relay OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2028 of 6000

6E–135 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0405 – EGR Pressure Sensor Low Voltage

StepNo Ye s Va l u e ( s ) Action

31. Turn off the ignition switch.

2. Remove the sensor connector connection.

3. Jumper between harness pins “red” and “blue”

wires.

4. Turn on the ignition switch “ON”.

Is the EGR pressure sensor voltage reading above the

specified value?

4 VGo to Step 5Go to Step 4

41. Turn off the ignition switch.

2. Remove the jumper wire.

3. Connect the relay & solenoid checker

(5-8840-0386-0) to the battery voltage, then check

the EGR pressure sensor signal circuit (blue wire).

4. Turn on the ignition switch.

Is the value displayed on the Tech 2 above the specified

value?

4 VGo to Step 6Go to Step 7

5Check the terminal connection at the EGR pressure

sensor and repair or replace terminal if necessary.

Is the action complete?

—Verify repair—

6Repair the 5V power circuit (red) harness or Replace

the ECM (Refer to the Data Programming in Case of

ECM change).

Is the action complete?

—Verify repair—

7Repair the signal circuit (blue) harness or Replace the

ECM (Refer to the Data Programming in Case of ECM

change).

Is the action complete?

—Verify repair—

Page 2032 of 6000

6E–139 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0406 – EGR Pressure Sensor High Voltage

StepNo Ye s Va l u e ( s ) Action

4Is the EGR pressure sensor voltage value displayed on

the Tech 2 below the specified value?

1 V

Refer to

Chart P0107

Refer to

Diagnostic

Aids

andSymp

tom

Diagnosis

5Connect the relay and solenoid checker

(5-8840-0386-0) to the battery voltage, then check the

sensor grounding circuit.

Does the checker lamp come on?

—Go to Step 7Go to Step 8

6A voltage short circuit occurs in the MAP signal circuit

or this circuit is shorted with the 5V power circuit.

Repair the harness or Replace the ECM (Refer to the

Data Programming in Case of ECM change).

Is the action complete?

—Verify repair—

7Replace the EGR pressure sensor hose or the EGR

pressure sensor.

Is the action complete?

—Verify repair—

8Repair the harness for open ground circuit.

Is the action complete?

—Verify repair—

Page 2063 of 6000

6E–170

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1655 (Flash DTC 17)

Thermo Relay Circuit Open/Short

060RW130

Circuit Description

The thermo relay circuit receives current through air con

10A fuse from the battery, current flowing in the order of

the thermo relay and thermo SW.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1655 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage.

Page 2064 of 6000

6E–171 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1655 – Thermo Relay Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Observe the “Batteri Voltage” display on the Tech 2.

Is the “Batteri Voltage” below the specified value?

11 VGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor the “Specific DTC” info for

DTC P1655.

Does the Tech 2 indicate DTC P1655 failed?

—Go to Step 4

Refer to

Diagnostic

Aids

4Check the Thermo Relay circuit for a poor connection

and replace the terminal if necessary.

Did the terminal require replacement?

—Verify repairGo to Step 5

5Check the Thermo Relay for damage.

Did the Thermo Relay require replacement?

—Verify repairGo to Step 6

6Check the Thermo Relay circuit for a poor connection

at the ECM and replace the terminal if necessary.

Did the terminal require replacement?

—Verify repairGo to Step 7

7Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2065 of 6000

6E–172

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1657 (Flash DTC 76)

ECM Main Relay Circuit Open/Short

060RW135

Circuit Description

The ECM main relay circuit receives current through ECM

50A fuse from the battery, current flowing in the order of

the ECM main relay and ECM.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1657 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage.

Page 2066 of 6000

6E–173 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1657 – ECM Main Relay Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Check the Fuse 50AꞏECM and 15AꞏEng.

2. If the Fuse is open, replace it as necessary.

Was the Fuse open?

—Verify repairGo to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor the “DTC” info for DTC

P1657.

Does the Tech 2 indicate DTC P1657 failed?

