relay OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2122 of 6000

6E–229 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Fuse and Relay Panel (Underhood Electrical Center) RHD

035RW109

Page 2123 of 6000

6E–230

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Fuse and Relay Panel (Underhood Electrical Center) LHD

035RW108

Page 2570 of 6000

WIPER/WASHER SYSTEM8B–1

WIPER / WASHER SYSTEM

CONTENTS

Service Precaution 8B–2. . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper/Washer System 8B–2. . . . . . . . .

General Description 8B–2. . . . . . . . . . . . . . . . . . . . .

Windshield Wiper And Washer Switch 8B–2. . . . .

Removal and Installation 8B–2. . . . . . . . . . . . . . .

Windshield Wiper Motor 8B–2. . . . . . . . . . . . . . . . . .

Removal 8B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Washer Motor 8B–3. . . . . . . . . . . . . . . .

Removal 8B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper Linkage 8B–4. . . . . . . . . . . . . . . .

Windshield Wiper Linkage and

Associated Parts 8B–4. . . . . . . . . . . . . . . . . . . . . .

Removal 8B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper Arm/Blade 8B–5. . . . . . . . . . . . . .

Removal 8B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade Rubber 8B–6. . . . . . . . . . .

Removal 8B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Wiper/Washer System 8B–7. . . . . . . . . . . . . .

General Description 8B–7. . . . . . . . . . . . . . . . . . . . .

Rear Wiper and Washer Switch 8B–7. . . . . . . . . . .

Removal 8B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Wiper Motor 8B–8. . . . . . . . . . . . . . . . . . . . . . .

Removal 8B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . Alarm & Relay Control Unit 8B–9. . . . . . . . . . . . . . .

Removal 8B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Washer Motor 8B–9. . . . . . . . . . . . . . . . . . . . . .

Removal 8B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Wiper Arm/Blade 8B–10. . . . . . . . . . . . . . . . . . .

Removal 8B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Washer Nozzle 8B–10. . . . . . . . . . . . . . . . . . . . .

Removal 8B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Washer Nozzle Angle Adjustment 8B–10. . .

Rear Wiper Blade Rubber 8B–11. . . . . . . . . . . . . . . .

Removal and Installation 8B–11. . . . . . . . . . . . . . .

Headlight Wiper/Washer 8B–11. . . . . . . . . . . . . . . . .

General Description 8B–11. . . . . . . . . . . . . . . . . . . . .

Headlight Wiper and Washer Switch 8B–12. . . . . . .

Removal 8B–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight Wiper Arm & Blade 8B–13. . . . . . . . . . . . .

Removal 8B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight Wiper Motor 8B–13. . . . . . . . . . . . . . . . . . .

Removal 8B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight Washer Motor 8B–14. . . . . . . . . . . . . . . . .

Removal and Installation 8B–14. . . . . . . . . . . . . . .

Main Data and Specifications 8B–14. . . . . . . . . . . . .

Page 2571 of 6000

8B–2WIPER/WASHER SYSTEM

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Windshield Wiper/Washer System

General Description

The circuit consists of the starter switch, windshield wiper

& washer switch, windshield wiper motor, windshield

washer motor and windshield intermittent relay.When the wiper & washer switch is turned on with the

starter switch on, the battery voltage is applied to the

wiper motor to activate the wiper.

The washer motor squirts glass cleaning fluid while the

washer switch is being pushed. The intermittent relay is

used to control motion of the wiper.

Windshield Wiper And Washer Switch

Removal and Installation

Refer to the Lighting Switch (Combination Switch) in

Lighting System section.

Windshield Wiper Motor

Removal

1. Disconnect the battery ground cable.

2. Disconnect the connector.

3. Remove 4 mounting bolts.

4. Remove the windshield wiper motor(1).

880RW007

Installation

To install, follow the removal steps in the reverse order.

Page 2576 of 6000

WIPER/WASHER SYSTEM8B–7

Rear Wiper/Washer System

General Description

The circuit consists of the starter switch, rear wiper &

washer switch, rear wiper motor, rear washer motor and

rear intermittent relay.When the wiper & washer switch is turned on with the

starter switch on, the battery voltage is applied to the

wiper motor to activate the wiper.

The washer motor squirts glass cleaning fluid while the

washer switch is being pushed. The intermittent relay is

used to control motion of the wiper.

