battery location OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4888 of 6000

6E–231 ENGINE DRIVEABILITY AND EMISSIONS

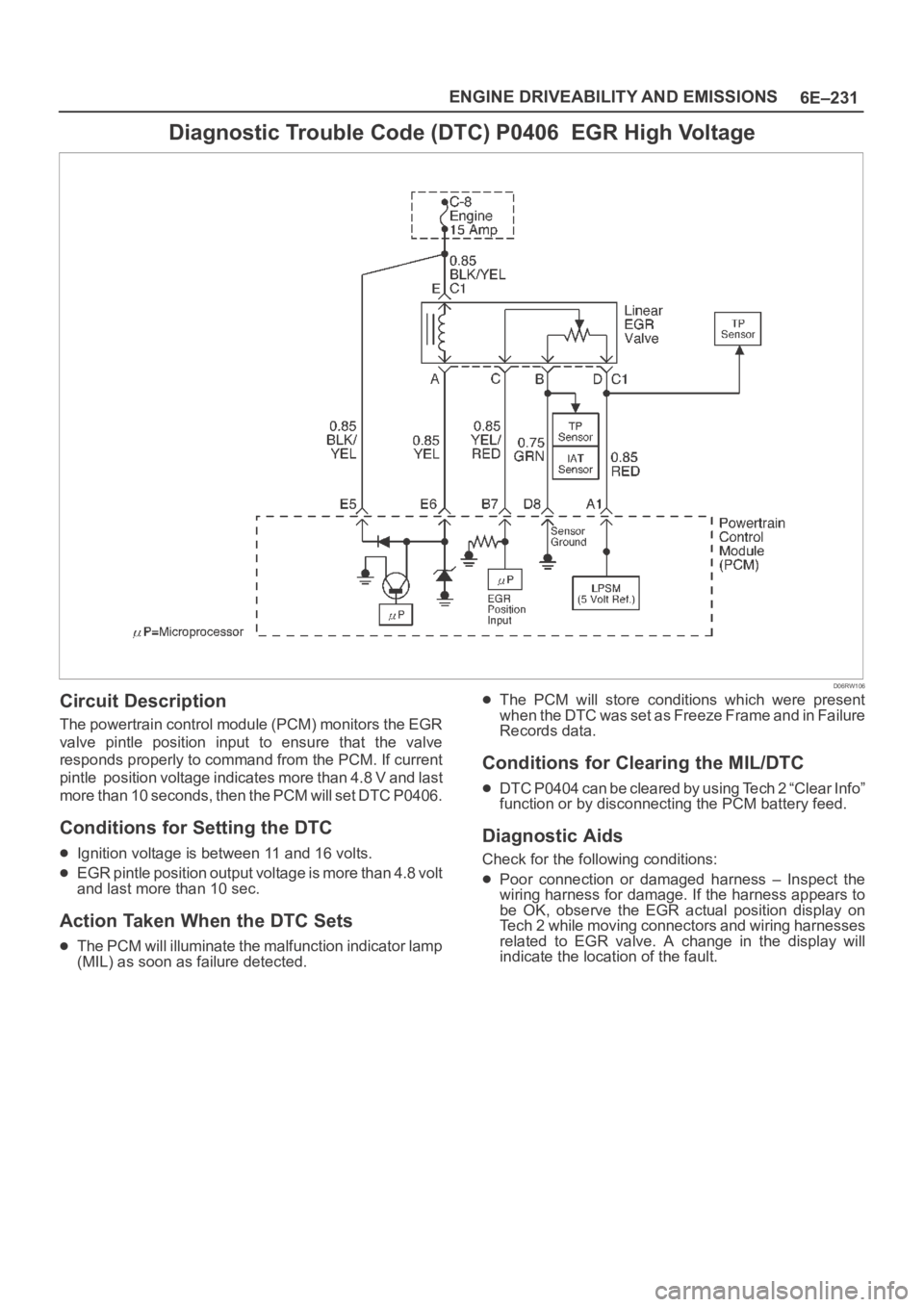

Diagnostic Trouble Code (DTC) P0406 EGR High Voltage

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to command from the PCM. If current

pintle position voltage indicates more than 4.8 V and last

more than 10 seconds, then the PCM will set DTC P0406.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

