handbrake

lever operating rod on the vehicle underbody

(see illustration).

7Detach the cable from the guides on the

underbody. Note that the cable can be fed

through certain guides, but in some cases, the

guide brackets must be bent away from the

underbody to allow the cable to be withdrawn.

8Detach the cable from the adjuster on the

torsion beam.

9Unhook the cable end from the lever on the

brake shoe, then using a screwdriver, prise

out the lockplate that secures the handbrake

cable in the backplate.

10Withdraw the cable from the vehicle,

releasing it from the guide on the torsion

beam.

Refitting

11Refitting is a reversal of removal,

remembering the following points.

12Screw the adjuster nut onto the threaded

rod to the position noted before removal.

13Ensure that the handbrake cable is routed

as noted before removal.

14Refit the brake drum, (Section 11).

15Before refitting the roadwheel(s) and

lowering the vehicle to the ground, adjust the

handbrake, as described in Section 26.

Shorter cable

Removal

16Note the length of exposed thread at the

handbrake cable adjuster on the torsion

beam, then unscrew the adjuster nut from the

threaded rod. Continue as described in

paragraphs 8 to 10.

Braking system 9•19

27.6 Handbrake cable connection to handbrake lever operating

rod

1 Handbrake cable

2 Connecting link3 Handbrake lever operating rod26.14 Using a screwdriver to turn the handbrake adjuster wheel -

model with rear disc brakes

9

Page 151 of 525

Refitting

17Proceed as described in paragraphs 11

to 15 inclusive.

Models with rear disc brakes

(SOHC)

General

18The procedure is as described for models

with rear drum brakes, remembering the

following points.

19Ignore the references to removal and

refitting of the brake drum.

20Note that there is no lockplate securing

the handbrake cable to the brake backplate,

but the return spring must be unhooked from

the cable end.

21On models with a catalytic converter,

when removing the longer cable, unscrew the

four securing nuts and withdraw the exhaust

centre box heat shield by carefully sliding it

round the centre box.

DOHC models

Removal

22The left and right-hand handbrake cables,

and the equaliser yoke, are removed as an

assembly on DOHC models.

23Loosen the rear roadwheel bolts, then

chock the front wheels, jack up the rear of the

vehicle, and support securely on axle stands

(see “Jacking and Vehicle Support”)

positioned under the body side members.

Remove the roadwheels.

24Note the routing of the handbrake cables,

as an aid to refitting.

25On models with a catalytic converter,

unscrew the four securing nuts and withdraw

the exhaust centre box heat shield by

carefully sliding it round the centre box.

26Note the length of exposed thread at the

cable equaliser yoke, then unscrew the

securing nut and disconnect the equaliser

yoke from the handbrake lever operating rod.

27Unhook the cable ends from the brake

shoe operating levers and the return springs

(see illustration).

28Detach the cable from the guides on the

underbody and the semi-trailing arms. Note

that the cables can be fed through certainguides, but in some cases, the guide brackets

may have to be bent away from the

underbody to allow the cables to be

withdrawn.

29Withdraw the cables and equaliser

assembly from the vehicle.

Refitting

30Refitting is a reversal of removal,

remembering the following points.

31Use a new self-locking nut to secure the

equaliser yoke to the handbrake lever

operating rod, and screw the nut onto the rod

to the position noted before removal.

32Ensure that the cables are routed as

noted before removal.

33Before refitting the roadwheels and

lowering the vehicle to the ground, adjust the

handbrake, as described in Section 26.

28Handbrake lever - removal

and refitting

3

Removal

1Disconnect the battery negative lead.

2Jack up the vehicle, and support on axle

stands (see “Jacking and Vehicle Support”)

positioned securely under the body side

members.

3On models with a catalytic converter,

unscrew the four securing nuts and withdraw

the exhaust centre box heat shield by

carefully sliding it round the centre box.

4On all SOHC models, note the length of

exposed thread at the handbrake cable adjuster

on the torsion beam, then slacken the adjuster

to enable the cable to be disconnected from the

handbrake lever operating rod. Disconnect the

cable from the operating rod and slide the

rubber sealing grommet from the underbody

and operating rod.

5On DOHC models, note the length of

exposed thread at the handbrake cable

equaliser yoke, then unscrew the securing nut

and disconnect the equaliser yoke from the

handbrake lever operating rod. Slide the

rubber sealing grommet from the underbody

and operating rod.