Rear Wiper and Washer Switch

Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

5. Remove the instrument panel cluster assembly(4).

Refer to the Instrument Panel Assembly in Body

Structure section.

6. Disconnect the connector and push the lock from the

back side of the instrument panel cluster assembly to

remove the rear wiper & washer switch(5).

821RW023

Installation

To install, follow the removal steps in the reverse order,

noting the following point:

1. Push the switch with your fingers until it locks

securely.

Page 2578 of 6000

WIPER/WASHER SYSTEM8B–9

Alarm & Relay Control Unit

Removal

1. Disconnect the battery ground cable.

2. Remove the glove box.

3. Remove the instrument panel passenger lower cover

assembly.

4. Remove the passenger Knee bolster reinforcement

assembly.

5. Remove the fixing bolts, disconnect the connectors

and then remove the alarm & relay control unit (1).

826RW020

Installation

To install, follow the removal steps in the reverse order.

Rear Washer Motor

Removal

1. Disconnect the battery ground cable.

2. Remove the tailgate trim pad(2).

3. Remove two screws, disconnect the connector,

remove the washer hose and then remove the rear

washer tank(3).

4. Pull out the rear washer motor(1) from the washer

tank.

885RS009

Installation

To install, follow the removal steps in the reverse order.

Page 2597 of 6000

The chassis electrical system is a 12–volt system with a

negative ground polarity.

Wire size are appropriate to respective circuits, and

classified by color. (The classification of harnesses by

color is shown on the circuit diagram for ease of harness

identification.)

The wire size is determined by load capacity and the

length of wire required.

The vehicle harnesses are: body harness, chassis

harness, engine room harness, instrument harness,

transmission harness, engine ECGI harness, dome light

harness, door harness, rear body harness, tailgate

harness, SRS harness and battery cables.

The harnesses are protected either by tape or corrugated

tube, depending on harness location.

The circuit for each system consists of the power source,

wire, fuse, relay, switch, load parts and ground, all of

which are shown on the circuit diagram.

In this section, each electrical device is classified by

system.

For major parts shown on the circuit based on the circuit

diagram for each system, a summary, diagnosis of

troubles and inspection procedures are detailed.