—Go to Step 4

Refer to

Diagnostic

Aids

4Check the ECM Main Relay circuit between the Fuse

and the ECM Main Relay for a poor connection and

repair the terminal if necessary.

Did the terminal require repair?

—Verify repairGo to Step 5

5Check the ECM Main Relay for a damage and Replace

the ECM (Refer to the Data Programming in Case of

ECM change) Main Relay if necessary.

Did the ECM Main Relay require replacement?

—Verify repairGo to Step 6

6Check the ECM Main Relay circuit for a poor

connection at the ECM and replace the terminal if

necessary.

Did the terminal require replacement?

—Verify repairGo to Step 7

7Check the ECM Main Relay Ground circuit for a poor

connection and repair the terminal if necessary.

Did the terminal require repair?

—Verify repairGo to Step 8

8Check the ECM Main Relay power circuit for a poor

connection and repair the terminal if necessary.

Did the terminal require repair?

—Verify repairGo to Step 9

9Replace the ECM (Refer to the Data Programming in

Case of ECM change) Main Relay.

Is the action complete?

—Verify repairGo to Step 10

10Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2084 of 6000

6E–191 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Starter Motor Doesn’t Rotate

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

As starter motor doesn’t rotate, engine is not cranked.

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was the bulletin found?

—Verify repairGo to Step 2

2Was a visual/physical check performed?

—Go to Step 3

Go to Visual/

Physical

Check

31. Check battery cord terminal for looseness & poor

contact due to corrosion.

2. Check battery voltage.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 4

41. Check fan belt for looseness & damage.

2. If a problem is found, adjust or replace as

necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check fuse bull link for disconnection & short.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Check generator for mount & damage (Refer to

Engine Mechanical).

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Check starter SW and starter relay for looseness

and damage.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check starter motor for mount and damage. (Refer

to

Engine Mechanical)

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records butter

All electrical connections within a suspected

circuit and/or system

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 2089 of 6000

6E–196

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

QOS System Doesn’t Work

StepActionVa l u e ( s )Ye sNo

1Was OBD System check performed?

—Go to Step 2

Go to OBD

System

Check

2Check glawplug indicator light. If bulb is broken,

replace.

Was a problem found?

—Verify repairGo to Step 3

31. Connect a circuit tester between glawplug & engine

ground.

2. With ignition on and engine off, check if the glaw

indicator and circuit tester indicate power voltage

for 9 to 13 sec. If not indicated, repair terminal & wire

harness.

Was repair needed?

—Verify repairGo to Step 4

41. Connect a circuit tester between glawplug and

engine ground.

2. With engine on, check if voltage continues for 180

sec. If not, inspect and repair glaw relay.

Was repair needed?

—Verify repairGo to Step 5

51. Remove the glawplug, and if damaged, replace.

2. Check glawplug resistance.

Was resistance as specified?

0.8 – 1Go to Step 7Go to Step 6

6Replace glawplug.

Was measure completed?

—Verify repairGo to Step 7

71. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records butter

All electrical connections within a suspected

circuit and/or system

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 2110 of 6000

6E–217 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Throttle Body (TB)

