relay OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1937 of 6000

6E–44

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

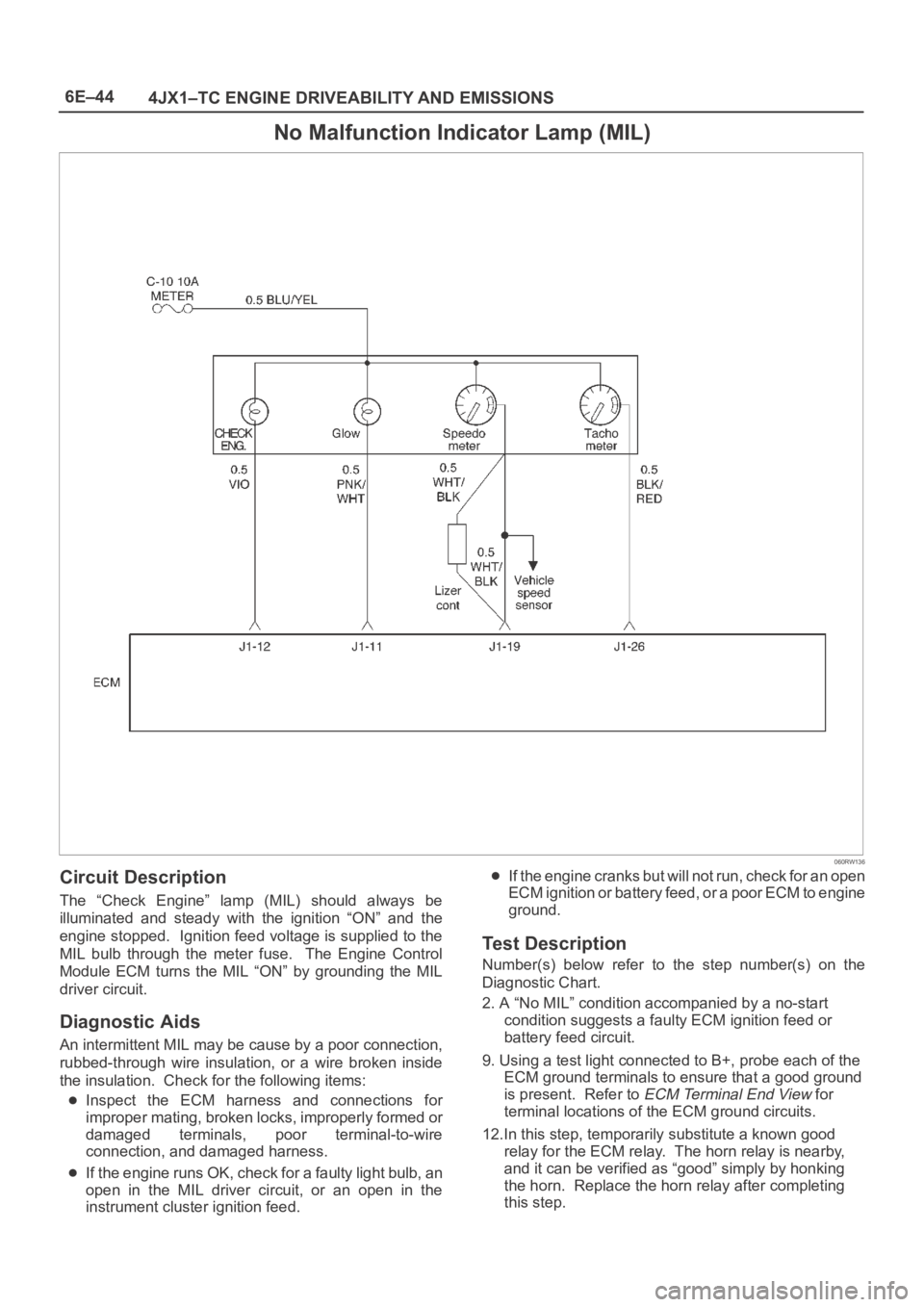

No Malfunction Indicator Lamp (MIL)

060RW136

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The Engine Control

Module ECM turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cause by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Inspect the ECM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire

connection, and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

If the engine cranks but will not run, check for an open

ECM ignition or battery feed, or a poor ECM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty ECM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

ECM ground terminals to ensure that a good ground

is present. Refer to

ECM Terminal End View for

terminal locations of the ECM ground circuits.