Notes for Working on Electrical

Items

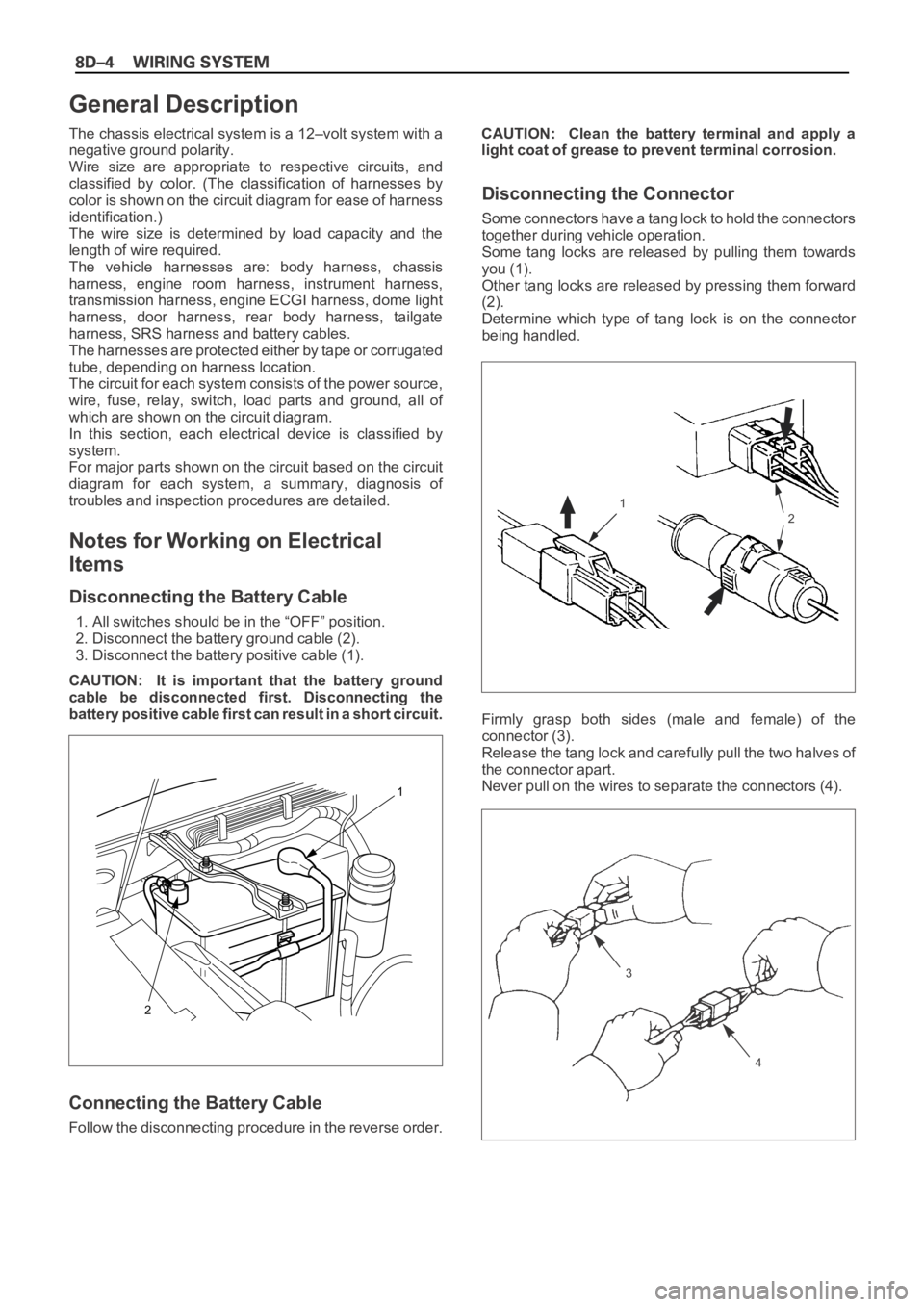

Disconnecting the Battery Cable

1. All switches should be in the “OFF” position.

2. Disconnect the battery ground cable (2).

3. Disconnect the battery positive cable (1).

CAUTION: It is important that the battery ground

cable be disconnected first. Disconnecting the

battery positive cable first can result in a short circuit.

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse order.CAUTION: Clean the battery terminal and apply a

light coat of grease to prevent terminal corrosion.

Disconnecting the Connector

Some connectors have a tang lock to hold the connectors

together during vehicle operation.

Some tang locks are released by pulling them towards

you (1).

Other tang locks are released by pressing them forward

(2).

Determine which type of tang lock is on the connector

being handled.

Firmly grasp both sides (male and female) of the

connector (3).

Release the tang lock and carefully pull the two halves of

the connector apart.

Never pull on the wires to separate the connectors (4).

2

1

General Description

1

2

3

4

Page 2598 of 6000

When removing the connector for relay (MR5B type) (5),

unfasten the tang lock of the connector by using a

screwdriver, then pull the relay out as shown in the figure.

Connecting the Connector

Firmly grasp both sides (male and female) of the

connectors. Be sure that both sides of the connectors are

aligned with each other.

Firmly but carefully push the two sides of the connectors

together until a distinct click is heard (2).

Do not connect them by force if they can not be connected

smoothly (1).

Connector Inspection

Use a circuit tester to check the connector for continuity.

Insert the test probes (1) from the connector wire side.

Never insert the circuit tester test probes (2) into the

connector open end to test the continuity.

Broken or open connector terminals will result.

5

1

2

1

2

Page 2609 of 6000

Circuit Breaker

The circuit breaker is a protective device designed to

open the circuit when a current load is in excess of rated

breaker capacity. If there is a short or other type of

overload condition in the circuit, the excessive current will

open the circuit between the circuit breaker terminals.

The reset knob (1) pops out when the circuit is open. Push

the reset knob in place to restore the circuit after repairing

it.

Relay

Battery and load location may require that a switch be

placed some distance from either component. This

means a longer wire and a higher voltage drop (1).

The installation of a relay between the battery and the

load reduces the voltage drop (2).

Because the switch controls the relay, amperage through

the switch can be reduced.

LOAD

12LOAD

RELAY

D08RW404

1

Page 2610 of 6000

Relay Specifications and Configurations

* Relay contact shown in the wiring diagram indicates condition before actuation.