Removal Procedure

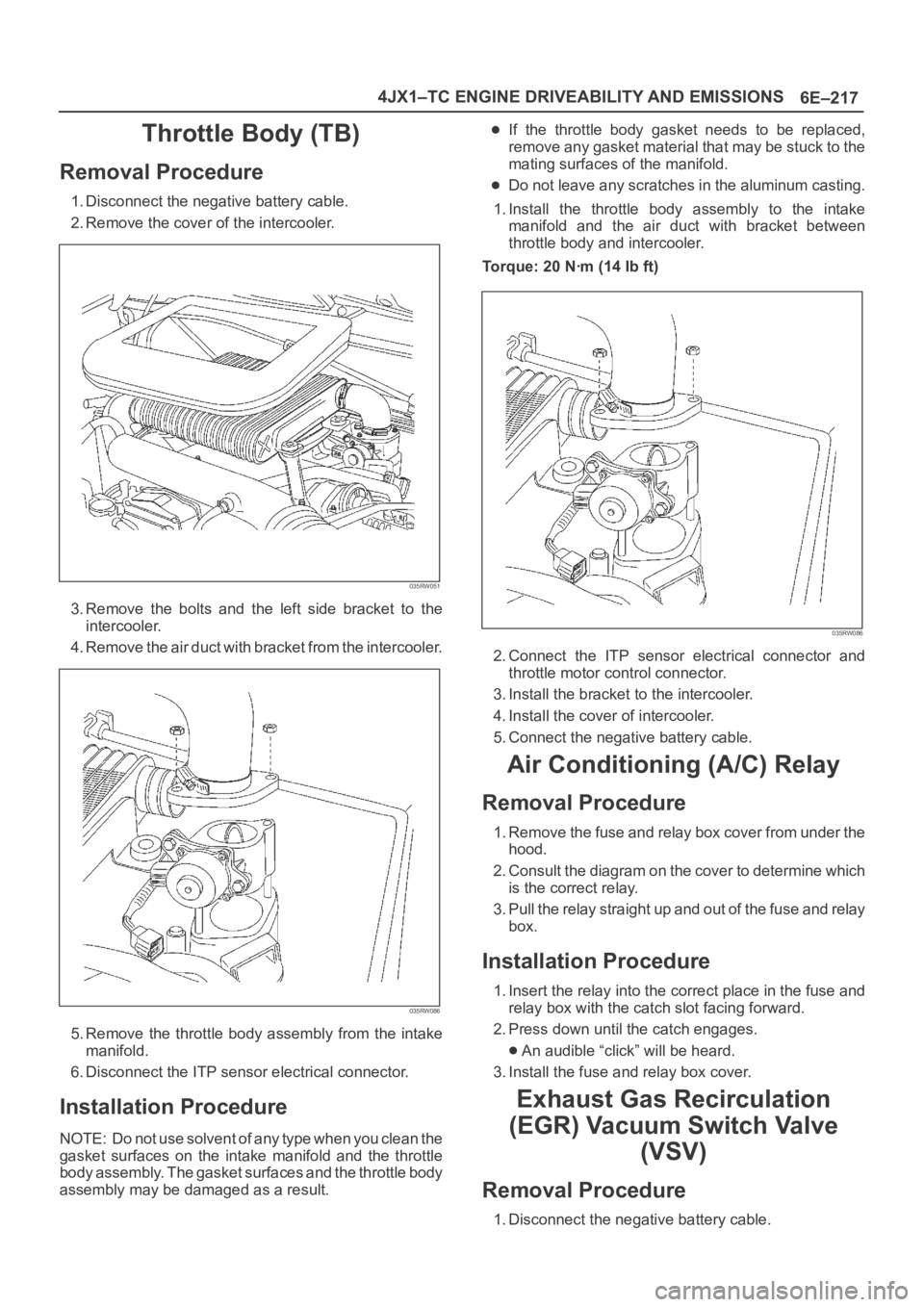

1. Disconnect the negative battery cable.

2. Remove the cover of the intercooler.

035RW051

3. Remove the bolts and the left side bracket to the

intercooler.

4 . R e m o v e t h e a i r d u c t w i t h b r a c k e t f r o m t h e i n t e r c o o l e r.

035RW086

5. Remove the throttle body assembly from the intake

manifold.

6. Disconnect the ITP sensor electrical connector.

Installation Procedure

NOTE: Do not use solvent of any type when you clean the

gasket surfaces on the intake manifold and the throttle

body assembly. The gasket surfaces and the throttle body

assembly may be damaged as a result.

If the throttle body gasket needs to be replaced,

remove any gasket material that may be stuck to the

mating surfaces of the manifold.

Do not leave any scratches in the aluminum casting.

1. Install the throttle body assembly to the intake

manifold and the air duct with bracket between

throttle body and intercooler.

Torque: 20 Nꞏm (14 Ib ft)

035RW086

2. Connect the ITP sensor electrical connector and

throttle motor control connector.