12.In this step, temporarily substitute a known good

relay for the ECM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

Page 1938 of 6000

6E–45 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

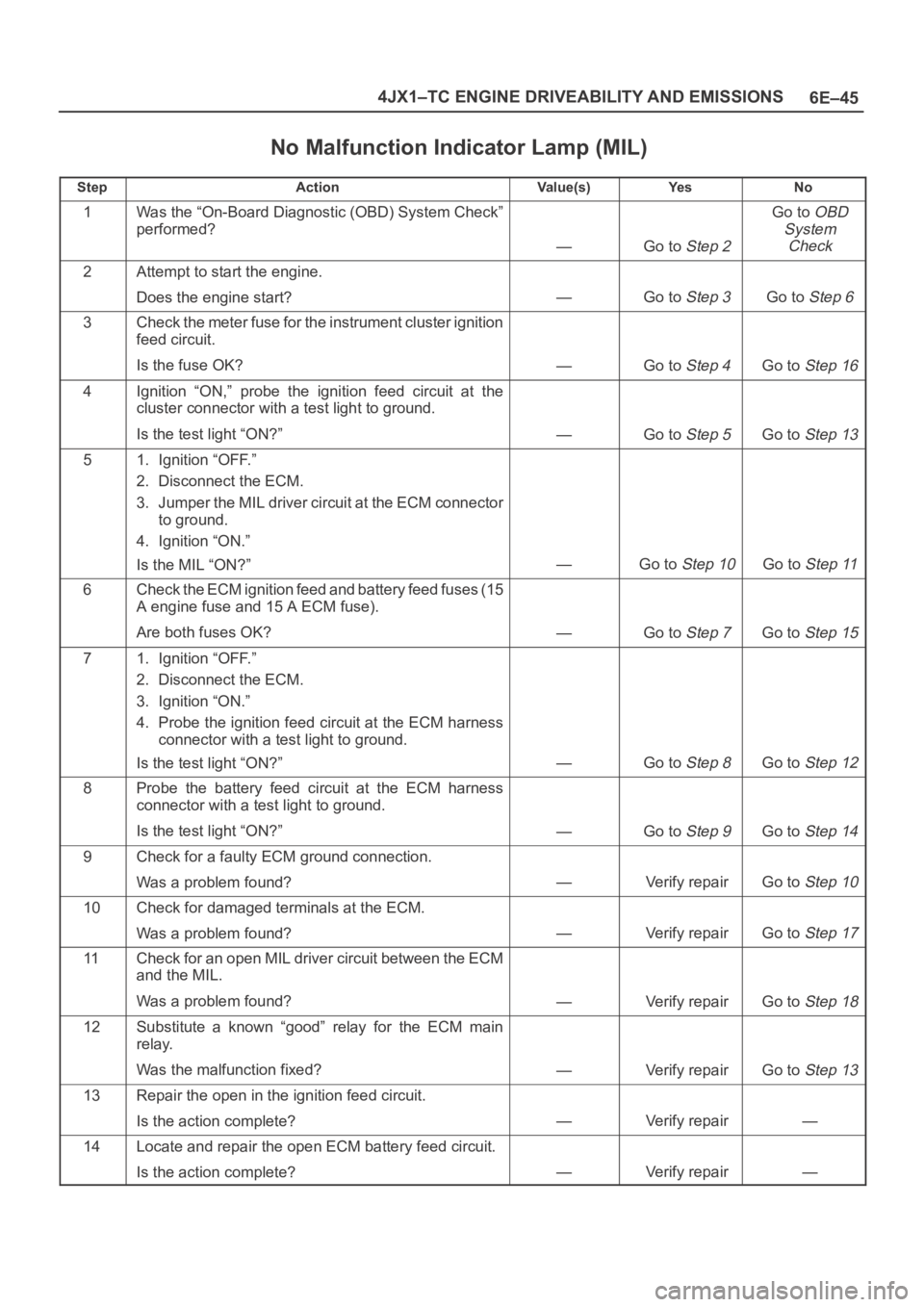

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Step 6

3Check the meter fuse for the instrument cluster ignition

feed circuit.