EGR pintle position output voltage is more than 4.8 volt

and last more than 10 sec.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) as soon as failure detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P0404 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

wiring harness for damage. If the harness appears to

be OK, observe the EGR actual position display on

Tech 2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

Page 4916 of 6000

6E–259 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1640 Driver-1-Input High Voltage

Circuit Description

Output driver modules (ODMs) are used by the

powertrain control module (PCM) to turn “ON” many of

the current-driven devices that are needed to control

various engine and transmission functions. Each ODM is

capable of controlling up to 7 separate outputs by

applying ground to the device which the PCM is

commanding “ON.”

Unlike the Quad Driver Modules (QDMs) used in prior

model years, ODMs have the capability of diagnosing

each output circuit individually. DTC P1640 set indicates

an improper voltage level has been detected on an ODM

output.

Since A/C is an option, No A/C will cause the air

conditioning clutch relay output to always fault. If a fault is

seen on the air conditioning clutch relay output, it will not

be logged as a fault until the A/C request input interrupts a

high voltage, indicating that A/C has been installed.

Conditions for Setting the DTC

Ignition “ON.”

Engine running.

No DTC 1618.

Ignition voltage is above 13.2 volts for 4 seconds.

Output voltage does not equal ignition voltage when

output is “OFF” or output voltage is not less than 1 volt

when output is “ON.”

Above conditions occur for at least 1 second.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set as Failure Records only. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

DTC P1640 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage, If the harness appears to be OK, disconnect

the PCM, turn the ignition “ON” and observe a

voltmeter connected to the suspect driver circuit at the

PCM harness connector while moving connectors and

wiring harnesses relates to the MIL. A change in

voltage will indicate the location of the fault.

Poor connection at component – Examine for

damaged connectors, unplugged connector, or

damaged terminals at the following locations:

Instrument cluster harness, canister purge solenoid,

A/C clutch relay. An open ignition feed circuit at any of

these components will cause DTC P1640 to be set.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

The following PCM pins are controlled by output driver

modules (ODMs):

A13 – “Check Engine Lamp”

A14 – SVS (”Check Trans”)

B14 – A/C Clutch

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

6. The Tech 2 Driver Module Status indicates the PCM

pin that is affected.

11. The Tech 2 may indicate “short circuit” even when

the problem is an open circuit. The cause of an

open circuit may be in the component itself-lamp,

purge, solenoid, or A/C compressor relay.

13.A short to ground on the ignition side of the

component will blow the fuse. Since the fuse was

checked in Step 4, a short to ground would be

between the affected component and the PCM.

Page 5011 of 6000

6E–354

ENGINE DRIVEABILITY AND EMISSIONS

ILLUSTRATIONTOOL NO.

TOOL NAME

5-8840-2607-0

(J 41413)

EVAP Pressure/Purge

Diagnostic Station

5-8840-2608-0

(J 41416)

Ultrasonic Leak Detector

1. 5-8840-2607-0 (J-41413)EVAP Pressure/Purge

Diagnostic Station is a multipurpose tool which is

used to perform several diagnostic procedures for

enhanced emission testing. The station will

accommodate a nitrogen gas filled cylinder which is

used to pressurize the vehicle EVAP system for a

leakdown test and leak location test when a vehicle is

repaired for leakage in the enhanced evaporative

emission control system. It also has two additional

gauges (inches of mercury and inches of water) which

are used to measure both source vacuum and EVAP

canister purge vacuum to verify correct operation and

vapor flow within the canister purge circuit.

