brake OPEL CORSA E 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: CORSA E, Model: OPEL CORSA E 2019Pages: 231, PDF Size: 6.87 MB

Page 187 of 231

Vehicle care1859Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel nuts, do not attach wheel

covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.

Page 188 of 231

186Vehicle care9Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is stowed in the load

compartment.

Depending on the equipment, the tyre repair kit is in a compartment in the

right sidewall or in a compartment

under the floor cover.

Vehicles with tyre repair kit under

the floor cover

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 193 of 231

Vehicle care191General informationNote

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

The adapters possibly supplied can

be used to pump up other items e.g. footballs, air mattresses, inflatable

dinghies etc. They can be located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them and lightly coat

the taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

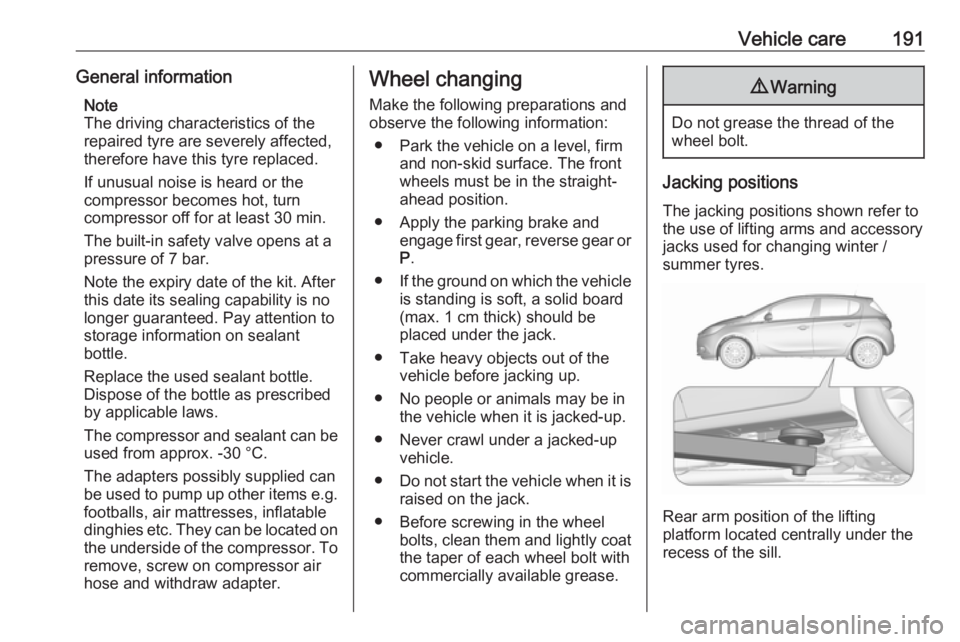

Jacking positions

The jacking positions shown refer to the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Rear arm position of the lifting

platform located centrally under the

recess of the sill.

Page 194 of 231

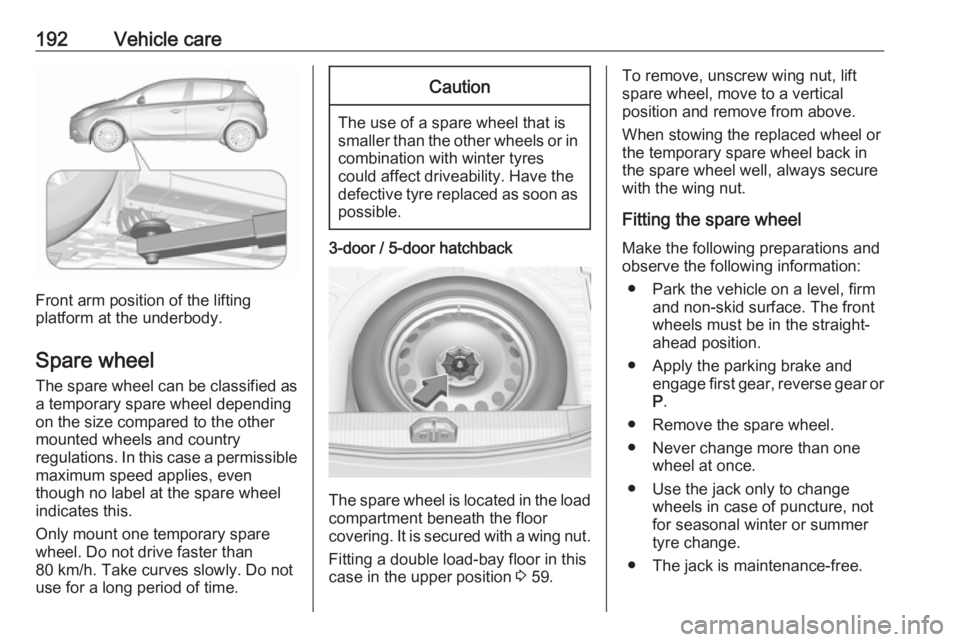

192Vehicle care

Front arm position of the lifting

platform at the underbody.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

3-door / 5-door hatchback

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Fitting a double load-bay floor in this

case in the upper position 3 59.