Is the fuse OK?

—Go to Step 4Go to Step 16

4Ignition “ON,” probe the ignition feed circuit at the

cluster connector with a test light to ground.

Is the test light “ON?”

—Go to Step 5Go to Step 13

51. Ignition “OFF.”

2. Disconnect the ECM.

3. Jumper the MIL driver circuit at the ECM connector

to ground.

4. Ignition “ON.”

Is the MIL “ON?”

—Go to Step 10Go to Step 11

6Check the ECM ignition feed and battery feed fuses (15

A engine fuse and 15 A ECM fuse).

Are both fuses OK?

—Go to Step 7Go to Step 15

71. Ignition “OFF.”

2. Disconnect the ECM.

3. Ignition “ON.”

4. Probe the ignition feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 8Go to Step 12

8Probe the battery feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 9Go to Step 14

9Check for a faulty ECM ground connection.

Was a problem found?

—Verify repairGo to Step 10

10Check for damaged terminals at the ECM.

Was a problem found?

—Verify repairGo to Step 17

11Check for an open MIL driver circuit between the ECM

and the MIL.

Was a problem found?

—Verify repairGo to Step 18

12Substitute a known “good” relay for the ECM main

relay.

Was the malfunction fixed?

—Verify repairGo to Step 13

13Repair the open in the ignition feed circuit.

Is the action complete?

—Verify repair—

14Locate and repair the open ECM battery feed circuit.

Is the action complete?

—Verify repair—

Page 1942 of 6000

6E–49 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

Circuit Description

In this type of injector system, the Engine Control Module

(ECM) triggers the correct driver inside the injector, which

then triggers the correct injector based on the 57X signal

received from the crankshaft position sensor (CKP).

During crank, the ECM monitors the CKP 57X signal. The

CKP signal is used to determine which cylinder will fire

first. After the CKP 57X signal has been processed by the

ECM, it will command all four injectors to allow a priming

shot of fuel for all the cylinders. After the priming, the

injectors are left “OFF” during the next four 57X reference

pulses from the CKP. This allows each cylinder a chance

to use the fuel from the priming shot. During this waiting

period, a camshaft position (CMP) signal pulse will have

been received by the ECM. The CMP signal allows the

ECM to operate the injectors sequentially based on

camshaft position. If the camshaft position signal is not

present at start-up, the ECM will begin sequential fuel

delivery with a 1-in-4 chance that fuel delivery is correct.

The engine will run without a CMP signal, but will set a

DTC code.

Diagnostic Aids

An intermittent problem may be caused by a poor

connection, rubbed-through wire insulation or a wirebroken inside the insulation. Check for the following

items:

Poor connection or damaged harness – Inspect the

ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wore connection, and

damaged harness.

Faulty engine coolant temperature sensor – Using a

Tech 2, compare engine coolant temperature with

manifold air temperature on a completely cool engine.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

4. An obvious cause of low fuel pressure would be an

empty fuel tank.

5. The engine will easily start and run if a few injectors

are disabled. It is not necessary to test all injectors

at this time since this step is only a test to verify that

all of the injectors have not been disabled by fuel

contamination.

8.If there is an open or shorted driver circuit, DTCs

0201-0204 should be set.

Engine Cranks But Will Not Run

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the 15 A injector fuse, the 15 A engine device

fuse, and the 15A ECM fuse.

Was a fuse blown?

—Go to Step 3Go to Step 4

3Check for a short to ground and replace the fuse.

Is the action complete?

—Verify repair—

4Is fuel tank empty?

—

Fill the fuel

tank

Go to Step 5

5Is the right fuel using?

—Go to Step 6

Replace the

fuel

6Is the right engine oil using?

—Go to Step 7

Replace the

engine oil

7Using the Tech–2.