2. 5-8840-2608-0 (J-41416) Ultrasonic Leak Detector is

a microprocessor-based device used to detect leaks

in the enhanced evaporative emission control

system. The evaporative system is pressurized to 30

inches of water using the 5-8840-2607-0 (J-41413)

EVAP Pressure/Purge Diagnostic System. Small

leaks in the EVAP system will emit sound at a high

frequency undetectable by a human ear but

detectable with the 5-8840-2608-0 (J-41416). The

technician traces along the evaporative system and

can pinpoint leaks due to corroded lines, cracked

hoses, or a damaged EVAP component. The

detector includes a high quality set of headphones to

block out surrounding shop noise and the LED

sensitivity meter allows a visual reference for locating

leaks in conjunction with the audio output heard

through the headphones. Powered by (1) nine volt

battery.

Page 5473 of 6000

6E–44

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

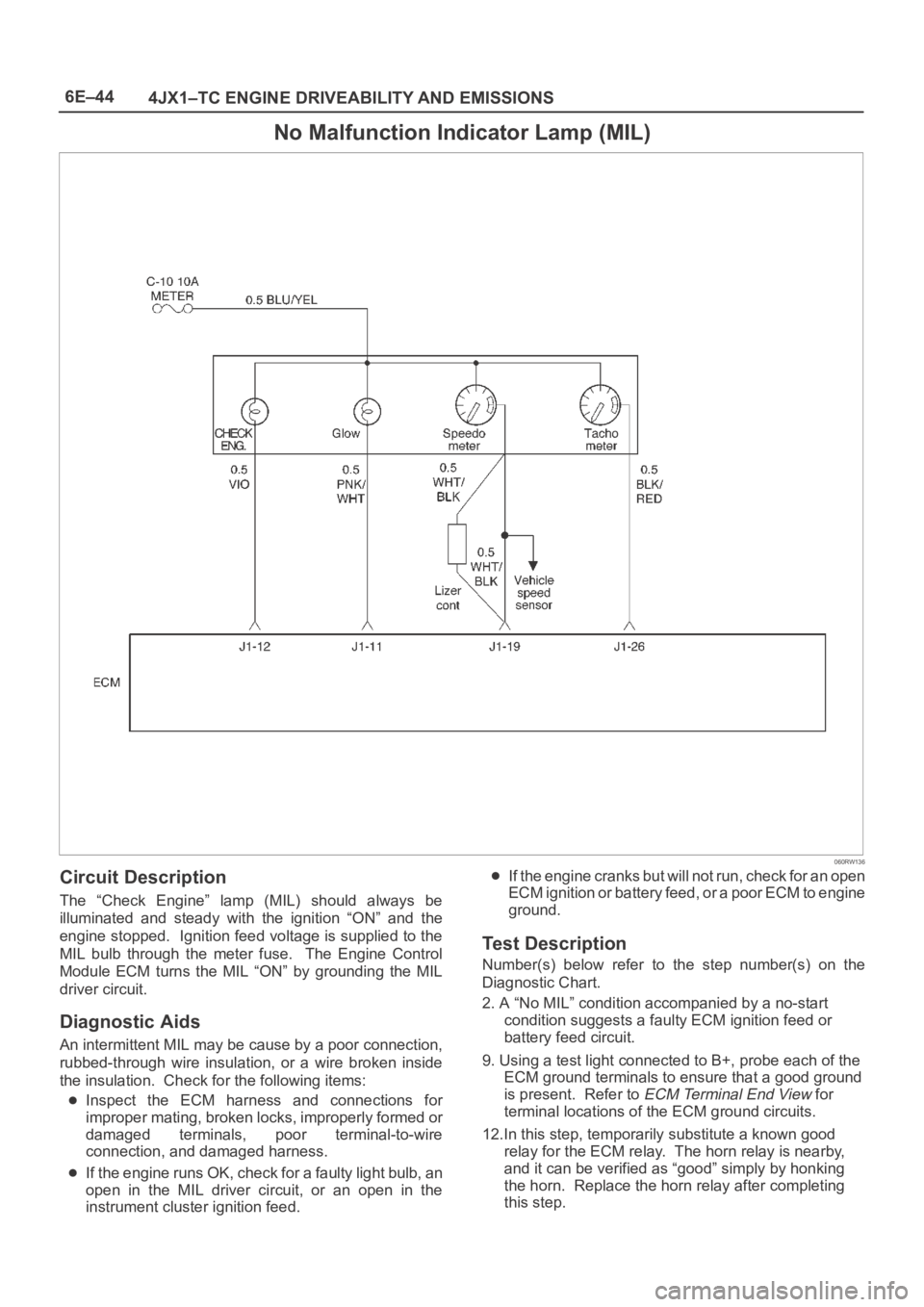

No Malfunction Indicator Lamp (MIL)