6Remove the front passenger seat, as

described in Chapter 11.7Remove the rear section of the centre

console, as described in Chapter 11.

8Access to the handbrake lever-to-floor

mounting bolts is provided by slits in the

carpet. If no slits are provided, either carefully

cut some, or release and fold back the carpet.

9Unscrew the mounting bolts, and withdraw

the handbrake lever sufficiently to disconnect

the handbrake “on” warning lamp switch

wiring (see illustration).

10Disconnect the wiring and withdraw the

handbrake lever and operating rod from the

vehicle.

11A worn ratchet segment can be renewed

by driving the securing sleeve from the

handbrake lever, using a metal rod or a bolt of

similar diameter (see illustration).

12Drive the new sleeve supplied with the

new segment into the lever to permit a little

play between the segment and lever.

13If desired, a new pawl can be fitted if the

original pivot rivet is drilled out (see

illustration).

14Rivet the new pawl so that the pawl is still

free to move.

15The handbrake “on” warning lamp switch

can be removed from the lever assembly after

unscrewing the securing bolt.

Refitting

16Refitting is a reversal of removal,

remembering the following points.

17Refit the rear section of the centre

console, as described in Chapter 11.

18Refit the front passenger seat, as

described in Chapter 11.

9•20Braking system

28.13 Drilling out the handbrake lever pawl

pivot pin

28.11 Driving out the handbrake lever

ratchet segment securing sleeve28.9 Handbrake lever securing bolts

(arrowed)27.27 Handbrake cable end fitting at brake

shoe - DOHC model

1 Operating lever

2 Cable bracket on semi-trailing arm

Page 159 of 525

9Fuel filter (‘Out-of-tank’ fuel

pump models) - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1The fuel filter is located on the fuel pump

bracket under the rear of the vehicle. Either on

the right-hand side of the spare wheel well or

in front of the fuel tank, depending on model

(see illustrations).

2Disconnect the battery negative lead.

3Have a container to hand, to catch the fuel

that will be released as the filter is removed.

4Clamp the fuel hoses on either side of the

filter, to minimise fuel loss when the hoses are

disconnected.

5Loosen the clamp screws, and disconnect

the fuel hoses from the filter. Be prepared for

fuel spillage, and take adequate fire

precautions.

6Loosen the clamp bolt(s), and withdraw the

fuel filter from its bracket. Note the orientation

of the flow direction arrow on the body of the

filter, and the position of the “AUS” (out)

marking on the filter end face.

Refitting

7Refitting is a reversal of removal, ensuring

that the flow direction markings are correctly

orientated.

8Run the engine and check for leaks on

completion. If leakage is evident, stop the

engine immediately, and rectify the problem

without delay.

10Fuel filter (‘In-tank’ fuel

pump models) - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1Depressurise the fuel system (Section 8).

2Chock the front wheels, jack up the rear of

the vehicle and support it on axle stands

placed under the body side members. (see

“Jacking and Vehicle Support”). The fuel filter

is located at the rear of the fuel tank, on the

right-hand side.3Unclip the fuel hose from the filter mounting

bracket.

4Note carefully any markings on the fuel filter

casing. There should be at least an arrow

(showing the direction of fuel flow) pointing in

the direction of the fuel supply hose leading to

the engine compartment. There may also be

the words “EIN” (in) and “AUS” (out)

embossed in the appropriate end of the

casing.

5Clamp the fuel filter hoses, then slacken the

clips and disconnect the hoses.

6Undo the single screw to release the

mounting bracket, then open the clamp with a

screwdriver to remove the fuel filter (see

illustration).

Refitting

7Fit the new fuel filter using a reversal of the

removal procedure, but ensure that the fuel

flow direction arrow or markings point in the

correct direction. Switch on the ignition and

check carefully for leaks; if any signs of

leakage are detected, the problem must be

rectified before the engine is started.

11Fuel pump - testing

2

Testing

1If the fuel pump is functioning, it should be

possible to hear it “buzzing” by listening

under the rear of the vehicle when the ignition

is switched on. Unless the engine is started,

the fuel pump should switch off after

approximately one second. If the noise

produced is excessive, this may be due to a

faulty fuel flow damper. The damper can be

renewed referring to Section 18, if necessary.

2If the pump appears to have failed

completely, check the appropriate fuse and

relay.