Is DTC P0192 or P0193 set? (Check rail pressure

system)

—

Go to DTC

P0192 or

DTC P0193

Go to Step 8

8Using the Tech–2.

Is DTC P0201 – P0204 set? (Check inject circuit fault)

—

Go to DTC

P0201 –

P0204

Go to Step 9

9Using the Tech–2.

Is DTC P1657 set? (Check ECM Main relay)

—

Go to DTC

P1657

Go to Step 10

Page 1947 of 6000

6E–54

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Diagnostic Trouble Codes

The following table lists the diagnostic trouble codes

supported a Tech 2 and to flash.If any DTCs not listedhere are displayed by a Tech 2, the Tech 2 data may be

faulty; notify the Tech 2 manufacturer of any DTCs

displayed that are not included in the following table.

ECM Diagnostic Trouble Codes

DTC

using a

Te c h 2

Flash DTCDescriptionMIL

P010734MAP Sensor Low VoltageON

P010834MAP Sensor High VoltageON

P011223Intake Air temp Sensor Low VoltageON

P011323Intake Air temp Sensor High VoltageON

P011714Engine Coolant Temp Sensor Low VoltageON

P011814Engine Coolant Temp Sensor High VoltageON

P012133Accel Position Sensor RationalityON

P012221Accel Position Sensor Low VoltageON

P012321Accel Position Sensor High VoltageON

P018215Fuel Temp Sensor Low VoltageON

P018315Fuel Temp Sensor High VoltageON

P019263Rail Pressure Sensor Low VoltageON

P019363Rail Pressure Sensor High VoltageON

P119364RPCV Circuit Open/Short—

P119461Rail Pressure System Low VoltageON

P119561Rail Pressure System High VoltageON

P119662Rail Pressure System High WarningON

P019716Oil Temp sensor Low VoltageON

P019816Oil Temp sensor High VoltageON

P020151Injector #1 Circuit FaultON

P020252Injector #2 Circuit FaultON

P020353Injector #3 Circuit FaultON

P020454Injector #4 Circuit FaultON

P021722High Coolant Temp WarningON

P121736High Oil Temp WarningON

P021911Engine Over Speed WarningON

P033643Crank Position Sensor Out of SyncroON

P033743Crank Position Sensor No SignalON