To remove, unscrew wing nut, lift

spare wheel, move to a vertical

position and remove from above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always secure

with the wing nut.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

Page 197 of 231

Vehicle care195Jump starting

Do not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

.

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both vehicle

batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

vehicle battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged vehicle battery.

Page 199 of 231

Vehicle care197

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: the vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases

and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap at the top and engage

downwards.

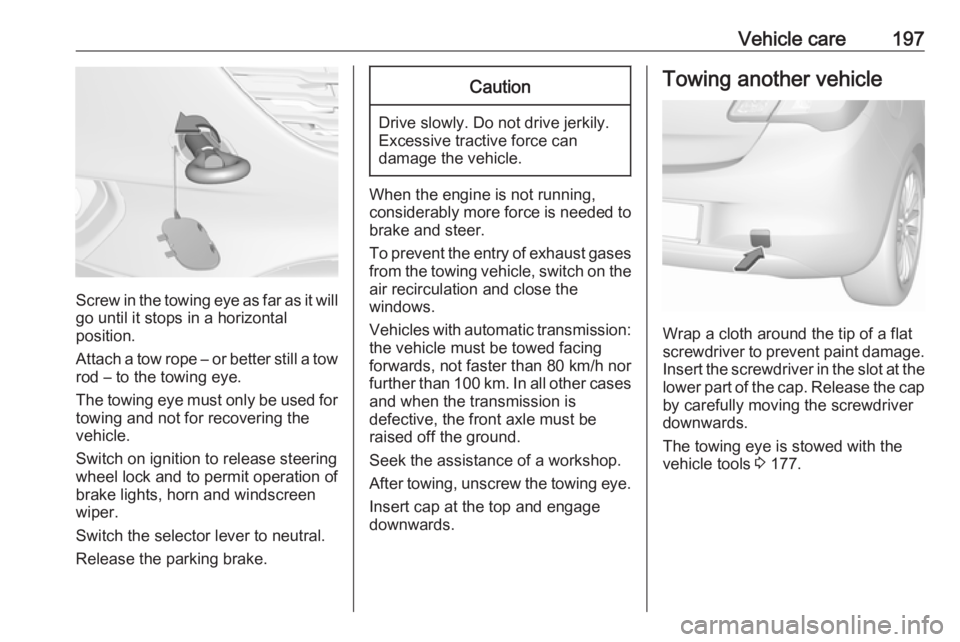

Towing another vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage. Insert the screwdriver in the slot at the

lower part of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 177.

Page 206 of 231

204Service and maintenanceSelect the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 207.

Additional engine oil additives

The use of additional engine oil

additives could cause damage and

invalidate the warranty.

Engine oil viscosity grades

The SAE viscosity grade gives

information of the thickness of the oil.

Multigrade oil is indicated by two

figures, e.g. SAE 5W-30. The first

figure, followed by a W, indicates the

low temperature viscosity and the

second figure the high temperature viscosity.

Select the appropriate viscosity grade

depending on the minimum ambient

temperature 3 207.

All of the recommended viscosity

grades are suitable for high ambient

temperatures.Coolant and antifreeze

Use only silicate-free long life coolant (LLC) antifreeze. Consult a

workshop.

The system is factory filled with

coolant designed for excellent

corrosion protection and frost

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37 °C. This concentration

should be maintained all year round.

The use of additional coolant

additives that intend to give additional

corrosion protection or seal against

minor leaks can cause function

problems. Liability for consequences

resulting from the use of additional

coolant additives will be rejected.

Washer fluid Use only washer fluid approved for

the vehicle to prevent damage of wiper blades, paintwork, plastic and

rubber parts. Consult a workshop.Brake and clutch fluid

Over time, brake fluid absorbs

moisture which will reduce braking

effectiveness. The brake fluid should therefore be replaced at the specified interval.

Page 223 of 231

Customer information221Operating data in the vehicleControl units process data for

operation of the vehicle.