3To test the fuel pump, special equipment is

required, and it is recommended that any

suspected faults are referred to a Vauxhall

dealer.

12Fuel pump (‘Out-of-tank’ fuel

pump models) - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1The fuel pump is located on a bracket

under the rear of the vehicle, either on the

right-hand side of the spare wheel well or in

front of the fuel tank on other models.

2Disconnect the battery negative lead.

3Have a container to hand, to catch the fuel

that will be released as the damper is

removed.

4Disconnect the wiring plug(s) from the fuel

pump (see illustration).

5Clamp the fuel hoses on either side of the

damper, to minimise fuel loss when the hoses

are disconnected.

6Loosen the clamp screws, and disconnect

the fuel hoses from the pump. Be prepared for

fuel spillage, and take adequate fire

precautions.

7Loosen the clamp bolt, and slide the pump

from its bracket.

Refitting

8Refitting is a reversal of removal, ensuring

that the pump is fitted the correct way round

in its bracket. Push the pump into the rubber

clamping sleeve as far as the rim on the pump

body (see illustration).

4B•6Fuel and exhaust systems - fuel injection models

9.1A Fuel filter (arrowed) - ‘out of tank’,

fuel pump models10.6 Fuel filter - ‘in tank’, fuel pump type

A Clamp screwB Hose clips

12.4 Disconnecting a fuel pump wiring

plug - ‘out of tank’, fuel pump model

9.1B Fuel component assembly - ‘out of

tank’, fuel pump models

1 Fuel filter

2 Fuel flow damper3 Fuel pump

Page 160 of 525

4B

9Run the engine and check for leaks on

completion. If leakage is evident, stop the

engine immediately, and rectify the problem

without delay.

13Fuel pump (‘In-tank’ fuel

pump models) - removal and

refitting

3

Removal

1Depressurise the fuel system (Section 8),

then remove and refit the fuel filler cap to

ensure that the pressure is equalised inside

and outside the tank.

2Disconnect the battery negative terminal.

3Fold forwards the rear seat cushion. Peel

back the floor covering beneath it, then

remove the cover plug from the vehicle floor

to reach the pump mountings (see

illustration).

4Noting exactly how it is connected, and

making your own marks or notes to ensure

that it can be reconnected the same way

round, disconnect the wiring plug from the

pump.

5Release the securing clip and disconnect

the fuel hose from the pump. Clamp or plug

the hose to prevent the loss of fuel and the

entry of dirt.

6Undo the pump mounting bracket screws,

then withdraw the mounting bracket and

pump assembly from the tank. Note the

position of the sealing ring and discard it, then

cover the tank opening as a safety measure

and to prevent the entry of dirt.

7If the pump is to be renewed, first move it to

a clean working area and carry out the

following.

8Prise off the filter at the base of the pump

assembly, then release the securing clamp

and disconnect the mounting

bracket-to-pump fuel hose.

9Making your own marks or notes to ensure

that they can be reconnected the same way

round, unsolder the wires connecting the

pump to the mounting bracket.

10Press the pump out of the rubber sleeve.

Refitting

11Reassembly and refitting are the reverse

of the removal and dismantling procedures,

noting the following points.a)Ensure that the pump is seated correctly

in the sleeve and that the hose is securely

fastened.

b)Ensure that the wires are correctly

reconnected and securely soldered.

c)Always renew the pump mounting

bracket’s sealing ring.

d)Apply a few drops of sealing compound

(i.e. Vauxhall part no. 90485251) to the

threads of the screws, then tighten them

securely, but take care not to distort the

sealing ring.

14Fuel pump relay - renewal

2

The relay is mounted in the engine

compartment relay box (Chapter 12). Where

more than one relay is fitted, the fuel pump

relay is the one with the black base.

15Fuel tank filler pipe - removal

and refitting

3

Removal

1Syphon out any remaining fuel in the tank

into a clean container that is designed for

carrying petrol and is clearly marked as such.

2Raise the bottom edge of the seal

surrounding the filler neck and undo the single

securing screw beneath.

3Chock the front wheels, jack up the rear of

the vehicle and support it securely on axle

stands (see “Jacking and Vehicle Support”)

placed under the body side members.

4Unscrew the single filler pipe mounting bolt

from the underbody, then work along the

length of the pipe, cutting or releasing any

clips or ties securing other pipes or hoses to

it. Releasing their clips, disconnect the filler

and vent hoses from the pipe’s lower end and

the small-bore vent hoses from the unions at

its upper end.