060RW136

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The Engine Control

Module ECM turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cause by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Inspect the ECM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire

connection, and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

If the engine cranks but will not run, check for an open

ECM ignition or battery feed, or a poor ECM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty ECM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

ECM ground terminals to ensure that a good ground

is present. Refer to

ECM Terminal End View for

terminal locations of the ECM ground circuits.

12.In this step, temporarily substitute a known good

relay for the ECM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

Page 5485 of 6000

6E–56

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0107 (Flash DTC 34)

MAP Sensor Circuit Low Voltage

060RW134

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum).

The ECM monitors the MAP signals for voltages outside

the normal range of the MAP sensor. If the ECM detects a

MAP signal voltage that is excessively low, DTC P0107

will be set.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0107 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Turn on the ignition switch and stop the engine. At this

time, the boost pressure will be equal to the

atmospheric pressure and the signal voltage will

increase.

Check for intermittent codes.

The MAP sensor shares a ground with the ECT sensor,

and the Transmission Fluid Temperature sensor.

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0107 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P0107 Diagnostic Chart may isolate

the cause of the fault.

Page 5487 of 6000

6E–58

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

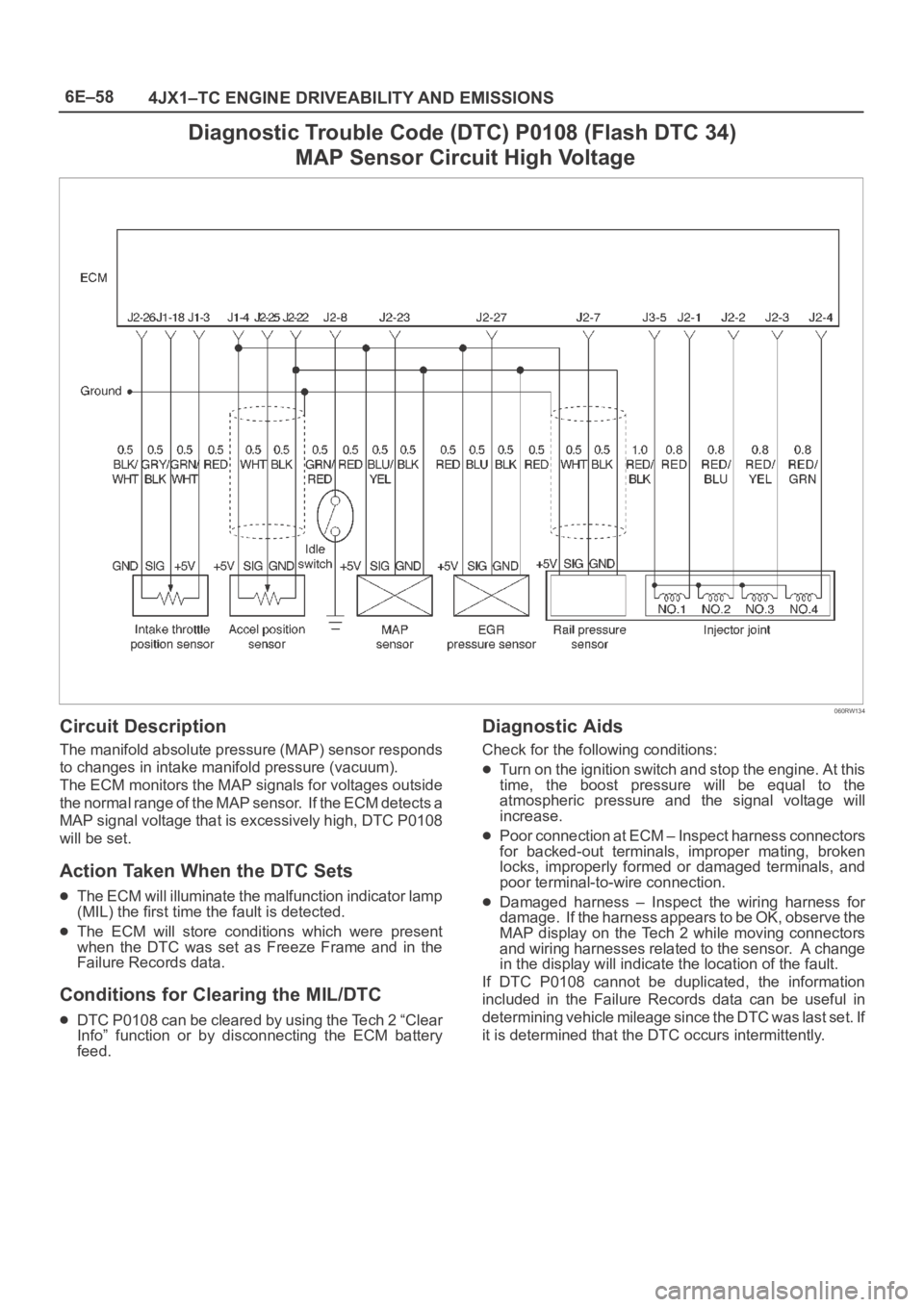

Diagnostic Trouble Code (DTC) P0108 (Flash DTC 34)

MAP Sensor Circuit High Voltage

060RW134

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum).

The ECM monitors the MAP signals for voltages outside

the normal range of the MAP sensor. If the ECM detects a

MAP signal voltage that is excessively high, DTC P0108

will be set.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0108 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Turn on the ignition switch and stop the engine. At this

time, the boost pressure will be equal to the

atmospheric pressure and the signal voltage will

increase.

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0108 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set. If

it is determined that the DTC occurs intermittently.

Page 5489 of 6000

6E–60

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0112 (Flash DTC 23)

IAT Sensor Circuit Low Voltage

060RW129

Circuit Description

The Intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The Engine Control Module ECM applies 5 volts