3. Install the bracket to the intercooler.

4. Install the cover of intercooler.

5. Connect the negative battery cable.

Air Conditioning (A/C) Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Pull the relay straight up and out of the fuse and relay

box.

Installation Procedure

1. Insert the relay into the correct place in the fuse and

relay box with the catch slot facing forward.

2. Press down until the catch engages.

An audible “click” will be heard.

3. Install the fuse and relay box cover.

Exhaust Gas Recirculation

(EGR) Vacuum Switch Valve

(VSV)

Removal Procedure

1. Disconnect the negative battery cable.

Page 2119 of 6000

6E–226

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

0018

Manifold Absolute Pressure (MAP) Sensor

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure. The MAP sensor

signal voltage to the ECM varies from below 2 volts at idle

(high vacuum) to above 4 volts.

The MAP sensor is used to determine the following:

Boost pressure for injector control.

Barometric pressure (BARO).

If the ECM detects a voltage that is lower than the

possible range of the MAP sensor, DTC P0107 will be set.

A signal voltage higher than the possible range of the

sensor will set DTC P0108. An intermittent low or high

voltage will set DTC P1107 or DTC P1106, respectively.

The ECM can detect a shifted MAP sensor. The ECM

compares the MAP sensor signal to a calculated MAP

based on throttle position and various engine load factors.

If the ECM detects a MAP signal that varies excessively

above or below the calculated value, DTC P0106 will set.

Engine Control Module (ECM)

The engine control module (ECM) is located in the engine

room.

The ECM constantly observes the information from

various sensors. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. It can recognize

operational problems, alert the driver through the MIL

(Service Engine Soon lamp), and store diagnostic trouble

codes (DTCs). DTCs identify the problem areas to aid the

technician in making repairs.

ECM Function

The ECM supplies 5, 12 and 110 volts to power various

sensors or switches. The power is supplied through

resistances in the ECM which are so high in value that a

test light will not light when connected to the circuit. In

some cases, even an ordinary shop voltmeter will not give

an accurate reading because its resistance is too low.

Therefore, a digital voltmeter with at least 10 megohms

input impedance is required to ensure accurate voltage

readings. The ECM controls output circuits such as theinjectors, glow relays, etc., by controlling the ground or

the power feed circuit through transistors or through

either of the following two devices:

Output Driver Module (ODM)

Quad Driver Module (QDM)

ECM Components

The ECM is designed to maintain exhaust emission levels

to government mandated standards while providing

excellent driveability and fuel efficiency. The ECM

monitors numerous engine and vehicle functions via

electronic sensors such as the crankshaft position (CKP)

sensor, and vehicle speed sensor (VSS). The ECM also

controls certain engine operations through the following:

Fuel injector control

Rail pressure control

ECM Voltage Description

The ECM supplies a buffered voltage to various switches

and sensors. It can do this because resistance in the

ECM is so high in value that a test light may not illuminate

when connected to the circuit. An ordinary shop

voltmeter may not give an accurate reading because the

voltmeter input impedance is too low. Use a 10-megohm

input impedance digital voltmeter to assure accurate

voltage readings.

The input/output devices in the ECM include

analog-to-digital converters, signal buffers, counters,

and special drivers. The ECM controls most components

with electronic switches which complete a ground circuit

when turned “ON.” These switches are arranged in

groups of 4 and 7, called either a surface-mounted quad

driver module (QDM), which can independently control up

to 4 output terminals, or QDMs which can independently

control up to 7 outputs. Not all outputs are always used.

ECM Input/Outputs

Inputs – Operating Conditions Read

Air Conditioning “ON” or “OFF”

Engine Coolant Temperature

Crankshaft Position

Electronic Ignition

Manifold Absolute Pressure

Battery Voltage

Intake Throttle Position

Vehicle Speed

Fuel Temperature

Oil Temperature

Intake Air Temperature

EGR boost pressure

Oil rail pressure

Camshaft Position

Accelerator position

Outputs – Systems Controlled

Exhaust Gas Recirculation (EGR)

Injector Control

QWS