5Having ensured that all components have

been removed or disconnected which mightprevent its removal, manoeuvre the pipe away

from the vehicle’s underside.

6To check the operation of the pipe’s

anti-leak valve, invert the filler pipe and fill the

lower union (now uppermost) with petrol. If

the valve is functioning correctly, no petrol will

leak from the other union. If petrol leaks from

the other union the valve is faulty and the

complete filler pipe must be renewed.

Refitting

7Refitting is the reverse of the removal

procedure, noting the following.

a)Check the condition of all hoses and

clips, renewing any components that are

found to be worn or damaged

b)When reconnecting the small-bore vent

hoses to the unions at the pipe’s upper

end, connect the hose from the charcoal

canister to the uppermost union and the

vent hose from the tank itself to the lower

union (see illustration).

c)Replacing any that were cut on removal

use the clips or ties provided to secure

any other pipes or hoses to the filler pipe.

d)Check carefully for signs of leaks on

refilling the tank; if any signs of leakage

are detected, the problem must be

rectified immediately.

16Fuel tank - removal and

refitting

4

Note: Refer to Section 2 before proceeding

Removal

SOHC models

1The procedure is similar as for models with

carburettors. Refer to Chapter 4A, however

note the following:

a)Depressurise the fuel system (Section 8).

b)On models with C16 NZ and X16 SZ

engines, disconnect the exhaust system

from the manifold.

c)When working on the fuel tank sender

unit, note that there is only one hose to be

disconnected.

Fuel and exhaust systems - fuel injection models 4B•7

15.7 Vent hose connections at fuel tank

filler pipe

A Charcoal canister hose

B Tank vent hose

13.3 Fuel pump - ‘in-tank’, fuel pump

model

A Wiring connector

B Fuel hose clampC Mounting bracket

screws

12.8 Fuel pump clamping sleeve should

rest against rim (arrowed)

Page 161 of 525

d)Disconnect the fuel pump hose and wiring

as described in Section 12.

e)When releasing the tank mounting straps,

note that the fuel filter must either be

moved aside or removed completely,

whichever is most convenient

f)One of the fuel hoses connects to a pipe

in the side of the tank.

DOHC models

2Disconnect the battery negative lead.

3Siphon out any remaining fuel in the tank

through the filler pipe. Siphon the fuel into a

clean metal container that can be sealed.

4Chock the front wheels, then jack up the

rear of the vehicle, and support on axle stands

placed under the body side members (see

“Jacking and Vehicle Support”).

5Open the fuel filler flap, then pull back the

rubber seal to expose the fuel filler pipe

securing screw (see illustration). Remove the

screw.

6Release the fuel tank vent hoses from the

clips on the underbody.

7Support the weight of the fuel tank on a

jack, with an interposed block of wood.

8Unscrew the securing bolts from the tank

mounting straps. Then remove the straps and

lower the tank sufficiently to enable the fuel

hoses, vent hoses and fuel tank sender unit

wiring to be disconnected (see illustration).

9Disconnect the vent hoses and the fuel tank

sender unit wiring. Note the positions of the

vent hoses as an aid to refitting.

10Disconnect the fuel hoses from the tank and

the fuel tank sender unit, making a note of the

hose positions for use when refitting. Be

prepared for fuel spillage, and take adequate fire

precautions. Plug the open ends of the hoses, to

prevent dirt ingress and further fuel loss.

11Lower the fuel tank, and withdraw it from

under the vehicle.

12If the tank contains sediment or water, it

may be cleaned out using two or three rinses

with clean fuel. Shake vigorously using

several changes of fuel, but before doing so,

remove the fuel tank sender unit, as described

in Section 17. This procedure should be

carried out in a well-ventilated area, and it is

vital to take adequate fire precautions - refer

to the “Safety first!” Section at the beginning

of this manual for further details.

Refitting

13Any repairs to the fuel tank should be

carried out by a professional.

14Refitting is a reversal of removal, ensuring

that all hoses are reconnected to their correct

locations as noted during removal.

15On completion, fill the fuel tank, then run

the engine and check for leaks. If leakage is

evident, stop the engine immediately, and

rectify the problem without delay.