through a pull-up resistor to the IAT sensor. When the

intake air is cold, the sensor resistance is high and the

ECM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower, causing the ECM to monitor a lower voltage. DTC

P0112 will set when the ECM detects an excessively low

signal voltage on the Intake air temperature sensor signal

circuit.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0112 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0112 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 5491 of 6000

6E–62

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0113 (Flash DTC 23)

IAT Sensor Circuit High Voltage

060RW129

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The Engine Control Module ECM applies 5 volts

through a pull-up resistor to the IAT sensor. When the

intake air is cold, the sensor resistance is high and the

ECM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower causing the ECM to monitor a lower voltage. DTC

P0113 will set when the ECM detects an excessively high

signal voltage on the intake air temperature sensor signal

circuit.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0113 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0113 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 5494 of 6000

6E–65 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0117 (Flash DTC 14)

ECT Sensor Low Voltage

060RW129

Circuit Description

The engine coolant temperature (ECT) sensor is a

thermistor mounted on a coolant crossover pipe at the

rear of the engine. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

ECM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes lower,

and the ECT signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0117 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, brokenlocks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0117 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

3. If DTC P0117 can be repeated only by duplicating

the Failure Records conditions, refer to the

“Temperature vs. Resistance Values” table. The

table may be used to test the ECT sensor at various

temperatures to evaluate the possibility of a

“shifted” sensor that may be shorted above or below

a certain temperature. If this is the case, replace

the ECT sensor. If the ECT sensor appears to be

OK, the fault is intermittent; refer to

Diagnostic Aids.

Page 5496 of 6000

6E–67 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0118 (Flash DTC 14)

ECT Sensor High Voltage

060RW129

Circuit Description

The engine coolant temperature (ECT) sensor is a

thermistor mounted in on a coolant crossover pipe at the

rear of the engine. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

ECM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes less, and

the ECT signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0118 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0118 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.