P034141Cam Position Sensor Out of SyncroON

P034241Cam Position Sensor No SignalON

P038066Glow Relay Circuit Open/Short—

P038167Glow Lamp Circuit Open/Short—

P140332EGR EVRV Fault—

P140431EGR VSV Circuit—

P040526EGR Pressure Sensor Low VoltageON

P140537EGR EVRV Circuit Open/Short—

P040626EGR Pressure Sensor High VoltageON

Page 1948 of 6000

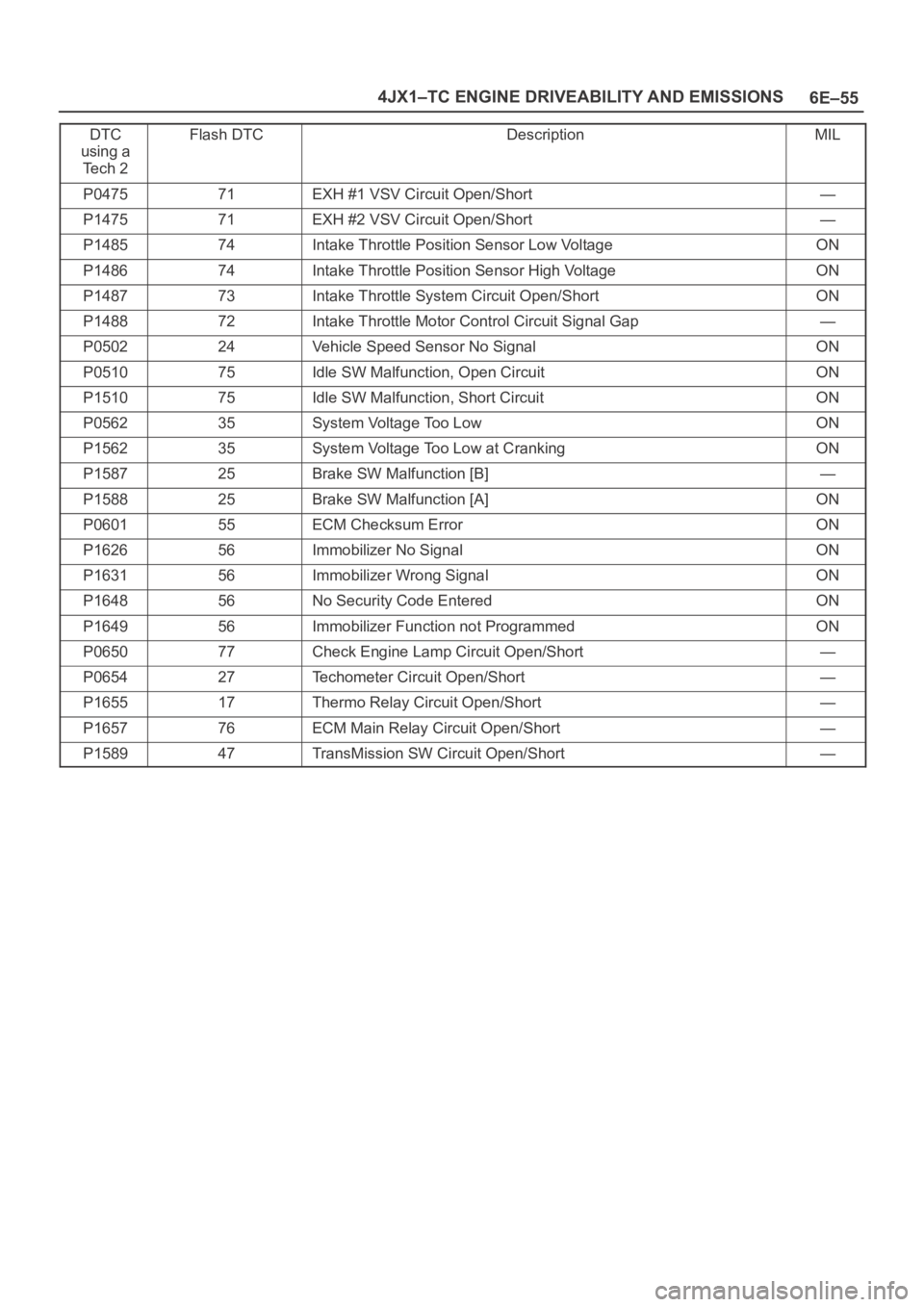

6E–55 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC

using a

Te c h 2Flash DTCDescriptionMIL

P047571EXH #1 VSV Circuit Open/Short—

P147571EXH #2 VSV Circuit Open/Short—

P148574Intake Throttle Position Sensor Low VoltageON

P148674Intake Throttle Position Sensor High VoltageON

P148773Intake Throttle System Circuit Open/ShortON

P148872Intake Throttle Motor Control Circuit Signal Gap—

P050224Vehicle Speed Sensor No SignalON

P051075Idle SW Malfunction, Open CircuitON

P151075Idle SW Malfunction, Short CircuitON

P056235System Voltage Too LowON

P156235System Voltage Too Low at CrankingON

P158725Brake SW Malfunction [B]—

P158825Brake SW Malfunction [A]ON

P060155ECM Checksum ErrorON

P162656Immobilizer No SignalON

P163156Immobilizer Wrong SignalON

P164856No Security Code EnteredON

P164956Immobilizer Function not ProgrammedON

P065077Check Engine Lamp Circuit Open/Short—

P065427Techometer Circuit Open/Short—

P165517Thermo Relay Circuit Open/Short—

P165776ECM Main Relay Circuit Open/Short—

P158947TransMission SW Circuit Open/Short—

Page 1950 of 6000

6E–57 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0107 – MAP Sensor Circuit Low Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Put the engine into an idling status.

Is the MAP voltage value displayed on the Tech 2 below

the specified value?

0.25 VGo to Step 3

Refer to

Diagnostic

Aids

and

Symptom

Diagnosis

31. Turn off the ignition switch.

2. Remove the sensor connector connection.

3. Jumper between harness pins “red” and “blue”

wires.