This data includes, e.g.: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate,

"seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient, not

stored for longer than an operational

cycle, and only processed on board

the vehicle itself. Control units often

include data storage (including the

vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.Depending on technical equipment

levels, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,brakes)

● system reactions in special driving situations (e.g. triggering

of an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used where necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating datawhich is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the

vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.

Page 226 of 231

224IndexAAccessories and vehicle modifications .......................... 156

Adjustable air vents ...................117

Airbag and belt tensioners ...........78

Airbag deactivation ................47, 79

Airbag label................................... 42 Airbag system .............................. 42

Air conditioning regular operation ................................ 118

Air conditioning system .............. 111

Air intake .................................... 118

Air vents...................................... 117

Antilock brake system ................ 131

Antilock brake system (ABS) .......80

Anti-theft alarm system ................27

Anti-theft locking system .............. 27

Appearance care ........................198

Ashtrays ....................................... 70

Automatic anti-dazzle ..................30

Automatic light control ...............101

Automatic locking ........................25

Automatic transmission .............127

Autostop ............................... 82, 122

B Battery discharge protection ......108

Battery voltage ............................. 92

Belts.............................................. 39

Bonnet ....................................... 158Brake and clutch fluid.................203

Brake and clutch system .............79

Brake assist ............................... 132

Brake fluid .................................. 161 Brakes ............................... 131, 161

Breakdown.................................. 196

Bulb replacement ....................... 164

C Capacities .................................. 212

Catalytic converter .....................126

Central locking system ................23

Centre high-mounted brake light 171

Changing tyre and wheel size ...184

Charging system .......................... 79

Child locks ................................... 25

Child restraint installation locations ................................... 52

Child restraints.............................. 48

Child restraint systems ................48

Cigarette lighter ........................... 70

City mode ................................... 134

Climate control ............................. 17

Climate control systems .............110

Clock ............................................ 68

Code ............................................. 89

Control indicators.......................... 75

Control of the vehicle .................119

Controls ........................................ 64

Convex shape .............................. 29

Page 227 of 231

225Coolant and antifreeze...............203

Corner lighting ............................ 103

Cruise control ...................... 83, 135

Cupholders .................................. 55

Curtain airbag system .................. 47

D Danger, Warnings and Cautions ...4

Daytime running lights ...............103

Declaration of conformity ............215

Door open .................................... 83

Doors ............................................ 26

Driver assistance systems ..........135

Driver Information Centre .............83

Driving hints ................................ 119

E Easy entry..................................... 37Electric adjustment ......................29

Electrical system......................... 172

Electronic climate control system 113

Electronic driving programmes ..128

Electronic Stability Control.......... 133

Electronic Stability Control and Traction Control system ............81

End-of-life vehicle recovery .......157

Engine compartment fuse box ...173

Engine coolant ........................... 160

Engine coolant temperature gauge ....................................... 74

Engine data ............................... 210Engine exhaust .......................... 125

Engine identification ...................206

Engine oil ...........159, 203, 207, 212

Engine oil pressure ......................81

Entry lighting .............................. 107

Event data recorders ..................220

Exhaust filter ......................... 81, 125

Exit lighting ................................ 108

Exterior care .............................. 198

Exterior light ................................. 82

Exterior lighting ....................14, 100

Exterior mirrors ............................. 29

F

Fault ........................................... 129

First aid ......................................... 61

First aid kit ................................... 61

Fixed air vents ........................... 118

Folding mirrors ............................. 29

Following distance indication ......140

Forward collision alert................. 138

Front airbag system .....................45

Front fog lights .............82, 104, 168

Front seats.................................... 35

Front storage ................................ 56

Front turn lights .......................... 168

Fuel............................................. 150

Fuel for liquid gas operation .......152

Fuel for petrol engines ...............150

Fuel gauge ................................... 72Fuel selector ................................ 73

Fuel tank ..................................... 212

Fuses ......................................... 172

G

Gauges ......................................... 71

Gear shifting ................................. 80

Glovebox ..................................... 55

H

Halogen headlights ....................164

Hand brake ......................... 131, 132

Hazard warning flashers ............104

Headlight flash ........................... 102

Headlight range adjustment ......102

Headlights................................... 100

Headlights when driving abroad 102

Head restraint adjustment .............8

Head restraints ............................ 34

Heated mirrors ............................. 30

Heated rear window ..................... 32

Heated steering wheel .................64

Heated windscreen .......................33

Heating ........................................ 38

Heating and ventilation system . 110

High beam ........................... 82, 102

Hill start assist ........................... 132

Horn ....................................... 15, 65