17Fuel tank sender unit -

removal and refitting

3

Note:Refer to Section 2 before proceeding

Removal

SOHC models

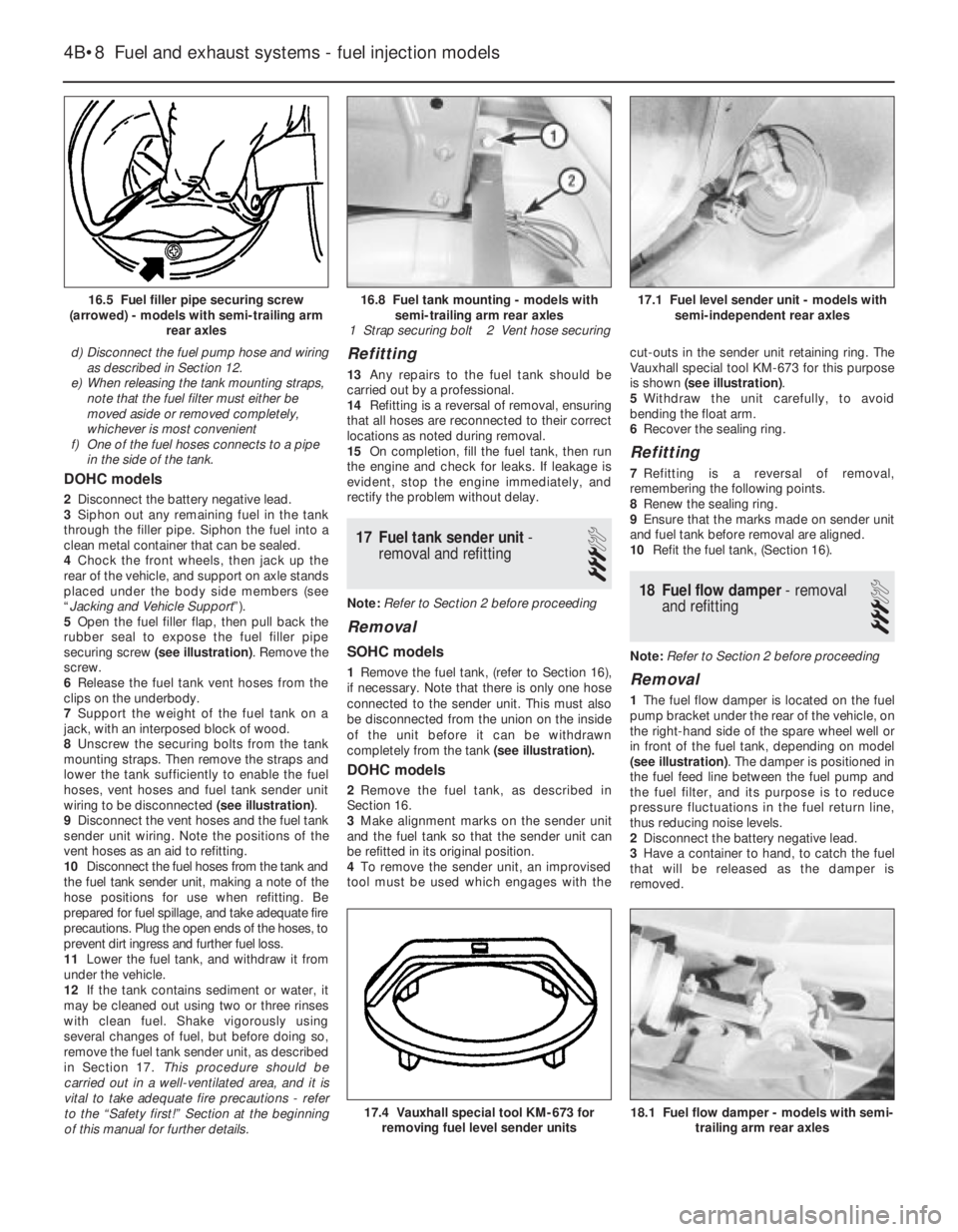

1Remove the fuel tank, (refer to Section 16),

if necessary. Note that there is only one hose

connected to the sender unit. This must also

be disconnected from the union on the inside

of the unit before it can be withdrawn

completely from the tank (see illustration).

DOHC models

2Remove the fuel tank, as described in

Section 16.

3Make alignment marks on the sender unit

and the fuel tank so that the sender unit can

be refitted in its original position.

4To remove the sender unit, an improvised

tool must be used which engages with thecut-outs in the sender unit retaining ring. The

Vauxhall special tool KM-673 for this purpose

is shown (see illustration).