4. Turn on the ignition switch “ON”.

Is the MAP voltage reading above the specified value?

4 VGo to Step 5Go to Step 4

41. Turn off the ignition switch.

2. Remove the jumper wire.

3. Connect the relay & solenoid checker

(5-8840-0386-0) to the battery voltage, then check

the MAP signal circuit (blue wire).

4. Turn on the ignition switch.

Is the value displayed on the Tech 2 above the specified

value?

4 VGo to Step 6Go to Step 7

5Check the terminal connection at the MAP sensor and

repair or replace terminal if necessary.

Is the action complete?

—Verify repair—

6Repair the 5V power circuit (red) harness or Replace

the ECM (Refer to the Data Programming in Case of

ECM change).

Is the action complete?

—Verify repair—

7Repair the signal circuit (blue) harness or Replace the

ECM (Refer to the Data Programming in Case of ECM

change).

Is the action complete?

—Verify repair—

Page 1952 of 6000

6E–59 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Sensor Circuit High Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Put the engine into an idling status.

Is the MAP voltage value displayed on the Tech 2

above the specified value?

4 VGo to Step 3Go to Step 4

31. Turn off the ignition switch.

2. Remove the sensor connector connection.

3. Turn on the ignition switch “ON”.

Is the MAP voltage value displayed on the Tech 2 below

the specified value?

1 VGo to Step 5Go to Step 6

4Is the MAP voltage value displayed on the Tech 2 below

the specified value?

1 V

Refer to

Chart P0107

Refer to

Diagnostic

Aids

and

Symptom

Diagnosis

5Connect the relay and solenoid checker

(5-8840-0386-0) to the battery voltage, then check the

sensor grounding circuit.

Does the checker lamp come on?

—Go to Step 7Go to Step 8

6A voltage short circuit occurs in the MAP signal circuit

or this circuit is shorted with the 5V power circuit.

Repair the harness or Replace the ECM (Refer to the

Data Programming in Case of ECM change).

Is the action complete?

—Verify repair—

7Replace the MAP sensor hose or the MAP sensor.

Is the action complete?

—Verify repair—

8Repair the harness for open ground circuit.

Is the action complete?

—Verify repair—

Page 1985 of 6000

6E–92

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1196 (Flash DTC 62)

Rail Pressure System High Warning

060RW178

Legend

(1) ECM

(2) Meter Panel

(3) Battery

(4) Oil Temp Sensor

(5) Rail Pressure Sensor

(6) Glow Relay

(7) Oil Rail

(8) Tech–2

(9) A/C Comp Relay

(10) RPCV

(11) Intake Air Temp Sensor

(12) Engine Coolant Temp Sensor

(13) MAP Sensor

(14) EGR Valve

(15) EGR Pressure Sensor(16) High Pressure Oil Pump

(17) Fuel Pump

(18) VSV

(19) EXH Throttle VSV1

(20) EXH Throttle VSV2

(21) EVRV

(22) Engine Harness Connector

(23) QWS Relay

(24) AP Sensor

(25) T.O.D

(26) ECT

(27) OBD

(28) TDC

(29) Injector

(30) Edge Filter

Page 2019 of 6000

6E–126

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0380 (Flash DTC 66)

Glow Relay Circuit Open/Short

060RW132

Circuit Description

Glow relay circuit receives current through Glow 50A fuse

from the battery. Glow relay is circuited to Glow plug.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0380 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage.