5Withdraw the unit carefully, to avoid

bending the float arm.

6Recover the sealing ring.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Renew the sealing ring.

9Ensure that the marks made on sender unit

and fuel tank before removal are aligned.

10Refit the fuel tank, (Section 16).

18Fuel flow damper - removal

and refitting

3

Note:Refer to Section 2 before proceeding

Removal

1The fuel flow damper is located on the fuel

pump bracket under the rear of the vehicle, on

the right-hand side of the spare wheel well or

in front of the fuel tank, depending on model

(see illustration). The damper is positioned in

the fuel feed line between the fuel pump and

the fuel filter, and its purpose is to reduce

pressure fluctuations in the fuel return line,

thus reducing noise levels.

2Disconnect the battery negative lead.

3Have a container to hand, to catch the fuel

that will be released as the damper is

removed.

4B•8Fuel and exhaust systems - fuel injection models

16.5 Fuel filler pipe securing screw

(arrowed) - models with semi-trailing arm

rear axles17.1 Fuel level sender unit - models with

semi-independent rear axles

18.1 Fuel flow damper - models with semi-

trailing arm rear axles17.4 Vauxhall special tool KM-673 for

removing fuel level sender units

16.8 Fuel tank mounting - models with

semi-trailing arm rear axles

1 Strap securing bolt 2 Vent hose securing

Page 164 of 525

regulator vacuum pipe should be routed over

the top of the camshaft cover breather hoses.

21On models with the Multec system note

also the following:

a)Fit the new diaphragm so that it locates in

the throttle body groove.

b)Ensure that the spring and spring seat are

correctly engaged with each other and

with the diaphragm and regulator cover.

Then press the cover over its locating

dowels and hold it in place while the

screws are tightened.

c)Tighten the screws carefully to the

specified torque wrench setting.

22On completion, check the regulator for

leaks, pressurising the system by switching

the ignition on and off several times, before

the engine is started.

22Idle speed adjuster - removal

and refitting

3

Note:Idle speed adjustment on models fitted

with Multec systems, is not possible, as it is

controlled by the ECU. Refer to Section 1.