Page 2020 of 6000

6E–127 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

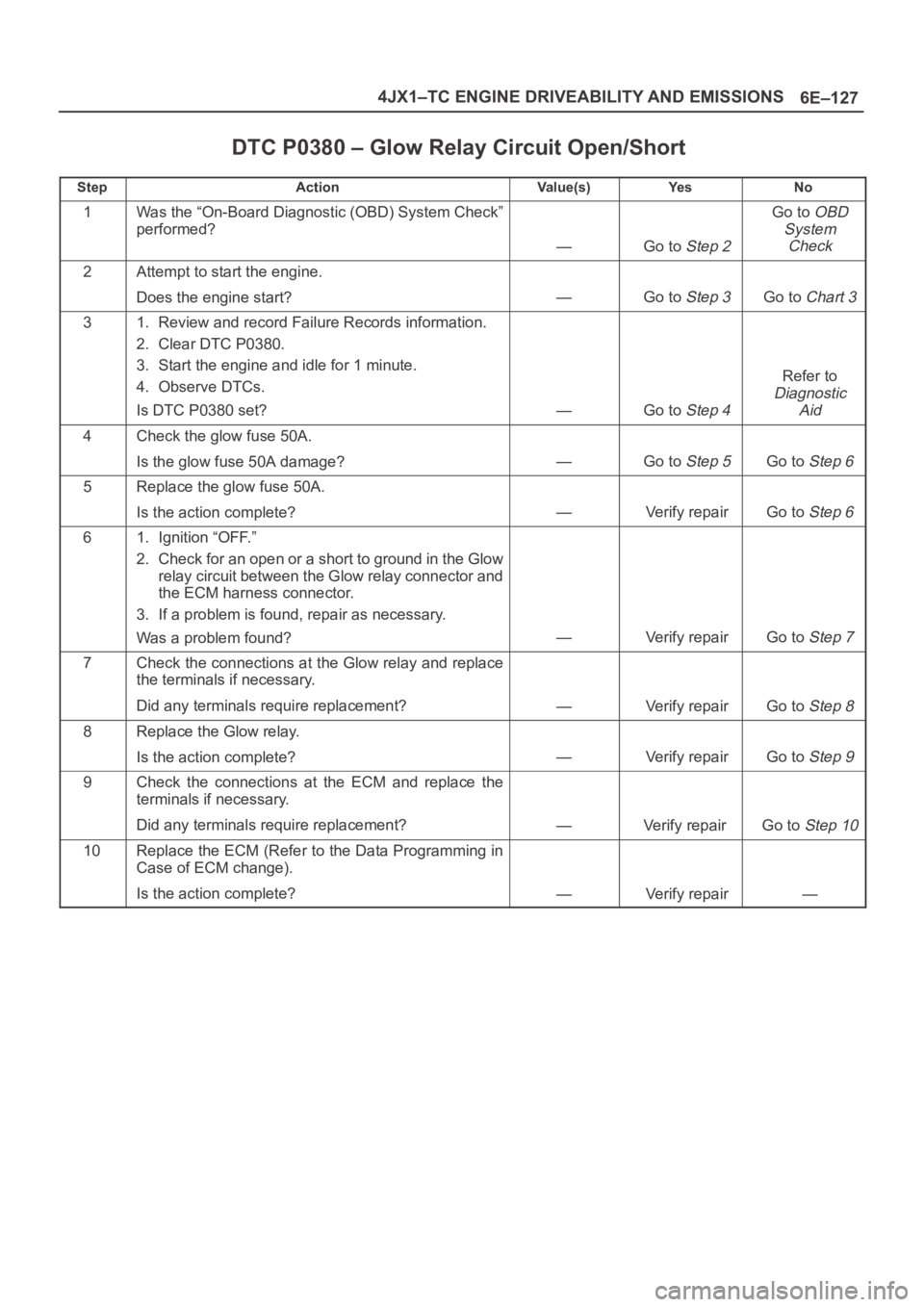

DTC P0380 – Glow Relay Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Chart 3

31. Review and record Failure Records information.

2. Clear DTC P0380.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P0380 set?

—Go to Step 4

Refer to

Diagnostic

Aid

4Check the glow fuse 50A.

Is the glow fuse 50A damage?

—Go to Step 5Go to Step 6

5Replace the glow fuse 50A.

Is the action complete?

—Verify repairGo to Step 6

61. Ignition “OFF.”

2. Check for an open or a short to ground in the Glow

relay circuit between the Glow relay connector and

the ECM harness connector.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

7Check the connections at the Glow relay and replace

the terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 8

8Replace the Glow relay.

Is the action complete?

—Verify repairGo to Step 9

9Check the connections at the ECM and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repair Go to Step 10

10Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—