Removal

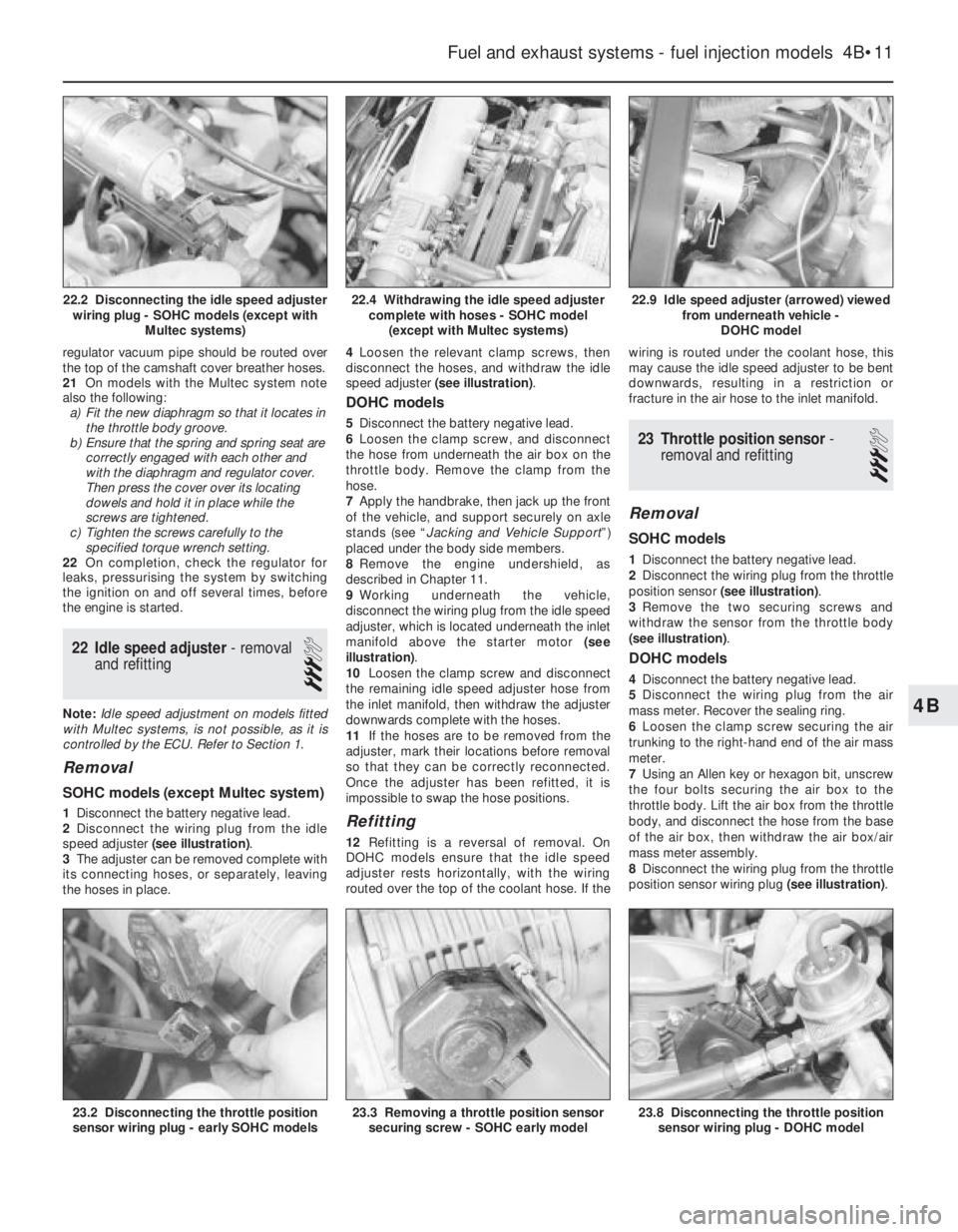

SOHC models (except Multec system)

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the idle

speed adjuster (see illustration).

3The adjuster can be removed complete with

its connecting hoses, or separately, leaving

the hoses in place.4Loosen the relevant clamp screws, then

disconnect the hoses, and withdraw the idle

speed adjuster (see illustration).

DOHC models

5Disconnect the battery negative lead.

6Loosen the clamp screw, and disconnect

the hose from underneath the air box on the

throttle body. Remove the clamp from the

hose.

7Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

placed under the body side members.

8Remove the engine undershield, as

described in Chapter 11.

9Working underneath the vehicle,

disconnect the wiring plug from the idle speed

adjuster, which is located underneath the inlet

manifold above the starter motor (see

illustration).

10Loosen the clamp screw and disconnect

the remaining idle speed adjuster hose from

the inlet manifold, then withdraw the adjuster

downwards complete with the hoses.

11If the hoses are to be removed from the

adjuster, mark their locations before removal

so that they can be correctly reconnected.

Once the adjuster has been refitted, it is

impossible to swap the hose positions.

Refitting

12Refitting is a reversal of removal. On

DOHC models ensure that the idle speed

adjuster rests horizontally, with the wiring

routed over the top of the coolant hose. If thewiring is routed under the coolant hose, this

may cause the idle speed adjuster to be bent

downwards, resulting in a restriction or

fracture in the air hose to the inlet manifold.

23Throttle position sensor -

removal and refitting

3

Removal

SOHC models

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the throttle

position sensor (see illustration).

3Remove the two securing screws and

withdraw the sensor from the throttle body

(see illustration).

DOHC models

4Disconnect the battery negative lead.

5Disconnect the wiring plug from the air

mass meter. Recover the sealing ring.

6Loosen the clamp screw securing the air

trunking to the right-hand end of the air mass

meter.

7Using an Allen key or hexagon bit, unscrew

the four bolts securing the air box to the

throttle body. Lift the air box from the throttle

body, and disconnect the hose from the base

of the air box, then withdraw the air box/air

mass meter assembly.

8Disconnect the wiring plug from the throttle

position sensor wiring plug (see illustration).

Fuel and exhaust systems - fuel injection models 4B•11

22.9 Idle speed adjuster (arrowed) viewed

from underneath vehicle -

DOHC model

23.8 Disconnecting the throttle position

sensor wiring plug - DOHC model23.3 Removing a throttle position sensor

securing screw - SOHC early model23.2 Disconnecting the throttle position

sensor wiring plug - early SOHC models

22.4 Withdrawing the idle speed adjuster

complete with hoses - SOHC model

(except with Multec systems)22.2 Disconnecting the idle speed adjuster

wiring plug - SOHC models (except with

Multec systems)

4B